How to Stay Cool with the Right Large Heat Sink

Choosing the right large heat sink helps your devices stay cool and safe. If your device gets too hot, it might stop working. Studies say that high heat causes about 55% of electronic failures. You must pick a cooling solution that fits your device’s needs. When you choose the right size and type, you keep your device safe and help it last longer. Staying cool is not hard to do.

Key Takeaways

- Know how much heat your device makes. Add up the heat from all parts to pick the right heat sink.

- Pick a heat sink with low thermal resistance. Lower thermal resistance helps heat move away faster. This keeps your device cooler.

- Pick the best material for your heat sink. Aluminum is cheap and light. Copper cools better for strong devices.

- Make the heat sink’s surface area bigger. More surface area lets heat leave faster. This helps your device stay cool.

- Match the heat sink’s size and how you attach it to your device. Make sure it fits well and can handle the heat for best results.

Large Heat Sink Requirements

Choosing the right large heat sink starts with understanding your device’s thermal needs. You must know how much heat your component produces, how well the heat sink can move that heat away, and what temperature limits you cannot exceed. Let’s break down each part.

Heat Load

You need to figure out how much heat your device makes. This is called the heat load. Most of the time, you can find this by looking at the power your device uses. For example, if you have a chip that uses 10 watts, most of that energy turns into heat.

- List all the parts that make heat, like chips or power supplies.

- Check their voltage and current, or just their watt rating.

- Use the formula:

Power (W) = Voltage (V) × Current (A) - Add up the power for all parts to get the total heat load.

Tip: If your device sits in the sun, it will get hotter. Dark colors absorb more heat, so think about where you place your device.

Thermal Resistance

Thermal resistance tells you how well a large heat sink can move heat away from your device. You want a low thermal resistance so heat leaves quickly. This value is measured in degrees Celsius per watt (°C/W). The lower the number, the better the cooling.

Thermal resistance shows how much the temperature rises for each watt of heat.

It depends on the material, size, and shape of the heat sink.

You can find different types of thermal resistance:

- Junction-to-case (ΘJC)

- Case-to-sink (ΘCS)

- Sink-to-air (ΘSA)

The total thermal resistance is the sum of these values:

ΘJA = ΘJC + ΘCS + ΘSA

Note: If you pick a large heat sink with high thermal resistance, your device may overheat. Always check the numbers before you buy.

Temperature Limits

Every electronic part has a maximum safe temperature. If you go over this limit, your device can fail. You must keep the temperature below this point.

Here is a table with some common limits:

| Component Type | Maximum Safe Operating Temperature |

|---|---|

| Microprocessors | 100°C (like Intel i5 4460) |

| Power Transistors | Check the datasheet |

You need to keep the temperature of your device below these numbers. To do this, you must consider both the case temperature and the air around your device. If the room is hot, your device will get even hotter.

Tip: Always check the temperature of the air around your device. If your device sits in a closed box, the air inside can get much warmer than the room.

Matching the Heat Sink to Your Needs

You must match the type and size of the large heat sink to your device. If your device makes a lot of heat, you need a bigger heat sink or one with better airflow. If you use a small heat sink on a high-power device, it will not cool well.

- Make sure the heat sink fits in your device.

- Check that it can handle the total heat load.

- Look for good airflow around the heat sink.

Remember: A large heat sink works best when you know your heat load, choose the right thermal resistance, and stay below the temperature limits. Always check the numbers before you decide.

Material Choice

Aluminum vs. Copper

When picking a heat sink, you often choose between aluminum and copper. Both metals help take heat away from your device, but they do it differently. Aluminum has a thermal conductivity of about 235 W/m·K. Copper can move heat almost twice as fast as aluminum. Aluminum only has about 60% of copper’s thermal conductivity.

Copper is very good at moving heat, so it is great for hard jobs. But you also need to think about price and weight. Copper heat sinks cost about three times more than aluminum ones. Aluminum is much lighter, which is good if your device needs to be easy to carry.

Here is a simple comparison:

| Material | Cost Comparison | Weight Comparison |

|---|---|---|

| Aluminum | About one-third the cost of copper | Much lighter due to lower density |

| Copper | Three times more expensive | Heavier due to higher density |

Aluminum does not rust easily and can be shaped into many designs. This makes it a favorite for lots of electronics.

When to Use Each

Pick the material that fits your device’s needs. Aluminum works well for most electronics people use at home. It is cheap, light, and easy to make. You can find it in laptops, gaming consoles, and home appliances. Aluminum can also be made into different fin shapes to help cool better.

Copper is best when you need to get rid of a lot of heat fast. You might use copper in a large heat sink for high-power LED systems or small devices with little space. Copper is also good for high-end lighting or when you care more about performance than price.

Tip: If you want to save money and keep things light, aluminum is usually the best pick. Use copper only if you need the most cooling.

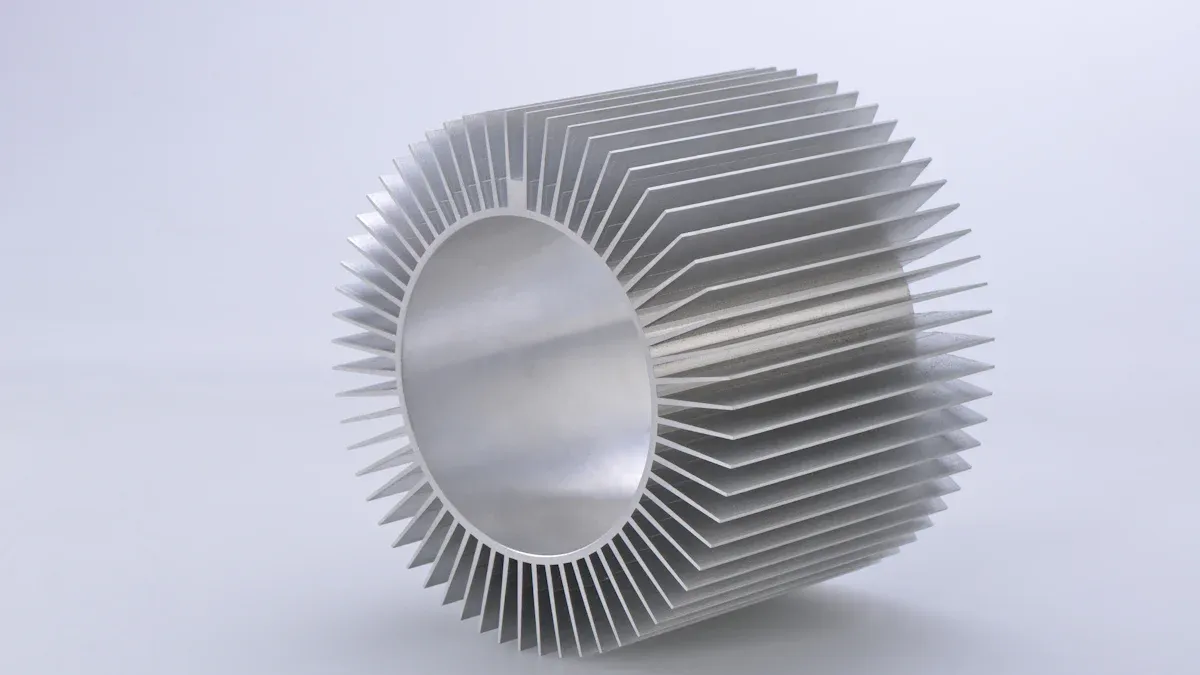

Surface Area & Fins

You can boost cooling power by increasing the surface area of your heat sink. When you add more surface, you give heat more places to escape. Studies show that a bigger surface area can lower temperatures by over 26%. You also get a 34% drop in thermal resistance, which means heat leaves faster. If you use textured surfaces instead of smooth ones, you can improve effectiveness by up to 40%.

Fin Design

Fin design plays a big role in how well your heat sink works. You have many choices, and each type helps in different ways. Here is a table that shows how some fin designs compare:

| Fin Design Type | Key Findings |

|---|---|

| Corrugated fins | Maximum fin effectiveness of 3.23 with the largest fin height. |

| Twisted band fin array | Creates vortices, mixing air and boosting heat transfer. |

| Variable height fins | Improves thermal performance by 225% compared to constant-height fins. |

| Double-height fin configuration | Better thermal performance per unit mass. |

| Split fins | More slots and wider slots increase heat transfer, reaching a coefficient of 9.08 W/m²K. |

You can also pick from straight, wavy, louvered, pin, annular, comb, or folded fins. Straight fins cost less and work well for simple jobs. Wavy and louvered fins stir up the air, which helps cool faster. Pin fins come in many shapes and help air move around the heat sink. Folded fins pack more surface into a small space.

Fin spacing and thickness matter too. If you make the space between fins less than 1 mm, air gets trapped and your device can overheat. Spacing between 1.5 and 3 mm gives you the best airflow for most uses. Wider spacing lets air move freely but reduces surface contact.

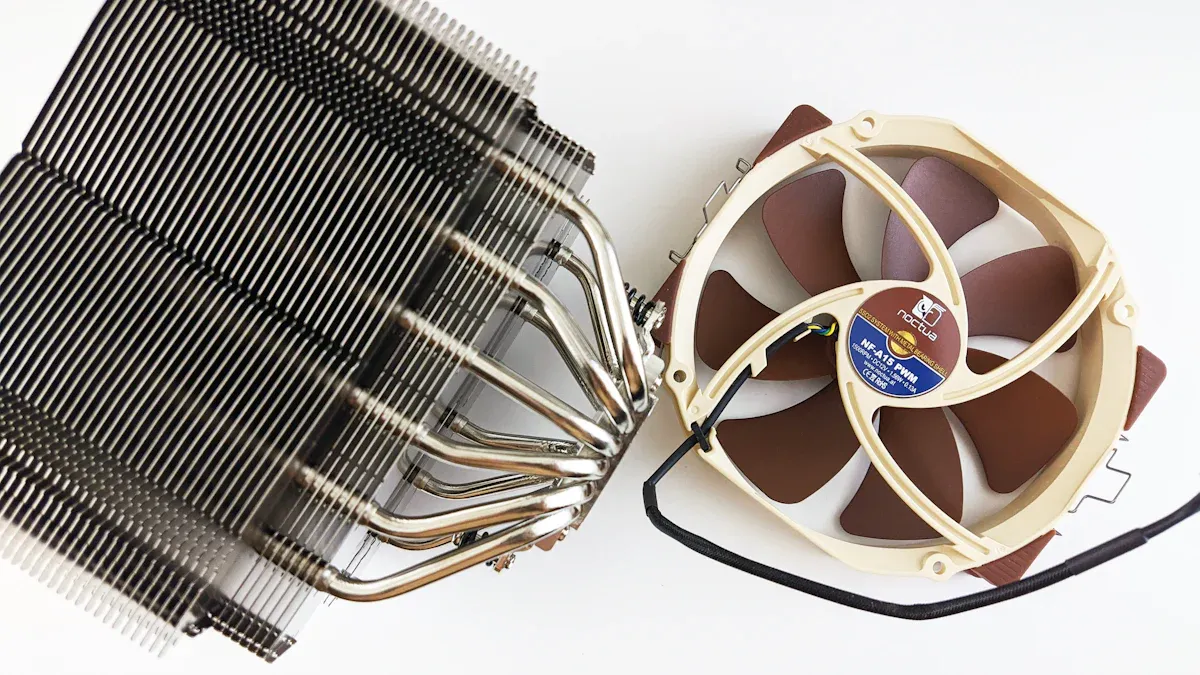

Active vs. Passive

You can cool your device with active or passive methods. Active cooling uses fans or blowers to push air over the heat sink. This works best for high heat loads and dense fin designs. Passive cooling relies on natural airflow and works well for low-power devices.

Here is a table to help you compare:

| Cooling Method | Mechanism | Advantages | Disadvantages |

|---|---|---|---|

| Active Cooling | Fans or pumps move air | Strong cooling, good for high heat | Needs power, can be noisy |

| Passive Cooling | Uses natural airflow | Simple, silent | Limited cooling, less effective |

You should use fans or blowers with a large heat sink when you need to cool high-power devices or when you have many fins packed close together. Blowers work well for heat exchangers and can handle higher pressure drops, making them ideal for tough jobs.

Tip: Clean your heat sink often. Dust can block airflow and lower cooling performance.

Mounting & Finish

Mounting Options

You need to choose the right way to attach your large heat sink. The mounting method affects how well your heat sink works and how long it lasts. Here are some common options:

| Mounting Option | Description |

|---|---|

| Screws | Strong and reliable; needs holes and careful tightening. |

| Spring Clips | Fast and gentle; needs space and correct pressure. |

| Push Pins | Quick and tool-free; not as strong. |

| Rivets | Permanent and strong; cannot remove easily. |

| Thermal Adhesive | Clean and simple; permanent, weaker hold. |

| Thermal Tape | Easy to use; weakest under heavy load or shaking. |

| Standoffs + Screws | Strong and flexible; needs more space and parts. |

Each mounting method changes how well your heat sink cools your device. Some methods give better thermal contact, while others make repairs easier. Look at this table to compare:

| Mounting Method | Thermal Performance | Reliability | Pros | Cons |

|---|---|---|---|---|

| Adhesive Bonding | Good | Moderate to High | Easy to use, keeps electricity apart | Can peel off, hard to fix |

| Solder Attachment | Excellent | High | Very low heat resistance | No electrical isolation, can crack |

| Clip-on Mechanisms | Good to Excellent | Moderate | Easy to put on and take off | Needs more board space, can loosen |

| Spring-loaded Pins | Good | Moderate to High | Handles size changes, easy to fix | Needs holes in the board, costs more |

| Phase Change Material | Excellent | High | Fills gaps well | Needs extra support, can move out |

Tip: Pick a mounting method that matches your device’s needs. If you want easy repairs, use clips or pins. For the best cooling, solder or phase change materials work well.

Surface Treatments

Surface treatments help your heat sink last longer and cool better. You can pick from several types:

- Anodizing: Adds a tough oxide layer. This helps your heat sink resist rust and improves how it gives off heat. Anodizing boosts the ability of aluminum heat sinks to radiate heat, making them more effective.

- Chemical Conversion Coating: Improves how heat moves through the surface and helps paint or glue stick better.

- Powder Coating: Makes your heat sink look good and protects it from scratches. However, powder coating can act like an insulator. This means it may lower the cooling power of your heat sink by 20-50%.

- Chemical Film Coating: Shields your heat sink from rust and keeps it working longer.

Note: Anodizing helps your heat sink cool better by increasing its ability to send heat into the air. Powder coating looks nice but can trap heat, so use it only if looks matter more than cooling.

Choosing the right mounting and finish helps your large heat sink work its best and last longer. Always match your choices to your device’s needs for the best results.

Custom vs. Off-the-Shelf

Custom Solutions

You may need a custom heat sink if your device has special cooling needs. Custom-designed large heat sinks help you solve unique thermal problems. You can work with engineers to create a heat sink that fits your device perfectly. This approach lets you pick the size, shape, and material that match your system. When you use a custom solution, you get better cooling and higher performance.

Custom heat sinks often cost more at first. However, they can save you money over time. You will see fewer repairs and better energy use. Here are some reasons to choose a custom heat sink:

- You get a design made just for your system, which means better cooling.

- The heat sink fits your space, so you do not need to change your layout.

- You pay more at the start, but you save money later because your device lasts longer and uses less energy.

Custom-designed large heat sinks are great for special jobs. They help you meet tough cooling needs and improve how your device works.

Standard Options

Standard, off-the-shelf heat sinks work well for most common devices. You can find many types, such as Skived Fin, Bonded Fin, and Extruded Heat Sinks. These models come in different sizes and shapes. You can use them for both normal and forced air cooling.

- Large aluminum heat sinks are easy to find and cost less.

- Standard models meet most thermal needs for home and office electronics.

- You can install them quickly without waiting for custom parts.

However, standard heat sinks have limits. They may not cool high-power devices as well as custom ones. For example:

“In a natural convection (no fan) setup, the performance difference is noticeable. But once you turn on a fan, the high-density fins of a skived heat sink come alive. The constant flow of cool air across so many thin fins creates a level of heat dissipation that extruded profiles simply can’t touch. It’s like comparing a rowboat to a speedboat.”

You should pick a standard heat sink if you want a quick, low-cost solution for regular devices. For special or high-power needs, a custom heat sink gives you the best results.

You can pick a large heat sink by using these steps. First, choose the material that fits your needs. Next, make sure the heat sink matches your device’s size and how you will attach it. Add more surface area to help cool better. Last, pick if you want a custom or standard design.

A good heat sink helps your device stay cool. It makes your device work better and saves you money on fixing it.

| Benefit | What You Gain |

|---|---|

| Improved Reliability | Your device breaks less often |

| Extended Lifespan | Your device works for more years |

| Enhanced Performance | Your device runs faster and steadier |

| Cost Savings | You spend less on repairs |

If you follow these steps, your device will work well and last longer.

FAQ

What size heat sink do you need for your device?

You need to match the heat sink size to your device’s heat load. Check your device’s power use. Use a heat sink that can handle the total heat in watts. Always check the manufacturer’s guide for best results.

Can you use a fan with a large heat sink?

Yes, you can add a fan to boost cooling. Fans help move air over the heat sink. This lowers the temperature faster. Use a fan if your device gets very hot or if you want extra safety.

How do you know if your heat sink works well?

Check your device’s temperature during use. If it stays below the safe limit, your heat sink works well. You can also touch the heat sink. If it feels warm but not hot, it removes heat as it should.

Is aluminum or copper better for most projects?

Aluminum works best for most home and office devices. It is light, cheap, and easy to shape. Copper cools better but costs more and weighs more. Use copper only if you need the highest cooling.

How often should you clean your heat sink?

You should clean your heat sink every few months. Dust blocks airflow and makes cooling less effective. Use a soft brush or compressed air to remove dust. Clean more often if your device sits in a dusty place.