How Black Anodized Heat Sinks Are Used in Industry

You need good cooling to keep your devices safe. A black anodized heat sink helps control heat in many things. It works in LED lights, servers, and medical electronics. Many industries use these heat sinks. Some examples are consumer electronics, telecom, and industrial control. The black surface helps get rid of heat faster. It also makes the heat sink stronger. You also get electrical isolation. This keeps sensitive parts safe.

Key Takeaways

- Black anodized heat sinks help cool devices well. Their black surface lets heat escape faster. This keeps electronics safe and working.

- The anodized layer makes them stronger. It stops rust and scratches. It also protects in tough places. This helps heat sinks last longer.

- Higher emissivity gives better results. Black anodized heat sinks release heat up to 20% better than plain aluminum. This helps devices stay cooler.

- Electrical isolation is very important. The anodized layer stops electricity from passing through. This keeps sensitive parts safe from short circuits.

- You can customize heat sinks. Companies can get them in different shapes and colors. This helps them fit special needs and looks.

What Is a Black Anodized Heat Sink?

Structure and Materials

A black anodized heat sink helps cool your devices. Most are made from aluminum alloys. Aluminum is light and moves heat well. You can find these heat sinks in computers and LED lights. The anodizing process adds a strong layer on top. This layer keeps the heat sink tough and looking nice.

- Aluminum alloys are used most of the time.

- The anodized layer gives extra strength and style.

- These heat sinks are in many electronics.

Ecotherm’s Anodized Aluminum Heatsinks use top-quality aluminum. You can pick custom shapes and sizes. CNC machining lets you get the shape you want.

Anodization Process

Anodization changes the outside of the aluminum. The heat sink goes into an acid bath. Electricity runs through it. This makes a thick oxide layer on the surface. The new layer makes the heat sink harder and tougher. It also helps the heat sink last longer in rough places.

Here is how anodization changes aluminum:

| Property | Change Due to Anodization |

|---|---|

| Surface Emissivity | Higher, so it gives off heat better |

| Corrosion Resistance | Gets stronger and lasts longer |

| Thermal Conductivity | A little lower than plain aluminum |

| Hardness | The surface gets harder |

| Melting Point of Oxide Layer | Much higher than regular aluminum |

CNC machining at Ecotherm gives very exact shapes. You get better cooling and more design choices. The process also makes the heat sink look and feel nicer.

Role of Black Finish

The black finish does more than look cool. It helps the heat sink get rid of heat faster. The black oxide layer lets more heat leave as infrared. This is up to 20% better than plain aluminum. The emissivity goes from 0.05 to 0.85 with black anodized aluminum. This means your devices stay cooler and work better.

- The black finish helps heat leave faster.

- Your devices stay cooler and last longer.

- The finish also keeps away scratches and rust.

When you pick a black anodized heat sink from Ecotherm, you get smart design and strong materials. The special surface treatment helps your electronics run safely and well.

Benefits of Black Anodized Heat Sink

Thermal Performance

You want your devices to stay cool and work well. A black anodized heat sink helps with this. The black finish lets the heat sink give off more heat. This is called “emissivity” by scientists. Bare aluminum does not give off much heat. Its emissivity is only about 0.04 to 0.06. With a black anodized heat sink, emissivity goes up to about 0.83 to 0.86. This means the heat sink can send away more heat. Your electronics stay cooler and last longer.

- The black surface helps the heat sink send out heat.

- Higher emissivity means your electronics cool down better.

- This matters a lot for computers, LED lights, and power equipment.

Corrosion and Wear Resistance

You want your heat sink to last a long time. The anodized layer on a black anodized heat sink keeps it safe from rust and scratches. The surface makes a special layer called Al₂O₃. This layer protects against water, salt, and strong chemicals. It also makes the heat sink harder and tougher.

- The oxide layer keeps out water and stops rust.

- Anodizing makes the surface hard, so it does not scratch easily.

- The heat sink works well inside and outside.

Tip: If you use your devices in wet or rough places, a black anodized heat sink will help them last longer.

Electrical Isolation

You want to keep your electronics safe from short circuits. The anodized layer on a black anodized heat sink acts as an insulator. This means electricity does not move through it easily. You can use these heat sinks near sensitive parts without worry.

| Feature | Black Anodized Heat Sink | Bare Aluminum Heat Sink |

|---|---|---|

| Electrical Property | Insulator | Conductor |

| Electrical Isolation (Breakdown Voltage) | Up to several hundred volts | Very low |

This table shows that a black anodized heat sink gives better electrical isolation than bare aluminum.

Aesthetic Versatility

You may want your devices to look good and work well. Black anodized heat sinks come in many colors. You can pick finishes that match your product. The anodized layer keeps its color and shine for a long time. This helps your devices look new, even after years.

| Feature | Description |

|---|---|

| Aesthetic Options | Many color choices for different designs |

| Customization | You can shape and color the heat sink to fit your needs |

| Durability | The finish stays bright and resists fading or scratching |

- Colored finishes let you match your heat sink to your brand or product.

- The surface stays nice, even in tough places.

A black anodized heat sink gives you strong performance, long life, and a great look. You can use it in many places, like computers or cars, and trust it to keep your devices safe and cool.

Industrial Applications

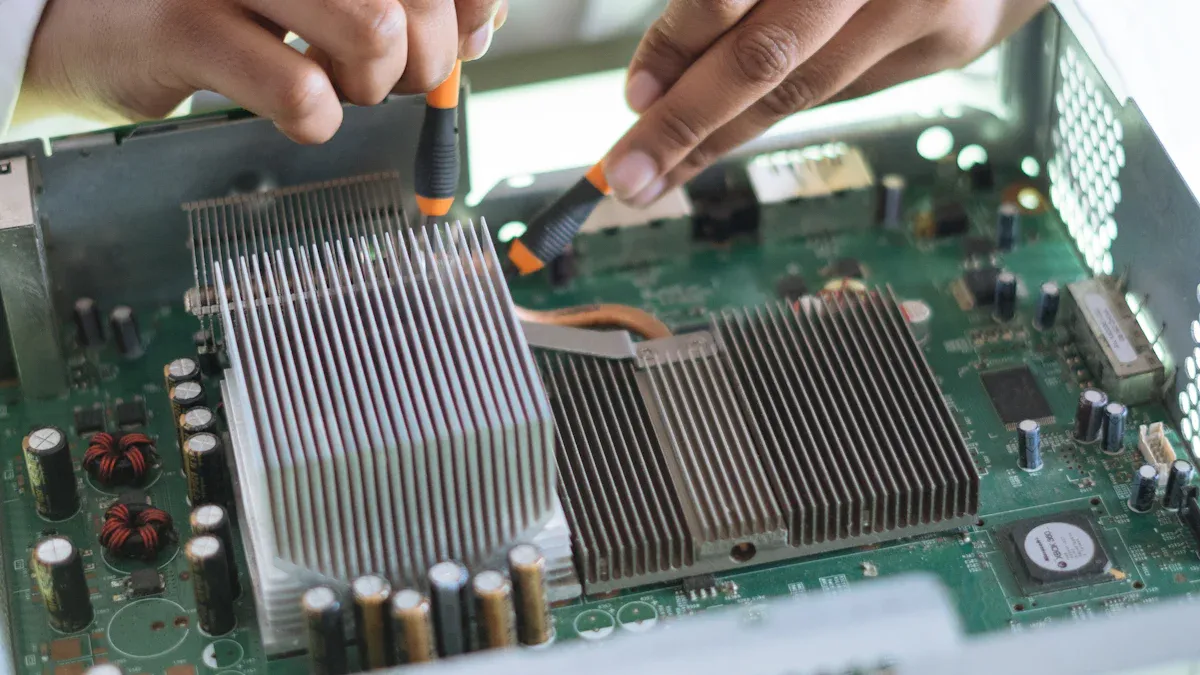

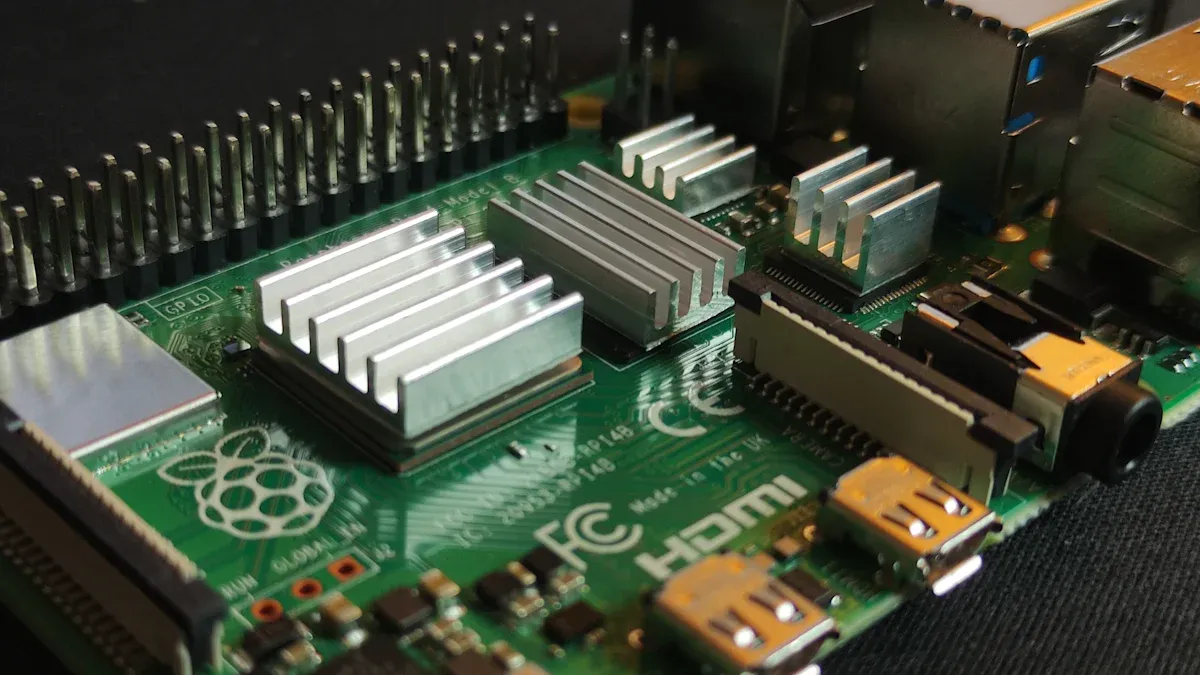

Electronics Cooling

You use lots of electronics every day. Computers and servers can get hot fast. Telecom equipment also makes heat inside. A black anodized heat sink helps cool CPUs and GPUs. It also cools power supplies. The black surface lets heat escape quickly. This keeps your devices from getting too hot. You can find these heat sinks in data centers and routers. They are also in medical electronics. Using them helps your devices stay cool and last longer.

Note: Tests show black anodized heat sinks keep electronics 5-8°C cooler than bare aluminum ones. This lower heat helps your devices work better and last longer.

Automotive Systems

Cars now have more electronics than before. Black anodized heat sinks are used in electric vehicles. They cool batteries and control units. The black finish helps move heat away fast. The anodized layer stops rust and blocks harsh chemicals. This keeps your car’s electronics safe, even in tough places.

Black anodized heat sinks are used in:

- Electric vehicle battery packs

- Motor controllers

- Infotainment systems

- Advanced driver-assistance systems (ADAS)

These heat sinks help your car’s electronics work well on the road.

LED and Power Equipment

LED lights can get very hot after running a long time. You need to keep them cool. A black anodized heat sink does this job well. The black finish helps send heat away faster. This keeps the LED cool, so it stays bright and lasts longer.

You also see these heat sinks in power supplies and machines. They help control heat in:

- High-power LED lighting

- Power inverters

- Industrial control panels

Using a black anodized heat sink helps your LEDs and power equipment work better and last longer.

- The black finish helps heat move away.

- Cooler LEDs shine brighter and last longer.

- The anodized surface stops scratches and rust.

Aerospace and Other Uses

Aerospace systems need strong parts for tough places. Black anodized heat sinks are used in satellites and airplanes. They are also in defense equipment. These heat sinks handle big temperature changes and strong shakes. The anodized layer keeps them light and strong.

| Requirement | Description |

|---|---|

| Extreme Environmental Variation | Works from freezing cold to very hot temperatures |

| Vibration and Shock Resistance | Stays in place during strong movement |

| Weight Optimization | Keeps weight low for aircraft and spacecraft |

| Reliability Requirements | Works for long times without needing repairs |

You also find these heat sinks in healthcare machines and telecom towers. They protect electronics and help them last longer.

Tip: If you need a heat sink for a hard job, a black anodized heat sink gives you strength, cooling, and reliability.

How Black Anodized Heat Sinks Extend Device Lifespan and Reliability

A black anodized heat sink does more than cool. It protects your devices from heat, rust, and scratches. This helps your electronics work better and last longer.

| Benefit | Description |

|---|---|

| Enhanced Heat Dissipation | The special oxide layer helps move heat away quickly. |

| Improved Surface Emissivity | The black finish lets the heat sink send out more heat, keeping devices cooler. |

| Increased Surface Area | The porous surface helps with heat radiation, stopping overheating. |

- Corrosion resistance keeps your heat sink working in wet or dirty places.

- The hard surface stops scratches, so cooling stays strong.

- Electrical isolation keeps your electronics safe from short circuits.

You see black anodized heat sinks in many industries:

- Automotive

- Aerospace and defense

- IT and telecom

- Healthcare

These heat sinks help your devices stay cool, safe, and reliable, even in tough jobs.

Comparison With Other Heat Sink Finishes

Bare Aluminum vs. Black Anodized

When you compare heat sinks, you see bare aluminum and black anodized types. Bare aluminum heat sinks look shiny and silver. They are light and move heat well. But they do not get rid of heat as fast as black anodized ones. The black anodized heat sink has a special layer on top. This layer helps it send heat away faster. The black layer also keeps the metal safe from rust and scratches. In tough places, you want a heat sink that lasts and keeps things cool. Black anodized heat sinks do both jobs well.

Tip: Pick a finish that cools and protects if you want your electronics to last.

Other Coatings

You can also find heat sinks with other coatings. Each coating has its own good points:

- High-emissivity acrylic coatings help heat sinks cool better than low-emissivity silver nanoparticle (AgNP) coatings. They can lower the temperature by more than 22°C.

- AgNP coatings make the temperature more even across the heat sink. They can lower the difference by about 4.4°C compared to acrylic coatings.

- AgNP coatings also make the inside temperature gap smaller by up to 0.39°C compared to acrylic.

These coatings help in special cases, but they may not last as long as black anodized finishes.

Why Industry Prefers Black Anodization

Many industries use black anodized heat sinks in their best machines. You see them in electronics, cars, and airplanes. The black finish gives great cooling and stands up to hard use. Companies trust this finish because it lasts longer and works better than most other coatings.

| Feature | Detail |

|---|---|

| Market Share | About 60% |

| Thermal Performance | Superior to other finishes |

| Applications | Electronics, Automotive |

| Growth Projection | 4.3% CAGR from 2025 to 2032 |

Several trends push this choice. Governments want greener products, so companies use eco-friendly anodizing and recyclable materials. More people living in cities and more need for electronics and medical devices also help this market grow. Health rules now say medical gear must cool better. All these things make black anodized heat sinks the top choice for today’s industry.

When you pick black anodized heat sinks, you get lots of good things. These heat sinks cool really well because they send out heat fast. Look at the table to see how they do:

| Metric | Black Anodized | Bare Aluminum |

|---|---|---|

| Thermal Emissivity | 0.85-0.9 | 0.1-0.2 |

| Cooling Improvement | Up to 40% | N/A |

The surface is tough and does not rust or wear out easily. Ecotherm checks each heat sink to make sure it works well. People who know a lot about the industry say black anodizing is best for heat control. You can count on these heat sinks to keep your devices safe and working well.

FAQ

What makes black anodized heat sinks better than plain aluminum ones?

You get better cooling with black anodized heat sinks. The black surface lets heat leave faster. The anodized layer also protects against rust and scratches. Your devices stay cooler and last longer.

Can you use black anodized heat sinks outdoors?

Yes, you can use them outdoors. The anodized layer keeps water and rust away. Your heat sink stays strong in rain, sun, or snow.

How do you clean a black anodized heat sink?

Use a soft brush or cloth. You can wipe dust away easily. Do not use harsh cleaners. The anodized surface stays clean and bright with gentle care.

Can you order custom shapes or sizes?

Yes, you can order custom shapes and sizes. Companies like Ecotherm use CNC machines to make heat sinks that fit your needs. You get the right size for your project.

How long does a black anodized heat sink last?

You can expect a long lifespan. The anodized layer protects against wear and rust. Your heat sink keeps working well for many years.