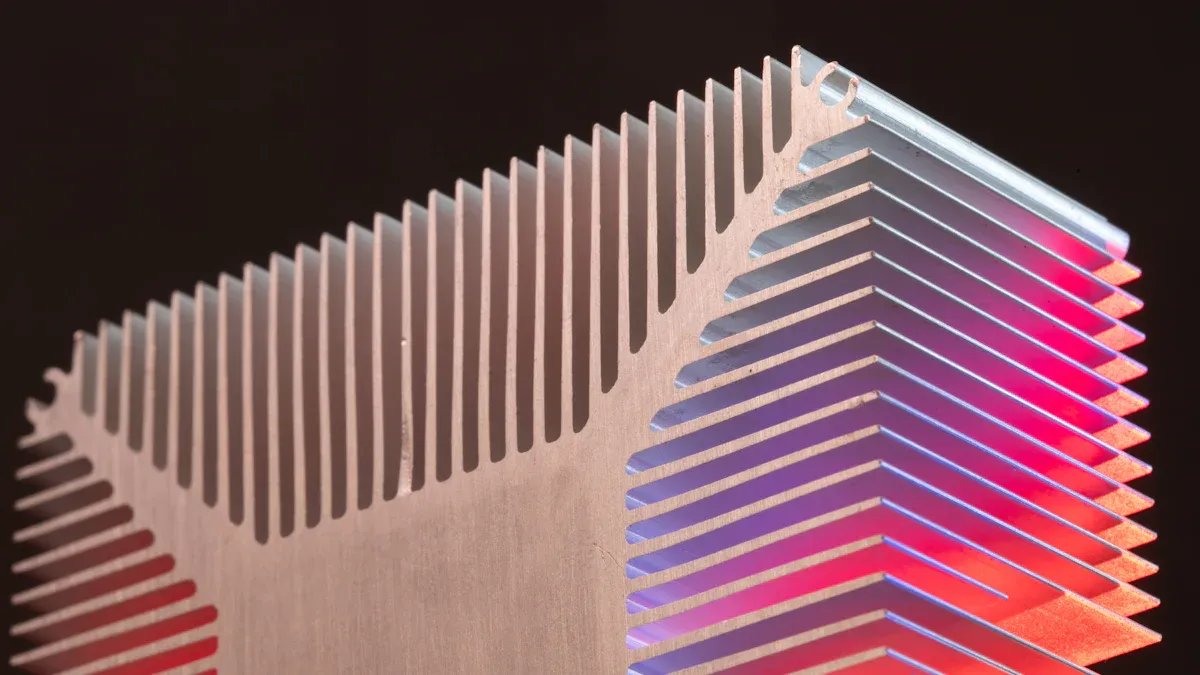

Anodized vs non-anodized heat sinks: Which is better?

If you want good performance and long-lasting use, pick an anodized heat sink. This type is better because it cools more and does not rust as fast as non-anodized ones. Things like price and where you use the heat sink also matter a lot. Think about what you need and compare these things to choose the best one.

Quick Comparison

Key Differences

You can see the main differences between anodized and non-anodized heat sinks by checking their features. The table below shows a simple comparison:

| Feature | Anodized Heat Sinks | Non-Anodized Heat Sinks |

|---|---|---|

| Emissivity | 0.83 to 0.86 | 0.04 to 0.06 |

| Surface Treatment | Electrochemical anodization increases durability and corrosion resistance | Bare aluminum surface |

| Oxide Layer Thickness | 1.8 to 25 microns (standard), >25 microns (hard anodizing) | N/A |

| Aesthetic Options | Can be dyed for cosmetic purposes | N/A |

| Dielectric Isolation | Yes | No |

Tip: If you want a heat sink that looks nice and lasts longer, pick the anodized one. You can also choose different colors for your project.

Performance, Durability, Cost

When you look at both types, think about how well they work, how long they last, and how much they cost. Here is a short summary to help you choose:

- Performance: Anodized heat sinks cool better. The special surface helps them get rid of heat faster. Emissivity goes from 0.04-0.06 for non-anodized to 0.83-0.86 for anodized. This means your device stays cooler, especially with natural airflow. Some tests show black anodized heat sinks can cool 20-35% better.

- Durability: Anodized heat sinks do not rust as fast as non-anodized ones. The oxide layer keeps water and damage away from the metal. Anodized finishes last longer and need less care.

- Cost: Anodized heat sinks cost more at first. The extra step makes the price higher. But you might save money later because you do not need to buy new ones as often.

- Aesthetics: Anodized heat sinks come in many colors. You can match them to your device or brand. Non-anodized heat sinks are only silver.

Note: If you want the best mix of cooling and lasting power, anodized heat sinks are a great choice. If you just need something simple and want to spend less, non-anodized heat sinks can work.

Performance

Anodized Heat Sink Cooling

Thermal Conductivity

A heat sink helps move heat away from your device. Aluminum is good at moving heat. Anodized heat sinks have a thin oxide layer on top. This layer is very thin and does not stop heat much. The aluminum underneath does most of the work. You get fast heat transfer and extra protection for the surface.

Surface Emissivity

Surface emissivity shows how well something gives off heat. Anodized heat sinks have much higher emissivity than bare aluminum. This means they can release more heat into the air. This is helpful when you do not use a fan. The anodized layer adds tiny bumps to the surface. These bumps make the surface area bigger. This helps the heat sink cool better, especially in passive systems.

- Anodized surfaces have emissivity between 0.83 and 0.86.

- Bare aluminum only has 0.04 to 0.06.

- Black anodized heat sinks can cool up to 40% better than non-anodized ones in some tests.

- You might see a temperature drop of up to 5°C when you use an anodized heat sink.

If you want your device to stay cooler without a fan, pick an anodized heat sink.

Non-Anodized Heat Sink Cooling

Heat Transfer Basics

Non-anodized heat sinks use bare aluminum. This metal still moves heat well. But the surface does not let go of heat as easily. Low emissivity means heat stays in the metal. Your device may get hotter, especially with a small heat sink or no fan.

Real-World Results

Lab tests show anodized heat sinks work about 20% better than non-anodized ones. You can see the difference when you compare devices side by side. Anodized heat sinks keep things cooler and work better in tough spots. If you use a fan, the difference is smaller. But anodized heat sinks still do a better job.

Emissivity and Heat Dissipation

You can see the emissivity values in the table below:

| Type of Heat Sink | Emissivity Value |

|---|---|

| Non-anodized Aluminum | 0.05 |

| Anodized Aluminum | 0.85 |

A higher emissivity value means the heat sink gets rid of heat faster. This matters a lot for small devices or when you do not use a fan. The tiny bumps from anodizing make the surface area bigger. This helps even more. You get steady performance, even after many heating and cooling cycles.

Some experts say the anodized layer can act as a small insulator at very high temperatures. For most electronics, the better radiation and bigger surface area are more important than this small effect.

If you want the best cooling for your device, choose an anodized heat sink. You get better heat dissipation, lower temperatures, and longer-lasting performance.

Durability

Corrosion Resistance

You want your heat sink to last a long time. Anodized aluminum is great at stopping rust. The anodizing process makes the oxide layer thicker. This thicker layer keeps water and chemicals away from the metal. If you use your device outside or in wet places, anodized heat sinks do not rust as fast. They protect your device from damage caused by water or salty air.

Tip: Pick an anodized heat sink for outdoor use or humid places. It helps keep your device safe from rust and corrosion.

Wear and Maintenance

You want a heat sink that does not scratch easily. Anodized aluminum is harder to scratch than bare aluminum. The anodized surface is tough and strong. If you use Type III hardcoat anodizing, it is even harder to damage. You do not have to clean it as much. Dirt and dust do not stick to the smooth anodized surface. You can wipe it clean with a soft cloth. Non-anodized heat sinks scratch and wear down faster, so they need more care.

- Anodized aluminum lasts longer outside.

- The anodized layer protects against rust.

- Anodized heat sinks help cool electronics better.

Anodized Heat Sink Longevity

You want your heat sink to last for many years. Anodized heat sinks last much longer than non-anodized ones. The table below shows how long each type can last:

| Type of Heat Sink | Average Lifespan |

|---|---|

| Anodized Heat Sink | 20 to 50 years or more |

| Non-Anodized Heat Sink | Shorter lifespan due to oxidation and wear |

If you pick an anodized heat sink, it will not scratch or rust easily. You do not need to replace it often. The anodized layer keeps it working well for a long time. You save money and do not have to fix it as much.

- Does not scratch as easily as bare aluminum.

- Type III hardcoat anodizing makes it even tougher.

- Helps aluminum get rid of heat better.

Note: If you want a heat sink that lasts a long time and is easy to care for, choose an anodized heat sink. It gives your device strong protection and works well for many years.

Application Suitability

When to Use Anodized Heat Sinks

Pick an anodized heat sink if your project needs strong cooling and long-lasting protection. This type works best where heat and moisture can cause trouble. You get better performance and more safety for your electronics.

- You want better corrosion resistance for outdoor or humid places.

- You need higher emissivity for better heat transfer, especially in passive cooling systems.

- You need better electrical isolation to protect sensitive parts.

- You want more durability for devices that run for long hours.

Anodized heat sinks are smart for devices that must stay cool and work well. You often see them in CPUs, LEDs, and servers. These devices need strong thermal management and high reliability. The anodized layer helps them last longer and work better, even in tough spots.

Tip: If you build a device that runs all day or works in harsh places, pick an anodized heat sink. You will get better cooling and worry less about rust or damage.

When Non-Anodized is Enough

Use non-anodized heat sinks for simple projects or when you want to save money. These heat sinks work well if your device does not get very hot or if you use a fan to help with cooling.

- Cost-sensitive projects, like basic consumer electronics, use non-anodized heat sinks.

- Weight-constrained systems, such as drones or automotive ADAS, often use non-anodized heat sinks to keep things light.

If you build a device that does not need to run all day or stay outside, a non-anodized heat sink can work. You save money and make your device lighter. These heat sinks work best in clean, dry places where corrosion is not a big problem.

Note: For low-cost or lightweight projects, non-anodized heat sinks give a simple and good solution. You get enough cooling without paying extra for features you may not need.

Cost and Value

Price Comparison

When you look at anodized and non-anodized heat sinks, you see they cost different amounts. Anodizing puts a special layer on aluminum. This step makes the price go up by about 15-25%. Bare aluminum heat sinks are cheaper because they skip this step. If you want to spend the least, bare aluminum is the lowest price. But you might have to pay more later for fixing or replacing it.

Here is a simple table that shows how much each surface treatment costs and what you get:

| Surface Treatment | Cost Increase (%) | Performance Benefits |

|---|---|---|

| Bare Aluminum | 0 | Lowest cost, needs more work to finish |

| Anodizing | 15-25 | Works better and looks nicer |

| Powder Coating | 20-35 | Toughest finish for rough places |

| Chemical Conversion | 10-15 | Costs a bit more, gives some extra benefits |

If you want a heat sink that looks good and works well, anodizing is worth the small extra cost.

Cost-Effectiveness

You might wonder if paying more for anodizing is a good idea. Anodized heat sinks last longer and work better. The oxide layer helps them give off heat faster, so your device stays cooler. Black anodizing can help the heat sink release heat up to 20 times better than bare aluminum. You get more cooling without losing much heat transfer.

Here are some reasons why anodized heat sinks are a good deal:

- You spend less fixing or replacing them because they do not rust or scratch easily.

- Your device uses less energy because it stays cooler.

- You can pick from more colors to match your device.

- You do not need to clean or fix them as much.

If your device works in tough places or needs to last many years, paying more for anodizing is smart. You protect your device and spend less over time. Bare aluminum heat sinks are fine for simple jobs, but they can rust and wear out faster.

Picking anodized heat sinks helps you get good value and strong performance. You pay a little more now, but you save money and problems later. If you want the best mix of price and reliability, anodized heat sinks are a smart pick.

Aesthetics and Customization

Color Options

When you pick anodized heat sinks, you can choose many colors. The anodization process lets you match colors to your device or brand. This helps your product look different from others. You can use color to show your company’s style or organize parts inside your device.

| Color Option | Heat Absorption | Heat Reflection | Performance Impact |

|---|---|---|---|

| Black | High | Low | Superior heat dissipation |

| Silver/White | Low | High | Limited heat dissipation |

| Blue/Red/Green/Bronze | Varies | Varies | Customization options available |

Black anodized heat sinks are best for cooling. They take in more heat and get rid of it faster. You see black heat sinks in many powerful devices. Silver or white heat sinks bounce heat away, so they do not cool as well. If you want a special look, you can pick blue, red, green, or bronze. These colors let you match your design, but cooling can change.

Tip: For the best cooling, pick black anodized heat sinks. For a cool look, try other colors, but check how they work.

Color helps users find different parts. For example, blue can mark one circuit and red another. This makes fixing and upgrading easier. In electronics, color choices make your product look new and stylish.

Design Flexibility

Anodized heat sinks give you more ways to design your device. The anodization process makes the surface harder and stops rust. You can use these heat sinks outside or in tough places. You do not need to worry about rust or scratches.

You can make custom shapes and sizes with anodized heat sinks. You can design thin fins, cool patterns, or special holes. The strong anodized layer keeps these features safe. Non-anodized heat sinks do not protect or let you design as much.

You can also add logos, words, or patterns during anodizing. This helps you show your brand or add labels. Your device looks professional and is easy to use.

- Pick anodized heat sinks for custom projects.

- Use special shapes or colors for your needs.

- Add logos or labels for a nice finish.

Anodized heat sinks help you make your product special. You get better looks, more choices, and strong performance.

If you want your device to look cool and last longer, pick anodized heat sinks. You get style and function together.

Anodized heat sinks are stronger and last longer. They do not rust as fast and cool better. Non-anodized heat sinks are cheaper but wear out sooner. Look at the table below for a quick guide:

| Feature | Anodized Heat Sinks | Non-Anodized Heat Sinks |

|---|---|---|

| Durability | High | Low |

| Corrosion Resistance | High | Low |

| Thermal Performance | Enhanced | Basic |

Tip: Pick anodized heat sinks for tough jobs. For easy and cheap projects, non-anodized heat sinks are fine.