What is a cold plate and how does it work

Cold plates serve as advanced thermal management devices that draw heat away from high-power electronics. Research shows that about 55% of failures in these devices result from overheating, highlighting the need for reliable cooling. Industries such as aerospace, defense, and data centers rely on custom cold plate solutions to maintain optimal performance in harsh environments. The global demand for efficient thermal solutions, including custom heat sink and heat pipe cooling module options, continues to rise. A leading heat sink supplier with strong heat sink manufacturing capabilities can provide tailored solutions for mission-critical needs.

Key Takeaways

- Cold plates cool high-power electronics by moving heat away using metal plates and liquid coolant inside channels.

- They use conduction and convection to transfer heat efficiently, making them better than air cooling for dense or compact systems.

- Materials like aluminum, copper, and stainless steel affect cold plate performance, weight, and durability.

- Microchannel designs increase surface area inside cold plates, improving heat transfer and cooling efficiency.

- Cold plates are widely used in industries like aerospace, defense, data centers, electric vehicles, and medical devices.

- Liquid cooling with cold plates lowers operating temperatures, extends equipment life, and saves energy.

- Designing cold plate systems requires balancing cooling performance, flow rate, pressure, and mechanical strength.

- Regular maintenance, including leak checks and coolant replacement, keeps cold plate systems reliable and safe.

Cold Plates Overview

Definition

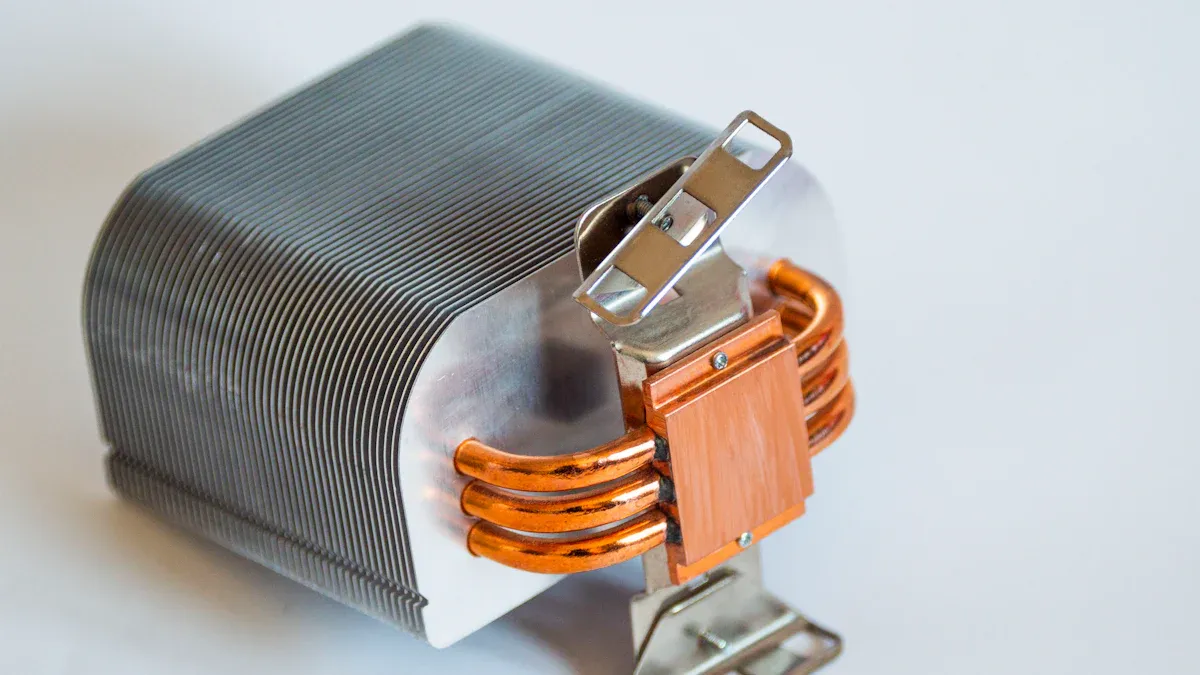

Cold plates are specialized devices used to manage heat in electronic systems. Engineers design these plates from metals like aluminum or copper because these materials conduct heat very well. Each cold plate contains a network of internal channels. These channels allow a liquid coolant to flow through the plate. The main purpose of a cold plate is to absorb heat from electronic components and move it away from sensitive parts.

Note: Cold plates play a key role in keeping high-power electronics safe from overheating. Their design allows them to fit into many types of equipment, from computers to aircraft systems.

Function

Cold plates work by combining two main cooling methods: conduction and convection. The plate sits directly against the hot electronic component. Heat moves from the component into the plate through direct contact. This process is called conduction. Inside the plate, a coolant flows through the channels. As the coolant moves, it picks up the heat from the plate and carries it away. This process is called convection.

- Liquid cooling with cold plates is much more effective than air cooling. Liquids can carry more heat because they have higher density and heat capacity.

- The coolant never touches the electronic parts. Instead, it stays inside the channels, making the system safe and reliable.

- The heated coolant travels to a heat exchanger or radiator, where it releases the heat into the air or another medium.

- Advances in manufacturing, such as microchannel designs, have made cold plates even more efficient. These tiny channels increase the surface area for heat transfer and lower thermal resistance.

- The efficiency of cold plates depends on several factors, including the material of the plate, the design of the channels, the type of coolant, and the flow rate.

Engineers often choose cold plates for systems that need to stay cool under heavy workloads. These devices help maintain safe temperatures, prevent damage, and ensure that electronics work reliably for a long time.

Structure

Design

Cold plates come in several design types, each suited for different cooling needs. Engineers select the design based on the required heat transfer, available space, and system constraints.

Channels

Channels inside cold plates guide the coolant flow and maximize heat transfer. Microchannel designs use many tiny channels machined into the plate. These channels increase the surface area in contact with the coolant, which improves heat removal. ThermAvant Technologies uses microchannel cold plates with intricate internal pathways. These designs often include structural “I-beam” features that add strength and stiffness, allowing the plate to support other components.

Other common channel designs include inlaid tube and brazed types. Inlaid tube cold plates have larger tubes pressed or embedded into grooves in the base plate. This method is simple and cost-effective, but it adds extra thermal interfaces and limits the complexity of the coolant path. Brazed cold plates use multiple layers with internal fins and turbulators. Vacuum brazing bonds these layers together, creating a strong, leak-resistant structure. The internal fins increase turbulence and surface area, which boosts heat transfer.

| Cold Plate Type | Structural Features | Key Applications |

|---|---|---|

| Microchannel | High-density microchannels, I-beam integration, monolithic design | High-performance, compact systems |

| Inlaid Tube | Large tubes in thick base, simple routing, extra thermal interfaces | Retrofit, cost-sensitive applications |

| Brazed | Multi-layer, internal fins and turbulators, vacuum brazed | Mission-critical, high heat loads |

Mounting

Mounting options for cold plates depend on the application and system layout. Some plates include threaded holes, bosses, or through-holes for easy attachment to electronic components or chassis. Custom shapes and mounting features allow integration into complex assemblies. ThermAvant offers cold plates with flat or 3D geometries, making them adaptable for unique system requirements.

Materials

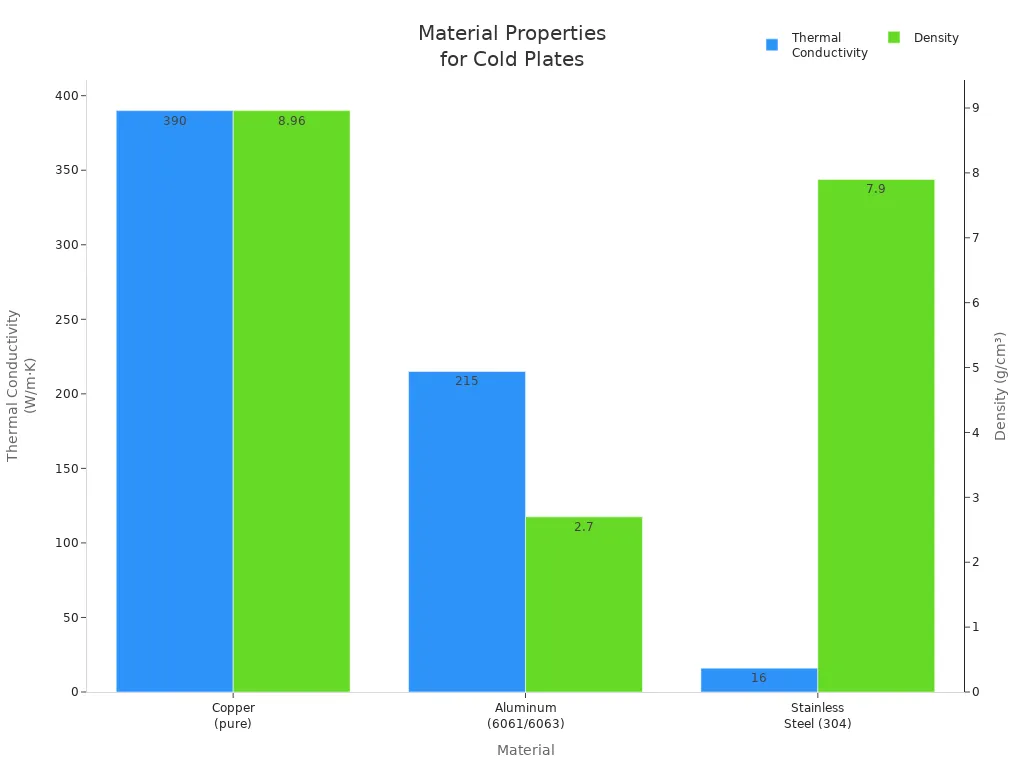

Material choice affects the performance, weight, and durability of cold plates. The most common materials are aluminum, copper, and stainless steel.

Aluminum

Aluminum is popular for its balance of moderate thermal conductivity, low weight, and excellent machinability. It is cost-effective and easy to shape into complex forms. Many mass-produced cold plates use aluminum, especially when weight and price matter most.

Copper

Copper provides the highest thermal conductivity among common cold plate materials. It transfers heat quickly, making it ideal for high-power or compact systems. However, copper is heavier and more expensive than aluminum. Machining copper also takes more effort, which can increase production time and cost.

Stainless Steel

Stainless steel offers lower thermal conductivity but excels in strength and corrosion resistance. Engineers choose stainless steel when mechanical durability is more important than maximum heat transfer. It is often used in environments where the cold plate faces harsh conditions or needs to withstand high pressure.

Note: The choice of material and design must match the cooling needs, weight limits, and budget of the project. ThermAvant Technologies customizes cold plates in thickness, length, width, and shape, ensuring the best fit for each application.

Working Principle

Heat Transfer

Contact

Cold plates manage heat by placing a metal plate in direct contact with the heat source. The surface of the plate touches the electronic component or device that generates heat. This setup allows heat to move quickly from the component into the plate. The process relies on conduction, which means heat travels through the solid metal. The choice of material, such as aluminum or copper, affects how fast the heat moves. A flat, smooth surface improves contact and helps transfer more heat. Engineers often use thermal interface materials to fill tiny gaps and remove air pockets. This step ensures the best possible connection between the plate and the component.

Good contact between the cold plate and the heat source is essential for efficient cooling. Even small gaps or rough surfaces can slow down heat transfer and cause higher temperatures.

Coolant Flow

Once heat enters the plate, the coolant inside the channels or tubes takes over. The coolant flows through the internal passages, picking up heat by direct contact with the metal. As the liquid moves, it carries the heat away from the plate. The flow rate of the coolant plays a major role in performance. Higher flow rates remove heat faster and keep temperatures more even across the plate. For example, when the flow rate drops below 4 liters per minute, chip temperatures can rise sharply, and temperature differences between chips increase. At higher flow rates, such as 10 liters per minute, the temperature difference between chips drops to about 4ºC. However, very high flow rates can increase pressure and require more pump power, so engineers must find the right balance.

- Increasing coolant flow rate lowers the maximum temperature and improves cooling.

- Channel design, such as variable widths or pin fins, helps distribute the flow and boost heat transfer.

- The arrangement of inlets and outlets affects how evenly the coolant spreads, which impacts temperature uniformity.

The design of the channels and the choice of coolant both influence how well the system works. Engineers often use water with additives, glycol mixtures, or special fluids to match the needs of each application.

Process Steps

The operation of cold plates follows a clear sequence to ensure effective heat removal and system reliability.

- Surface Preparation: Technicians clean the surfaces of both the cold plate and the heat source. They remove burrs and check for flatness to improve contact.

- Thermal Interface Material Application: They apply a thin, even layer of thermal interface material. This step fills any small gaps and prevents air pockets.

- Mounting: The cold plate is mounted onto the heat source using the correct torque and sequence. Proper mounting ensures even pressure and good contact.

- Hydraulic Connections: Technicians attach the coolant lines using the right fittings and seals. They avoid overtightening to prevent leaks.

- Coolant Circulation: The pump starts moving coolant through the plate’s channels. The coolant absorbs heat and carries it away to a radiator or heat exchanger.

- Routine Inspection: Regular checks look for leaks, inspect tubing, and verify pump operation. Technicians also check coolant levels and properties, such as pH and corrosion inhibitors.

- Coolant Maintenance: Over time, they top off or replace the coolant to keep the system running smoothly.

These steps help cold plates maintain safe temperatures in high-power electronics, battery packs, and data centers. The process ensures that heat moves efficiently from the source, through the plate, and out with the coolant.

A well-designed cold plate system uses the right materials, channel shapes, and flow rates to achieve the best cooling performance. Engineers test and adjust each part of the process to match the needs of the application.

Cold Plates Applications

Electronics

Electronics systems generate significant heat during operation. Cold plates help manage this heat to prevent damage and maintain performance. Engineers use cold plates in many electronic devices because they offer efficient cooling for high-power components. These devices include:

- Power electronics for high-voltage applications

- Conventional electronics in consumer and industrial products

- Computers and server towers in data centers

- IGBT power modules for switching and control

- Automotive electronics, especially in electric vehicles

- Wind turbines for renewable energy systems

- Lasers, including those used in directed energy weapons

Cold plates also play a vital role in data centers and telecommunication equipment. They keep processors and memory modules at safe temperatures, which helps prevent system failures. Many electric vehicles rely on cold plates to cool battery packs and power electronics, supporting longer life and better safety.

Note: Cold plates provide a reliable solution for electronics cooling, especially in systems with high power density or limited airflow.

Aerospace

Aerospace systems demand lightweight, efficient, and reliable cooling solutions. Cold plates meet these needs by absorbing heat from electrical components and transferring it to a coolant. The coolant flows through channels machined into the plate, carrying heat away from sensitive parts. This method offers a simpler and more energy-efficient alternative to traditional air conditioners or compressors.

Engineers often choose custom-designed cold plates for aerospace because they can handle large thermal loads. Stacked or layered designs allow for greater flexibility and improved performance. Lightweight aluminum construction reduces overall system weight, which is critical in aircraft and spacecraft. Advanced manufacturing methods, such as additive manufacturing and friction stir welding, help create cold plates with complex internal structures and high thermal-hydraulic performance.

Experimental studies confirm that cold plates deliver reliable and efficient cooling in aviation. Mathematical models and real-world tests show excellent agreement, proving that these devices can handle the unique challenges of aerospace environments.

Defense

Defense systems operate in some of the harshest and most demanding environments. Cold plates serve as high-efficiency heat exchangers in mission-critical defense applications. Precision microchannels circulate coolant directly beneath heat-generating components, removing heat quickly and evenly. This direct liquid cooling keeps high-density electronics at safe temperatures, even under heavy workloads.

Mechanical robustness and leak integrity are essential for defense systems. Cold plates must withstand high pressures, vibrations, and extreme conditions. Copper cold plates offer excellent thermal performance and corrosion resistance, making them ideal for cooling sensitive avionics and mission-critical equipment. Friction stir welding enhances the strength and leak-tightness of cold plates, preventing coolant leaks that could lead to system failure.

In defense applications, cold plates ensure uninterrupted peak performance and system reliability, supporting the stability and longevity of advanced electronics.

Industrial

Industrial systems often generate large amounts of heat during operation. Factories, power plants, and manufacturing lines use advanced cooling solutions to keep equipment running safely. Engineers rely on liquid cooling to manage the heat from high-power machinery, automation controls, and sensitive electronics.

Data centers represent a major industrial application for advanced cooling technology. Modern data centers house thousands of servers, each producing significant heat. As computing power increases, so does the need for efficient thermal management. Microchannel designs now allow facilities to cool CPUs, GPUs, and AI accelerators with high precision. These systems support power densities greater than 50 kilowatts per rack, which helps companies save space and energy.

Medical devices also depend on precise temperature control. MRI machines, CT scanners, and surgical lasers require stable temperatures to function correctly. Engineers use liquid cooling to protect sensitive components and ensure accurate results. Even a small temperature change can affect the performance of medical imaging equipment.

Electric vehicles (EVs) use similar cooling technology. Battery packs, power inverters, and electric motors all produce heat during operation. Efficient cooling extends battery life and improves vehicle safety. Engineers design cooling systems to fit tight spaces and withstand vibration and movement.

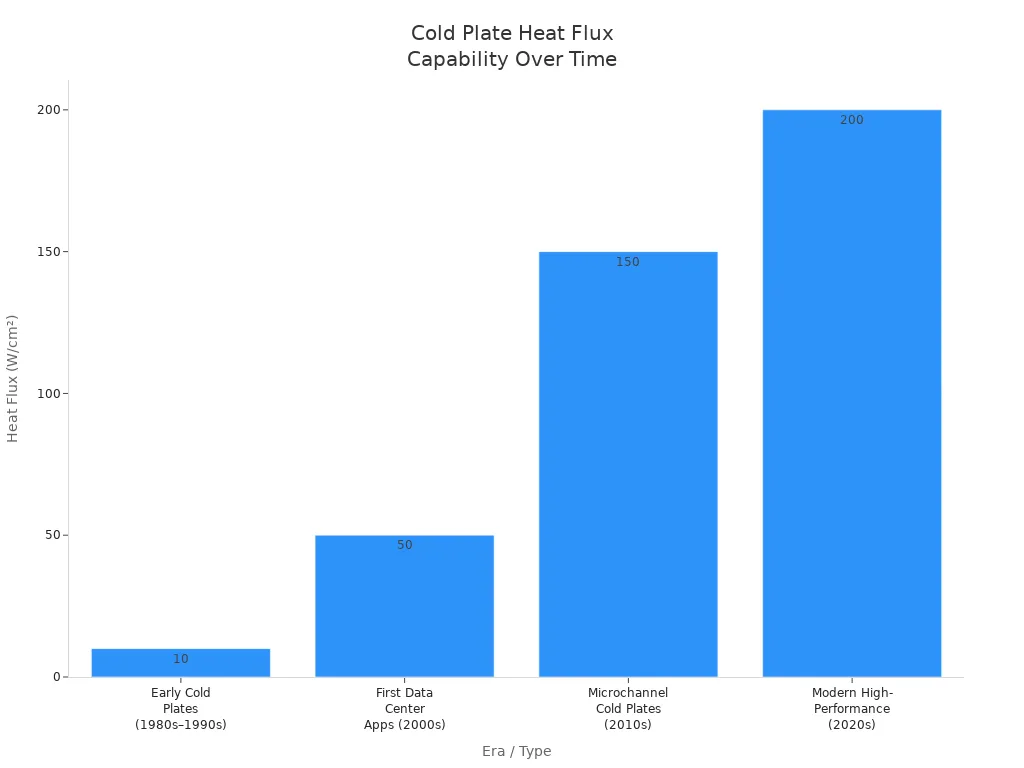

The table below shows how cooling technology has improved over time in industrial settings:

| Era / Type | Heat Flux Capability (W/cm²) | Application / Notes |

|---|---|---|

| Early Cold Plates (1980s–1990s) | ~5–10 | Aerospace, industrial; aluminum/copper with tubing |

| First Data Center Applications (2000s) | Up to 50 | Machined channel cold plates for HPC CPUs/GPUs |

| Microchannel Cold Plates (2010s) | Up to 150 | Increased surface area and turbulence for GPUs/CPUs |

| Modern High-Performance (2020s) | >200 | Two-phase cooling, hybrid designs, AI-driven control |

Note: Modern cooling systems in data centers and medical devices can handle much higher heat loads than older designs. This progress allows for more powerful and compact equipment.

Engineers select the right cooling method based on the equipment, space, and safety needs. Microchannel and two-phase designs offer the best performance for high-density applications. Tubed and machined channel types provide reliable cooling for less demanding systems. In every case, the goal remains the same: keep equipment cool, safe, and efficient.

Comparison

Heat Sinks

Engineers often use heat sinks to cool electronic devices. These components rely on metal fins and airflow to remove heat from surfaces. Air passes over the fins, carrying heat away from the device. Heat sinks work well for low-power electronics and consumer products. However, they face limits in high-density or compact systems.

- Liquid coolant in cold plates has higher thermal conductivity than air, which allows faster and more efficient heat dissipation.

- Cold plates provide uniform cooling across the surface, preventing hotspots and ensuring consistent thermal management.

- Their compact design eliminates bulky fins and fans, which helps in space-constrained applications.

- Cold plates maintain lower operating temperatures, improving reliability and extending component lifespan.

- The liquid cooling approach works better in environments with high heat density or limited space where air-cooled heat sinks may be insufficient.

Heat sinks depend on air movement and suit lower heat loads. Cold plates absorb heat through an internally flowing liquid coolant, which enables more efficient heat removal. This design performs better in environments with concentrated heat and limited space.

Liquid Cooling

Liquid cooling systems use fluids to transfer heat away from electronic components. Cold plates represent a specialized form of liquid cooling. They use microchannels or tubes to guide coolant directly beneath heat sources. This method increases heat transfer and supports stable operation in advanced computing hardware.

| Aspect | Liquid Cold Plates | Traditional Cooling Systems (Air Cooling, Heat Sinks) |

|---|---|---|

| Efficiency | Higher thermal conductivity and heat capacity of liquids enable superior heat dissipation, especially for high-power components. | Less efficient, struggles with high power density and compact spaces. |

| Size and Space | Compact, customizable, suitable for space-constrained, high-density applications. | Bulkier, larger footprint, less suitable for compact or dense designs. |

| Cost | Higher initial investment but lower operating and maintenance costs; long-term energy savings. | Lower upfront cost but higher operational and maintenance expenses. |

| Maintenance & Reliability | Fewer moving parts, lower maintenance frequency, higher reliability. | Moving parts (fans) prone to failure, require frequent maintenance. |

| Environmental Impact | More energy-efficient, reduces carbon footprint. | Higher energy consumption, larger carbon footprint. |

| Applications | Data centers, electric vehicles, medical devices, power electronics requiring high-performance cooling. | Consumer electronics, low-power or cost-sensitive applications. |

Liquid cold plate systems leverage the high thermal conductivity and heat capacity of liquids to achieve better heat dissipation and energy efficiency. Scientific studies show that liquid cooling reduces energy consumption and noise. These systems also enable waste heat recovery, which supports sustainability by lowering carbon emissions. Microchannel designs further enhance heat transfer, making liquid cold plates ideal for high-performance environments.

Selection

Selecting the right cooling solution requires careful consideration of several factors. Engineers must match the cooling method to the application’s needs.

- Thermal resistance, fluid channel dimensions, and materials optimize heat dissipation.

- High-quality materials like copper offer excellent thermal conductivity, while aluminum provides lighter, cost-effective options.

- Liquid channels should fit component dimensions to reduce thermal resistance.

- Coolant compatibility with plate materials and operating conditions ensures long-term reliability.

- Surface treatments such as anodizing or passivation enhance corrosion resistance and thermal efficiency.

- Define heat dissipation requirements, operating temperature, and physical constraints before customization.

- Precision CNC machining supports uniform performance and complex channel geometries.

- Size and shape impact cooling capacity and fit; larger plates dissipate more heat but may not fit tight spaces.

- Flow rate and pressure drop of coolant affect cooling efficiency and system performance.

- Mounting options should match design and installation needs, considering vibration resistance and maintenance.

- Cost and lead time vary with materials and configurations; budget and timeline constraints must be considered.

- Simpler designs like embedded tube or extruded cold plates are easier to handle and install.

- Operational environment, including temperature, humidity, and exposure to corrosive elements, guides material and coating selection.

- Modular and integrable designs support scalability and future upgrades.

Engineers should seek expert advice to match cooling solutions with specific requirements and ensure proper installation. Balancing materials, design, and customization helps optimize thermal performance and system longevity.

Advantages

Efficiency

Engineers value liquid cooling systems for their ability to transfer heat quickly and keep devices at lower temperatures. This efficiency leads to less power consumption and lower operating costs. In real-world settings, such as electric vehicles and high-performance computers, liquid cooling systems help reduce energy use while improving thermal management. For example, these systems can lower the maximum temperature of a battery by up to 17.6°C compared to natural air cooling and by 11.7°C compared to forced flow immersion cooling.

| Cooling Method | Maximum Battery Temperature Reduction (°C) |

|---|---|

| Compared to Natural Air Cooling | 17.6 |

| Compared to Forced Flow Immersion | 11.7 |

Lower temperatures mean that electronic parts last longer and work more reliably. As a result, companies save money on repairs and replacements. Efficient cooling also supports higher performance in devices that need to run at full power for long periods.

Compactness

Compact cooling systems offer several benefits for high-density electronics and tight spaces. These systems provide high cooling density, which means they can remove a lot of heat from a small area. Engineers can use modular designs to fit these systems into different layouts. Lightweight construction makes them easy to handle and install.

- High cooling density supports powerful devices in small packages.

- Modular configuration allows for flexible system design.

- Lightweight and low noise operation suit mobile and sensitive environments.

- Ultra-compact designs fit into tight enclosures, such as those found in electric vehicles or aerospace systems.

- Easy integration and scalability help manufacturers adapt to changing needs.

Advanced microchannel designs increase the surface area inside the cooling plate. This feature promotes turbulent flow, which helps spread heat evenly and prevents hotspots. Improved cooling leads to better system reliability and longer device life.

Versatility

Engineers use liquid cooling systems in many industries because of their adaptability. These systems can handle a wide range of thermal management challenges, from small electronics to large industrial machines. They work with different coolants, such as water or special fluids, to match the needs of each application.

- Systems support data centers, electric vehicles, industrial machinery, aerospace, and renewable energy.

- Material advances, like lightweight alloys, improve durability and heat transfer.

- Custom designs fit unique shapes, sizes, and performance requirements.

- Scalability allows use in both small and large systems.

- Sustainable features include recirculating coolant loops and eco-friendly fluids.

- Integration with smart monitoring and AI-driven controls is possible for dynamic performance.

Manufacturers use advanced techniques like CNC machining and friction stir welding to create precise and reliable cooling solutions. These systems can cool CPUs, lasers, batteries, and more, making them a top choice for complex and demanding environments.

Limitations

Complexity

Designing and integrating advanced cooling systems involves many challenges. Engineers must address several sources of complexity to ensure reliable performance.

- Achieving uniform cooling across all components prevents thermal imbalances that can damage electronics.

- Space constraints often limit the size and shape of cooling plates, making custom designs necessary.

- Material selection requires balancing thermal conductivity, weight, corrosion resistance, and cost.

- Mechanical robustness is important for withstanding vibration and pressure changes, especially in aerospace and defense.

- Manufacturing complex features, such as microchannels, increases production difficulty.

- Integration with pumps, sensors, and heat exchangers must meet strict regulatory standards.

- Designers must balance thermal performance with pressure drop and pump power consumption.

- Traditional design methods sometimes lack flexibility and limit optimization.

- The process often involves thermal, mechanical, and systems engineering, making it multidisciplinary.

The table below highlights some main sources of complexity and their impact:

| Source of Complexity | Description | Impact on Design and Integration |

|---|---|---|

| High pressure drop | Serpentine channels cause significant pressure drops, needing more pump power. | Lowers system efficiency and raises energy use. |

| Limited design flexibility | Fixed geometric parameters restrict innovation and optimization. | Limits performance improvements. |

| Manufacturing complexity | Complex channel shapes like microchannels are hard to produce. | Raises production cost and difficulty. |

| Balancing thermal and hydraulic needs | Optimizing heat transfer while minimizing pressure drop is challenging. | Requires careful trade-offs. |

| Material and structural constraints | Materials must provide thermal conductivity and strength. | Affects durability and integration. |

| System integration | Cooling plates must work with pumps, sensors, and heat exchangers. | Adds system-level design challenges. |

Thermal-hydrodynamic modeling shows that predicting thermal resistance and pressure drop can vary with channel configuration. Straight and serpentine channels are easier to model, but manifold designs need strict conditions for accuracy. These factors make the design and integration process more complex.

Maintenance

Cooling systems require regular maintenance to ensure safe and efficient operation. Technicians must check for leaks, inspect tubing, and verify pump performance. Coolant levels and properties, such as pH and corrosion inhibitors, need routine monitoring. Over time, coolant may need replacement to prevent corrosion or buildup.

- Regular inspections help catch problems early and prevent system failures.

- Cleaning channels and replacing seals or gaskets can extend system life.

- Maintenance schedules depend on the environment and application, with harsher conditions needing more frequent checks.

Tip: Keeping a maintenance log helps track service intervals and identify recurring issues.

Cost

The cost of advanced cooling systems can be higher than traditional air-cooled solutions. Several factors contribute to this:

- Complex manufacturing processes, such as CNC machining and vacuum brazing, increase production expenses.

- High-quality materials like copper or stainless steel cost more than standard metals.

- Custom designs and tight tolerances add to engineering and fabrication costs.

- Integration with pumps, sensors, and control systems raises the total investment.

While the initial cost may be higher, these systems often provide better performance and longer service life, which can reduce long-term expenses. Companies must weigh upfront costs against the benefits of improved reliability and efficiency.

Cold plates play a vital role in modern thermal management.

- They offer superior heat dissipation, compact design, and reliable performance in demanding environments like data centers, electric vehicles, and aerospace.

- Benefits include enhanced cooling efficiency, longer equipment life, and energy savings, while challenges involve careful design and maintenance.

- Engineers prefer cold plates when air cooling cannot meet high heat loads or space is limited.

ThermAvant Technologies provides advanced solutions for industries that require the highest standards in cooling performance.

FAQ

What is the main purpose of a cold plate?

A cold plate removes heat from electronic components. It uses a metal plate and circulating coolant to keep devices at safe temperatures. This process helps prevent overheating and improves reliability.

Which industries use cold plates most often?

Engineers use cold plates in aerospace, defense, data centers, medical devices, and electric vehicles. These industries need efficient cooling for high-power electronics and mission-critical systems.

What materials do manufacturers use for cold plates?

Manufacturers often choose aluminum, copper, or stainless steel. Aluminum offers low weight and good conductivity. Copper provides excellent heat transfer. Stainless steel gives strength and corrosion resistance.

How does coolant flow affect cold plate performance?

Coolant flow rate controls how quickly heat leaves the plate. Higher flow rates improve cooling but may need stronger pumps. Engineers balance flow rate with system pressure and energy use.

Can cold plates be customized for specific applications?

Yes, manufacturers like ThermAvant Technologies offer custom cold plates. They adjust thickness, length, width, and shape. Custom features include threaded fittings, bosses, and 3D geometries.

What maintenance do cold plate systems require?

Technicians inspect for leaks, check coolant levels, and clean channels. They replace seals and monitor fluid properties. Regular maintenance keeps the system running safely and efficiently.

Are cold plates more efficient than air-cooled heat sinks?

Cold plates use liquid coolant, which absorbs heat better than air. This design provides higher cooling efficiency, especially in compact or high-power systems.

What types of coolant work with cold plates?

Common coolants include deionized water with corrosion inhibitors, ethylene glycol water, propylene glycol water, and polyalphaolefin. The choice depends on system requirements and compatibility with plate materials.