How Heat Pipes Improve Thermal Management in Electronic Devices

You face increasing challenges as electronic devices grow more powerful and compact. Heat pipes provide a critical solution by moving heat away from sensitive components. Their phase change mechanism, which uses evaporation and condensation of a working fluid, achieves faster heat transfer than traditional cooling methods. Capillary action inside the pipe drives the fluid back to its origin, keeping the process continuous. Over 55% of electronic device failures link to temperature issues, so using advanced thermal management like heat pipes improves efficiency, reliability, and design flexibility.

Key Takeaways

- Heat pipes use a phase change process to transfer heat quickly, making them more efficient than traditional cooling methods.

- The capillary action in heat pipes allows them to operate in any orientation, providing flexibility in design.

- Heat pipes require no external power source, leading to energy savings of up to 80% compared to traditional cooling systems.

- Their silent operation and lack of moving parts reduce maintenance needs and increase reliability.

- Heat pipes excel in compact electronic devices, preventing overheating and extending the lifespan of components.

- Choosing the right working fluid and wick structure is crucial for optimizing heat pipe performance.

- Heat pipes are essential in extreme environments, functioning effectively in space, polar regions, and deserts.

- Innovations in heat pipe technology, such as graphene and 3D printing, promise to enhance their efficiency and application in future electronics.

Heat Pipe Basics

Working Principle

Heat pipes use a unique two-phase heat transfer process that sets them apart from conventional cooling solutions. You benefit from their ability to move heat quickly and efficiently, even across longer distances inside electronic devices.

Phase Change

When you apply heat to one end of a heat pipe, the working fluid inside absorbs this energy and changes from a liquid to a vapor. This process, called vaporization, uses the latent heat of vaporization, which means the fluid can carry a large amount of energy without a big temperature increase. The vapor then travels to the cooler end of the pipe, where it releases heat and condenses back into a liquid. This cycle continues as long as there is a temperature difference between the two ends.

- The phase change process allows heat pipes to transfer heat much faster than solid metal conductors.

- You do not need any external power source for this process; the temperature difference alone keeps it running.

- The efficiency of this mechanism makes heat pipes ideal for compact and high-performance electronics.

Capillary Action

After condensation, the liquid must return to the hot end to repeat the cycle. Here, the wick structure inside the pipe plays a crucial role. The wick uses capillary action, which relies on surface tension, to draw the liquid back to the evaporator section. This movement happens even against gravity, so you can install heat pipes in almost any orientation.

- The wick structure ensures a continuous flow of the working fluid.

- Capillary action keeps the system self-sustaining and reliable.

- You gain consistent thermal management without moving parts or extra energy input.

Tip: The combination of phase change and capillary action allows heat pipes to outperform traditional heat sinks, which only use conduction and convection without a phase change.

Main Components

Every heat pipe contains several key components that work together to manage heat effectively. Understanding these parts helps you select the right design for your application.

| Component | Role in Thermal Management |

|---|---|

| Evaporator | Absorbs heat from the source and vaporizes the working fluid, transferring heat to the condenser. |

| Condenser | Releases heat and condenses the vaporized working fluid back into a liquid, in contact with the heat sink. |

| Wick Structure | Transports the working fluid from the cooler end to the hotter end via capillary action, using materials like sintered metal powders or woven metal mesh. |

You often find copper, stainless steel, or aluminum used for the shell, depending on the temperature range and weight requirements. The wick structure may use sintered metal, grooves, or mesh to optimize fluid movement. Water is the most common working fluid for electronics, but other fluids like ammonia or sodium suit higher or lower temperature ranges.

- The evaporator section sits near the heat source, such as a processor or power module.

- The condenser section connects to a heat sink or the device casing, where it can release heat safely.

- The wick structure ensures the working fluid keeps moving, so the heat pipe never stops working as long as a temperature difference exists.

By understanding these basics, you can see why heat pipes have become essential in modern electronics. Their design supports efficient, reliable, and flexible thermal management.

Heat Pipes vs. Traditional Cooling

Thermal Conductivity

You need to move heat away from electronic components quickly to prevent overheating. Thermal conductivity measures how well a material transfers heat. Heat pipes outperform traditional copper and aluminum heat sinks by a wide margin. The following table shows the difference in thermal conductivity between these solutions:

| Material | Thermal Conductivity (W/m-K) | Thermal Conductivity (BTU/(hr·ft⋅°F)) |

|---|---|---|

| Heat Pipes | 20,000 – 50,000 | N/A |

| Copper | 401 | 231 |

| Aluminum | 237 | 136 |

You can see that heat pipes transfer heat much faster than solid metals. This high conductivity allows you to maintain lower temperatures in compact devices, even when power density increases. You gain better performance and longer component life.

Efficiency

You want your cooling system to work efficiently without wasting energy. Heat pipes use a passive mechanism, relying on phase change and capillary action, so they do not require electricity to operate. Traditional active cooling solutions, such as fans, consume more power and generate additional heat.

- Heat pipe systems (SPICS) can save energy consumption by 62.9% to 80.0% compared to traditional active cooling solutions (ACS).

- Another variant of heat pipe systems (SPICS-CT) shows energy savings of 75.4% to 77.6% compared to ACS.

- The life cycle cost (LCC) of ACS is significantly higher, ranging from 1.52 to 3.94 times that of SPICS.

You reduce your energy bills and lower your environmental impact when you choose heat pipes. The historical costs associated with heat pipes have decreased significantly due to their widespread adoption in high-volume markets, such as portable computers. Although initial implementation costs may be higher than traditional cooling solutions, the efficiency and performance improvements, along with the declining costs from increased production, position heat pipes as a competitive option for mass-produced electronics.

Noise and Power

You may notice that traditional cooling systems use fans or pumps, which create noise and require regular maintenance. Heat pipes operate silently because they have no moving parts. You benefit from a quieter device and fewer mechanical failures.

Heat pipe systems are characterized by their passive cooling mechanism and lack of moving parts, leading to minimal maintenance needs and a longer lifespan. In contrast, traditional fan-based cooling systems have mechanical components that are prone to wear and tear, resulting in more frequent maintenance and potential repairs.

Researchers have found that graphene-based heat pipes can help solve the problems of cooling electronics and power systems used in avionics, data centres, and other power electronics. Heat pipes are one of the most efficient tools for this purpose, because of their high efficiency and unique ability to transfer heat over a large distance. The graphene enhanced heat pipe exhibits a specific thermal transfer coefficient which is about 3.5 times better than that of copper-based heat pipe.

You achieve quieter operation, lower power consumption, and reduced maintenance when you select heat pipes for your electronic devices.

Reliability

You expect your electronic devices to work reliably for years. Reliability becomes a critical factor when you compare cooling solutions. Heat pipes stand out because they have no moving parts. This design choice means you avoid the mechanical wear and tear that often causes failures in traditional fan-based or liquid cooling systems.

Traditional cooling systems, especially those using pumps or fans, require regular maintenance. Moving parts can break down, and liquid coolants may evaporate or react chemically over time. These issues can lead to sudden performance drops or even complete system failure. In contrast, heat pipes offer robust operation. Their sealed construction prevents leaks and contamination. You do not need to worry about evaporation or chemical reactions inside the pipe.

Long-term studies show that heat pipes have a much lower failure rate than traditional liquid cooling systems. You benefit from consistent performance and fewer unexpected breakdowns. This reliability reduces downtime and maintenance costs, which is especially important in mission-critical applications like servers, medical devices, and aerospace electronics.

Note: When you choose heat pipes, you invest in a cooling solution that keeps your devices running smoothly with minimal intervention.

Design Factors

Working Fluid

Selecting the right working fluid is essential for the performance of heat pipes in electronic devices. You must consider several factors to ensure the fluid matches your device’s requirements. The fluid should remain stable and compatible with the pipe materials. It must operate efficiently within the temperature range of your application. The fluid also needs to vaporize and condense at temperatures that match your heat source and heat sink.

| Key Factor | Description |

|---|---|

| Material Compatibility | The fluid must be chemically stable with the heat pipe materials to prevent degradation. |

| Operating Temperature Range | The fluid should operate effectively between its triple point and critical point. |

| Vaporization and Condensation | The fluid must vaporize within the heat source’s operating range and condense at the heat sink. |

Water is the most common choice for electronics because it offers excellent thermal properties and compatibility. For devices operating at extreme temperatures, you might use ammonia or sodium. By choosing the right fluid, you ensure reliable operation and long service life.

Tip: Always check the compatibility of the fluid with the shell material to avoid corrosion and leaks.

Wick Structure

The wick structure inside a heat pipe drives capillary action, which keeps the fluid moving. You need to select a wick that matches your device’s orientation and heat load. Different wick types offer unique benefits and limitations.

| Wick Structure Type | Influence on Capillary Action | Performance Characteristics |

|---|---|---|

| Grooved | Enables fluid transfer | Limited by manufacturing constraints |

| Sintered | Enables fluid transfer | Limited by manufacturing constraints |

| Combined Structures | Improved properties | Requires complex manufacturing routes |

Layer thickness and permeability also affect performance. Thinner layers with higher permeability provide better fluid movement. Additive manufacturing allows you to customize wick structures, giving you superior performance compared to conventional methods.

| Layer Thickness (µm) | Wick Permeability (K) | Effective Pore Radius (reff) | K/reff Ratio |

|---|---|---|---|

| 40 | Highest value | Small effect | Highest |

| 60 | High | Small effect | High |

Note: Advanced manufacturing methods help you create wicks that boost capillary action and improve heat transfer.

Shell Material

The shell material determines the durability, weight, and thermal conductivity of your heat pipe. You must balance cost, compatibility, and performance when choosing the shell.

| Materials | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|

| aluminum | Low cost, light weight, easy processing | Poor compatibility, easy corrosion, low conductivity | Aerospace and weight-sensitive fields |

| Stainless steel | High strength, corrosion resistance, high temperature tolerance, good compatibility | Difficult processing, low conductivity | Extreme environments, long service life |

| copper | High conductivity, easy processing, good compatibility, low cost | High material cost, heavy | Electronics, communications, solar energy |

Copper is popular for electronics because it transfers heat efficiently and is easy to process. Stainless steel works well in harsh environments, while aluminum suits applications where weight matters most.

Choosing the right shell material helps you achieve the best balance between performance and reliability.

Shape and Layout

You must pay close attention to the shape and layout of heat pipes when designing thermal solutions for compact electronic devices. The physical configuration directly impacts how efficiently your device manages heat. Mini flat heat pipes, with their slim and compact structure, fit easily into tight spaces inside modern electronics. This design helps you achieve uniform temperature distribution across critical components. Uniformity prevents thermal stress, which can damage sensitive parts and reduce the reliability of your device.

You can also explore advanced layouts, such as tree-shaped configurations. These layouts use branching pathways to spread heat more evenly and quickly. By combining innovative wick architectures with these layouts, you improve capillary action and boost thermal conductivity. This approach works especially well for devices with irregular shapes or multiple heat sources. You gain flexibility in your design, allowing you to cool hotspots that traditional straight pipes might miss.

Innovative designs often use ultra-fine fibers and bi-porous sintered materials in the wick structure. These materials enhance capillary action, which speeds up fluid movement inside the pipe. Faster fluid movement means quicker heat transfer, which is vital for devices that experience sudden changes in thermal load. Sintered copper powder stands out as a wick material because it supports strong capillary action. This feature allows your heat pipes to function efficiently, even in challenging orientations or low-gravity environments.

When you select the shape and layout, consider the available space, the location of heat sources, and the desired temperature uniformity. You may need to use simulation tools to predict how different layouts will perform. Prototyping and testing help you confirm that your chosen design meets the thermal requirements of your device.

Tip: Always match the shape and layout of your heat pipes to the unique needs of your device. A well-designed configuration ensures reliable performance and extends the lifespan of your electronics.

Heat Pipe Applications

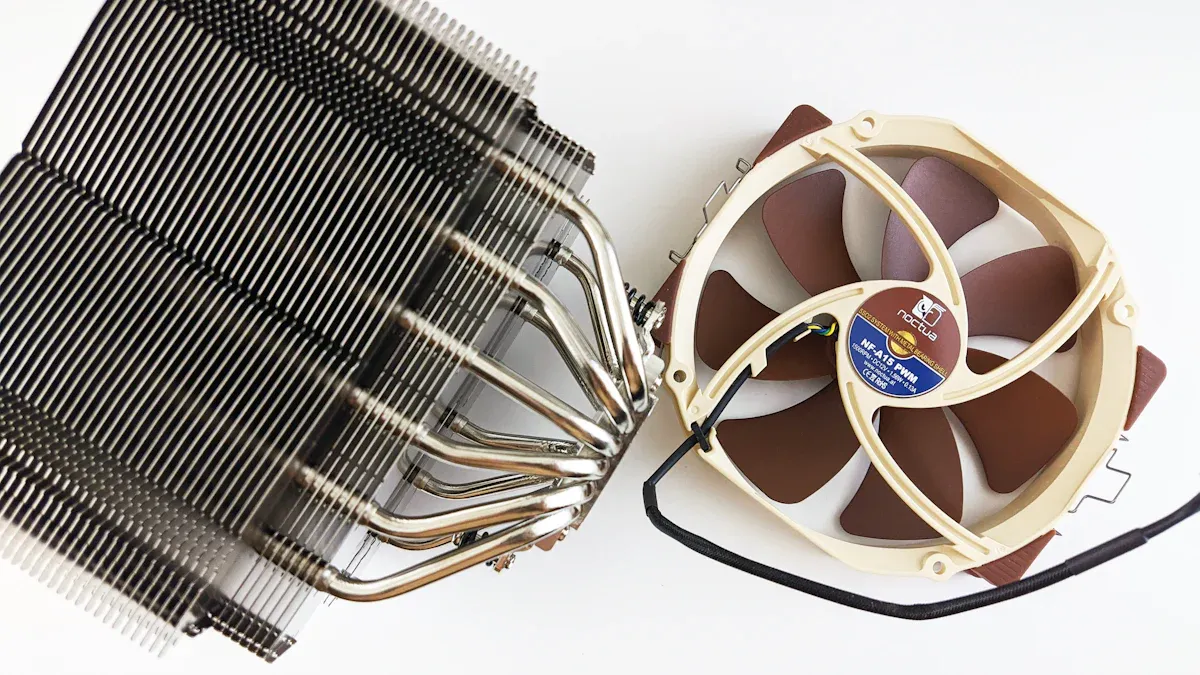

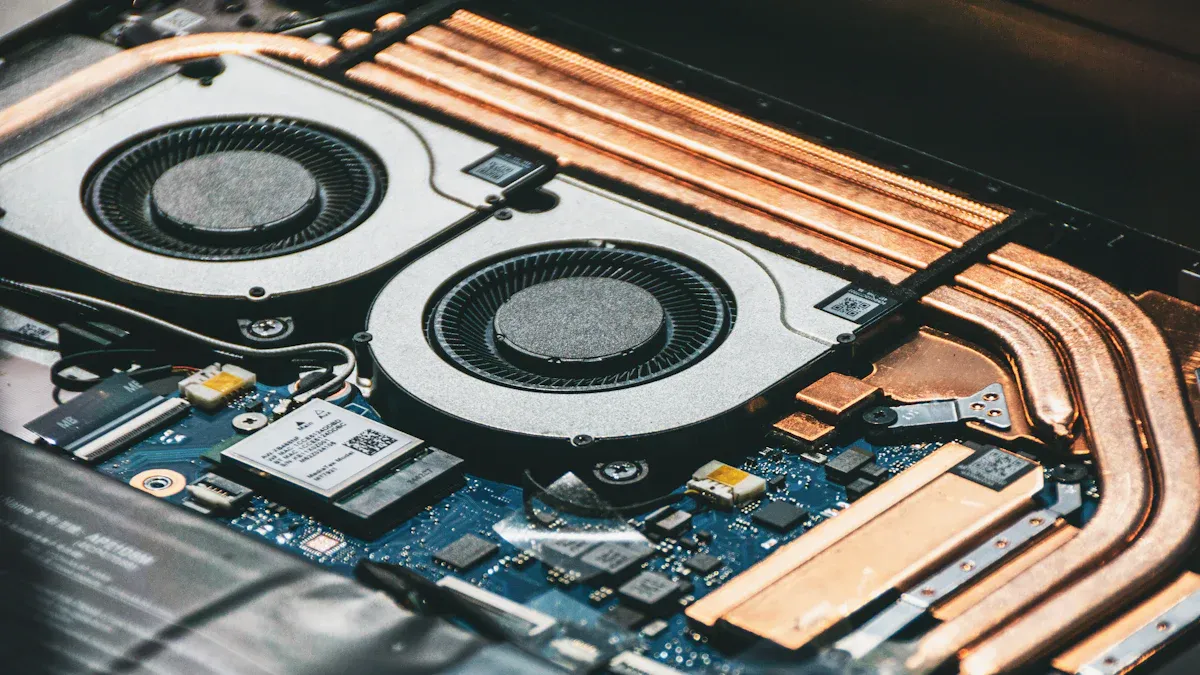

Consumer Electronics

You rely on many devices every day that demand efficient cooling in tight spaces. Heat pipes play a vital role in keeping these electronics cool and reliable. You find them in:

- Laptops

- Smartphones

- Gaming consoles

- High-performance computers

- Tablets

Tablet and smartphone cooling where device thickness is very limited.

Manufacturers use heat pipes in modern consumer electronics, including desktops, laptops, tablets, and high-end smartphones. These devices generate significant heat in small spaces. Heat pipes move this heat away from sensitive components, preventing overheating and performance drops. You benefit from longer device life, stable performance, and thinner, lighter products.

Industrial Equipment

You see heat pipes used in factories and power plants where machines run hot for long hours. These systems must stay cool to avoid breakdowns and costly repairs. Heat pipes use phase change to move heat quickly, keeping equipment at safe temperatures. This process helps you maintain high performance and extend the life of expensive machinery.

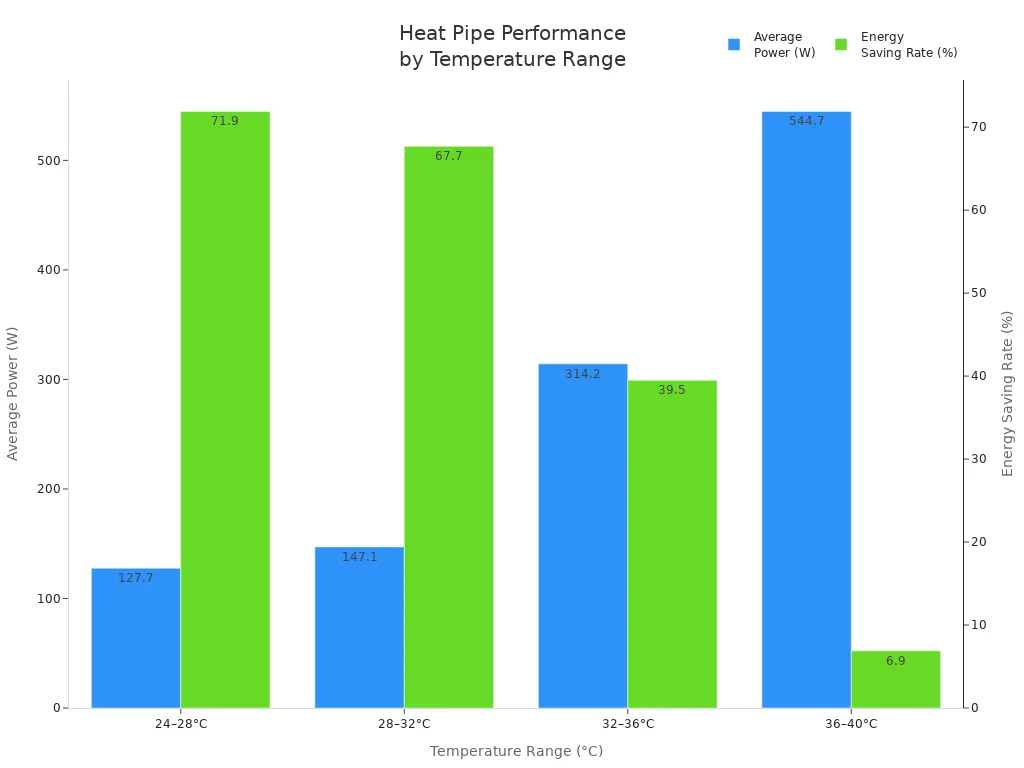

The following table shows how heat pipes help save energy in industrial settings:

| Temperature Range (°C) | Average Power (W) | Energy Saving Rate (%) |

|---|---|---|

| 24–28 | 127.7 | 71.9 |

| 28–32 | 147.1 | 67.7 |

| 32–36 | 314.2 | 39.5 |

| 36–40 | 544.7 | 6.9 |

You notice that energy savings are highest at lower temperatures. By using heat pipes, you reduce the risk of overheating and lower your energy costs. This improvement leads to fewer shutdowns and more reliable operations.

Medical and Aerospace

You depend on precise temperature control in medical and aerospace technology. Heat pipes use evaporation and condensation to move heat or cold exactly where you need it. In medical devices, they help remove excess heat during procedures, protecting both equipment and patients. Some medical tools use cryogenic heat pipes for freezing tissue with pinpoint accuracy.

- Heat pipes transport both heat and cold, making them versatile for medical and aerospace systems.

- In medical devices, they prevent damage to surrounding tissues by managing heat during procedures.

- Cryogenic heat pipes allow for precise cooling, such as freezing tissue.

- As medical devices shrink and grow more powerful, you see heat pipes become even more important for safe and effective operation.

In aerospace, you rely on heat pipes to keep satellites, avionics, and other systems within safe temperature limits. Their ability to work in zero gravity and extreme conditions makes them essential for space missions and high-altitude flights.

Extreme Environments

You often face unique challenges when you design electronics for extreme environments. Devices in space, polar regions, deserts, or deep-sea locations must survive harsh temperatures and unpredictable conditions. In these settings, traditional cooling methods often fail or require too much power. You need a solution that works reliably, even when maintenance is impossible.

Heat pipes give you a powerful tool for thermal management in these demanding scenarios. Their closed-loop system moves heat using temperature differences, not mechanical parts. This design allows you to manage thermal energy without powered equipment, which is critical when you have limited access to electricity or must minimize weight.

Consider how heat pipes perform in space. Satellites and small spacecraft operate in a vacuum, where convection does not work. You cannot use fans or pumps because there is no air to move. Heat pipes transfer heat from sensitive electronics to radiators, where it can escape into space. You benefit from their ability to function passively, which saves both mass and power—two of your most precious resources in aerospace engineering.

You also see heat pipes excel in arctic or desert environments. In the Arctic, electronics must stay warm enough to function, even when outside temperatures drop far below freezing. Heat pipes can move heat from internal sources to areas that need it most, preventing cold spots and condensation. In deserts, you face the opposite problem—extreme heat. Heat pipes quickly move excess heat away from critical components, protecting them from thermal damage.

Tip: When you use heat pipes in extreme environments, you gain a reliable, maintenance-free solution that adapts to both hot and cold conditions.

You can find heat pipes in communication equipment on mountain tops, scientific instruments in Antarctica, and exploration vehicles on Mars. Their ability to operate in any orientation, resist vibration, and function without gravity makes them ideal for unpredictable or remote locations.

- Heat pipes use a closed-loop system to move heat through temperature gradients.

- They manage thermal energy without powered equipment.

- You find them especially useful in small spacecraft with strict mass and power limits.

When you choose heat pipes for extreme environments, you ensure your devices stay safe, efficient, and reliable—no matter where you deploy them.

Advanced Features

Thermal Diode

You can improve directional heat transfer in your electronic devices by using a thermal diode. This device allows heat to flow more easily in one direction than the other. You achieve this effect by arranging materials with positive and negative temperature coefficients in series. You also find thermal switches useful for controlling heat flow. These switches minimize thermal contact resistance by bringing two conducting surfaces together when needed.

| Component | Description |

|---|---|

| Thermal Diode | A device that enhances directional heat transfer by using materials with positive and negative temperature coefficients arranged in series. |

| Thermal Switch | A mechanism that minimizes thermal contact resistance by allowing two thermally conducting surfaces to come into contact, controlling heat flow effectively. |

Tip: You can use thermal diodes and switches to protect sensitive components from overheating and to direct heat away from critical areas.

Multi-Source Cooling

You often face challenges when cooling densely packed electronic assemblies. Heat pipes help you solve these problems by transporting heat from high heat flux regions to cooler areas. This process is essential for managing thermal issues in tight spaces. You benefit from effective removal of heat, which keeps your devices running smoothly.

Heat pipes operate using phase-change processes and two-phase flow circulation. You activate these mechanisms by creating a temperature difference between the evaporator and condenser sections. This design allows you to redistribute heat efficiently. You can cool multiple sources at once, making heat pipes ideal for complex systems with many components.

You can rely on heat pipes for multi-source cooling in advanced electronics, such as servers, communication equipment, and power modules.

Innovation

You see rapid advancements in heat pipe technology for electronic devices. Researchers continue to develop new materials and manufacturing methods to make heat pipes more effective and compact. You benefit from breakthroughs such as graphene and 3D printing, which show great promise for future applications.

- You can use heat pipes in IoT-enabled devices for real-time thermal management.

- Integration with phase change materials gives you better thermal responsiveness under changing loads.

- Custom solutions help you address unique challenges in complex assemblies or extreme conditions.

- Ultra-fine fibers and novel materials improve capillary action, allowing for faster heat transfer.

You stay ahead of thermal management challenges by adopting these innovations. You ensure your devices remain efficient, reliable, and ready for the demands of tomorrow.

You gain significant advantages when you use heat pipes in electronic devices. The table below highlights the main benefits:

| Benefit | Description |

|---|---|

| High thermal conductivity | Heat pipes transfer heat efficiently, outperforming copper and other traditional conductors. |

| Energy efficiency | They minimize heat loss and distribute heat reliably. |

| Robust construction | You rely on their long service life and consistent performance. |

| Compact design suitability | Their small size fits modern electronics with limited space. |

| Low maintenance | You spend less time on upkeep compared to other cooling solutions. |

You see heat pipes deliver efficient, reliable, and flexible thermal management. As device designs evolve, flexible and ultra-thin heat pipes will support foldable and wearable electronics. You can expect eco-friendly materials and dynamic thermal adjustment to shape the future of electronic cooling.

FAQ

What devices use heat pipes for cooling?

You find heat pipes in laptops, smartphones, gaming consoles, and industrial equipment. Manufacturers use them in medical devices and aerospace systems. You benefit from their ability to keep electronics cool in compact spaces.

How long do heat pipes last in electronics?

You can expect heat pipes to last for many years. Their sealed design prevents leaks and corrosion. Most heat pipes outlast the devices they cool, so you rarely need to replace them.

Can you install heat pipes in any orientation?

You can install heat pipes in almost any position. The wick structure uses capillary action to move fluid against gravity. You achieve reliable cooling whether the device sits flat, vertical, or at an angle.

Do heat pipes require maintenance?

You do not need to perform regular maintenance on heat pipes. Their passive operation and lack of moving parts mean you avoid common issues like fan failure or coolant leaks.

Are heat pipes safe for consumer electronics?

You use heat pipes safely in consumer electronics. Their sealed construction prevents exposure to fluids. You avoid risks of leaks or electrical shorts, making them ideal for everyday devices.

What limits the performance of a heat pipe?

You see performance limits based on the working fluid, wick structure, and temperature range. You must select the right materials and design for your specific application to achieve optimal results.

Can heat pipes replace fans completely?

You can use heat pipes to reduce or eliminate fans in some devices. In high-power systems, you may still need fans for extra cooling. You often combine both for maximum efficiency.

How do you choose the right heat pipe for your device?

You select a heat pipe based on your device’s size, heat output, and operating environment. You consider the working fluid, shell material, and wick type. You may consult with thermal engineers for complex designs.