Common heat sink materials

You often see aluminum, copper, graphite, and composite materials used to make a heat sink. Aluminum is popular, especially alloy 1050. It moves heat well and does not cost much. Copper is in some designs too. It works better for heat but is heavier and costs more. Aluminum heat sinks are used most around the world. China makes the most, with over 45% of the market. Europe and North America each have about 30%.

Key Takeaways

- Aluminum is the most common heat sink material. It costs less and is light. It moves heat well. It works well for most electronics.

- Copper moves heat very well. It is good for high-performance uses. Copper is heavier than aluminum. It also costs more than aluminum.

- Graphite is light and easy to shape. It is great for thin devices like smartphones. It spreads heat well in small spaces.

- Composite heat sinks use more than one material. They are strong and do not rust easily. They help in special uses like electric cars.

- When picking a heat sink material, think about heat movement, weight, cost, and the effect on the environment. This helps you choose the best one for your project.

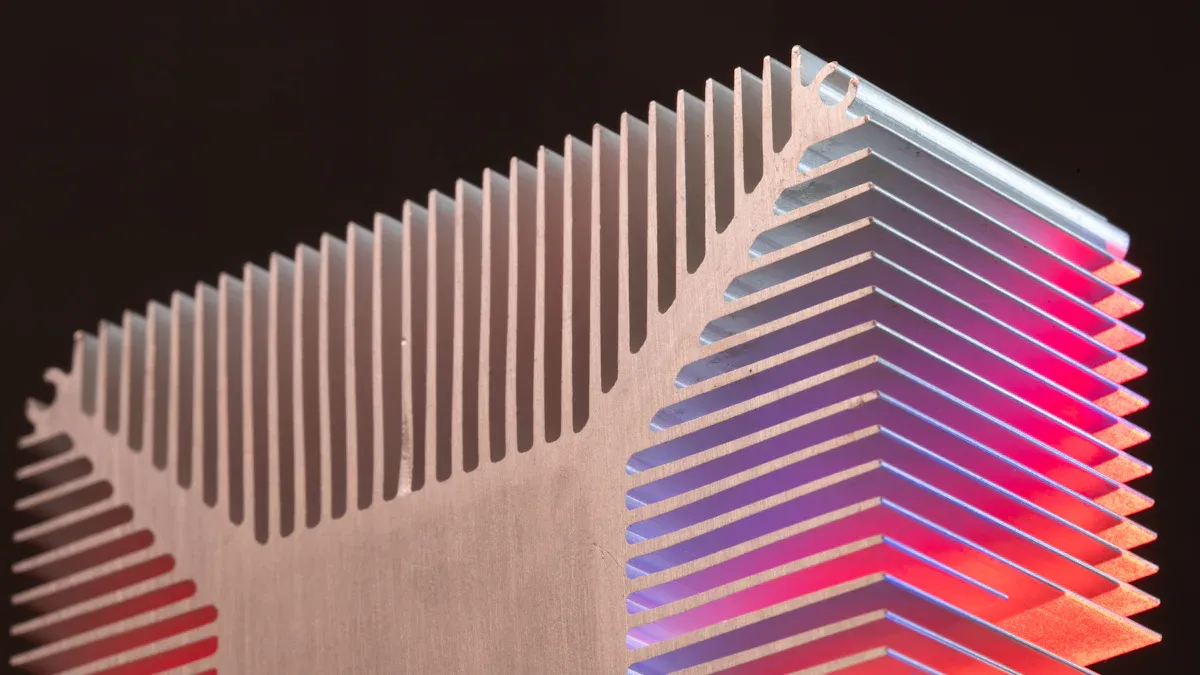

Aluminum heat sink materials

Aluminum properties

Aluminum is used a lot for heat sinks. It works well and is practical. Aluminum moves heat away from important parts. You can shape aluminum without much effort. This makes it easy for companies to use. Aluminum does not rust easily, so it lasts longer. You do not have to worry about rust in most places. Aluminum is also light. This helps if you want your device to be easy to carry.

Alloy 1050 and thermal conductivity

Alloy 1050 is a special kind of aluminum. It lets heat move through it very fast. This helps the heat sink cool things down better. Alloy 1050 is also easy to shape into different forms. You can make many designs with it. This material is good for both working well and making things.

Cost and weight benefits

Aluminum is cheaper than many other metals. You can save money by picking aluminum for your heat sink. Aluminum is light, so your device will not be heavy. This is important for things like laptops and phones. It also makes shipping and moving easier because it weighs less.

Tip: If you want a heat sink that is not expensive and works well, aluminum is a good pick.

Common applications

Aluminum heat sinks are used in many ways. Here are some examples:

- Passive heatsinks use air or liquids to move heat.

- Active heatsinks use fans to cool things faster.

- Custom heat sinks are used in cars, snow machines, and gas systems.

Aluminum heat sinks stop electronics and machines from getting too hot. You can trust them for simple or hard jobs.

Copper heat sink materials

Copper properties

You find copper in many heat sink designs because it moves heat very well. Copper has a reddish color and feels heavy when you hold it. You notice that copper does not bend easily. It stays strong even when you use it in tough places. Copper resists corrosion, so you do not see it rust quickly. You can trust copper to last a long time in your devices.

Thermal performance

Copper gives you excellent thermal conductivity. This means copper pulls heat away from hot parts faster than most other metals. If you need to cool something that gets very hot, copper works better than aluminum. You see copper used in computers, LED lights, and power electronics. These devices need quick cooling to keep working well.

Note: Copper heat sinks help you keep your electronics safe from overheating. You get better cooling when you use copper in high-power systems.

Cost and weight factors

Copper costs more than aluminum. You pay a higher price for copper heat sinks. Copper also weighs more. If you want a light device, copper may not be the best choice. You need to think about your budget and how heavy you want your product to be. Aluminum gives you a cheaper and lighter option, but copper gives you better heat movement.

| Material | Cost | Weight | Thermal Conductivity |

|---|---|---|---|

| Copper | High | Heavy | Excellent |

| Aluminum | Low | Light | Good |

Preferred uses

You see copper heat sinks in places where heat control matters most. High-performance computers use copper to keep processors cool. LED lights use copper to stay bright and safe. Power supplies and industrial machines also use copper for better cooling. If you need top thermal performance, you should choose copper for your heat sink.

Other heat sink materials

Graphite heat sinks

Graphite is used to cool electronics. It moves heat fast and spreads it out. Graphite is much lighter than metal. You can make it into thin sheets or pads. This makes it easy to fit in small spaces. Graphite is found in smartphones and tablets. These devices need to be thin and stay cool.

Tip: Graphite is good if you need something light for small spaces.

Composite heat sinks

Composite heat sinks are made from two or more materials. You get the good parts of each material in one. Some composites mix metal and plastic. Others use carbon fibers or ceramics. Composites can be made to fight rust and stay strong. You find them in electric cars and airplane parts. These places need special shapes and strong materials.

- Composites can be made just for your needs.

- You can pick composites for hard jobs or special shapes.

Ceramic heat sinks

Ceramic heat sinks have special features. They move heat well and can handle high heat. Ceramics do not carry electricity, so they are safe near sensitive parts. Ceramics are light and do not rust. But ceramics can break more easily than metal. Making ceramic heat sinks costs more and takes more work.

Here is a table that shows what is good and bad about ceramic heat sinks:

| Advantages of Ceramic Heat Sinks | Limitations of Ceramic Heat Sinks |

|---|---|

| Moves heat very well | Can break easily |

| Handles high heat | Harder to make |

| Does not carry electricity | Costs more |

| Light and small | Needs special thermal materials |

| Does not rust |

Niche applications

These materials are used in special places. Graphite is used in phones and thin laptops. Composites are found in cars, planes, and satellites. Ceramics are used in power electronics and medical tools. You pick these materials when you need something different from a normal heat sink.

Heat sink material comparison

Picking the right heat sink material is important. It helps your device stay cool. You should check a few key things. These are thermal conductivity, weight, cost, and corrosion resistance. Every material has good and bad points. The table below lets you compare aluminum, copper, graphite, and composites.

| Property | Aluminum | Copper | Graphite | Composites |

|---|---|---|---|---|

| Thermal Conductivity | Good | Excellent | Very Good | Moderate |

| Weight | Light | Heavy | Very Light | Light |

| Cost | Low | High | Moderate | Varies |

| Corrosion Resistance | High | High | High | High |

Thermal conductivity

Thermal conductivity shows how fast heat moves away. Copper is the best at moving heat. You find copper where cooling is most needed. Aluminum also moves heat well, but not as fast as copper. Graphite spreads heat quickly in thin spaces. Composites move heat at a medium speed. You might use composites for special shapes or extra strength.

Tip: Copper cools things the fastest. Aluminum and graphite are good for most uses.

Weight

Weight is important if you want a light device. Aluminum is light and helps make things easy to carry. Graphite is even lighter and fits in thin designs. Copper is heavy. You may not want copper if you need something light. Composites are usually light, but weight can change with different mixes.

- Aluminum and graphite help make light products.

- Copper is heavier but cools better.

- Composites let you balance weight and strength.

Cost

Cost is about how much money you spend. Aluminum is cheaper than copper. You save money by choosing aluminum. Copper costs more because it is harder to get and heavier. Graphite costs more than aluminum but less than copper. Composites can be cheap or expensive, depending on what is in them.

Note: Aluminum is best if you want to save money. Copper cools better but costs more.

Corrosion resistance

Corrosion resistance means how well something avoids rust. Aluminum does not rust easily. Copper does not rust much, but it can change color. Graphite does not rust and stays strong. Composites often do not rust, especially with plastics or ceramics. All these materials last a long time in most places.

- Aluminum and graphite protect well against rust.

- Copper stays safe but may look different later.

- Composites can be made to fight rust.

This comparison helps you pick the best heat sink material. Think about what is most important for your device. You might want the fastest cooling, the lightest weight, or the lowest price. Each material gives you something special.

Choosing a heat sink material

Application needs

First, think about what your device needs. Some devices get very hot. These need fast cooling. Other devices only need simple cooling. The best material depends on how much heat your device makes. It also depends on how strong the heat sink should be. If weight is not important, copper is a good choice. Copper moves heat quickly. If you want a light device, aluminum or graphite might be better. You should also think about how the heat sink will be made. Some shapes are easier to make with certain materials.

Here is a table that shows how different things can change your choice:

| Factor | Influence on Material Selection |

|---|---|

| Thermal Conductivity | Materials like copper work best when weight does not matter. |

| Mechanical Properties | You need to balance strength and heat movement. |

| Cost | Better performance can mean higher costs. |

| Manufacturability | How you make the heat sink can change what material you pick. |

| Design Constraints | Fin size and shape must be right for good cooling. |

| Alternative Materials | New materials may be cheaper and easier to use, but may not cool as well. |

Budget considerations

Think about your budget before you choose a heat sink material. Aluminum costs less and works well for most jobs. Copper costs more but cools better. Graphite and composites can cost more or less. It depends on what you need. If you want to save money, pick aluminum. If you need the best cooling and have more money, copper is a good choice.

Tip: Match your budget with your cooling needs. You do not always need the most expensive material.

Environmental factors

You should think about the environment when you pick a heat sink material. Using recycled aluminum saves energy and helps nature. It also helps reuse materials instead of throwing them away. This lowers pollution and helps the earth. Many companies recycle aluminum waste from making heat sinks. This makes the process better for the planet.

Note: Picking materials that can be recycled helps the earth and keeps the planet healthy.

You read about aluminum, copper, graphite, and composites. Aluminum is light and does not cost much. It works well for most devices. Copper cools things better when they get very hot. Other materials are good for special uses.

- Use aluminum for most things.

- Pick copper if you need strong cooling.

- Try graphite or composites for special shapes.

Look at the tips and tables to help you pick the best heat sink for your project.

FAQ

What is the best material for most heat sinks?

Most heat sinks are made from aluminum. Aluminum is light and not expensive. It moves heat away well. Many electronics use aluminum because it works and saves money.

Why do some heat sinks use copper instead of aluminum?

Copper is used when things need to cool down faster. Copper moves heat better than aluminum. High-power computers and LED lights often use copper. Machines that get very hot also use copper.

Can you recycle heat sink materials?

Aluminum and copper heat sinks can be recycled. Recycling saves energy and helps the earth. Many companies use old heat sinks to make new ones.

Are graphite and composite heat sinks safe for electronics?

Graphite and composites are safe for electronics. They do not rust and are often lighter than metals. You find them in thin devices like smartphones and tablets.