Cold plate solutions for custom cooling needs

You have special cooling problems with strong electronics or new systems. Custom cold plate solutions help with these needs. They give you thermal management made just for you. Some industries like AI, electric vehicles, and aerospace use custom designs. These designs give better performance and reliability. Teams often work with engineers to make these plates. They use advanced design methods. If you want to learn how custom solutions can help your cooling, you are in the right place.

What is a custom cold plate?

Definition and Function

A custom cold plate is a metal plate that helps cool things. It moves heat away from electronics or batteries. You put the cold plate on your device. Coolant goes through small paths inside the plate. The plate takes heat from your device. The coolant carries the heat away.

Here’s how a cold plate works to move heat:

| Heat Transfer Mechanism | Description | Importance |

|---|---|---|

| Conduction | Heat travels through the plate from your device. | This step puts heat into the plate. |

| Convection | Coolant flows and removes heat from the plate. | This step keeps your device cool. |

| Radiation | Heat leaves as waves you cannot see. | This part is not very big in most cold plates. |

You can use coolants like ethylene glycol, propylene glycol, or deionized water. Each coolant works best for different jobs. Ethylene glycol is cheap and used a lot. Deionized water is safe and cools well. But it needs care so it does not freeze.

Custom vs. Standard Cold Plates

You might wonder why not use a regular cold plate. Standard cold plates have set shapes and sizes. They work for easy jobs. Sometimes your project needs something special. Maybe your space is small or your device gets very hot. Then you need a custom cold plate.

Here are some types:

| Type of Cold Plate | Structure Description | Thermal Performance Description | Manufacturing Process Description |

|---|---|---|---|

| Stamped Liquid Cold Plate | Channels stamped in aluminum, often with fins. | Very good at cooling, better than tube types. | Uses brazing and always gets checked for leaks. |

| CNC-Machined Liquid Cold Plate | Channels cut by machines, can be very detailed. | Great for even cooling and low pressure drop. | Takes longer and costs more. |

| Embedded Round Tube Cold Plate | Tubes pressed into grooves in a plate. | Good for medium heat, but not as good as others. | Simple and cheap to make. |

| Flat Tube Manifold Cold Plate | Flat tubes with special shapes inside for better flow. | Works well with thick fluids and gives even cooling. | Made in one piece, good for big orders. |

A custom cold plate lets you choose the size, shape, and channel design. You get the best fit and cooling for your needs.

Applications

Custom cold plates are used in many places. They help cool things that get hot and need to stay safe.

| Industry | Applications |

|---|---|

| New Energy Sector | EV battery plates, energy storage, fuel cell systems, wind turbines, solar inverters, chargers. |

| Electronics | Cooling power electronics, CPUs, GPUs. |

| Aerospace | Avionics and power systems in planes. |

| Automotive | Battery cooling in electric cars. |

| Renewable Energy | Inverters and other solar power parts. |

Tip: If you work with high-power electronics, electric vehicles, or renewable energy, you may need a custom cold plate to keep things cool and safe.

Custom cold plates help solve hard cooling problems. You get a solution that fits your project, not just a regular part.

Why choose a custom cold plate?

Limitations of Standard Solutions

You may think a regular cooling plate is enough. But many times, it does not work well. Standard plates have set shapes and simple channels. These are fine for easy jobs. But they do not work for high power or special needs.

Here are some problems with standard solutions:

| Limitation | Description |

|---|---|

| Inefficient Heat Transfer | Regular channels do not touch much of the heat source, so they do not move heat well. |

| Restricted Flow Characteristics | Sharp turns and simple shapes make the coolant flow slow and rough. |

| Non-Uniform Cooling Distribution | Standard channels do not cool every spot the same, so some parts get too hot. |

If you see hot spots or uneven cooling, you need something better. Custom designs help you cool the right spots and work better.

Industry Use Cases

Custom cold plates are used when cooling needs are hard or special. You find them where regular plates do not work.

Electronics Cooling

You use strong CPUs, GPUs, or other electronics. These get hot very fast. Custom cold plates help keep them cool, even when working hard. Data centers with AI chips use custom cooling to stop overheating.

Industrial Systems

Factories use machines all day long. Some jobs, like pasteurizing food, need exact temperatures. Custom cold plates help control heat in these places.

Medical Devices

Medical machines must stay cool to work right. You want them to be safe and reliable. Custom cold plates keep important parts at the right temperature.

Aerospace and Defense

Military and aerospace gear faces tough conditions. You need cooling that fits small spaces and handles lots of heat. Custom cold plates give you the right fit and power for these jobs.

DIY and Custom-Drilled Plates

Sometimes you build your own projects or change old ones. You might drill holes or change the shape to fit your needs. Custom cold plates let you make what you want for hobbies or new ideas.

Tip: If you work in food, military, aerospace, or data centers with AI, you should use a custom cold plate. These jobs often need special cooling that regular plates cannot give.

Custom cold plates let you pick flow, cooling, and shape. You fix problems that regular plates cannot. If you want better cooling and safety, custom is best.

Customization options for cold plates

When you want the best cooling for your project, you need to look at all the ways you can customize your cold plate. Let’s break down the main choices you have.

Material Choices

The material you pick for your cold plate changes how well it moves heat and how much it costs. Here’s a quick look at the most common options:

| Material | Thermal Conductivity (W/m·K) | Best For |

|---|---|---|

| Aluminum | ~205 | General purpose, weight-sensitive, budget-friendly |

| Copper | ~400 | High heat flux, top thermal performance |

| Composites | Varies | Special jobs, extreme weight savings |

Aluminum

Aluminum is a favorite for many people. It is light, easy to shape, and does not cost much. You can use it in most jobs where you want good cooling but do not need the very best. Aluminum also fights rust, so it lasts longer in wet places. If you care about weight or your budget, aluminum is a smart pick.

- Pros: Light, affordable, easy to work with, resists rust.

- Cons: Not as good at moving heat as copper, not for very hot jobs.

Copper

Copper is the king when you need the best cooling. It moves heat almost twice as fast as aluminum. You see copper in places where things get very hot, like in big computers or power stations. Copper costs more and weighs more, but it gives you top performance.

- Pros: Best at moving heat, lasts a long time, great for tough jobs.

- Cons: Heavy, costs more than aluminum.

Hybrid Materials

Sometimes you want the best of both worlds. Hybrid materials mix metals or add special layers. You might see a plate with copper on the inside and aluminum on the outside. This gives you strong cooling and saves weight or money. Some new plates even use special graphite sheets or nano-materials for extreme jobs.

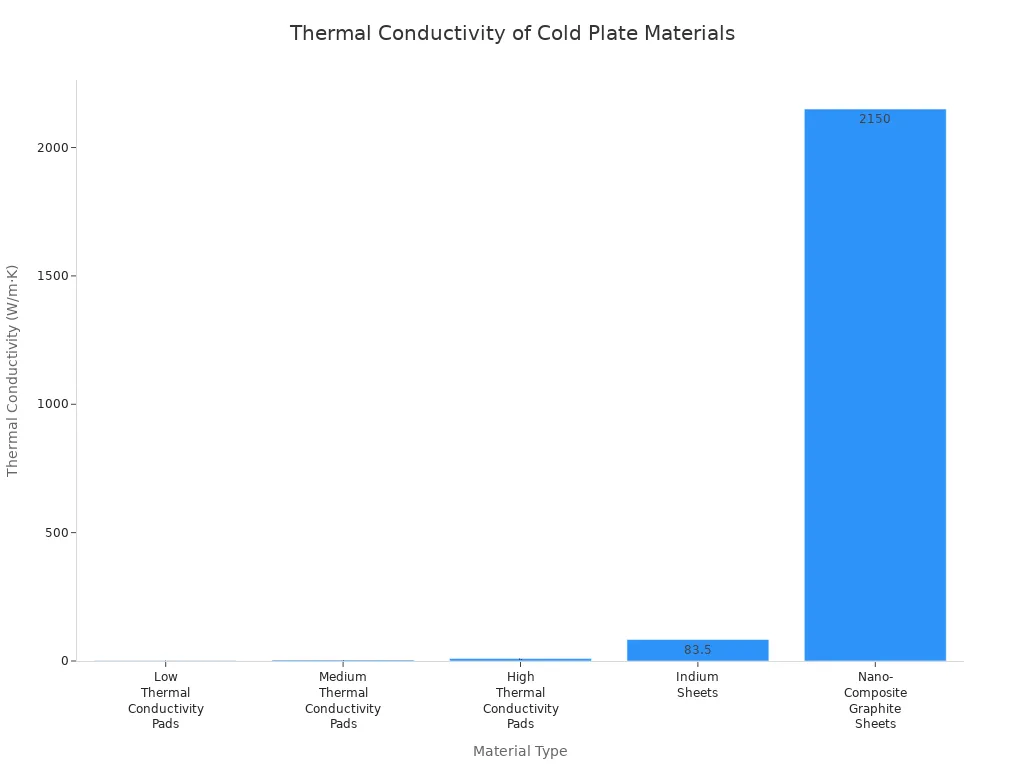

Here’s a table showing how different materials compare for moving heat:

| Material Type | Thermal Conductivity (W/m·K) | Application Suitability |

|---|---|---|

| Low Thermal Conductivity Pads | 1-3 | Emergency use only, not for main cooling |

| Medium Pads | 4-6 | Okay for medium jobs, not for full power |

| High Pads | 7-12 | Good for heavy loads, like 750W |

| Indium Sheets | 81-86 | Very high, but used for special cases |

| Nano-Composite Graphite | 1800-2500 | Used for extreme cooling, very advanced |

Tip: If you want the best cooling, look at copper or hybrid plates. If you want to save money or weight, aluminum is a great choice.

Channel Design

The way the channels run inside your cold plate changes how well it cools. You can pick from different shapes and layouts.

Serpentine

Serpentine channels twist and turn like a snake. The coolant moves through every part of the plate. This design spreads the cooling out and helps stop hot spots. If you want even cooling, serpentine is a good pick.

- Fins at a 30° angle work best for cooling in serpentine channels.

- A 90° fin gives the highest heat transfer.

Parallel

Parallel channels split the coolant into many paths. The coolant moves straight through, so it does not slow down much. This design works well if you want low pressure and fast flow. It is good for big jobs where you need to cool many spots at once.

Pin Fin & Microchannel

Pin fin and microchannel designs use lots of tiny pins or very small channels. These give the coolant more places to touch, so they move heat away fast. Pin fins boost the cooling power and help in tough jobs. Microchannels are great for small spaces or when you need the best cooling.

- Adding pin fins makes the plate much better at moving heat.

- Hybrid mini-channel designs can cool better than regular ones.

| Channel Design Type | Impact on Heat Transfer Rates |

|---|---|

| Tesla Channel Design | Makes the coolant move in a way that boosts heat transfer. |

| Structural Changes | Wider channels and special shapes lower the hottest spots. |

| Flow Resistance | Special shapes let the coolant flow better without moving parts. |

| Cooling Efficiency | Smart channel designs make the whole system work better and save energy. |

Note: The right channel design depends on your space, how much heat you need to move, and how fast you want the coolant to flow.

Size and Shape

You can make your cold plate almost any size or shape. This helps you fit it into tight spaces or odd spots in your system. Some plates are flat, while others have curves or layers. You can even make plates with different zones for different parts.

| Customization Aspect | Description |

|---|---|

| Size | Must fit your space and mounting spots. |

| Shape | Can be flat, curved, multi-layered, or have special zones. |

| Integration | Should work well with the rest of your cooling system. |

- Make sure your plate matches your system’s space and cooling needs.

- The inside channels matter as much as the outside shape.

Tip: Always measure your space and check how the plate will fit with other parts before you order.

When you look at all these options, you can build a cold plate that fits your needs perfectly. You get better cooling, save space, and make your system work better.

Mounting and Integration

You want your cold plate to fit your system well. You need to think about how to attach it and connect it to other parts. If you do this right, your cooling will work better and look neat.

There are different ways to mount a cold plate. Some plates use bolts or screws to stay in place. Others can slide into slots or use clamps to hold them. Some plates have special holes or brackets made just for your project. The way you mount your plate depends on your space and what you need to cool.

Integration is important too. Your cold plate might need to connect to sensors, pumps, or other cooling parts. Some plates have special ports or fittings for this. Others have places for temperature sensors or flow meters. If you plan ahead, you can make sure everything fits and works together.

Let’s see how different cold plate types give you more or less choices:

| Cold Plate Type | Design Flexibility | Application Suitability |

|---|---|---|

| Tubed Cold Plate | High | Excellent for targeting specific hot spots |

| Extruded Plates | Moderate | Cost-effective for simpler applications |

| Brazed Assemblies | Low | High-performance but less adaptable to custom needs |

If you need to cool a hard-to-reach spot, a tubed cold plate gives you the most options. You can bend the tubes or put them where you want. Extruded plates are good for simple jobs and save money. Brazed assemblies are strong for tough jobs, but they are harder to change.

Tip: Always check your system before you buy. Think about where you will put the cold plate and how you will connect it to your cooling system.

Fluid Compatibility

Picking the right fluid for your cold plate is very important. The fluid takes heat away from your device. If you pick the wrong one, you could get leaks, rust, or even break your system.

Here are some common fluids and what you should know:

| Fluid Type | Properties | Compatibility Considerations |

|---|---|---|

| Water | High thermal conductivity, superior heat transfer properties | Corrosion potential with certain materials, impurities may cause clogging, freezing risk. |

| Ethylene Glycol | High boiling point, low freezing point, high specific heat, thermal conductivity | Toxicity concerns, but excellent thermal management properties. |

| Propylene Glycol | Non-toxic, suitable for food applications | Less effective than ethylene glycol, but safer for applications where toxicity is a concern. |

Water cools things very well and is easy to get. But it can cause rust if your plate is not made from the right metal. Water can also freeze in cold places, so you need to be careful.

Ethylene glycol stops freezing and boiling. It works well in cars and big machines. But it is toxic, so you must be careful when using it.

Propylene glycol is safe and not toxic. It is used in food and medical cooling systems. It does not cool as well as ethylene glycol, but it is much safer if it leaks.

Note: Always match your fluid to your cold plate material. If you use the wrong mix, you could get leaks or damage. Ask your manufacturer if you are not sure which fluid to use.

When you think about mounting, connecting, and picking the right fluid, your custom cold plate will work well for your project. You get better cooling, longer life, and fewer problems later.

Benefits of custom cold plate solutions

Enhanced Performance

You want your system to run cool and fast. Custom cold plates help you reach that goal. They move heat away from your devices much better than standard solutions. You get direct heat transfer to the coolant, which means your electronics stay cooler even when they work hard. This is important if you use high-performance computers or run lots of servers.

Take a look at how custom cold plates compare to standard options:

| Feature | Custom Cold Plates | Standard Solutions |

|---|---|---|

| Efficiency | Higher efficiency in thermal management | Lower efficiency in heat transfer |

| Cooling Method | Direct heat transfer to liquid coolant | Indirect cooling (like air cooling) |

| Energy Use | Reduced energy consumption | Higher energy consumption |

| Compute Density | Handles more powerful systems | Limited by cooling ability |

| Application | Great for data centers and HPC | Good for simple environments |

| Adoption Factors | Works with many server types | May need big changes to fit |

With a custom cold plate, you can push your hardware harder without worrying about overheating. You also save energy, which helps lower your costs.

Tip: If you want to run more powerful devices in a small space, a custom cold plate gives you the cooling you need.

Reliability and Lifespan

You want your cooling system to last a long time and need little care. Custom cold plates help you with that. They often have no moving parts, so there is less that can break. You do not have to worry about pumps or fans failing. This means less time fixing things and more time working.

- Custom cold plates remove moving parts and fluids, which makes them more reliable and easier to maintain.

- Some systems, like Boyd’s AI liquid cooling, have worked for over 30 billion hours in the field with a 99.9% leak-free record.

You can trust your system to keep running, even in tough jobs. This is great for places like data centers, factories, or hospitals where you cannot afford downtime.

Design Flexibility

Every project is different. You need a cooling solution that fits your exact needs. Custom cold plates give you that freedom. You can pick the size, shape, and features that work best for your system.

- Companies like JetCool and Flex offer cooling that grows with your needs and works in many places.

- You can design your cold plate to match your device’s shape and cooling needs, making it easy to fit into your system.

- If you plan to upgrade or change your hardware later, custom cold plates can adapt without needing a full redesign.

- They handle high heat and work in different cooling setups, so you can use them in many types of projects.

Note: Custom cold plates help you build systems that last and can change as your needs grow. You do not have to start over each time you upgrade.

System Efficiency

When you want your system to run at its best, you need to think about efficiency. Custom cold plates help you get there. They do more than just keep things cool—they make your whole setup work smarter and save energy.

You might notice that traditional cooling systems use big fans or air handlers. These take up space and use a lot of power. With custom cold plates, you can skip those bulky parts. The cold plate sits right on the hot spot, like a chip or battery, and pulls the heat away fast. This direct-to-chip cooling means you do not waste energy blowing air around the whole system.

Here’s what happens when you use custom cold plates:

- You cut down on the size and number of fans or air handlers.

- Your system uses less electricity because it does not have to move so much air.

- You target the heat right where it starts, so you do not waste energy cooling parts that do not need it.

Did you know? Some pumped two-phase direct-to-chip cooling systems with custom cold plates can lower cooling energy use by up to 82%. That is a huge drop in your power bill!

Let’s look at how this works in real life. Imagine you run a data center. If you use air cooling, you need giant fans and lots of space for airflow. The fans run all day and night, using tons of electricity. When you switch to custom cold plates, you cool each chip directly. The fans can be smaller, or you might not need them at all. Your servers stay cooler, and your energy costs go down.

Here’s a quick comparison:

| Cooling Method | Energy Use | Space Needed | Cooling Target |

|---|---|---|---|

| Air Cooling | High | Large | Whole system |

| Custom Cold Plate | Low | Compact | Direct to hot spot |

You also help the environment. Using less energy means your system makes less heat and pollution. You get a greener setup without giving up performance.

Tip: If you want to save money and help the planet, custom cold plates are a smart choice for system efficiency.

You do not have to settle for old, wasteful cooling. With custom cold plates, you get a system that runs cooler, uses less power, and works better for you.

Ordering considerations

Application Requirements

Before you order a custom cold plate, you need to know what your project really needs. Every system is different, so you want to make sure your cold plate matches your setup. Here’s a handy table to help you think through the main requirements:

| Requirement | Description |

|---|---|

| Heat Source Parameters | List the power range, heat flux, and size of the hot spots. This helps you get the right cooling. |

| Material Selection | Pick between aluminum (light and affordable) or copper (better at moving heat). Check coolant match. |

| Flow Channel Design | Choose the channel shape—straight, serpentine, or microchannel. Each works best for different jobs. |

| Interface Installation | Decide where you want the inlets, outlets, and mounting holes. This makes sure it fits your system. |

| Quality Inspection | Ask for leak testing and high-precision machining. Set clear delivery times in your contract. |

You want to get these details right from the start. If you skip any, you might end up with a cold plate that does not fit or cool well. Always talk with your team and write down your needs before you order.

Tip: Make a checklist of your system’s heat sources, space, and cooling goals. This will help you explain your needs to the manufacturer.

Budget and Lead Time

Money and time matter just as much as the design. Right now, many companies face delays when ordering cooling parts. Global supply chain problems can make some components take 6 to 9 months to arrive. Prices can also go up because of these delays. If you have a tight deadline, you need to plan ahead.

Your budget will shape your choices. High-end materials like copper cost more than aluminum. Complex channel designs or special shapes can also raise the price. Sometimes, you might want the best performance, but your budget says otherwise. You have to balance what you want with what you can afford.

When you plan your order, ask yourself:

- How much can you spend?

- How soon do you need the cold plate?

- Can you wait for special parts, or do you need something faster?

If you know your limits, you can work with the manufacturer to find the best solution for your project.

Manufacturer Collaboration

Working closely with your manufacturer makes the whole process smoother. You want a partner who listens to your needs and helps you solve problems. Good communication helps you avoid mistakes and delays.

Here’s how you can get the most out of your collaboration:

- Share your application requirements and budget early.

- Ask for advice on materials and channel designs.

- Request updates on lead times and production steps.

- Review design drawings and prototypes before final approval.

Note: A strong partnership with your manufacturer leads to better results. You get a cold plate that fits your needs, arrives on time, and works as expected.

When you focus on these ordering considerations, you set your project up for success. You get the cooling you need, when you need it, without surprises.

Prototyping and Testing

You want your custom cold plate to work right the first time. Prototyping and testing help you catch problems early and make sure your design does what you need. Let’s walk through the best ways to get your cold plate ready for real-world use.

Here’s a simple step-by-step approach you can follow:

Model Early, Validate Often

Start with computer models. Use CFD (computational fluid dynamics) simulation to see how coolant flows and how heat moves through your cold plate. This lets you spot trouble areas before you even build anything. You can try different channel shapes and materials on the computer. If you see a problem, you can fix it fast.Focus on Contact Resistance

When you build your prototype, pay close attention to how the cold plate touches your device. You want tight, even contact. If there are gaps or loose spots, heat won’t move well. Use thermal pads or paste if needed. A good fit means better cooling.Balance Flow and Power

Think about your pump. You want enough flow to keep things cool, but not so much that you waste energy. Try different pump sizes and flow rates during testing. Watch how the temperature changes. Find the sweet spot where you get strong cooling without using too much power.Plan for Maintenance Access

Make your cold plate easy to check and service. Design it so you can reach the coolant lines, fittings, and sensors. If you need to replace the coolant or clean the plate, you don’t want to take apart your whole system. Good access saves you time and trouble later.Test Under Real Conditions

Don’t just test in a quiet lab. Try your cold plate in real situations. If you use it for fast-charging batteries, run those tests. Watch how it handles quick changes in temperature or heavy loads. Real-world testing shows you if your design is tough enough.

Tip: Always keep notes during testing. Write down what works and what doesn’t. Photos and temperature charts help you spot patterns and make better choices for your final design.

Testing and prototyping may take extra time, but they save you headaches later. You get a cold plate that fits your needs, works well, and lasts longer. If you follow these steps, you’ll feel confident when you move to full production.

Getting started with a custom cold plate

Consultation and Needs Assessment

You start your custom cooling journey with a good talk. This first step helps you and your team figure out what you really need. You look at your project, your goals, and any limits you face. Here’s a simple table that shows what you should think about during this stage:

| Step | Description |

|---|---|

| Battery Type and Characteristics | Think about what kind of batteries or devices you use. Each one makes heat in a different way. |

| Quantified Heat Dissipation Requirements | Figure out how much heat you need to move. Check if you need even cooling or have limits on coolants. |

| Fluid Resistance Considerations | Look at how hard it is to push fluid through your system. Make sure your pump can handle it. |

| Structural Strength Requirements | Check if your cold plate needs to be strong or handle heavy loads. Plan for how you will install it. |

| Comprehensive Cost Assessment | Think about the price now and later. Include maintenance and energy savings in your plan. |

| Certification and Standard Compliance | Make sure your design meets safety and environmental rules for your industry. |

You want to get these details right. If you miss something, your cold plate might not work as you hoped. Take your time and ask lots of questions.

Tip: Write down your needs and share them with your design team. This helps everyone stay on the same page.

Design and Engineering

Once you know what you need, you move to the design and engineering stage. Here, you work with experts to turn your ideas into a real plan. You get to see drawings, models, and maybe even 3D images of your future cooling solution.

- You get a design that fits your exact needs. No two projects are the same, so your cold plate will be unique.

- Engineers and designers work together to make sure your plate cools well and is easy to build.

- You can talk about different materials, shapes, and channel designs. The team helps you pick what works best for your job.

- Some companies, like Baknor, focus on cooling for high-power electronics and electric vehicles. They use different ways to make your plate, so you get the best mix of cost and performance.

You stay involved during this step. You can ask for changes or give feedback. The goal is to make sure your cold plate will work well before anyone starts building it.

Note: Good teamwork during design means fewer problems later. You save time and money by fixing issues early.

Prototyping

Now it’s time to see your design come to life. Prototyping lets you test your ideas before you order a big batch. You get to check if everything fits and works as planned.

Here’s a quick look at the usual stages and how long each one takes:

| Stage | Timeline |

|---|---|

| Initial specifications review | Immediate |

| Design evaluation | 1 week |

| Prototyping (using existing tools) | Under 4 weeks |

| Custom design (if needed) | Additional 4-6 weeks (if tooling is required) |

You start with a review of your needs. The team checks your design and makes a sample. If you use standard tools, you can get a prototype in less than a month. If you need special shapes or tools, it might take a bit longer.

During this stage, you test the prototype in real conditions. You look for leaks, check the fit, and see how well it cools. If you find a problem, you can fix it before you move to full production.

Tip: Always test your prototype in the same way you will use it. This helps you catch any surprises early.

By following these steps, you make sure your cooling solution is ready for action. You get a cold plate that fits your needs and works the way you want.

Production and Delivery

You have finished your prototype and approved the design. Now, it is time to move into production and delivery. This stage brings your custom cold plate from the drawing board to your hands. You want this process to go smoothly, so you get a high-quality product on time.

First, you need to keep communication open with your manufacturer. Share all your requirements and double-check the details. If you have questions or changes, speak up early. When you and your manufacturer talk often, you avoid mistakes and delays. You both stay on the same page, which helps your project move forward.

A single point of contact makes things easier. You know who to call if you need an update or have a concern. This person can answer your questions fast and keep you informed about each step. You do not have to chase down different people for answers.

Manufacturers use project management to keep everything on track. They break the job into smaller tasks and work on some at the same time. This helps them finish your order faster. If a problem pops up, they can fix it before it slows down the whole project.

You can help by sharing your future needs and forecasts. If you know you will need more cold plates later, let your supplier know. They can plan ahead and make sure they have enough materials and workers ready. This can speed up your next order and help you avoid long waits.

Here is a quick checklist to help you manage production and delivery:

- Stay in touch with your manufacturer and share updates.

- Make sure you have one main contact for all questions.

- Review your order details before production starts.

- Ask for regular progress reports.

- Let your supplier know about future needs.

Tip: Good teamwork with your manufacturer leads to better quality and faster delivery. If you work together, you can solve problems before they grow.

When your cold plates are ready, the manufacturer will pack and ship them to you. Check the delivery as soon as it arrives. Look for any damage and test a few plates to make sure they meet your standards. If you find a problem, contact your supplier right away.

By following these steps, you can feel confident that your custom cold plate will arrive on time and work as expected. You get a cooling solution that fits your needs and helps your project succeed.

Trends in cold plate technology

Advanced Manufacturing

Cold plate technology is getting better every year. Companies now use new ways to make cold plates stronger and last longer. They shape and build each plate with special tools. Here are some top ways they make cold plates:

| Manufacturing Technique | Pros | Cons |

|---|---|---|

| Machining | Makes smooth surfaces and detailed shapes. | Costs a lot, takes time, wastes material. |

| Extrusion + tube insertion | Cheaper, works well for medium heat jobs. | Not as flexible, can leak sometimes. |

| Vacuum-brazed bonding | Moves heat well, has tiny channels. | Costs more, hard to change, needs special tools. |

| Additive manufacturing (3D printing) | Makes cool shapes, helps coolant flow better. | Not as strong, costs more, not good for big batches. |

| Other methods / hybrid approaches | Makes special shapes, fits tight spaces. | No big problems listed. |

Some cold plates use new alloys like CP1. These alloys help move heat and make the plate strong. Some companies use computers to design better shapes. This is called generative design. It helps make plates that cool better and use less metal. These new ways help you get a cold plate that fits your project faster.

Tip: If you want a cold plate with a special shape or better cooling, ask about 3D printing or computer design. These choices give you more options and faster results.

Smart Monitoring Integration

Smart tech is now in cold plates too! You can add sensors and monitors to your cooling system. These tools watch temperature, flow, and leaks all the time. If something is wrong, you get a warning right away.

- Temperature sensors help you find hot spots fast.

- Flow meters show if coolant is moving right.

- Some systems connect to your phone or computer, so you can check from anywhere.

Smart monitoring lets you fix problems before they get big. You save money and time because you catch issues early. This makes your system safer and more dependable.

Note: Adding smart sensors helps your equipment last longer and keeps you from losing time and money.

Sustainable Materials

Many people care about the earth, and so do cold plate makers. Now, more cold plates use light aluminum and new composites. These materials cool well and weigh less, which helps in cars and planes.

- Many companies use materials that can be recycled.

- Some cold plates use coolants that are safer for nature.

- You can get designs that use less metal but still cool well.

Using green materials means your cold plate works great and helps the planet. If you want to help the earth, ask your supplier about eco-friendly choices.

Picking green cold plates is good for your business and the planet.

You’ve seen how a custom cold plate can solve tough cooling problems. Take a look at your own setup. Ask yourself if your system needs better cooling. You might want to:

- Talk with a manufacturer about your options

- Write down your cooling requirements

- Try a prototype before you order a full batch

Ready to improve your cooling? Start exploring custom solutions today.

FAQ

What is a custom cold plate?

A custom cold plate is a cooling device made just for your project. You pick the size, shape, and features. It helps move heat away from your electronics or batteries fast.

How do I choose the right material for my cold plate?

Think about your cooling needs and budget. Aluminum works well for most jobs and costs less. Copper cools better but weighs more. Ask your manufacturer for advice if you are not sure.

Can I use any coolant with my cold plate?

No, you need to match the coolant to your cold plate material. Water, ethylene glycol, and propylene glycol are common choices. Some fluids work better with certain metals. Always check compatibility first.

How long does it take to get a custom cold plate?

Most projects take 4 to 12 weeks from design to delivery. The timeline depends on your design, material, and how busy the manufacturer is. Ask for an estimated lead time when you order.

Do I need special tools to install a custom cold plate?

Usually, you only need basic tools like wrenches or screwdrivers. Some plates have special fittings or mounts. Your supplier will tell you if you need anything extra.

What industries use custom cold plates?

You see custom cold plates in data centers, electric vehicles, medical devices, aerospace, and factories. They help cool high-power electronics and batteries in many fields.

Can I test a prototype before full production?

Yes! Most manufacturers offer prototyping. You can test the cold plate in your system and make changes before you order a large batch.

Tip: Always test your prototype under real working conditions for the best results.