How to manufacture skived heat sinks

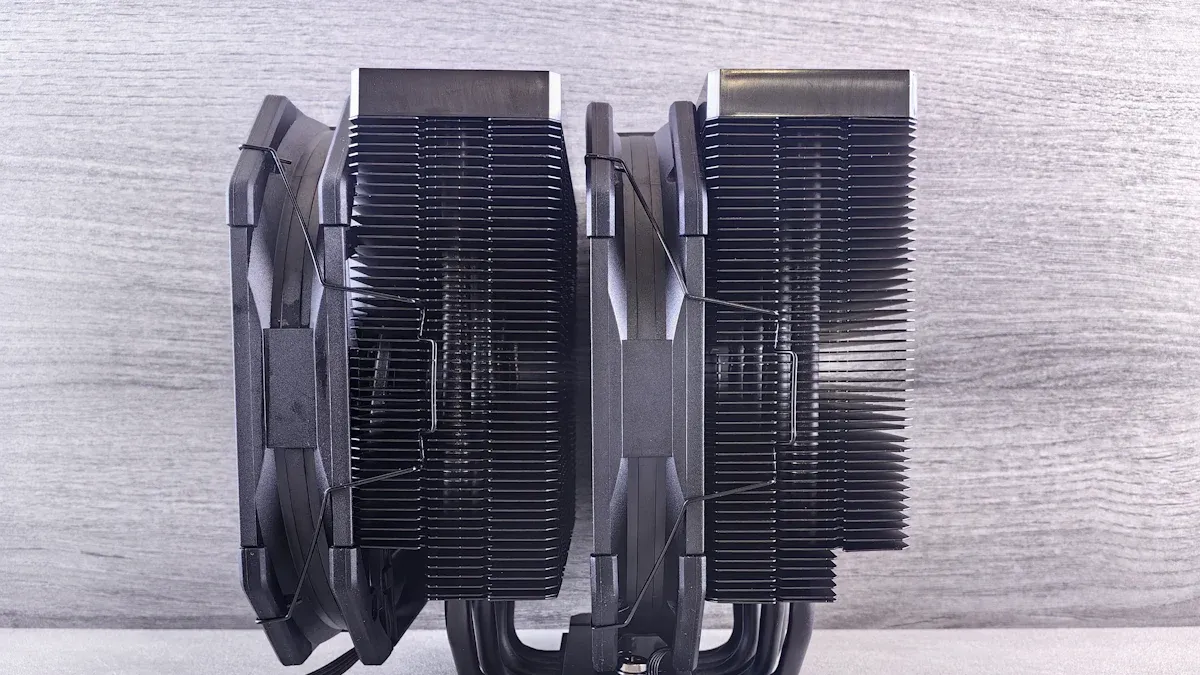

You make skived heat sinks by cutting and bending thin fins from a solid block of copper or aluminum using a sharp blade. This process is called heat sink skiving. It creates one piece without any thermal joints. The fins are very thin and close together, so you get high fin density. This design gives more surface area for heat to leave. Skived heat sinks cool better than other types.

Key Takeaways

- Skived heat sinks use one block of metal. The metal is usually copper or aluminum. This helps heat move better. It also makes the design stronger.

- The skiving process makes thin fins. The fins are close together. This gives more surface area. More surface area helps cooling work better than other heat sinks.

- Picking the right material is very important. Copper moves heat better. Aluminum is lighter and costs less.

- Quality control is very important. Check for any problems. Do thermal resistance tests. This makes sure the heat sink works well in tough jobs.

- Skived heat sinks work best for strong electronics. They are good for cars and data centers. These places need good cooling.

Skived Heat Sink Overview

What Is a Skived Heat Sink

A skived heat sink is a cooling tool made from one block of metal. The metal is usually copper or aluminum. A sharp blade cuts and bends thin fins from the block. This makes the base and fins one solid piece. There are no welds, glue, or joints in this design.

- The base and fins are joined as one piece.

- Heat moves easily from the base to the fins.

- There are no barriers for heat to cross.

- This helps heat move faster and better.

- The heat sink is strong and does not have weak spots.

- Parts will not come apart or break off.

Skived heat sinks help cool electronics well. The solid design means less chance of breaking. It works well even in hard conditions.

Key Features and Benefits

Skived heat sinks have many good points compared to other types. Here is a table that shows how skived heat sinks and extruded heat sinks are different:

| Feature/Benefit | Skived Heat Sinks | Extruded Heat Sinks |

|---|---|---|

| Thermal Performance | Great at moving heat away | Good, but not as strong |

| Design | Fins are packed close together | Fins are spaced farther apart |

| Weight | Lighter, good for things that need less weight | Heavier |

| Production Complexity | Harder to make, needs more care | Easier and quicker to make |

| Cost | Costs more because it needs precision | Costs less, good for making many |

| Applications | Used in laptops, LEDs, medical tools | Used in regular electronics |

Skived heat sinks cool better because they have thin fins and many fins. This gives more space for heat to leave. The solid design makes them tough and less likely to break. If you want a strong and good cooling part for important electronics, skived heat sinks are a smart choice.

Heat Sink Skiving Process

Material Selection

First, you pick a metal for the heat sink skiving process. Most companies use copper or aluminum. These metals move heat well. Copper has a thermal conductivity of 401 W/mK. Aluminum, like A6061 or A6063, has a thermal conductivity of 167 W/mK. You can see the difference in this table:

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Copper | 401 |

| Aluminum (A6061/A6063) | 167 |

Copper cools better, so it is used for high-performance devices. Aluminum is lighter and costs less. You choose aluminum when you want to save weight or money. Both metals help make strong and efficient heat sinks.

You also need to pick the right alloy. For aluminum, 6063-T5 is good for extrusion and gives a smooth surface. 6061-T6 is stronger and welds well. These choices change how your heat sink works.

| Alloy | Best For | Thermal Conductivity (W/mK) | Key Advantage |

|---|---|---|---|

| 6063-T5 | Extrusion | ~200 | Smooth surface, complex shapes. |

| 6061-T6 | CNC Machining | ~170 | Stronger, welds well. |

Tip: Use copper for the best cooling. Pick aluminum if you want a lighter heat sink or need to spend less.

Skiving and Fin Formation

After you choose your metal, you use a skiving machine. The machine slices thin fins from a solid block and bends them up. This step makes the base and fins one piece. There are no joints in the structure.

A sharp blade cuts each fin. You control how deep the blade goes to set the fin thickness. Spindle stability keeps the fins even and smooth. Chip evacuation removes metal scraps and keeps the surface clean. The table below shows important things for fin formation:

| Critical Parameter | Description | Impact on Fin Formation |

|---|---|---|

| Depth of Cut | Sets how thick the fins are. | Changes the fin’s strength and performance. |

| Spindle Stability | Keeps the fin shape and size the same. | Needed for even fins. |

| Chip Evacuation | Removes metal chips during cutting. | Reduces tool wear and keeps the surface nice. |

You can make fins as thin as 0.1 mm. Thin fins let you put more fins close together. This gives more surface area and helps heat escape faster. The table below shows how fin thickness changes cooling:

| Fin Thickness | Typical Range | Impact on Heat Dissipation |

|---|---|---|

| ~0.1 mm | Thinnest possible | More fins and surface area, better heat escape |

| 0.05 mm | Very rare | More surface area but may be too weak |

| 0.1 mm – 2 mm | Normal range | Thicker fins are stronger but have less surface area |

| Feature | Thicker Fins | Thinner Fins |

|---|---|---|

| Conduction | Higher | Lower |

| Fin Density | Lower | Higher |

| Surface Area | Lower | Higher |

New skiving machines can make fins as thin as 0.081 mm for copper and 0.1 mm for aluminum. You can also make heat sinks up to 2,900 mm long and 900 mm wide. Fins can be as tall as 180 mm. These new machines help you build heat sinks for many devices.

Note: The shape of skived fins depends on how much force you use to bend them. Thin and tall fins are harder to make. You must balance fin thickness, height, and spacing for the best cooling.

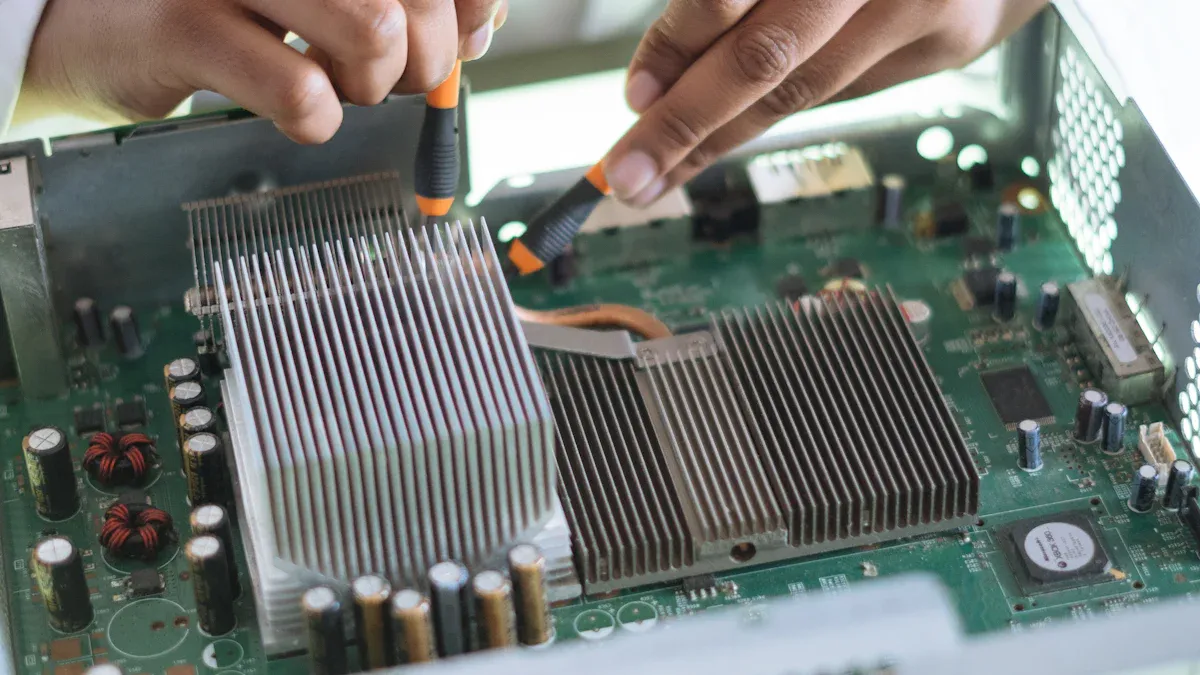

Post-Processing Steps

When skiving is done, you clean and trim the heat sink. You remove sharp edges and leftover metal chips. Cleaning makes the surface smooth and free from dirt. You may anodize or coat the heat sink to protect it from rust and wear.

You check the fins for damage. Bent or broken fins can lower cooling. You fix any problems before shipping. Some companies add labels or marks for tracking and quality control.

- Trim sharp edges for safety.

- Clean the surface to remove dust and chips.

- Check fins for damage.

- Add coatings if needed.

Heat sink skiving takes more time and costs more than other ways. You need special machines and skilled workers. The process is slower than extrusion or die casting. You may wait longer for big orders. Skived fins are not as strong as extruded fins, so do not use them where they might get hit or bent.

| Process | Advantages | Limitations |

|---|---|---|

| Skiving | High fin density, better cooling | Needs special machines |

| Aluminum Extrusion | Cheaper, easy to change | Size limits |

| Die Casting | Fast, accurate | Costs more to start |

Tip: Use heat sink skiving when you need high cooling and can wait longer for production.

Quality Control

Inspection Methods

You have to check each skived heat sink for quality. First, look for bent fins or rough edges. Also, check for leftover metal chips. Use calipers or gauges to measure fin thickness and height. This makes sure the fins are the right size. Cameras or microscopes help you find small cracks or flaws. You also need to check for certifications. These show your heat sinks are safe and follow rules. Here is a table of common certifications:

| Certification | Description |

|---|---|

| RoHS | Restricts hazardous substances in electrical and electronic equipment |

| REACH | Addresses the production and use of chemical substances and their potential impacts on human health and the environment |

| UL | Ensures products meet specific safety standards for electrical devices |

If you want to sell heat sinks for medical, car, or airplane use, you must meet these standards. Always keep records of your checks and certifications.

Tip: Careful checking helps you avoid mistakes and keeps customers happy.

Performance Testing

You need to test how well your heat sinks work. Start with a thermal resistance test. This test checks how fast heat moves from the base to the fins. You want low thermal resistance for better cooling. Next, do mechanical testing to see if the heat sink can handle shocks or drops. This test makes sure the fins do not bend or break.

If you use liquid cooling, you must do fluid testing. This test checks for leaks under pressure. It keeps your devices safe from water damage. You also need to measure the thermal resistance value again to make sure the heat sink stays stable during use.

Here is a table of common performance tests:

| Test Type | Description |

|---|---|

| Thermal Resistance Test | Evaluates the thermal conductivity of the heat sink material and checks for potential leakage in heat pipes under high-temperature conditions. |

| Mechanical Testing | Assesses shock resistance and impact to ensure there is no deformation or damage to the heat sink. |

| Fluid Testing | Tests for leakage in liquid-cooled plates under specific fluid pressure conditions, ensuring the stability of the welding process. |

| Thermal Testing | Measures the thermal resistance value, which is crucial for the stability of the chipset. |

You should always do these tests when making skived heat sinks. Good testing helps you give customers reliable products every time.

Advantages and Applications

Why Choose Skived Heat Sinks

You get many benefits when you use skived heat sinks. These heat sinks come from a single block of metal. This means you do not need glue or joints. The design helps heat move fast and keeps the structure strong. You will see fewer problems with cracks or loose parts over time.

Here is a table that shows the main advantages:

| Advantage | Description |

|---|---|

| Seamless Construction | Made from one block of metal, so you do not need adhesives or joints. |

| Reduced Thermal Barriers | No glue or joins means heat moves better and more evenly. |

| Enhanced Fatigue Resistance | Fewer weak spots, so the heat sink lasts longer under stress. |

| Stable Fin Structure | Fins stay in place and do not break off, so you need less maintenance. |

| Improved Acoustic Performance | Simple structure means less noise from loose parts, especially in fanless systems. |

You can trust skived heat sinks for tough jobs. They work well in places where you need strong and steady cooling. The process of heat sink skiving gives you a product that handles heat and stress better than other types.

Common Uses

You will find skived heat sinks in many industries. They help cool important parts in different devices. Here are some common uses:

- Electronics: You see them in computers, where they cool CPUs and GPUs. These parts get very hot and need good cooling.

- Automotive: Electric cars and hybrid vehicles use these heat sinks to manage heat from batteries and power electronics.

- Telecommunications: Telecom equipment and consumer gadgets use them for thermal management.

- Data Centers: Servers and storage systems use skived heat sinks to keep running without overheating.

The market for skived heat sinks keeps growing. Experts expect the market to rise from $500 million in 2025 to $850 million by 2033. This growth comes from the need for better cooling in high-performance electronics and electric vehicles. New materials and smaller devices also help the market grow.

Tip: If you need fast custom orders, built-to-print skived heat sinks can be ready in as little as four months. Full development projects may take five to twelve months.

You use three main steps to make skived heat sinks. First, you machine a block of metal. This gives a strong base for the fins. The metal helps heat move well. Next, you cut the fins with special tools. You can change the size of the fins for different needs. Last, you make sure the fins and base connect without gaps. This helps heat move quickly from the base to the fins. The table below explains how each step helps:

| Step | Description | Contribution to Efficiency |

|---|---|---|

| 1 | Machining a metal block | Makes a strong base and helps heat move fast. |

| 2 | Cutting fins with special tools | Lets you pick fin sizes for better cooling. |

| 3 | Making a smooth connection between fins and base | Helps heat move better and keeps things cool. |

This process gives you lots of fins close together. It also helps heat leave the device quickly. Skived heat sinks are great for powerful electronics. They stop devices from getting too hot and keep them safe. Now you know how skived heat sinks are made and why this way works well.

FAQ

What makes skived heat sinks different from extruded heat sinks?

You get skived heat sinks with thinner and more closely packed fins. This design gives you more surface area for cooling. Extruded heat sinks have thicker fins and less surface area.

Can you use skived heat sinks for custom shapes?

Yes, you can. Skiving lets you create many shapes and sizes. You can adjust fin height, thickness, and spacing to fit your needs.

How do you clean a skived heat sink?

You can use compressed air to blow away dust. For sticky dirt, use a soft brush or a damp cloth. Avoid bending the thin fins.

Are skived heat sinks expensive?

Skived heat sinks usually cost more than extruded ones. You pay for higher precision and better cooling. The price depends on the metal, size, and design.