Inverter Heat Sinks

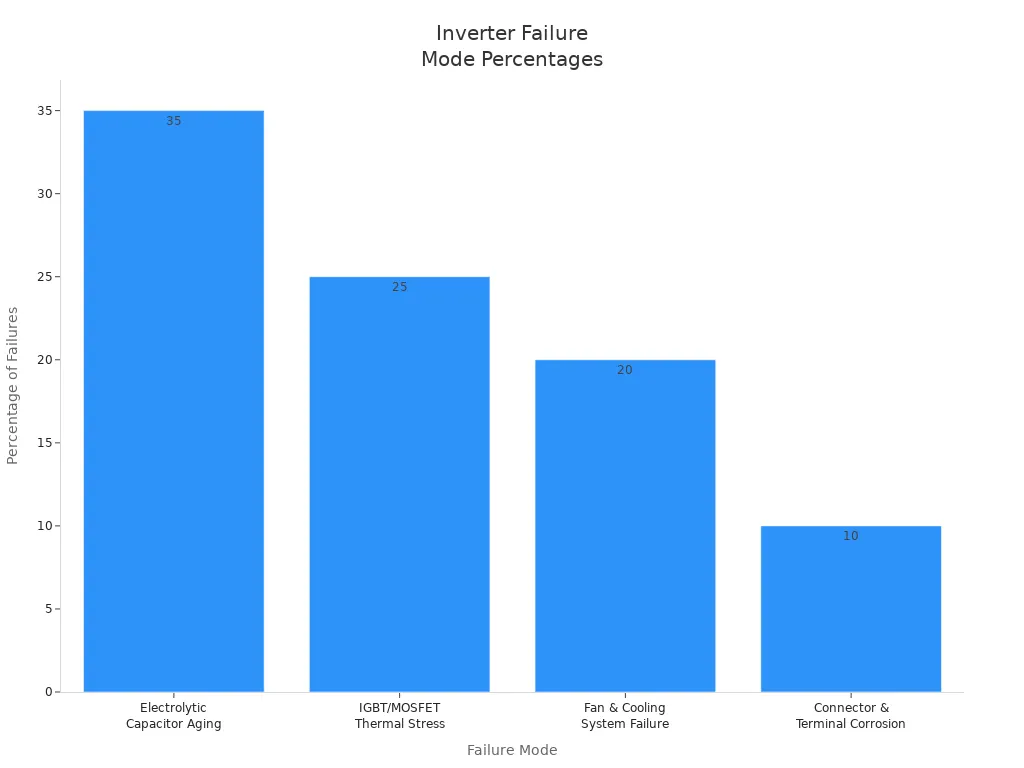

You might ask why an inverter heat sink is so important. This part takes heat away from the inverter’s power electronics. It helps everything work well and not get too hot. If you check the facts, almost half of inverter problems happen because of too much heat or bad cooling.

| Failure Mode | Percentage of Failures |

|---|---|

| Electrolytic Capacitor Aging | 35% |

| IGBT/MOSFET Thermal Stress | 25% |

| Fan & Cooling System Failure | 20% |

| Connector & Terminal Corrosion | 10% |

If you control heat well, you can make some parts last twice as long. You only need to lower the temperature by 10°C. This is why picking and taking care of the right inverter heat sink is very helpful.

Key Takeaways

- Inverter heat sinks are very important for cooling. They stop the inverter from getting too hot. Too much heat can make the inverter break.

- Picking the right heat sink can make your inverter last twice as long. If you lower the temperature by 10°C, it helps a lot.

- Good airflow around the heat sink is very important. If air cannot move, the inverter can get too hot and break.

- Clean the heat sink often to keep it working well. Check it every three to six months to stop dust from building up.

- Choose a heat sink that matches your inverter’s size and power. The right one keeps your inverter cool and working well.

Inverter Heat Sink Function

Heat Absorption and Dissipation

When you run an inverter, it starts to get warm. Most of this heat comes from the power transistors inside. If you let the heat build up, the inverter can slow down or even stop working. The inverter heat sink steps in to help. It grabs the heat from the transistors and moves it away so your inverter stays cool.

Here’s how it works:

- The inverter heat sink absorbs heat through conduction. The hot transistors touch the base of the heat sink, and the heat flows into the metal.

- Fins on the heat sink boost the surface area. This lets more heat escape into the air through convection.

- A small amount of heat leaves by radiation, but most goes out by air movement.

- If you add thermal grease between the transistor and the heat sink, you lower the resistance to heat flow. This makes cooling even better.

You might see heat sinks made of aluminum. Aluminum works well because it moves heat fast and doesn’t rust. Some designs use fans to push air over the fins, which helps even more.

Tip: Good airflow around the heat sink is key. If you block the air, the heat can’t escape, and your inverter gets too hot.

Protecting Power Transistors

Power transistors are the heart of your inverter. They switch electricity on and off very fast, and that makes them heat up. If you don’t keep them cool, they can break down. The inverter heat sink protects these parts by keeping their temperature in check.

Let’s look at some numbers:

| Device Type | Maximum Junction Temperature | Reliability Impact |

|---|---|---|

| Discrete Power Devices | 85°C | Good reliability at this temperature. |

| Integrated Circuits | 65°C | Lower reliability at higher temperatures. |

Most inverters work best when their power transistors stay between 50°C and 75°C. If you let them get hotter than this, you risk thermal runaway. That means the transistor gets so hot it can’t stop heating up, and it fails.

Here’s why keeping cool matters:

- You avoid thermal stress, which can shorten the life of your inverter.

- You keep efficiency high, so your inverter works like it should.

- You prevent sudden shutdowns or damage that can cost you money.

In smaller inverters, you might see simple aluminum heat sinks. Bigger systems use fans and special thermal paste to move heat even faster. No matter the size, the cooling system is what keeps your inverter running strong.

Note: If you keep your inverter heat sink clean and make sure it fits well, you help your power transistors last longer. That means fewer repairs and more reliable power.

How Inverter Heat Sinks Work

Heat Conduction Principles

When your inverter runs, it creates heat. This heat needs a way out, or your device could get damaged. The inverter heat sink steps in to help. It pulls heat away from the hot parts and sends it into the air.

Conduction is the transfer of heat through a solid material due to the vibration and movement of atoms and molecules. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material(s), the heat sink’s base, and the fins. In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink.

Here’s how the process works:

- Heat travels from the inverter’s components to the heat sink through metal or semiconductor parts.

- The better the contact and the higher the thermal conductivity, the faster the heat moves.

- The heat sink then releases this heat into the air. This happens by convection, which means the air carries the heat away. Sometimes, a fan helps move the air faster.

If you want your inverter to last, you need this heat transfer to work well. Good conduction and airflow keep everything cool.

Types and Materials (AL6063 Alloy)

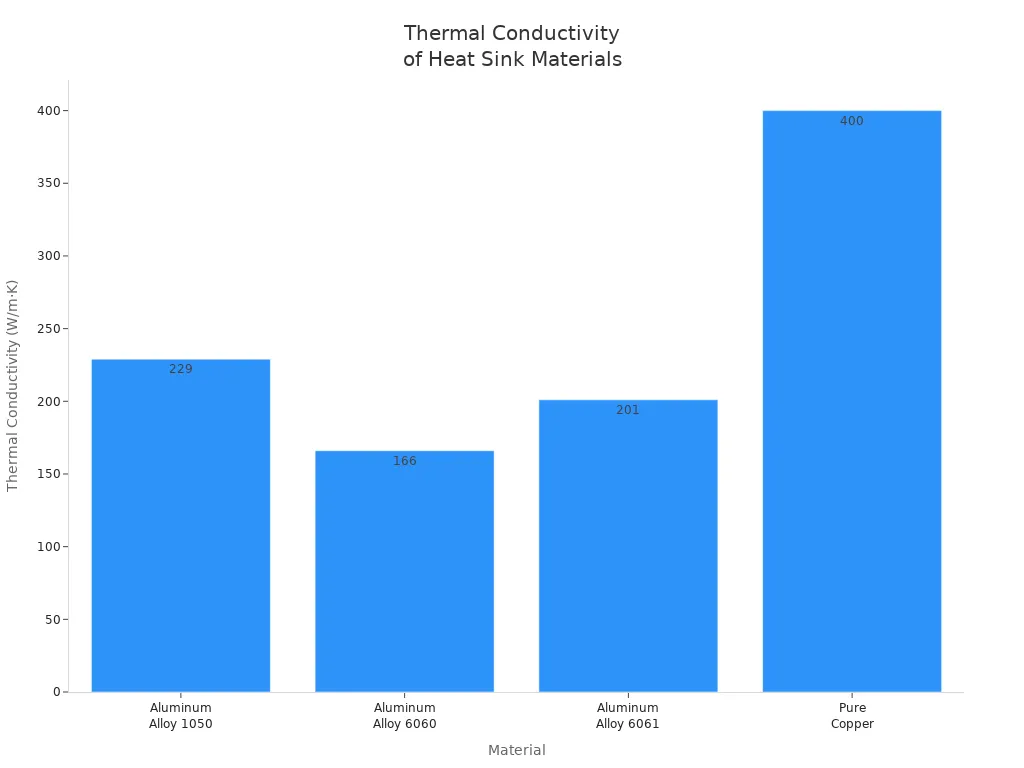

Not all heat sinks are the same. The material you choose makes a big difference. Most inverter heat sinks use aluminum alloys. AL6063 is a popular choice because it balances performance and cost.

Let’s compare some common materials:

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Aluminum Alloy 1050 | 229 |

| Aluminum Alloy 6060 | 166 |

| Aluminum Alloy 6061 | 201 |

| Aluminum Alloy 6063 | 180-220 |

| Pure Copper | 380-400 |

| Graphite (PGS, in-plane) | 700-1700 |

Why do so many people pick AL6063 for their inverter heat sink? Here are some reasons:

- Good thermal conductivity, so it moves heat quickly.

- Easy to shape into fins, which gives more surface area for cooling.

- Lightweight, so it doesn’t add much weight to your device.

- Cheaper to make than copper or special composites.

If you want a heat sink that works well and doesn’t cost too much, AL6063 is a smart pick. It keeps your inverter cool and helps it last longer.

Importance for Performance

Overheating Risks

Sometimes, you may not see when your inverter gets too hot. Overheating can happen slowly and cause big problems. Here are some reasons why inverters get too warm:

- If it is hot outside, your inverter has trouble cooling down, especially outdoors.

- Bad airflow keeps heat inside, making the inverter feel like a closed box.

- Sunlight shining right on the inverter can make it much hotter.

- Old capacitors do not work as well, so overheating gets worse.

- Fans that are blocked or a dirty heat sink stop heat from leaving.

If you do not fix these problems, your inverter can get damaged. Here is what could go wrong:

| Consequence | Explanation |

|---|---|

| Reduced Efficiency | When the inverter is too hot, it does not work as well and wastes energy. |

| Component Failure | Parts like capacitors can break, so your system is not as reliable. |

| Damage to Inverter Materials | Too much heat can hurt the inside parts, so the inverter does not last as long. |

Benefits of Proper Cooling

Most of these problems can be stopped with good cooling. An inverter heat sink helps keep the temperature safe. When you control heat, you get many good things:

- Your inverter works longer because the parts do not wear out fast.

- You are less likely to have sudden problems or pay for repairs.

- You save money because your system keeps working without stopping.

Did you know that lowering the temperature by 10°C can make some parts last twice as long? Good cooling also helps your inverter give more power and work better. If you choose a good cooling system, you protect your inverter and save money.

Choosing an Inverter Heat Sink

Size and Compatibility

Picking the right inverter heat sink starts with size. You want a heat sink that fits your inverter and can handle the heat it makes. If you choose one that is too small, it will not cool well. If you pick one that is too big, it might not fit in your space.

Here are some things you should look at:

| Factor | Description |

|---|---|

| Size | Bigger heat sinks can move more heat, but you need enough space to install them. |

| Material Conductivity | Materials like aluminum and copper move heat fast. |

| Airflow | Good airflow helps the heat sink work better. |

| Thermal Resistance | Lower thermal resistance means better cooling. |

You also need to match the heat sink to your inverter’s power rating. Higher power inverters need larger heat sinks made from materials like aluminum or copper. This helps keep everything cool and safe.

Tip: Always check if the heat sink matches your inverter model. Some designs use special features, like vapor chambers or high-density fins, to lower temperatures and boost reliability.

Design and Cooling Efficiency

The design of your inverter heat sink matters a lot. Fins, channels, and the way air moves all play a part. If you want the best cooling, look for these features:

- Thin fins and wide heat sinks help move more heat.

- Long fins add cooling, but after a point, they do not help as much.

- Special channels, like serpentine shapes, spread heat evenly.

- Placing cooling channels right under the power parts works best.

Many new heat sinks use computer models to test designs before making them. This helps make sure the heat sink fits your inverter and cools it well.

If you pick a heat sink with the right size, material, and smart design, your inverter will run cooler and last longer. You will have fewer problems and better performance.

Installation and Maintenance

Installation Tips

Getting your inverter heat sink set up the right way makes a big difference. Start by picking a heat sink with good thermal conductivity, like aluminum. Make sure the base is thicker where it touches the hottest parts and thinner at the edges. This helps spread the heat out. If your heat sink has fins, keep at least 4mm between them. This spacing lets air move through and cool things down. Some heat sinks have a special coating, like anodizing, which helps them release heat even better.

When you install, check that the heat sink fits tightly against the inverter. Use thermal paste if needed. This paste fills tiny gaps and helps heat move from the inverter to the heat sink. If you use a fan, make sure nothing blocks the airflow.

Watch out for these common mistakes:

| Installation Error | Explanation |

|---|---|

| Incorrect inverter size | A small inverter can overheat if it handles too much power. |

| Proximity to heat-generating devices | Placing the inverter near hot equipment makes cooling harder. |

Tip: Always install your inverter heat sink in a spot with good airflow and away from other heat sources.

Cleaning and Inspection

Keeping your inverter heat sink clean helps it work well. In most homes, clean it every three to six months. If you live near the ocean, in a dusty place, or in a factory, check it every month.

Here’s how you can clean it safely:

- Turn off the inverter and unplug it.

- Let it cool down before you start.

- Wipe the outside with a dry cloth.

- Use a soft brush or blower to clean the fins and vents.

- Never use water or spray cleaners.

- If you know how, use a can of compressed air to blow dust out of the vents.

Look for signs that your heat sink is not working right:

- The inverter feels very hot.

- It shuts down often or shows high-temperature warnings.

If you notice these problems, move the inverter to a cooler spot, clean the heat sink, or check for loose connections. Good care keeps your inverter running strong!

You can keep your inverter running strong by choosing the right heat sink and taking care of it. Clean the area, check for dust, and make sure the fan works. Here are some easy ways to spot trouble early:

- Watch the cooling fan and see if it spins when the inverter is on.

- Look for dust blocking air vents.

- Keep the room cooler than 40°C.

- Vacuum dust from the heat sink.

- Blow out dirt to stop clogs.

- Clean around the inverter for better performance.

| Benefit | Description |

|---|---|

| Higher Conversion Efficiency | Cooler inverters keep working at top speed and waste less energy. |

| Extended Lifespan | Lowering the temperature by 10°C can help your inverter last up to 50% longer. |

| Improved ROI | Steady power means you get your money back faster. |

| Lower O&M Costs | Fewer breakdowns mean less money spent on repairs. |

| Reliability | Well-cooled inverters work over 98% of the time, even in tough weather. |

Keep an eye on your inverter. Regular checks and cleaning help you avoid overheating and keep your system reliable.

FAQ

What does an inverter heat sink do?

An inverter heat sink pulls heat away from the inverter’s power parts. You keep your inverter cool and safe. If you use a good heat sink, your inverter lasts longer and works better.

How often should I clean my inverter heat sink?

You should clean your heat sink every three to six months. If you live in a dusty area or near the ocean, check it every month. Use a soft brush or compressed air for best results.

Can I use any heat sink for my inverter?

No, you need a heat sink that matches your inverter’s size and power rating. If you pick the wrong one, your inverter may overheat. Always check the manufacturer’s recommendations before buying.

What signs show my inverter heat sink needs attention?

Look for these signs:

- The inverter feels hot to the touch.

- You see dust on the fins.

- The inverter shuts down or shows a temperature warning.

Do I need thermal paste when installing a heat sink?

Yes, thermal paste helps heat move from the inverter to the heat sink. You fill tiny gaps and improve cooling. If you skip this step, your inverter may run hotter than it should.