Cold Plate Cooling

You use cold plate cooling to manage heat in powerful electronics. A cold plate is a metal device that transfers heat from components to a liquid coolant, such as water or water-glycol mixtures. This process keeps equipment safe and efficient, especially in high-density environments. You rely on cold plate cooling when air cooling cannot meet your system’s demands. You benefit from its advanced thermal performance, reliability, and compact design.

Key Takeaways

- Cold plate cooling efficiently transfers heat from electronics to a liquid coolant, ensuring safe operation in high-density environments.

- Select a cold plate with optimized channel geometry and fin structures to enhance heat transfer for your specific thermal needs.

- Regularly inspect your cold plate for signs of corrosion or wear to maintain efficient heat transfer and extend system life.

- Cold plates save space compared to traditional air cooling methods, allowing for denser layouts in electronics and improved design flexibility.

- Choose corrosion-resistant materials and compatible coolants to enhance the durability and reliability of your cold plate system.

- Cold plate cooling operates quietly, making it ideal for environments where noise control is important, such as labs and data centers.

- For optimal performance, match the cold plate design to your device’s heat output and ensure proper installation with thermal interface materials.

- Consider custom cold plate designs for unique cooling challenges, allowing for precise temperature control and integration with complex systems.

Cold plate cooling: how it works

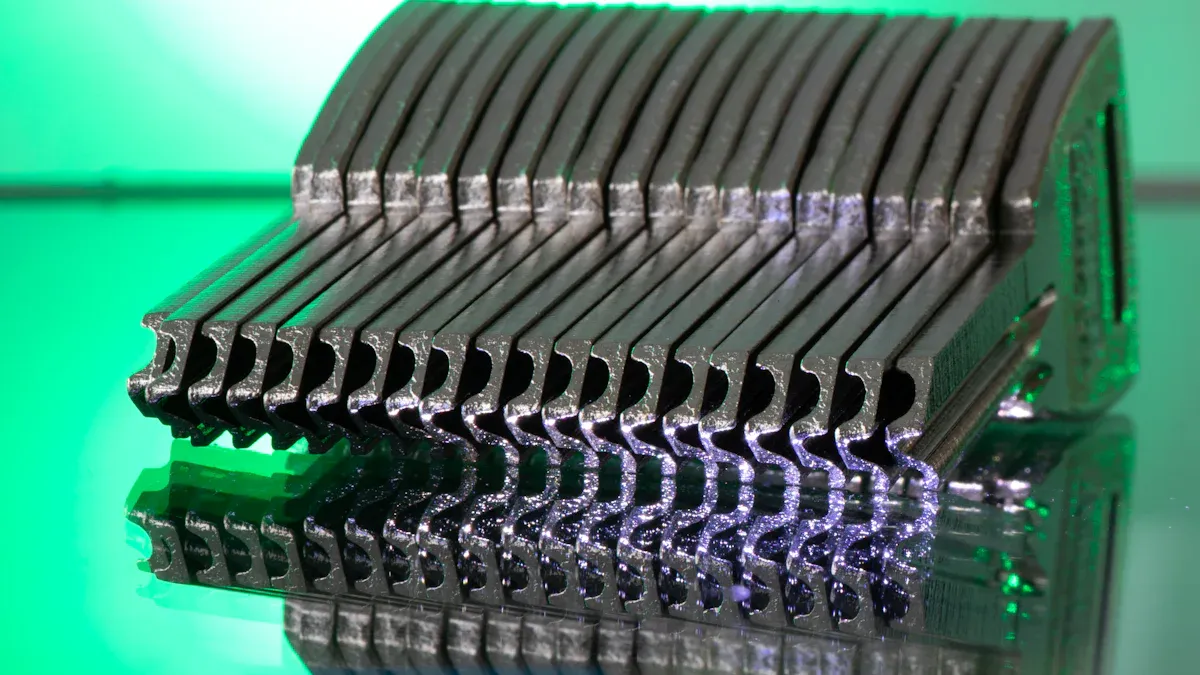

Cold plate structure

A cold plate uses a combination of design features to maximize heat transfer. You rely on its mounting surface, internal passages, and inlet and outlet points to achieve efficient cooling.

Mounting surface

You attach high-power electronic components directly to the mounting surface. This surface, usually made from copper or aluminum, provides excellent thermal conductivity. The smooth finish ensures close contact, which helps transfer heat quickly from your device to the cold plate.

Internal passages

Inside the cold plate, you find a network of channels and fins. These structures guide the coolant and increase the area available for heat exchange. The geometry of these channels affects how fast the coolant moves and how much heat it can carry away. Fins boost the surface area, allowing more heat to transfer from the plate to the liquid.

Tip: You should select a cold plate with optimized channel geometry and fin structures for your specific thermal requirements.

Inlet and outlet points

You connect the cold plate to your cooling system using inlet and outlet ports. Coolant enters through the inlet, flows through the internal passages, and exits through the outlet. This setup ensures continuous movement of liquid, which is essential for removing heat.

| Structural Component | Contribution to Heat Transfer Efficiency |

|---|---|

| Channel Geometry | Affects velocity distribution and pressure drop, optimizing thermal energy removal. |

| Fin Structures | Increases surface area for thermal dissipation, tailored to thermal requirements. |

| Material Selection | High thermal conductivity materials (e.g., copper, aluminum) enhance heat conduction. |

| Fluid Dynamics | Optimized channel arrangements ensure efficient coolant distribution and energy dissipation. |

Liquid flow process

You depend on the liquid flow process to keep your electronics cool. The cold plate absorbs heat from your components through its surface. The absorbed heat transfers to the circulating liquid coolant, such as water or a water-glycol mixture. The coolant then carries the heat away from the component, maintaining safe operating temperatures.

- The cold plate absorbs heat from high-heat components through its surface.

- The absorbed heat is transferred to a circulating liquid coolant.

- The liquid coolant carries the heat away from the component, facilitating effective heat removal.

You should choose a coolant that resists corrosion and works well with your cold plate material. Water-glycol mixtures offer good thermal performance and help prevent corrosion inside the system.

Key components

You find several key components in a cold plate system. The plate itself forms the core, with its mounting surface and internal passages. You also need reliable inlet and outlet fittings to connect the plate to your cooling loop. The choice of coolant is critical. Water and water-glycol mixtures are common because they transfer heat efficiently and protect against corrosion.

Mechanical integrity and corrosion resistance play a major role in cold plate performance. Studies show that corrosion can reduce the strength and durability of metal structures. For example, research by Karagah et al. found that corrosion affects the axial capacity of steel columns, especially when flange thickness decreases. Nie et al. observed that increased corrosion leads to lower elastic modulus and yield strength. You should select materials and coolants that minimize corrosion to maintain long-term reliability.

| Study | Findings |

|---|---|

| Saad et al. [27] | Significant reductions in load-carrying capacity for beams from aging ship structures. |

| Karagah et al. [28] | Corrosion affects axial capacity in steel I-shaped columns; flange thickness degradation has a more pronounced impact. |

| Nie et al. [29] | Compression and bending tests revealed decreases in elastic modulus, yield strength, and ultimate strength with increased corrosion severity. |

| Imperatore et al. [33] | Tension tests showed significant ductility loss in rebars due to accelerated corrosion. |

| Zhang et al. [20] | Pitting corrosion had a more significant impact on elongation than uniform corrosion. |

| Paik et al. [37] | DOP significantly affects the ultimate shear strength of pitted plates. |

Note: You should inspect your cold plate regularly for signs of corrosion or wear. Proper maintenance ensures efficient heat transfer and extends the life of your cooling system.

Cold plate: main benefits

Efficient heat transfer

You need a cooling solution that can handle high heat loads. A cold plate gives you efficient heat transfer by moving heat away from your electronics quickly. The metal surface of the cold plate sits in direct contact with your components. This setup allows heat to move from the device into the plate with little resistance. Inside, the coolant flows through channels and absorbs the heat. You get a system that keeps your equipment at safe temperatures, even when you push it to its limits.

You can see the difference in performance when you compare cold plate cooling to air cooling. Air cooling relies on fans and airflow, which can struggle with dense or high-power devices. A cold plate uses liquid, which has a much higher capacity to absorb and carry away heat. This means you can run your electronics harder and longer without overheating.

Tip: For the best results, you should match the cold plate design to your device’s heat output and choose a coolant that works well with your system.

Space-saving design

You often face space constraints in modern electronics. Cold plate cooling helps you save space because it does not need large fans or bulky heat sinks. The slim profile of a cold plate fits easily into tight spaces. You can stack components closer together, which lets you build more compact and powerful systems.

Many industries, such as data centers and electric vehicles, use cold plates for this reason. You can fit more computing power or battery cells in the same area. This approach gives you flexibility in your designs and helps you meet strict size requirements.

- Cold plates allow for denser layouts.

- You reduce the need for extra airflow channels.

- You can achieve higher performance in smaller packages.

Reliability

You want your cooling system to work every time you power up your equipment. Cold plate cooling gives you high reliability. The design has few moving parts, which means less risk of mechanical failure. You do not have to worry about fan breakdowns or dust clogging up your system.

The materials used in cold plates, such as copper or aluminum, resist corrosion and wear. When you use the right coolant, you protect the system from rust and buildup. Regular checks and simple maintenance keep your cold plate working for years.

| Benefit | How It Helps You |

|---|---|

| Fewer moving parts | Less chance of failure |

| Durable materials | Long service life |

| Simple upkeep | Easy to maintain and inspect |

Note: You should schedule routine inspections to catch any early signs of wear or corrosion. This habit ensures your system stays reliable and efficient.

Quiet operation

You want your electronics to run smoothly without adding extra noise to your environment. Cold plate cooling gives you a major advantage in this area. Unlike traditional air cooling systems that rely on fans, a cold plate system operates with minimal moving parts. You do not hear the constant hum or whir that comes from spinning fans. This makes your workspace, lab, or data center much quieter and more comfortable.

When you use a cold plate, you reduce the need for large, high-speed fans. Fans can generate noise levels that distract you or even interfere with sensitive equipment. In contrast, the main sound you might notice from a liquid cooling system comes from the pump. Modern pumps run quietly and often include vibration-dampening features. You can further reduce noise by selecting high-quality tubing and fittings that prevent rattling or vibration.

Tip: If you want the quietest operation possible, choose a pump rated for low noise and install your system on vibration-absorbing mounts.

A quiet cooling solution benefits you in several ways:

- You create a more pleasant work environment. Less noise means you can focus better and communicate more easily.

- You protect sensitive equipment. Some devices, such as laboratory instruments or audio systems, require low-noise conditions to function properly.

- You improve user experience. In offices, hospitals, or classrooms, a quiet system helps everyone stay comfortable and productive.

You also avoid the maintenance issues that come with fan-based systems. Fans collect dust and wear out over time, which can lead to increased noise and reduced performance. With a cold plate system, you have fewer moving parts to worry about. This means less maintenance and a longer lifespan for your cooling solution.

| Cooling Method | Typical Noise Level | Maintenance Needs | Suitability for Quiet Spaces |

|---|---|---|---|

| Air Cooling (Fans) | Moderate to High | Frequent | Low |

| Cold Plate Cooling | Low | Minimal | High |

You should consider cold plate cooling if you need a silent or low-noise environment. This approach works well in places where noise control matters, such as research labs, medical facilities, and high-performance computing centers. By choosing this method, you ensure your equipment stays cool without adding unwanted sound to your space.

Cold plate applications

Power electronics

You often work with power electronics in industries such as renewable energy, industrial automation, and telecommunications. These systems generate large amounts of heat during operation. You need a cooling solution that can handle high thermal loads and maintain stable temperatures. A cold plate gives you direct contact cooling, which helps you remove heat quickly from devices like inverters, rectifiers, and power supplies. You can mount these components directly onto the cold plate surface. This setup keeps your electronics safe and extends their lifespan.

You also benefit from the compact design of cold plates. You can fit them into tight spaces, which is important in control cabinets and compact power modules. You reduce the risk of overheating and avoid costly downtime. When you use cold plate cooling, you improve the reliability and efficiency of your power electronics.

Electric vehicles

You see electric vehicles (EVs) everywhere, from passenger cars to buses and trucks. These vehicles rely on batteries, power converters, and electric motors, all of which produce significant heat. You need to keep these components cool to ensure safety and performance. Cold plate cooling offers a solution that fits the unique demands of EVs.

You can use cold plates to cool battery packs and power electronics. This method helps you maintain optimal temperatures, which improves battery life and charging speed. You also prevent thermal runaway, a dangerous condition that can damage batteries. Cold plates fit easily into the limited space inside vehicles. You get a quiet, efficient cooling system that supports the push for cleaner transportation.

Tip: You should choose cold plates with corrosion-resistant materials for EV applications. This choice helps you avoid damage from coolant leaks or harsh operating environments.

Data centers

You manage data centers that run servers, storage systems, and networking equipment. These facilities support cloud computing, artificial intelligence, and high-performance computing (HPC). You face the challenge of cooling densely packed hardware that generates intense heat. Air cooling often falls short in these environments. You need a more effective solution.

Cold plate cooling provides direct-to-chip cooling for your servers and HPC clusters. You attach cold plates to processors and other heat-generating components. This approach keeps temperatures low and prevents overheating. You can increase rack density, which means you fit more computing power into the same space. You also improve energy efficiency, which helps you control operating costs.

| Aspect | Description |

|---|---|

| Efficient thermal management | Cold plate cooling provides direct-to-chip cooling methods that help maintain optimal temperatures. |

| Energy efficiency | This technology enhances energy efficiency, crucial for high-performance computing and AI workloads. |

| Higher rack densities | Supports higher rack densities, essential for handling increasing computational demands. |

| Minimizes overheating risk | Reduces the risk of overheating, maintaining reliability and performance of HPC hardware. |

| Improves system performance | Enhances overall system performance by applying cooling directly to heat-generating components. |

You rely on cold plate cooling to support advanced workloads, such as AI training and scientific simulations. You maintain system reliability and maximize performance, even as computational demands grow.

Medical and industrial equipment

You rely on advanced cooling solutions to keep medical and industrial equipment running safely and efficiently. In hospitals, clinics, and laboratories, you use devices that generate significant heat during operation. Imaging systems, such as MRI and CT scanners, require precise temperature control to maintain accuracy and prevent damage. You also depend on diagnostic analyzers and laser equipment, which need stable thermal environments for reliable results.

Industrial settings present similar challenges. You operate machinery that runs continuously and produces high thermal loads. Automation controllers, welding systems, and high-power lasers all demand effective cooling. If you allow these devices to overheat, you risk costly downtime and equipment failure.

A cold plate provides direct contact cooling for sensitive components. You mount heat-generating parts, such as power modules or sensors, onto the cold plate surface. The plate absorbs heat and transfers it to a circulating liquid coolant. This process keeps temperatures within safe limits and extends the lifespan of your equipment.

You benefit from the compact design of cold plates. Many medical devices have limited space for cooling hardware. You can install a cold plate without adding bulk or interfering with other components. In industrial machines, you fit cold plates into tight enclosures, which helps you maximize productivity and minimize maintenance.

Tip: You should select corrosion-resistant materials for your cold plate, especially if you use water-based coolants. This choice protects your equipment from leaks and chemical reactions.

You improve reliability and safety when you use cold plate cooling. Medical equipment must operate without interruption, especially during critical procedures. Industrial systems need consistent performance to avoid production delays. Cold plates offer fewer moving parts than fan-based systems, which reduces the risk of mechanical failure.

Consider the following advantages when you choose cold plate cooling for medical and industrial applications:

- Precise temperature control for sensitive electronics

- Space-saving installation in compact devices

- Enhanced reliability with minimal maintenance

- Quiet operation for noise-sensitive environments

| Application Area | Cooling Challenge | Cold Plate Solution |

|---|---|---|

| Medical Imaging | High heat, tight spaces | Direct contact, compact design |

| Laboratory Analysis | Stable temperatures | Reliable, low-maintenance cooling |

| Industrial Automation | Continuous operation | Efficient heat removal, durability |

You ensure patient safety and product quality when you maintain optimal temperatures. Cold plate cooling helps you meet strict regulatory standards and deliver consistent results. You protect your investment in advanced equipment and support innovation in healthcare and industry.

Types of cold plates

Tubed

You often choose tubed cold plates when you need a straightforward and cost-effective cooling solution. In this design, you see metal tubes—usually copper or stainless steel—embedded or pressed into a metal plate. Coolant flows through these tubes, picking up heat from the plate and carrying it away from your electronic components.

Tubed cold plates work well for moderate heat loads. You can install them easily and connect them to your existing liquid cooling system. The simple construction keeps manufacturing costs low. You also benefit from the flexibility to shape the tubes into different patterns, such as serpentine or parallel layouts, to match your cooling needs.

However, you should know that tubed cold plates have some performance limits. The contact area between the tube and the plate restricts how much heat can transfer. This design may not provide the best temperature uniformity across the surface. When you compare tubed cold plates to more advanced designs, you notice differences in temperature control and surface homogeneity.

Here is a comparison of two common cold plate types used for battery cooling:

| Aspect | Mini Channel Cold Plate | Serpentine Cold Plate | Improvement (%) |

|---|---|---|---|

| Maximum Average Battery Temp (°C) | Reduced by 5.7 | Higher | N/A |

| Surface Temperature Homogeneity | Improved by 40% | Lower | N/A |

You see that mini channel cold plates can reduce the maximum average battery temperature by 5.7°C compared to serpentine tubed designs. They also improve surface temperature homogeneity by 40%. If you need basic cooling for less demanding applications, a tubed cold plate offers a reliable and affordable choice. For high-performance or temperature-sensitive systems, you may want to explore other options.

Tip: You should check the tube material for corrosion resistance, especially if you use water-based coolants. This step helps you extend the life of your cooling system.

Custom designs

You often face cooling challenges that standard cold plates cannot solve. Custom cold plate designs give you the flexibility to meet unique requirements in your application. You work with engineers to create solutions that fit your exact specifications. You choose custom designs when you need to cool irregular shapes, handle extreme heat loads, or integrate with complex assemblies.

You start by identifying the thermal demands of your system. You measure the heat output of each component and map out the available space. You select materials that match your performance goals. Copper and aluminum remain popular choices because they conduct heat well. You may also consider stainless steel or advanced composites for specialized needs.

You collaborate with design teams to create cold plates that match your mounting patterns and fluid connections. You specify the location of inlet and outlet ports. You decide on the channel geometry inside the plate. You can request microchannels, pin fins, or serpentine paths to optimize heat transfer. You also choose surface finishes that improve contact with your devices.

Tip: You should provide detailed drawings and thermal simulations to your manufacturer. This step helps you avoid design errors and ensures your cold plate meets your cooling targets.

Custom cold plates support integration with sensors, heaters, or insulation. You add temperature sensors to monitor performance in real time. You include heating elements if you need to maintain a minimum temperature. You use insulation to reduce heat loss and improve efficiency.

You benefit from custom designs in industries such as aerospace, medical devices, and high-performance computing. You cool avionics in tight enclosures. You protect sensitive medical equipment from overheating. You support advanced processors in AI servers.

Consider these advantages of custom cold plates:

- You achieve precise temperature control for critical components.

- You maximize space utilization in compact systems.

- You improve reliability by matching the cold plate to your operating environment.

- You reduce maintenance by choosing corrosion-resistant materials and optimized fluid paths.

| Custom Feature | Benefit for You |

|---|---|

| Unique geometry | Fits complex assemblies |

| Material selection | Matches thermal and chemical needs |

| Integrated sensors | Enables real-time monitoring |

| Specialized channels | Boosts heat transfer efficiency |

You should evaluate your cooling needs before choosing a custom design. You balance performance, cost, and manufacturability. You work closely with suppliers to ensure quality and reliability. Custom cold plates give you the power to solve demanding thermal problems and keep your equipment running safely.

Cold plate: selection factors

Material choice

You must select the right material for your cold plate to achieve optimal thermal performance and durability. Copper and aluminum are the most common choices. Copper offers excellent thermal conductivity, which helps you transfer heat quickly. Aluminum provides a lighter weight and resists corrosion better than copper. You may choose stainless steel for environments with harsh chemicals or high humidity. Each material affects the efficiency, weight, and lifespan of your cooling system.

You should consider the compatibility of the material with your coolant. Some metals react with certain fluids, which can lead to corrosion or reduced performance. You also need to think about mechanical strength. If your application involves vibration or pressure changes, select a material that can withstand these conditions. You improve reliability and reduce maintenance when you match the material to your operating environment.

Tip: You can extend the life of your cold plate by choosing a material with a protective coating or surface treatment.

Fluid compatibility

You need to pay close attention to fluid compatibility when designing your cooling system. The fluid you select must work well with the cold plate material and other system components. Water is a popular choice because it transfers heat efficiently. You may use water-glycol mixtures to prevent freezing and reduce corrosion risk.

Fluid compatibility is essential for the durability and efficiency of cold plate systems. Incompatible fluids can cause corrosion, seal degradation, and microbial growth. These problems may lead to leaks and pressure drops. Compatible fluids help maintain the integrity of the system, reduce maintenance needs, and enhance heat transfer efficiency. You should always check manufacturer recommendations before selecting a coolant.

You can use additives to improve fluid performance. Corrosion inhibitors protect metal surfaces. Biocides prevent microbial growth. You must monitor fluid quality regularly to avoid buildup or contamination.

System integration

You face several challenges when you add a cold plate to an existing system. You may need to redesign layouts or change infrastructure to fit the new cooling solution. You must consider the cost of retrofitting and the impact on your workflow. Leak prevention and corrosion control are critical for maintaining system reliability. You also need to think about how to capture and reuse waste heat for sustainability.

| Challenge Type | Description |

|---|---|

| Adapting to existing infrastructure | Integrating cold plates with traditional air cooling systems requires significant redesign and layout changes. |

| Cost implications | The initial investment for cold plate systems and retrofitting existing facilities can be substantial. |

| Leak and corrosion prevention | Ensuring the reliability of coolant systems is critical to prevent damage to equipment and maintain efficiency. |

| Efficient waste heat utilization | Capturing and reusing waste heat presents technical and logistical challenges but offers sustainability benefits. |

You should plan for integration early in your design process. Work with engineers to map out connections, mounting points, and fluid paths. Test your system for leaks and monitor for corrosion. You improve efficiency and reliability when you address these challenges before installation.

Cost considerations

When you select a cold plate for your system, you must think about the total cost. The price of a cold plate includes more than just the purchase price. You need to look at the full picture to make a smart investment.

1. Initial purchase cost

You pay for the cold plate itself. The price depends on the material, size, and design. Copper plates usually cost more than aluminum ones. Custom designs and advanced features, such as microchannels, increase the price. Standard tubed plates are often the most affordable.

2. Installation expenses

You may need to spend money on installation. Some cold plates fit easily into your system. Others require special fittings, mounting hardware, or changes to your layout. If you need to retrofit an existing system, you might face extra costs for labor and downtime.

3. Operating costs

You must consider the cost of running your cooling system. Pumps use electricity to move coolant through the cold plate. The type of coolant you choose can also affect your budget. Water is cheap, but water-glycol mixtures or specialty fluids cost more. Efficient cold plates can lower your energy bills by reducing the need for high-speed fans.

4. Maintenance and lifespan

You save money in the long run by choosing a durable cold plate. Materials that resist corrosion and wear last longer and need fewer repairs. Regular maintenance, such as checking for leaks or cleaning the system, helps you avoid costly breakdowns. If you pick the right materials and fluids, you reduce the risk of early replacement.

5. Long-term value

You should look at the total cost of ownership. A higher upfront price may pay off if the cold plate lasts longer and works more efficiently. Cheap options can lead to more repairs and higher energy use.

| Cost Factor | What to Consider | How It Affects You |

|---|---|---|

| Purchase Price | Material, size, design complexity | Upfront investment |

| Installation | Labor, hardware, system changes | Initial setup cost |

| Operation | Pump energy, coolant type | Ongoing expenses |

| Maintenance | Durability, corrosion resistance | Repair and upkeep costs |

| Lifespan | Quality of materials and design | Replacement frequency |

Tip: You should compare the total cost of different cold plate options, not just the sticker price. Think about how much you will spend over the life of your system.

You make the best choice when you balance performance with cost. Investing in a high-quality cold plate can save you money and trouble in the future. Always ask suppliers for detailed cost breakdowns and warranty information before you buy.

Installation and maintenance

Setup tips

You achieve reliable cold plate cooling when you follow best practices during installation. Start by reviewing the manufacturer’s instructions for your specific cold plate model. You ensure proper alignment by placing the cold plate flat against the mounting surface. Use thermal interface material, such as thermal paste or pads, to improve heat transfer between your device and the cold plate.

Secure the cold plate with the recommended torque on all fasteners. Uneven pressure can reduce thermal performance. Connect the inlet and outlet fittings tightly to prevent leaks. Use compatible tubing and clamps for your coolant lines. You should flush the system before adding coolant to remove debris.

Tip: Always check for compatibility between your coolant and cold plate material. This step helps you avoid corrosion and extends system life.

You can follow this checklist for a smooth setup:

- Inspect the cold plate and mounting surface for damage.

- Apply thermal interface material evenly.

- Tighten fasteners to the specified torque.

- Connect coolant lines securely.

- Flush the system before filling with coolant.

- Test for leaks before powering up electronics.

Routine checks

You maintain peak performance by performing regular inspections. Schedule routine checks every few months or as recommended by the manufacturer. Look for signs of corrosion, leaks, or buildup on the cold plate and fittings. Monitor coolant levels and top off as needed. Clean the cold plate surface and remove dust or debris from surrounding areas.

You should verify pump operation and listen for unusual noises. Check temperature readings to confirm the system is cooling effectively. Replace coolant at intervals to prevent contamination and maintain heat transfer efficiency.

| Maintenance Task | Frequency | What to Look For |

|---|---|---|

| Visual inspection | Monthly | Corrosion, leaks, debris |

| Coolant level check | Monthly | Low fluid, discoloration |

| Pump operation test | Quarterly | Noise, vibration |

| Temperature monitoring | Ongoing | Unusual spikes |

| Coolant replacement | Annually | Contamination, loss |

Note: You improve reliability and extend equipment life when you keep a maintenance log.

Troubleshooting

You solve most cold plate cooling issues by following a systematic approach. If you notice rising temperatures, first check for coolant flow. Inspect the pump and tubing for blockages or air bubbles. If you find leaks, tighten fittings or replace damaged hoses. Corrosion on the cold plate or fittings signals a need for material review or coolant change.

You address uneven cooling by checking thermal interface material placement. Reapply or replace if needed. If the pump makes excessive noise, inspect for wear or debris. Replace faulty components promptly to avoid further damage.

⚠️ If you cannot resolve the issue, contact technical support or consult the manufacturer’s troubleshooting guide.

You keep your system running smoothly by acting quickly and documenting each step. You prevent downtime and protect your investment with proactive maintenance and prompt repairs.

You rely on cold plate cooling to manage heat in high-power and space-limited systems. Proper design, material selection, and routine maintenance help you achieve reliable performance and long equipment life.

Cold plates offer efficient, quiet, and compact thermal management for advanced electronics.

- Consider cold plate solutions for your next project if you need superior cooling.

- For specialized needs, consult with thermal management experts or explore technical resources.

FAQ

What coolant should you use with a cold plate?

You should use water or a water-glycol mixture. These fluids transfer heat efficiently and help prevent corrosion. Always check compatibility with your cold plate material.

How often should you inspect your cold plate system?

You should inspect your cold plate system monthly. Look for leaks, corrosion, and debris. Regular checks help you maintain performance and extend equipment life.

Can you retrofit a cold plate into an existing system?

You can retrofit a cold plate into most systems. You may need to adjust layouts or add fittings. Consult with your manufacturer for best integration practices.

Why does corrosion matter in cold plate cooling?

Corrosion reduces heat transfer and weakens metal parts. You protect your system by choosing corrosion-resistant materials and compatible coolants.

How do you improve cold plate performance?

You improve performance by using thermal interface materials, optimizing coolant flow, and selecting the right channel geometry. Routine maintenance also boosts efficiency.

What industries use cold plate cooling?

You find cold plate cooling in data centers, electric vehicles, medical devices, and industrial automation. These sectors need reliable and efficient thermal management.

Is cold plate cooling quieter than air cooling?

You experience less noise with cold plate cooling. The system uses fewer moving parts. Pumps run quietly, making it ideal for noise-sensitive environments.

What maintenance tasks should you perform regularly?

You should check coolant levels, inspect for leaks, clean surfaces, and monitor temperatures. Replace coolant annually to prevent contamination.

Tip: Keep a maintenance log to track inspections and repairs. This habit helps you spot issues early.