What heat sinks are made of

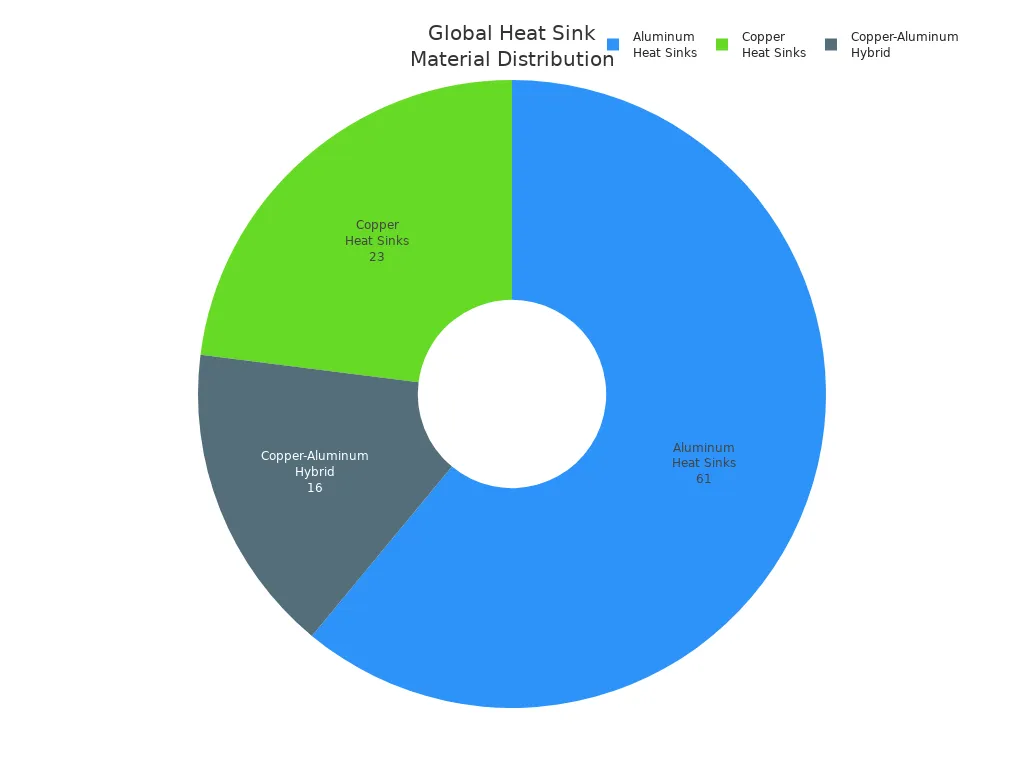

When you pick a heat sink for electronics, you see three main materials. These are aluminum, copper, and sometimes hybrid blends. The material you choose depends on how well it moves heat. It also depends on how heavy it is and how much it costs. Most devices use aluminum. Aluminum covers 61% of the world market. Copper is used in 23% of devices. Hybrid types make up 16%. The chart below shows how these materials are used around the world.

| Material Type | Percentage of Global Market |

|---|---|

| Aluminum Heat Sinks | 61% |

| Copper Heat Sinks | 23% |

| Copper-Aluminum Hybrid | 16% |

Key Takeaways

- Aluminum is the most used heat sink material. It makes up 61% of the market. Aluminum is light and cheap. It is also easy to shape.

- Copper has better thermal conductivity than aluminum. This makes copper good for high-performance uses like gaming PCs. But copper is heavier and costs more than aluminum.

- Hybrid heat sinks use both aluminum and copper. They balance weight, cost, and cooling power. These are good for many electronic devices.

- When picking a heat sink, think about thermal conductivity, weight, and cost. Copper cools best. Aluminum is good for light and cheap designs.

- How easy it is to make depends on the material. Aluminum is easy to shape by extrusion. Copper needs harder methods like skiving.

- Durability is important. Copper lasts longer and handles heat well. Aluminum does not rust and works in most places.

- Custom heat sinks can use special materials like ceramics or graphite. These are for needs like electrical insulation or lighter weight.

- Always choose the heat sink material that fits your device. This helps your electronics stay cool and last longer.

Heat Sink Materials

Aluminum

Aluminum is the most common material for heat sinks. It is popular because it moves heat well, is light, and does not cost much. Aluminum is about one-third the weight of copper. This makes it good for devices where weight is important. Aluminum is easy to shape. This helps companies make special designs for better cooling.

| Advantages | Disadvantages |

|---|---|

| Good thermal conductivity | Lower thermal conductivity compared to copper |

| Low density (one-third the weight of copper) | May limit effectiveness in high-performance applications |

| Excellent machinability | |

| Cost efficiency (50-70% less than copper) | |

| Manufacturing flexibility |

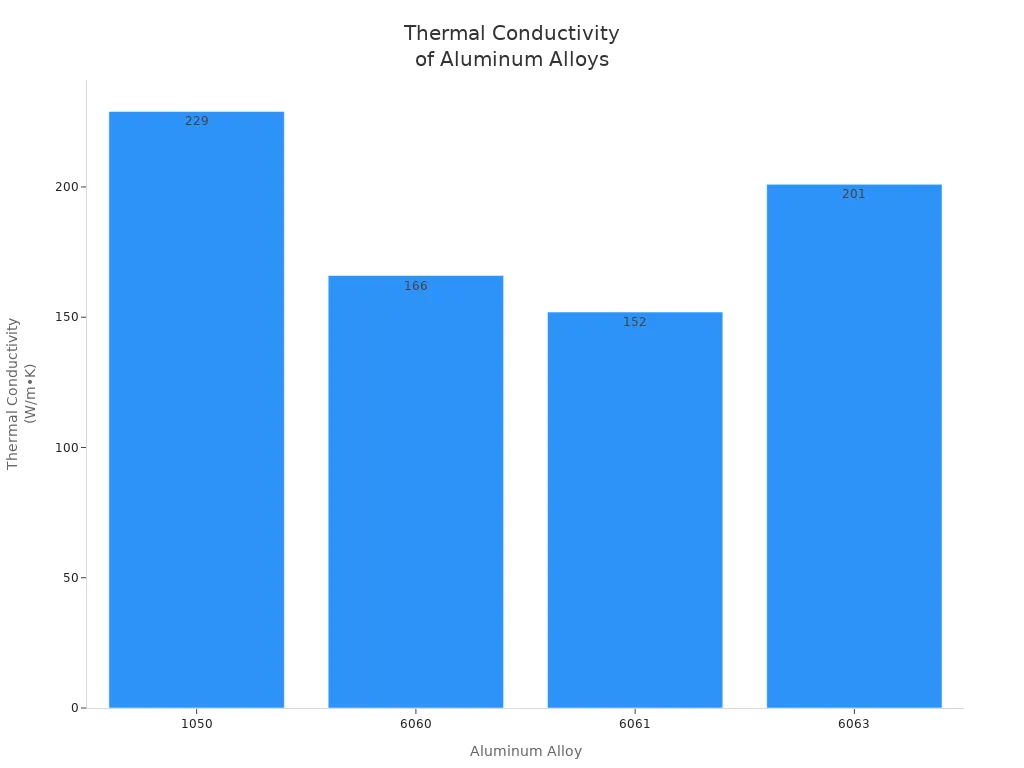

Aluminum heat sinks use different alloys for different needs. The 6000 series, like 6060, 6061, and 6063, are strong and can be made into many shapes. Grade 6061 is strong and resists rust. Grade 6063 is similar but not as strong. Grade 1100 moves heat very well, which helps with detailed designs. Grade 3003 is strong and resists rust, so it works in tough places.

- Common Aluminum Alloys for Heat Sinks:

- Grade 6061: High strength, good corrosion resistance, excellent thermal conductivity.

- Grade 6063: Similar to 6061 but with slightly lower strength.

- Grade 1100: Excellent thermal conductivity, ideal for intricate designs.

- Grade 3003: Good strength and corrosion resistance, suitable for harsh environments.

| Aluminum Alloy | Thermal Conductivity (W/m•K) |

|---|---|

| 1050 | 229 |

| 6060 | 166 |

| 6061 | 152 |

| 6063 | 201 |

The 1050 alloy moves heat the best. The 6061 alloy is stronger. You can pick the right alloy for your device.

Copper

Copper is known for moving heat very well. If you need to get rid of heat fast, copper is the best. You see copper heat sinks in gaming computers and big machines. Copper can handle more heat and keeps things cooler when they work hard.

| Advantages | Disadvantages |

|---|---|

| Superior Thermal Conductivity | Weight |

| Efficient Heat Dissipation | Cost |

- Advantages:

- Superior thermal conductivity allows for handling higher thermal loads.

- Efficient heat dissipation improves cooling efficiency.

- Disadvantages:

- Heavier than aluminum, which may be a concern for weight-sensitive applications.

- Higher cost compared to aluminum, affecting overall device pricing.

- More challenging to manufacture due to its hardness.

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Copper | 389 |

| Aluminum | 205 |

| 6061 Aluminum | 167 |

Copper moves heat almost twice as well as aluminum. But copper costs more and is heavier. This can be a problem for small or portable devices.

Other Materials

Some heat sinks use hybrid materials or special mixes. These mix the good parts of aluminum and copper. For example, aluminum-copper hybrid heat sinks use aluminum for the main part and copper for the base or pipes. This gives a good mix of weight, price, and heat movement.

- Aluminum Heatsinks: Light and cheap, good for electronics, computers, and cars.

- Copper Heatsinks: Moves heat best, used in gaming PCs and big servers.

- Aluminum-Copper Hybrid Heatsinks: Mixes aluminum’s light weight and price with copper’s heat movement.

Heat sink designs with heat pipes or vapor chambers can lower thermal resistance. This helps engineers keep devices cooler.

Some special heat sinks use ceramics or graphite. These are good when you need electrical insulation or very light parts. But most heat sinks you see are made from aluminum or copper.

Material Selection Factors

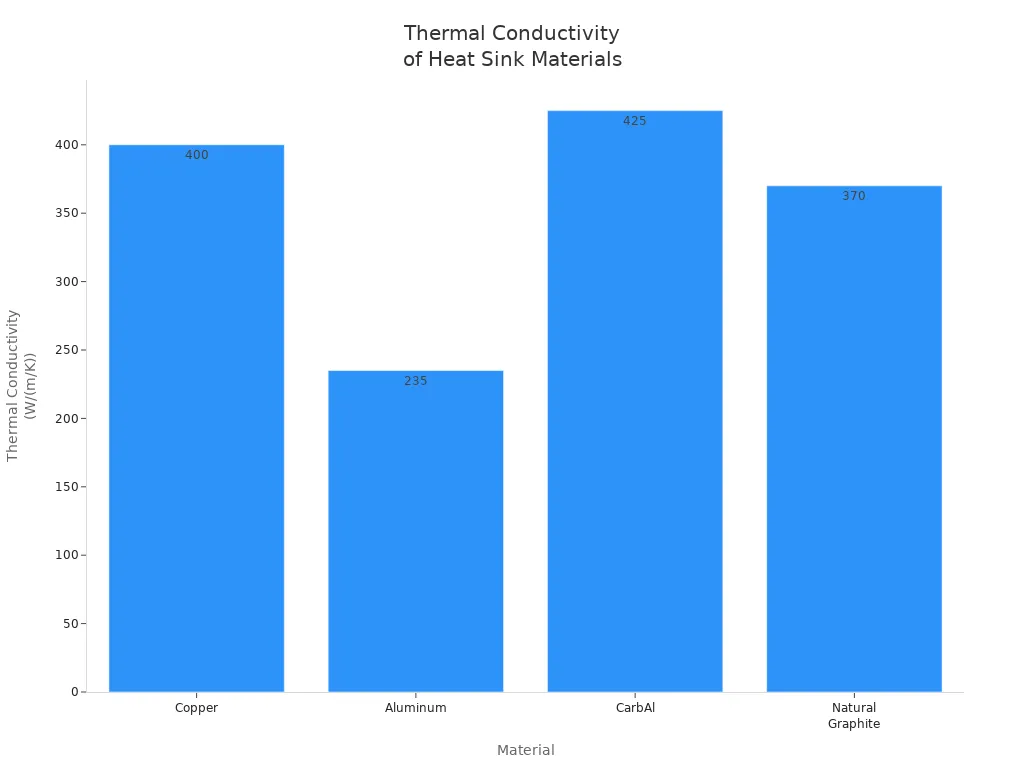

Thermal Conductivity

Thermal conductivity is very important when picking a material for cooling. It shows how fast heat leaves your device. If you want the best cooling, pick materials with high thermal conductivity. Copper is the best with a value of 400 W/(m/K). Aluminum is next with 235 W/(m/K). Some new materials, like CarbAl and natural graphite composite, have even higher values. CarbAl is 425 W/(m/K) and natural graphite is 370 W/(m/K).

If a material has high thermal conductivity, your device stays cooler. Copper and CarbAl move heat quickly, so they are good for powerful electronics.

| Material | Thermal Conductivity (W/(m/K)) | Cost | Weight |

|---|---|---|---|

| Copper | 400 | Higher | Heavier |

| Aluminum | 235 | Lower | Lighter |

| CarbAl | 425 | N/A | N/A |

| Natural Graphite | 370 | N/A | N/A |

Weight and Cost

You should think about weight and cost before choosing a material. Copper moves heat well, but it is heavy and costs more. Aluminum is much lighter and cheaper. If you make laptops or small devices, you want them to be light. Aluminum helps keep things light. It also saves money, which is good for big projects.

- Aluminum is lighter than copper, so it is good for designs that need to be light.

- Aluminum costs less, which helps you save money.

- Copper is more expensive and heavier, so it is not used much in portable products.

- Copper is harder to shape, so it costs more to make.

Manufacturability

The way you make a heat sink depends on the material. Aluminum is easy to shape by extrusion. This method is cheap and lets you make special shapes. Copper needs special ways, like skiving, to make thin fins. Skiving makes more fins and cools better, but it needs special machines and adds weight.

| Manufacturing Process | Suitable Material | Advantages | Disadvantages |

|---|---|---|---|

| Extrusion | Aluminum | Cheap, can make custom shapes | Width is limited |

| Skiving | Copper | More fins, better cooling | Heavier, needs special machines |

| Bonding | Copper/Aluminum | Mixes materials, can be big | Costs more, heavier |

| Stamping | Aluminum/Copper | Cheap, easy to automate | Not as good performance |

| Machining | Aluminum/Copper | Can make hard shapes, high conductivity | Costs more, slower |

Tip: If you want a special shape or need to save money, aluminum is best. For the best cooling, use copper, but it will cost more and be heavier.

Aluminum vs. Copper

Aluminum Pros and Cons

Aluminum is light and easy to use. It weighs much less than copper. This helps when you need your device to be light. Aluminum costs a lot less than copper. You save money if you pick aluminum. It is simple to shape into many designs. This makes it good for custom parts.

- Aluminum heat sinks are used in electronics and computers.

- They work well when you need to spread heat over a big area.

- Aluminum is great for cheap and portable devices.

But aluminum does not move heat as fast as copper. It cools less quickly than copper. Aluminum may not work well for very hot electronics. It also does not last as long in tough places.

Tip: Pick aluminum if you want something light and cheap for most electronics.

Copper Pros and Cons

Copper moves heat very fast. It works better than aluminum for cooling. Copper is best for devices that get very hot. You see copper heat sinks in gaming computers and small spaces. Copper can handle quick jumps in heat. It keeps important parts cool.

- Copper is used for CPUs that get very hot.

- It is good for small areas and sudden heat changes.

- Copper lasts longer and does not rust easily.

Copper is heavy and costs more money. It adds weight to your device. Copper is harder to shape, so it costs more to make.

Note: Use copper if you need the best cooling, but remember it is heavy and expensive.

Comparison Table

Here is a simple table to help you choose between aluminum and copper:

| Feature | Aluminum | Copper |

|---|---|---|

| Thermal Conductivity | 237 W/m·K | 401 W/m·K |

| Weight | 70% lighter than copper | Heavy |

| Cost | 85% cheaper per kilogram | Expensive |

| Lifespan | Shorter under tough conditions | Longer, more durable |

| Manufacturability | Easy to shape | Harder to shape |

| Common Use Cases | General electronics, laptops | High-performance CPUs, gaming PCs |

| Heat Dissipation | Good for large surface areas | Best for small contact areas |

Pick aluminum for light and cheap projects. Choose copper for strong cooling in hard jobs.

Specialized and Custom Heat Sinks

Heat Pipe Cooling Module

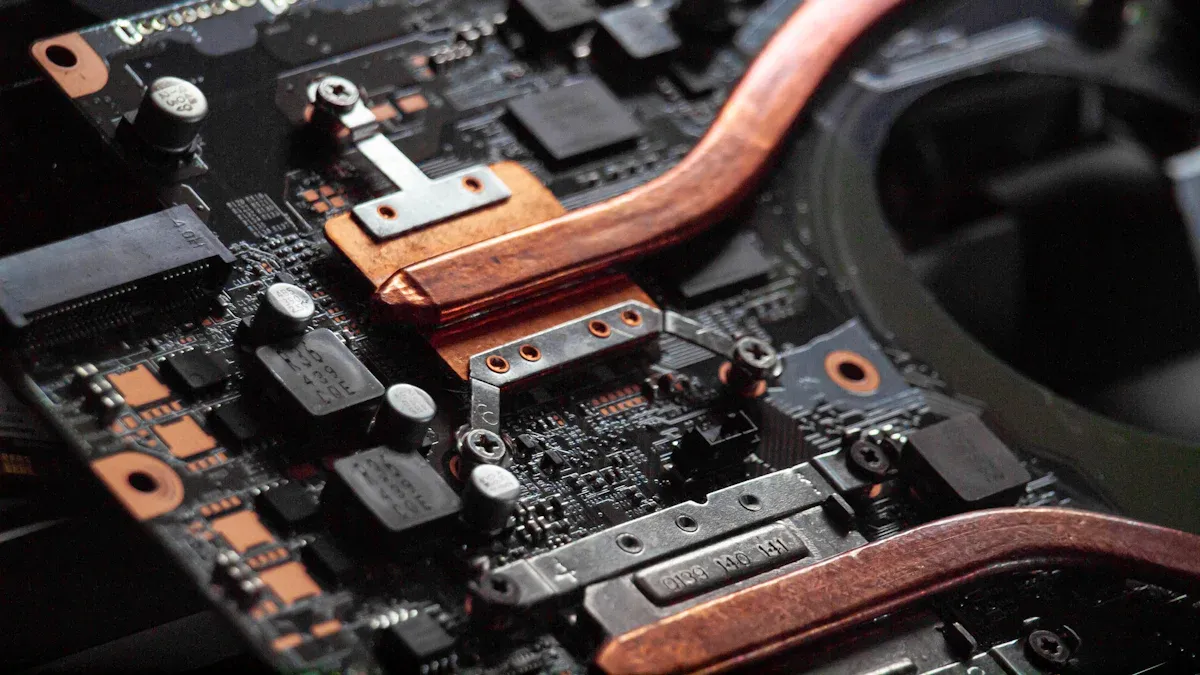

Heat pipe cooling modules are found in laptops and game consoles. They are also in powerful electronics. These modules use a closed pipe to move heat away fast. Inside the pipe is a special liquid. When the pipe gets hot, the liquid turns into vapor. The vapor moves to a cooler spot. There, it turns back into liquid. This cycle keeps repeating. The materials in these modules are picked for good heat movement. They also must work well with the liquid inside.

| Material Type | Description |

|---|---|

| Sealed Envelope | Usually copper, because it moves heat well and works with water. |

| Working Fluid | Deionized water, chosen for its ability to vaporize at the right temperature. |

| Wick Structure | Porous copper powder or mesh, which helps move the liquid back to the hot area. |

You can find other mixes too. Some use copper pipes with water for electronics. Others use copper or steel pipes with refrigerant R134a in HVAC. Spacecraft may use aluminum pipes with ammonia. Very hot systems use superalloy pipes with alkali metals.

Tip: Copper is used most in electronics. It gives good cooling and is reliable.

Skived Heat Sink

A skived heat sink has thin fins cut from a metal block. This makes more surface area for cooling. It helps your device cool down faster. You can pick copper or aluminum for these heat sinks. Each one has its own benefits.

- Copper moves heat about twice as fast as aluminum. This is good for cooling without fans.

- Aluminum is lighter and costs less money. It works well if you use fans to help cool.

- Both copper and aluminum are good at moving heat. Your choice depends on if you want better cooling or a lighter, cheaper part.

Note: Pick copper for the best cooling if weight and cost do not matter. Choose aluminum for lighter devices or if you want to save money.

Liquid Cold Plate

Liquid cold plates use moving liquid to take heat away. You see them in power electronics, data centers, and electric cars. The material you choose changes how well it cools and how heavy it is.

| Material | Application Context | Benefits |

|---|---|---|

| Copper | Brazed cold plates | Moves heat very well, best for performance |

| Aluminum | Microchannel designs | Lightweight, good for managing heat |

Copper is best for cooling in powerful computers. Aluminum is used in cars and telecom gear because it is light and still cools well. Some plates use special welding to make them stronger.

Remember: Pick your heat sink material based on your device, how much heat you need to move, and how much weight you can add.

Custom Heat Sink Materials

Sometimes, a device needs a special heat sink. Standard materials may not work for every job. Custom heat sinks use unique materials to fix hard cooling problems. You can pick advanced metals, ceramics, or composites. Each one helps your design in a different way.

1. Advanced Metal Alloys

You might choose special aluminum or copper alloys for better results. Some alloys do not rust or can take more heat. For example, aluminum alloy 7075 is stronger than normal types. Copper alloys like beryllium copper work well in tough places.

2. Ceramic Materials

Ceramic heat sinks stop electricity from passing through. They also move heat well. You see these in high-voltage electronics or LED lights. Ceramics like aluminum nitride (AlN) and silicon carbide (SiC) move heat but do not carry electricity. This keeps your circuits safe.

3. Graphite and Carbon-Based Composites

Graphite heat sinks are lighter than metal ones. They spread heat fast in one direction. You find these in smartphones and tablets where space and weight matter. Carbon composites can handle quick changes in temperature.

4. Metal Matrix Composites (MMC)

You can use MMCs if you need both strength and good heat movement. These materials mix metals with ceramics or carbon fibers. They work well in aerospace and military electronics.

| Material Type | Key Benefit | Typical Application |

|---|---|---|

| Advanced Alloys | High strength, durability | Industrial, automotive |

| Ceramics | Electrical insulation | Power electronics, LEDs |

| Graphite/Carbon | Lightweight, fast heat spread | Mobile devices, wearables |

| MMCs | Strength + thermal control | Aerospace, defense |

Tip: Always pick the right material for your device. If you need insulation, use ceramics. If you want something light, try graphite.

Custom heat sinks often use more than one material. For example, you might see a copper base with aluminum fins. Some use a ceramic plate with metal parts. This helps balance cost, weight, and cooling.

When you design a custom heat sink, talk to your supplier. Tell them about your device’s size, how much heat it makes, and where it will be used. Picking the right material helps your heat sink last longer and work better. You get the best results when you match the material to your device.

Heat Sink Performance

Efficiency

You want your cooling system to work well. Efficiency means how fast the heat sink moves heat away. Engineers use different ways to check this. The most important is thermal resistance. This shows how easy it is for heat to move through the material. If thermal resistance is low, the cooling is better.

| Metric | Description |

|---|---|

| Thermal Resistance | Shows how well the heat sink transfers heat. Lower values mean better performance. |

| Temperature Measurement | Measures how hot the device gets after a set time. |

| Airflow Consideration | Checks if air moves easily through the fins for better cooling. |

- Thermal resistance uses °C/W as its unit. You want this number to be low.

- Copper has lower thermal resistance than aluminum. This means copper cools better.

- The design and the thermal interface material can make cooling up to 30% better.

If you pick the right material and design, your device stays cooler and lasts longer.

Application Suitability

You need to pick the right heat sink material for your device. Each material has good and bad points. Aluminum is light and does not rust. This makes it good for laptops and small electronics. Copper moves heat faster. It is best for gaming computers and big machines.

| Factor | Description |

|---|---|

| Thermal Conductivity | Tells you how well the material moves heat. |

| Electrical Resistivity | Shows how safe the material is around electricity. |

| Thermal Expansion | Explains how much the material grows when it gets hot. |

| Young’s Modulus | Measures how stiff the material is, which affects strength. |

- Power use and temperature help you choose the best material.

- Copper is great for high-performance devices like gaming GPUs or CPUs.

- Aluminum is better for portable devices where weight matters more.

Always think about where your device will be used and how much heat it makes before you choose a material.

Durability

Durability means how long your heat sink will last. You want a heat sink that works for many years. Aluminum moves heat well and costs less. That is why many devices use it. Copper moves heat even better, but it costs more.

| Material | Thermal Conductivity | Notes |

|---|---|---|

| Aluminum | High | Cost-effective and reliable for most uses. |

| Copper | Very High | Best for tough jobs but costs more. |

- Aluminum does not rust and works in most places.

- Copper lasts longer and can take more heat, but it is heavier.

- Picking the right material helps you avoid problems and keeps your device safe.

If you choose well, your cooling system will protect your electronics and save you money over time.

Choosing the Right Heat Sink

Key Considerations

When you select a heat sink, you need to think about several important factors. Each choice affects how well your device stays cool and how much it costs. Here are the main points you should keep in mind:

- High thermal conductivity helps your device get rid of heat quickly. Copper works best for this, but aluminum also does a good job at a lower price.

- The material you pick changes both the cost and the cooling power of your heat sink.

- You must match the material to your device’s needs. If you want the best cooling, copper is the top choice. If you want to save money and weight, aluminum is a strong option.

- The right material makes your heat sink design more effective.

Tip: Always check if your project needs the highest cooling or if you can balance cost and performance.

Application Examples

You see different materials used in real-world devices. Each device has its own needs, so engineers pick the best material for the job. The table below shows some common examples:

| Device Type | Heat Sink Material Used |

|---|---|

| Smartphones | Vapour chamber cooling |

| Automotive ECUs | Aluminium-finned heat sinks |

| LED Lights | Compact heat sinks |

| Industrial Automation | Heat sinks for electronic modules |

Smartphones often use vapor chambers because they need to stay thin and cool. Cars use aluminum-finned heat sinks to keep control units safe. LED lights use compact heat sinks to manage heat in small spaces. Factories use heat sinks in their machines to protect electronic parts.

Selection Tips

You can make a better choice by following expert advice. Here are some tips to help you pick the right material:

- Choose copper for high-power devices that need the best cooling.

- Pick aluminum or graphite if you want to keep your device light.

- Use aluminum if you need to save money but still want good cooling.

- Select materials with good corrosion resistance, like aluminum, for wet or harsh places.

- Always match the material to your device’s special needs.

Remember: The best heat sink for your project depends on how much heat you need to move, how much weight you can add, and your budget.

You can pick from a few materials for your heat sink. Copper cools the best out of all the choices. Aluminum is cheaper and still cools well. Graphite foam is not used much. It is only for special, light devices.

| Material | Thermal Performance | Cost-Effectiveness | Notes |

|---|---|---|---|

| Copper | Highest | Moderate | Best for demanding cooling needs |

| Aluminum | Moderate | High | Lightweight and widely used |

| Graphite Foam | Lower | Variable | Suited for specific, lightweight uses |

- Think about how much heat your device makes. Also, check the size and where it will be used. Pick a material that fits your cooling needs and how much you want to spend. For custom jobs, look at how much heat needs to move, how air flows, and where the device will work.

Picking the right material keeps your electronics safe and working well.

FAQ

What is the best material for a heat sink?

You get the best cooling with copper. Aluminum works well for most devices and costs less. Your choice depends on your device’s needs, weight limits, and budget.

Can you mix materials in one heat sink?

Yes, you can. Many heat sinks use copper for the base and aluminum for the fins. This design gives you strong cooling and keeps the weight and cost down.

Why do some heat sinks use ceramic or graphite?

Ceramic gives you electrical insulation and good heat movement. Graphite makes the heat sink lighter and spreads heat fast. You see these in special devices like LEDs or smartphones.

How do I know which heat sink material to choose?

Check your device’s heat output, size, and where you will use it. Pick copper for high heat. Choose aluminum for light weight and lower cost. Ask your supplier for advice if you are unsure.

Do heat sink materials affect durability?

Yes. Copper lasts longer and handles more heat. Aluminum resists rust and works well in most places. Ceramics do not rust and insulate electricity.

Are custom heat sinks better than standard ones?

Custom heat sinks fit your device’s exact needs. You get better cooling and performance. Standard heat sinks cost less and work for many common devices.

Can I use a heat sink without a fan?

You can use a heat sink alone for low-power devices. For high-power electronics, you need a fan or liquid cooling to move heat away faster.

Does the color of a heat sink matter?

Color does not change how well the heat sink moves heat. Some companies use black coatings to reduce glare or for looks, but the main factor is the material’s thermal conductivity.