Heat Sink Materials

When you pick heat sink materials, you should think about how well they move heat. You also need to think about their price and weight. Aluminum is popular because it is light and moves heat well. This makes it the top choice in the world. Copper moves heat even better, but it is heavier and costs more. Graphite and alloys have special features for better cooling.

- The world market for heat sinks was $6.7 billion in 2024, and aluminum is the leader because it is cheap and works well.

- New studies show that choosing the right material can help electronics last longer by moving heat better.

Key Takeaways

- Aluminum is the best pick for heat sinks. It is light, not expensive, and moves heat well. Copper moves heat even better. But copper is heavy and costs more. This makes copper good for high-performance uses. Graphite is another choice that is light. It works well in some electronics. Graphite cools well and does not rust. Think about how well a material moves heat. Also, think about its price and weight when picking heat sinks. This helps you get the best results. Always choose a heat sink design that fits your device. This gives you the best cooling and helps your device last longer.

Common Heat Sink Materials

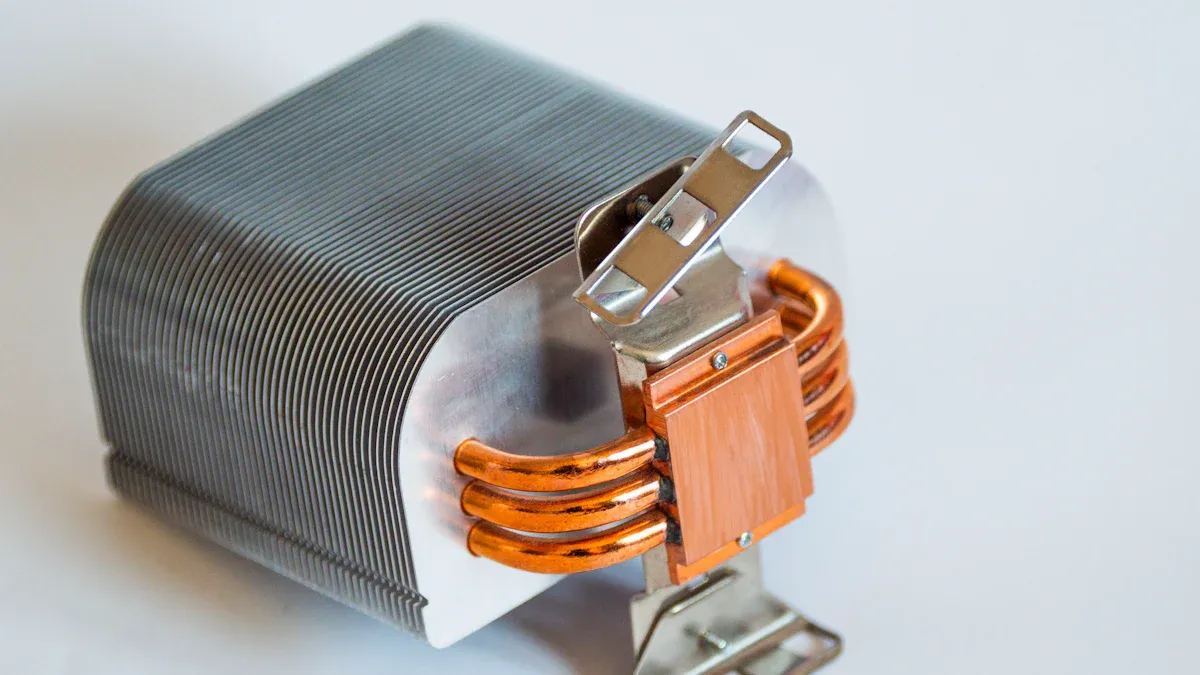

Aluminum and Alloys

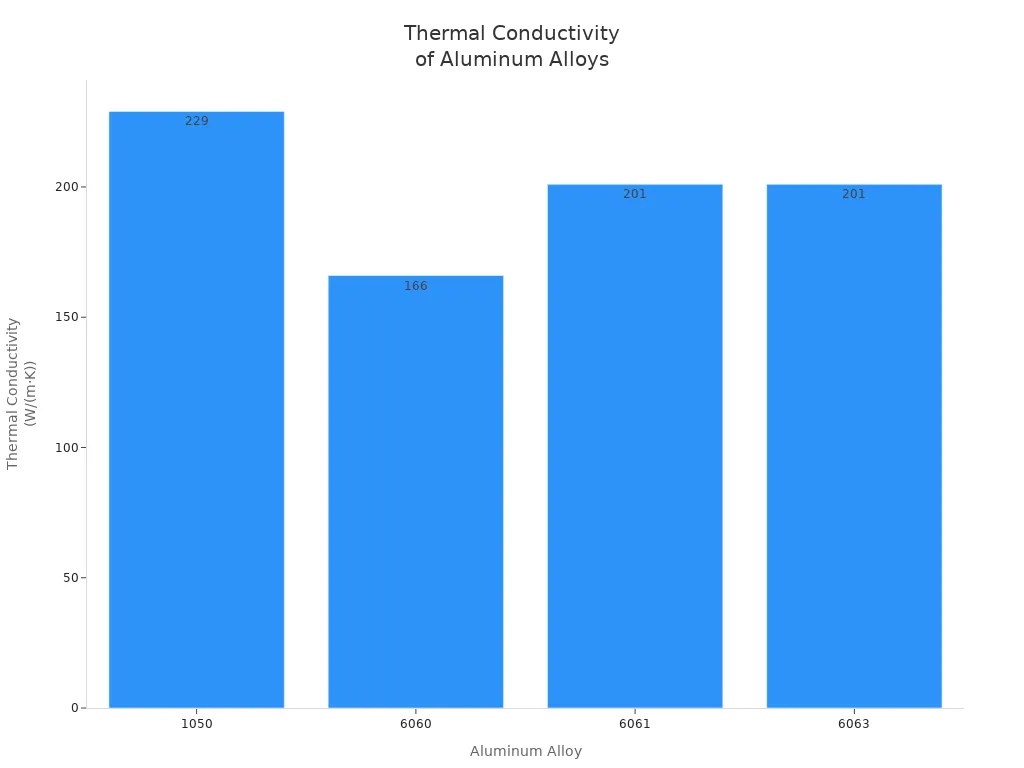

Aluminum and its alloys are used in most heat sinks. Aluminum is light and does not rust. It is easy to shape into many forms. You can find aluminum in laptops and LED lights. It is also in other electronics. The 1050A alloy moves heat away from parts very well. Other alloys like 6060, 6061, and 6063 are also good. Each alloy has its own strong points. The chart below shows how much heat four aluminum alloys can move:

| Aluminum Alloy | Thermal Conductivity (W/(m·K)) | Heat Capacity (J/(kg·K)) | Mechanical Properties |

|---|---|---|---|

| 1050 | 229 | 922 | Mechanically soft |

| 6060 | 166 | N/A | Low-stress |

| 6061 | 201 | N/A | N/A |

| 6063 | 201 | N/A | N/A |

Tip: Using recyclable aluminum helps the planet and supports reuse.

Copper

Copper moves heat very well. You see copper in strong devices and big machines. It is also in HVAC systems. Copper is heavier than aluminum. It costs more too. But copper lasts a long time and does not rust easily. You pick copper when you need the best cooling for strong electronics.

| Material | Thermal Conductivity (W/(m·K)) | Common Applications |

|---|---|---|

| Copper | ~400 | High-performance devices, industrial equipment, HVAC systems |

Graphite and Mixed Compositions

Graphite moves heat very well and is much lighter than metal. You find graphite in special electronics and high-tech tools. It does not rust and works well where weight matters. Some heat sinks use both aluminum and copper. This mix helps balance cost, weight, and how well it cools.

- Graphite: Light, does not react, does not rust, great at moving heat.

- Hybrid (Aluminum & Copper): Mixes light weight and good heat movement for better results.

Ceramics and Stainless Steel

Ceramics and stainless steel have special uses. Ceramics do not rust and work in tough places. But ceramics break easily and cost more to make. Stainless steel does not rust or scratch. But it does not move heat as well as aluminum or copper. These materials are used in special cases. They are not common for strong cooling.

| Material | Limitations |

|---|---|

| Ceramics | Breaks easily, hard to make |

| Stainless Steel | Scratches, can be hurt by quick temperature changes |

Note: Pick heat sink materials that fit your needs for strength, price, and the environment.

Heat Sink Materials Comparison

Thermal Conductivity

Thermal conductivity is very important when picking heat sink materials. Materials with high thermal conductivity move heat away fast. This helps keep electronics cool and working well. Copper has the highest thermal conductivity of these choices. Aluminum also works well and is much lighter. Stainless steel and ceramics do not move heat as well.

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Aluminum | 237 |

| Copper | 401 |

| Stainless Steel | 15-30 |

If a material has high thermal conductivity, it cools better. But you should also think about other things.

Cost and Weight

You need to think about both cost and weight. Aluminum is cheaper than copper and is much lighter. That is why many electronics use aluminum. Copper cools better but is heavier and costs more. Stainless steel and ceramics can cost more and weigh more. But they are good at stopping rust.

| Material | Thermal Conductivity (W/mK) | Cost Comparison | Weight Consideration |

|---|---|---|---|

| Aluminum | 235 | 30% of copper | Lightweight |

| Copper | 401 | Higher cost | Heavier |

| Heat Pipes | 100x faster than metals | Integrated with aluminum | 40% weight savings |

- Aluminum heat sinks are cheap and light.

- Copper heat sinks cool better but cost more and are heavier.

Tip: If you want to save money and weight, aluminum is usually best.

Application Suitability

Different heat sink materials work best in different places. You should pick the right one for your needs.

- Aluminum: Good for passive cooling. It is cheap and moves heat well.

- Copper: Great for active cooling. It handles more heat but costs more.

- Graphite: Good if you need something light. It works in special electronics.

- Ceramics: Good for stopping electricity and rust. Used in passive systems.

- Stainless Steel: Not great for cooling, but it is strong and does not rust.

You can find heat sinks in many devices:

- Power electronics and LED lights use heat sinks to stay cool and last longer.

- High-power electronics, like AI chips and 5G gear, need special materials like vapor chambers or graphene-based thermal interface materials.

- Low-power devices use simple heat sinks because they do not get very hot.

Note: Good thermal management keeps electronics safe and working well.

Data Table Overview

Here is a quick look at the main heat sink materials. This table shows how they compare in thermal conductivity, cost, and weight.

| Material | Thermal Conductivity | Cost | Weight | Special Properties |

|---|---|---|---|---|

| Aluminum | High | Lower | Lighter | Good for most electronics |

| Copper | Highest | Higher | Heavier | Best for high-performance cooling |

| Graphite | Moderate-High | Moderate | Light | Good for weight-sensitive applications |

| Ceramics | Low-Moderate | Varies | Moderate | Electrical insulation, corrosion resistant |

| Stainless Steel | Low | Higher | Heavier | Corrosion resistant, strong |

How these materials are made can change how well they move heat. Methods like extrusion, die casting, and forging help improve performance and change the cost.

Remember: Always balance thermal conductivity, cost, and weight when you pick heat sink materials for your project.

Material Selection Guide

Form Factor and Mounting

When you pick a heat sink, think about its shape. You also need to know how you will attach it. The form factor shows if the heat sink fits in your device. Check the space you have. Make sure the heat sink does not block other parts. You can use clips, screws, or adhesives to mount it. Each way works better for some designs. Look at the airflow around the heat sink. Good airflow helps it cool better. In medical devices, rules say you must use safe and strong materials. These rules keep parts safe and protect patients.

Tip: Always pick a heat sink size and mounting style that fits your device for the best cooling.

Design Constraints

You face some limits when you pick heat sink materials. High-density circuit boards need good thermal management. This helps electronics last longer. Space can be small, so you need a heat sink that fits. It should not be too heavy. It can be hard to attach the heat sink if the board is crowded. Think about how much heat your parts make. Also, think about where your device will be used.

- Thermal management keeps your device safe.

- Space limits the heat sink size and type.

- It can be hard to attach in small spaces.

- Rules say you must use safe and good thermal solutions.

Common Steps for Selection:

- Find out how much heat your parts make.

- Check the air and temperature around your device.

- Figure out the thermal resistance you need to keep parts cool.

- Look at the space and weight limits for your design.

Surface Area Impact

The surface area of a heat sink is very important for cooling. A bigger surface area lets more heat leave into the air. You can add fins or use special shapes to make it bigger. The material you choose also changes how well the heat sink uses its surface area. Copper and aluminum are good because they spread heat fast. You must balance the surface area with space and weight. Sometimes, you need to check the thermal resistance to make sure your heat sink keeps your device safe.

Note: More surface area gives better cooling, but the heat sink must fit inside your device.

Practical Tips for Choosing Heat Sink Materials

Off-the-Shelf vs. Custom Options

When you choose a heat sink, you often decide between off-the-shelf and custom options. Off-the-shelf heat sinks are ready-made and easy to buy. They work well for many standard electronics. Custom heat sinks fit your exact needs and can improve cooling in special cases.

- Check the airflow, temperature, and power your device needs.

- Use online calculators to find out how much airflow and thermal resistance you need.

- Build prototypes to test custom designs. Make sure the heat sink is not too big or too small.

- Think about how you will make the heat sink if you need many units.

- Look at the cost. Custom heat sinks cost more at first, but they can save money later by reducing repairs and improving energy use.

- Plan for fans if your device needs extra cooling.

- Pick the best way to attach the heat sink, like clips or screws.

Custom heat sinks can help your device last longer and work better. They give you more control over size, shape, and material. Standard heat sinks cost less at first, but they may not cool as well in special cases.

Tip: For small-scale production, custom heat sinks may cost more upfront, but they can save you money over time by improving device performance and reducing repairs.

Key Considerations Recap

You need to think about several things when you pick heat sink materials. Each factor helps your device stay cool and last longer.

- Thermal Resistance: Lower thermal resistance means better cooling.

- Material Choice: Aluminum is light and conducts heat well. Copper cools even better but is heavier and costs more.

- Size and Shape: The heat sink must fit your device and cover the hot parts.

- Airflow: Good airflow helps the heat sink work better.

- Mounting Method: Choose a strong and simple way to attach the heat sink.

- Surface Area: More surface area lets more heat escape.

- Fin Design: Fins help spread heat and cool faster.

- Base Size: The base must touch the hot part for good heat transfer.

You should balance cost, cooling, and fit for your project. Custom heat sinks offer better cooling and reliability, especially for special devices. Off-the-shelf heat sinks work well for simple needs and cost less.

Note: Always match the heat sink material and design to your device’s needs for the best results.

When you pick a heat sink material, you need to think about a few main things. These include thermal conductivity, cost, density, and what your device needs. It is important to match the material to your device. The table below helps you see what is most important:

| Property | Why It Matters |

|---|---|

| Thermal Conductivity | Better cooling |

| Weight and Size | Easier for portable devices |

| Cost and Availability | Stays within your budget |

| Manufacturing Feasibility | Simple to make and use |

You can make good choices if you know how heat moves, check your device’s temperature needs, and balance cost with how well it works.

FAQ

What is the best material for most heat sinks?

Aluminum works best for most heat sinks. You get good cooling, low cost, and light weight. Many electronics use aluminum because it is easy to shape and does not rust.

Why would you choose copper over aluminum?

You should pick copper if you need the best cooling. Copper moves heat faster than aluminum. It works well in high-power devices. Copper costs more and weighs more, so use it when top performance matters.

Can you use graphite for heat sinks?

Yes, you can use graphite. Graphite is very light and moves heat well. You find it in special electronics where weight matters. It does not rust and works well in thin designs.

How does surface area affect heat sink performance?

A bigger surface area helps your heat sink cool better. More fins or special shapes let more heat escape. You should match the surface area to your device size for the best results.