What Is an Active Heat Sink and How Does It Work

Active heat sinks keep devices cool. They use fans or blowers to move air. This air goes over electronic parts. Ecotherm gives advanced solutions for cooling. These solutions help high-performance electronics work well. Good heat management stops heat from building up. Too much heat can make parts get too hot. Hot parts can get damaged or stressed. Good cooling keeps devices safe. It helps them last longer and work better.

What Are Active Heat Sinks

Simple Definition

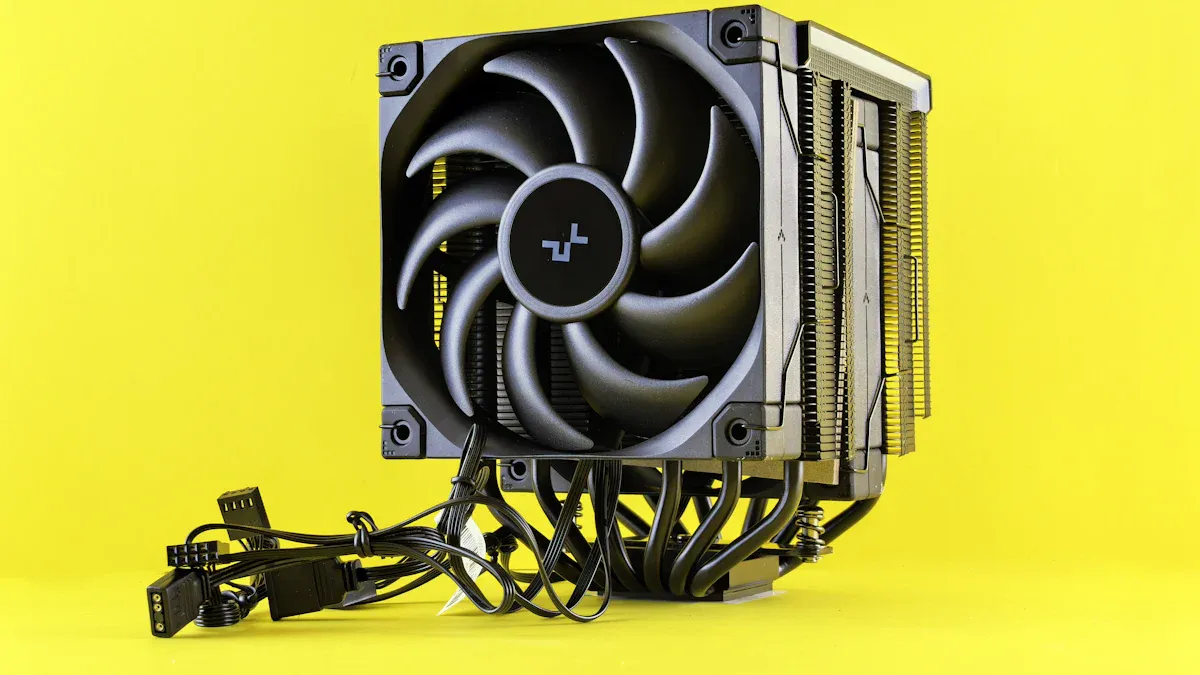

You can find active heat sinks in many electronics today. These cooling tools use things like fans or blowers to move air or liquid. The air or liquid goes across the surface of the heat sink. This helps get rid of heat fast from important parts.

- An active heat sink uses powered parts to push air or liquid over its fins.

- Forced convection swaps hot air for cooler air, so heat moves away faster.

- You get smaller and lighter devices because forced air cools better.

Active heat sinks are groups of parts that use powered devices, like fans or blowers, to help get rid of heat. They work better because forced air moves across the fins, so the design can be smaller and lighter.

Main Function

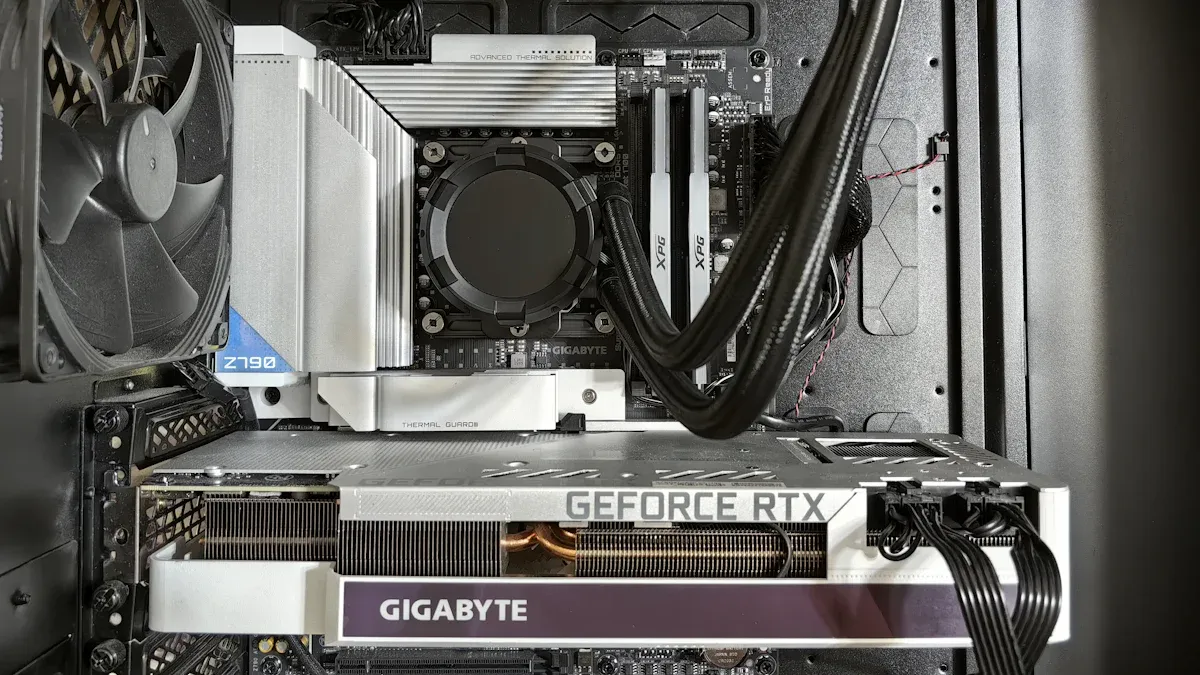

You need active heat sinks to keep electronics safe and working well. These devices help control heat from parts like CPUs and GPUs. If there is no good cooling, these parts can get too hot and stop working.

- Active heat sinks help you keep your devices cool.

- They move heat away from important parts so they do not overheat.

- Fans or liquid cooling systems work together to keep things at safe temperatures.

The main job of active heat sinks is to protect electronics from too much heat. You see them in computers, gaming consoles, and other strong devices. Their design lets them fit in small spaces but still cool well.

Here is a quick comparison between passive and active heat sinks:

| Feature | Passive Heatsinks | Active Heatsinks |

|---|---|---|

| Cooling Mechanism | Uses natural convection, radiation, and conduction | Uses powered parts like fans or pumps to cool better |

| Efficiency and Performance | Good for low or medium heat | Made to handle high heat well |

| Cost and Maintenance | Usually costs less and needs little care | Costs more at first and may need fixing because of moving parts |

| Size and Design | Often bigger to cool well | Smaller because they cool better |

You pick active heat sinks when you need strong cooling for devices that get very hot. Their smart design and moving parts make them important for high-performance electronics.

How Active Heat Sinks Work

Key Components

When you look at active heat sinks, you find several important parts that work together to keep your electronics cool. Each part has a special job. Here is a table that shows the main components and what they do:

| Component | Description |

|---|---|

| Base Plate | This part touches the hot electronic component and pulls heat away quickly. It uses materials that move heat well. |

| Cooling Fins | These thin pieces stick out from the base plate. They give more space for air to touch, which helps move heat away faster. |

| Heat Pipes | These tubes move heat from the base plate to the fins. They use a special liquid inside that changes from liquid to gas and back, carrying heat with it. |

| Thermal Interface Material | This layer sits between the heat sink and the electronic part. It fills tiny gaps so heat moves smoothly from the part to the heat sink. |

You also find fans or blowers in active heat sinks. These powered parts push air over the fins and base plate. The moving air helps carry heat away much faster than if the air just sat still. You get better cooling, especially when your device works hard.

Materials matter, too. Most active heat sinks use aluminum or copper. Here is a quick look at why these materials work so well:

| Material | Thermal Conductivity (W/m·K) | Advantages |

|---|---|---|

| Aluminum | 205 | Lightweight, cost-effective, easy to shape, good for most uses. |

| Copper | 400 | Moves heat even better, perfect for devices that get very hot, like gaming computers or servers. |

Kingka Tech uses both aluminum and copper in their designs. You get the right balance of weight and cooling power for your needs.

Cooling Process

You need to understand how active heat sinks move heat away from your device. The process starts when the base plate touches the hot part, like a CPU. The base plate pulls heat away and sends it to the cooling fins. Heat pipes can help move this heat even faster.

Fans or blowers play a big role. They push cool air over the fins and base plate. This moving air is called forced convection. Forced convection works much better than just letting air move on its own. You get faster cooling, and your device stays at a safe temperature.

Fans or blowers constantly move air that is in contact with a device or heat sink to eliminate pockets of warmer air that will not remove heat as efficiently as fresh, cooler air.

Here is how the cooling process works step by step:

- The base plate absorbs heat from the electronic part.

- Heat moves from the base plate to the fins and heat pipes.

- Fans or blowers push cool air over the fins.

- The moving air carries heat away from the heat sink.

- Your device stays cool and works better.

The design of the heat sink matters, too. More fins and better airflow mean less thermal resistance. That means heat leaves your device faster.

Kingka Tech brings new ideas to active heat sinks. You can find hybrid heat sinks that use both copper and special cold spray methods. These designs lower thermal resistance by almost half compared to regular aluminum heat sinks. Kingka Tech also uses a patented clip system. You can install your heat sink without screws or holes, making setup quick and easy. Some models have variable speed fans. These fans change speed based on how hot your device gets. You get the best cooling with less noise.

When you choose active heat sinks from Ecothemrgroup, you get advanced cooling, smart design, and easy installation. Your electronics stay safe, even when they work hard.

Active vs. Passive Heat Sinks

Key Differences

It is important to know how these heat sinks are different. Active heat sinks use things like fans or pumps. These parts need power to work. Passive heat sinks do not use powered parts. They let air move naturally to cool things down. Each type works in its own way and has special features.

Here is a table that shows the main differences:

| Feature | Active Cooling | Passive Cooling |

|---|---|---|

| Mechanism | Uses mechanical parts (fans, pumps) | Relies on natural heat dissipation |

| Cooling Capacity | Higher cooling capacity | Often limited cooling capacity |

| Response Time | Quicker response times | Slower response due to natural processes |

| Power Requirement | Requires power and maintenance | No power required, silent operation |

| Complexity | More complex due to moving parts | Simpler design, no moving parts |

Active heat sinks cool things faster and better. You use them for devices that get very hot. Gaming computers and servers need this strong cooling. Passive heat sinks are good for devices that do not get very hot. They do not make noise or use extra power.

You should also think about energy and cost. Here is a quick look:

| Factor | Active Heat Sinks | Passive Heat Sinks |

|---|---|---|

| Cost | Higher operational costs due to power consumption. | Lower operational costs since they don’t consume extra power. |

Active heat sinks need power for fans or pumps. This can make your energy bill go up. Passive heat sinks do not need extra power. They cost less to use.

Tip: If you want quiet and easy care, pick passive heat sinks for cool devices. If your electronics get very hot, choose active heat sinks for better cooling.

Hybrid Heat Sinks Overview

Hybrid heat sinks mix both cooling styles. They use fins for natural airflow. They also have fans for extra cooling when needed.

Here is a table that shows the main advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| Enhanced cooling performance | Complexity associated with active components |

| Versatility for various applications | Potential maintenance needs |

| Compact design suitable for space | |

| Noise reduction |

Hybrid heat sinks cool well and stay quiet. You can use them in many devices. They fit in small spaces and handle different heat levels. You may need to check the fans sometimes. But you get strong cooling and less noise.

Note: Ecotherm makes hybrid heat sinks with smart features. You can get custom designs for your device and cooling needs.

Applications and Benefits

Where Active Heat Sinks Are Used

Active heat sinks are used in many different industries. These include data centers, consumer electronics, cars, factories, phone networks, and medical machines. You can find active heat sinks in computers, servers, LED lights, and electric cars. As electronics get more powerful, they make more heat. Better cooling is needed to keep them safe. High-performance computers, 5G networks, and electric cars all need active heat sinks to stay cool.

Active heat sinks can handle a lot of heat. They are used in CPUs, GPUs, IGBT inverters, fast chargers, and robot motors. These parts get very hot, so good cooling is important to keep them working well.

Tip: If you have a small device, you can get a custom active heat sink. It will fit your space and cool your device the right way.

Here is a table that shows how custom designs help in small spaces:

| Feature | Description |

|---|---|

| Efficient Heat Dissipation | Custom active heat sinks move heat away fast, so devices work well. |

| Tailored Design | You can make the heat sink the right size for your device. |

| Flexibility | You get a heat sink that fits anywhere, even in tight spots. |

Advantages for High-Performance Devices

Kingka Tech’s active heat sinks give you many good things. They keep your devices cool, even when you use them a lot. Your electronics last longer because they do not get too hot. The heat sinks are small, so you can put them in crowded places. You can use them in computers, servers, cars, and factory machines.

Ecothermgroup uses strong materials like aluminum and copper. These materials help move heat away and keep your system safe. Some fans can change speed, so your device stays cool and quiet at the same time.

When you pick a heat sink, think about thermal resistance, what it is made of, the shape of the fins, and how you attach it. These things help you get the best cooling for your device.

Note: Good heat management stops your device from getting too hot and breaking. You protect your device and make sure it works well.

You need active heat sinks to keep electronics cool and working well. These devices use fans and special materials to move heat away from important parts. Ecothemrgoup has more than 15 years of experience. They follow strict ISO 9001 rules and use advanced methods like vacuum brazing. This helps protect your devices, makes them work better, and lowers how much you spend on fixing them.

Companies that use good thermal management have up to 70% fewer repairs and their devices last longer.

- Pick Ecothermgroup for trusted and strong thermal solutions.