What Is a Heat Pipe Heat Sink and How Does It Work

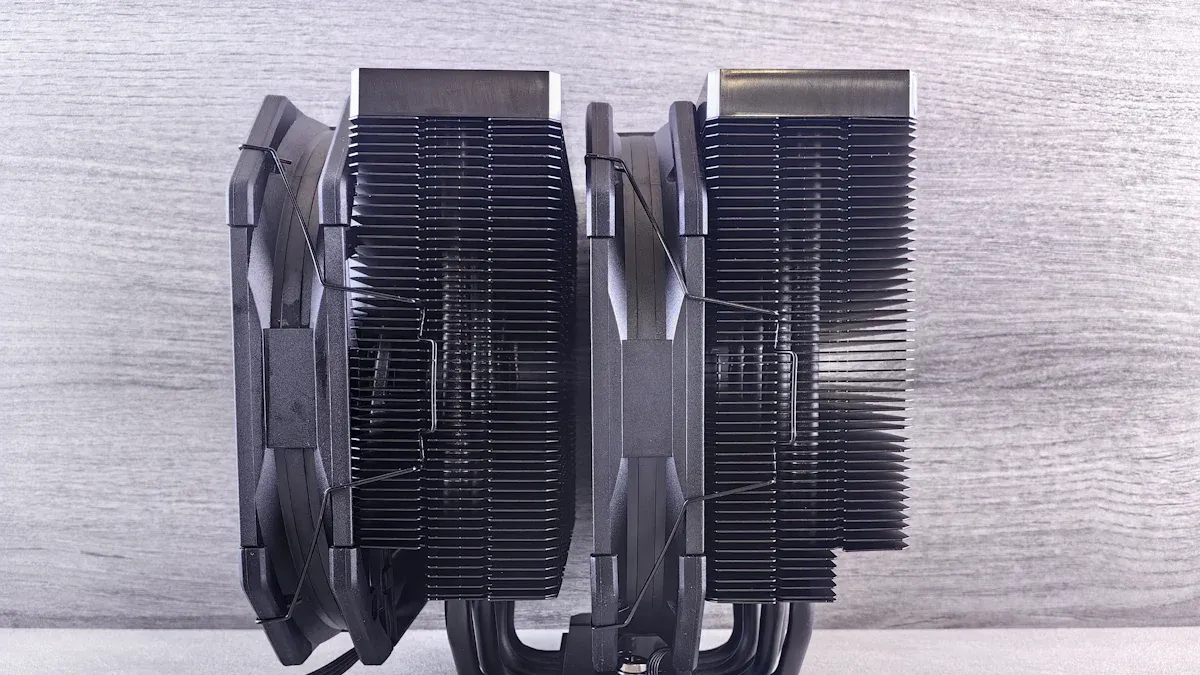

You use a Heat Pipe Heat Sink to cool electronics fast and well. This cooling tool works better than regular copper base designs.

- You can get temperature drops from 10 to 40 percent.

- It also lowers surface temperature differences by up to 65 percent.

This helps your devices stay cool and work well, even when used a lot.

Key Takeaways

- Heat Pipe Heat Sinks cool electronics better than old designs. They lower temperatures by 10 to 40 percent.

- These heat sinks have a special liquid inside heat pipes. The liquid moves heat fast. This makes them work well for a long time.

- The wick structure lets heat pipes work in any position. This gives more choices when making devices.

- Buying heat pipe heat sinks can save money over time. They use less energy and need fewer repairs.

- Heat pipes are found in many things, like laptops and satellites. They help devices stay cool and work well.

What Is a Heat Pipe Heat Sink

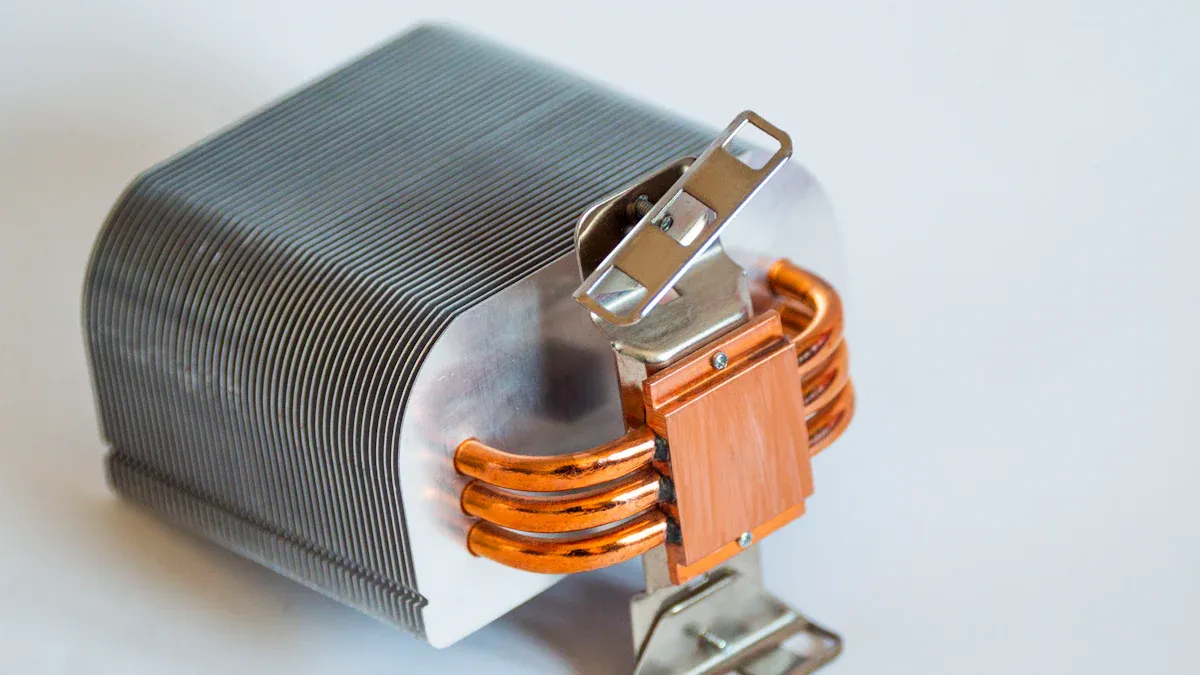

Definition & Main Parts

A Heat Pipe Heat Sink helps move heat away from electronics fast. This device has heat pipes, a metal base, and fins. The heat pipes have a special liquid inside. They use a sealed design to move heat much faster than just metal. You can find these in computers, LED lights, and other electronics that need strong cooling.

Tip: For better cooling, pick a heat sink with heat pipes. These cool better than plain metal blocks.

Each part of a Heat Pipe Heat Sink helps keep your device cool. Here is a table that shows what each part does:

| Component | Role in Heat Dissipation |

|---|---|

| Base | Spreads heat across the heat sink and takes heat from the device. |

| Fins | Adds more surface area so heat can leave faster. |

| Heat Pipes | Moves heat from the base to the fins using phase change and convection. |

| Thermal Interface Material (TIM) | Helps heat move from the device to the base by filling air gaps. |

| Mounting Hardware | Holds the heat sink on the device for good heat transfer. |

These parts are often made from copper, aluminum, nickel, or stainless steel. Some high-end heat sinks use diamond or graphene for even better cooling. Here are some common materials:

- Copper

- Aluminum

- Nickel

- Stainless steel

- Carbon steel

- Titanium

- Graphene

- Diamond

Function in Electronics

A Heat Pipe Heat Sink keeps electronics from getting too hot. When your device works, it makes heat. The heat sink takes in this heat and moves it away from important parts. The heat pipes use a process called phase change. The liquid inside turns to vapor when hot, moves to a cooler spot, and turns back to liquid. This cycle moves heat away very quickly.

A Heat Pipe Heat Sink is more reliable than regular cooling. The heat pipes can move heat over ten times faster than copper. For example, heat pipes and vapor chambers can reach over 5000 W/m°C, but copper only gets to 401 W/m°C. Diamond can go even higher, but it costs a lot more.

| Material | Thermal Conductivity (W/m°C) |

|---|---|

| Pure Copper | 401 |

| Diamond | 1000-2000 |

| Heat Pipe/Vapor Chamber | >5000 |

These heat sinks also last a long time. Most work for at least 20 years and can handle many freeze-thaw cycles. Problems only happen if they are made poorly or face very harsh conditions.

| Lifespan | Durability | Failure Causes |

|---|---|---|

| At least 20 years | Thousands of freeze-thaw cycles | Poor manufacturing, harsh conditions |

If you want your electronics to stay cool and last longer, use a Heat Pipe Heat Sink. This gives you strong cooling, better reliability, and a long life.

How Heat Pipe Heat Sink Works

Structure & Materials

A Heat Pipe Heat Sink has a special design. It is different from regular heat sinks. The main parts are a vacuum-sealed enclosure, a wick structure, and a working fluid. The enclosure keeps the fluid inside. It stops leaks from happening. The wick helps move the fluid back to the right spot. The working fluid is often water or ammonia. It changes between liquid and vapor to carry heat.

Here is a table that shows how Heat Pipe Heat Sinks are different from regular heat sinks:

| Feature | Heat Pipe Heat Sinks | Conventional Heat Sinks |

|---|---|---|

| Wick Structure | Sintered powder, screen, grooves, felt | Primarily conduction and convection |

| Orientation Capability | Works in any orientation, including against gravity | Limited to specific orientations |

| Heat Transport Capacity | Handles up to 250 W/cm² (sintered powder) | Typically 5-10 W/cm² (groove/screen) |

The wick structure is very important. Different wick types change how well the heat sink works. Here is another table that explains this:

| Wick Structure Type | Performance Impact |

|---|---|

| Lattice-based filigree | Improved thermal and capillary performance |

| Flat plate heat pipes | Specific design and performance parameters discussed |

| Vapor chambers | Enhanced heat transfer capabilities |

| Cylindrical heat pipes | Operational limits and measurement methods analyzed |

Materials used in a Heat Pipe Heat Sink include copper and aluminum. Sometimes, advanced materials like graphene or diamond are used. These materials help move heat fast. They keep your electronics safe.

Note: The wick structure lets the heat pipe work in any position. It even works upside down. You can use it in many different devices.

Working Principle

A Heat Pipe Heat Sink works in a simple way. The heat pipe has a working fluid inside. When your device gets hot, the fluid at the hot end turns into vapor. The vapor moves to the cooler end of the pipe. At the cool end, it turns back into liquid. It releases the heat there. The wick pulls the liquid back to the hot end. This cycle keeps going as long as there is a temperature difference.

The phase transition is very important. Some heat pipes use solid-solid phase change materials, like Neopentyl glycol (NPG). These materials store and release a lot of energy when they change phase. This helps manage heat better. It avoids problems like leaks or swelling that happen with other materials.

Tip: The phase change process lets the heat pipe move heat much faster than just metal.

Heat Transfer Process

The heat transfer process in a Heat Pipe Heat Sink has simple steps:

- The working fluid vaporizes at the hot end. It absorbs heat from your device.

- The vapor travels to the cooler end of the pipe.

- The vapor condenses at the cool end. It releases the heat to the surroundings.

- The wick returns the liquid to the hot end. The cycle repeats.

- The fluid inside the heat pipe evaporates at the hot spot. It carries heat away.

- The vapor moves to the cool end and condenses. It gives off heat.

- This cycle of evaporation and condensation keeps your electronics cool and safe.

This process is very efficient. The vapor carries a lot of heat quickly. The wick keeps the cycle going. This makes the Heat Pipe Heat Sink a great choice for cooling electronics that get very hot.

Alert: If you need strong and reliable cooling, the heat pipe design works better than regular heat sinks.

Heat Pipe vs. Conventional

Efficiency & Performance

You want your electronics to stay cool and work well. Heat pipe heat sinks use phase change and special heat transfer methods. These features help move heat quickly and evenly. You get better thermal management compared to regular heat sinks. Heat pipe designs can handle more power and keep temperatures steady. You avoid hot spots, which helps your device last longer.

Here is a table that shows how different heat sinks perform:

| Heat Sink Type | Thermal Resistance (K/W) | Power Handling (W) |

|---|---|---|

| Copper-base Heat Pipe | 0.118 | 135 |

| Solid Aluminum | 0.327 | N/A |

| Solid Copper | N/A | 20% less than vapor chamber at 35°C ΔT |

Heat pipe heat sinks move heat far with little temperature change. They keep the temperature even across your device. This protects your electronics from damage. The best heat pipe heat sinks have low thermal resistance. They can keep a CPU under 70 °C at 130 W.

Note: Heat pipe heat sinks are more reliable than regular fin-bonded designs.

Size & Design

You may need a cooling solution for a small device. Heat pipe heat sinks fit well in tight spaces. Their compact design lets you cool electronics without using much room. Mini and micro heat pipes work well in phones, laptops, and other small gadgets. You can flatten or bend heat pipes to fit your design.

| Design Variation | Impact on Effectiveness |

|---|---|

| Sintered copper heat pipes | Can be flattened to 30%-60% of original diameter, affecting thermal performance limits. |

| One-piece vapor chambers | Can be flattened to 90%, enhancing flexibility in design. |

| Wick and vapor limits | Wick porosity and thickness can be tuned for specific applications, impacting Qmax and gravity performance. |

| Bend radius | Minimum bend radius is three times the diameter; each 45-degree bend reduces Qmax by 2.5%. |

Heat pipes let you make smaller and lighter devices. You do not lose cooling power when you use them.

Choosing the Right Solution

You want to pick the best cooling for your needs. Heat pipe heat sinks may cost more at first, but they save money over time. They reduce weight and volume, which lowers shipping costs. You get better reliability and fewer repairs. Conventional heat sinks seem cheaper, but they may lead to higher costs later.

Heat pipe heat sinks work better and are smaller. This can make their price worth it. Regular heat sinks look cheaper, but they can cost more later. Some engineers pick less effective options to save money. This can hurt how well the device works.

Tip: Think about long-term savings and reliability when you choose a cooling solution.

Benefits & Uses

Cooling & Reliability

You want your electronics to stay cool. You do not want problems. Heat pipes move heat fast and spread it out. This stops hot spots from forming. It keeps the temperature steady. Devices with heat pipes do not overheat. They last longer and work better. You get fewer breakdowns and better performance.

| Improvement Type | Description |

|---|---|

| Heat Spreading Efficiency | Heat pipes make air cooled heat sinks work 20% better than regular materials. |

| Local Hot Spot Removal | Heat pipes inside the device remove hot spots. This makes cooling stronger. |

| Faster Heat Distribution | Heat spreads out more evenly. This helps cool electronics faster. |

Tip: You can control high heat in small spaces. Put the heat source on the heat pipe’s evaporator. The heat moves to the cooler part and leaves safely.

Energy Efficiency

You save energy when you use heat pipes. These devices do not have moving parts. They do not need extra power. Heat pipes keep the temperature even. This helps electronics run better and use less energy.

| Feature | Contribution to Energy Efficiency |

|---|---|

| High Effective Thermal Conductivity | Moves heat far with little temperature change. |

| Passive Operation | Needs no extra power, so it saves energy. |

| Isothermal Operation | Keeps temperature steady for better efficiency. |

Data centers use heat pipes in hybrid cooling systems. This helps them use less energy. You can see big savings in energy use:

| Cooling System Description | Energy Savings Percentage |

|---|---|

| Hybrid cooling system using lake water | 34.9 % – 52.4 % |

| Hybrid cooling system with evaporative cooling | Up to 34.16 % |

| Hybrid system with thermosiphon and vapor compression | 5.4 % – 47.3 % |

| Optimized hybrid cooling system | Up to 20.08 % |

Applications in Electronics

You find heat pipes in many industries. Electric vehicles use them to cool batteries, motors, and inverters. This keeps cars safe and working well. Aerospace engineers use heat pipes for light cooling. They work in places with little air movement. Medical devices need quiet cooling. Heat pipes help without making noise or shaking the equipment.

Real-World Examples

- The Coronagraph instrument on the NGR space telescope uses heat pipes. They keep optical sensors cool.

- U R Rao Satellite Centre (URSC) made over 600 heat pipes for ISRO satellites.

- The GOES-R satellite uses 14 different heat pipe shapes. These cool its Advanced Baseline Imager.

Note: You see heat pipes in many high-tech products. They help keep devices safe, reliable, and energy efficient.

You now know how a Heat Pipe Heat Sink keeps electronics cool and safe. These cooling tools have many strong points:

| Advantage | Description |

|---|---|

| Passive and Reliable | No moving parts, no power needed, and no noise. |

| High Effective Thermal Conductivity | Moves heat quickly and keeps temperatures even. |

| Design Flexibility | Fits small spaces and works with many devices. |

| Cost-Effective Performance | Gives good cooling for less money than active systems. |

You get value for a long time with less fixing and fewer problems. In the future, there will be new designs, more uses in energy and health, and better safety for the environment. Think about using these for your next project.

- Better designs will help heat move faster.

- More fields will use these cooling tools.

- Saving the planet will be more important.

Tip: Pick advanced cooling to keep your devices safe and use less energy.

FAQ

What is the main advantage of a heat pipe heat sink?

You get faster and more even cooling. Heat pipes move heat away from hot spots quickly. This keeps your device safe and helps it last longer.

Can you use a heat pipe heat sink in any position?

Yes, you can. The wick structure inside the heat pipe lets it work in any direction—even upside down. You do not need to worry about how you mount it.

Do heat pipe heat sinks need maintenance?

No, you do not need to maintain them. Heat pipe heat sinks have no moving parts. They work passively and last for many years without attention.

Where do you find heat pipe heat sinks?

You see heat pipe heat sinks in laptops, gaming consoles, LED lights, and even satellites. Engineers use them in places where strong and reliable cooling matters.