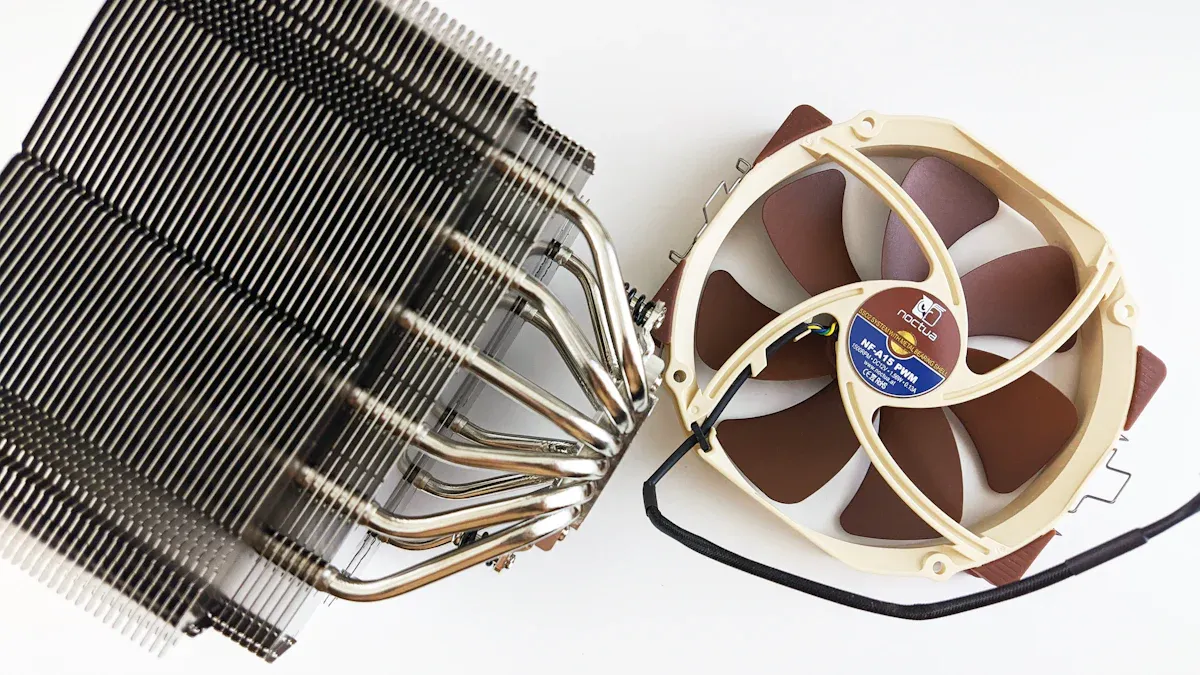

Custom aluminum vapor chamber and heat pipe

You use custom aluminum vapor chamber and heat pipe solutions for quick cooling. These solutions move heat away from important parts. This helps your electronics, LED lights, or computers stay cool. Technology has gotten much better in the last ten years. You can see these changes in the table below:

Aspect | Description |

|---|---|

Efficiency Improvements | Heat pipes now work better and cost less for cooling electronics. |

Passive Device Benefits | They cool with two phases but do not make your system harder to use. |

Material and Fluid Choices | Companies pick water, methanol, or acetone to save money and help performance. |

Advanced Configurations | New designs handle more heat and give engineers more choices. |

Many researchers like Naphon, Attia, and Koito have studied vapor chambers and flat heat pipes. They test how well these things cool. You can trust the aluminum heat pipe because it is light and works well in tough industries.

Key Takeaways

Custom aluminum vapor chambers and heat pipes help cool electronics. They stop devices from getting too hot and make them work better. These cooling tools are light and save money. They can make cooling systems half as heavy. They also lower the temperature of parts a lot. Aluminum heat pipes can be made in many shapes. This helps them fit different devices. They work well in small spaces. Special ways to make them and good materials keep them working well. This helps devices last longer. Working with suppliers can make designs better. You can change and improve them for your cooling needs.

How aluminum vapor chambers and heat pipes work

Phase change and heat transfer principles

Aluminum vapor chambers and heat pipes move heat using a special process. This process is called phase change. When the hot part, called the evaporator, gets warm, the working fluid inside turns into vapor. The vapor moves to a cooler part called the condenser. There, it gives off heat and turns back into liquid. The liquid goes back to the hot part. This cycle happens again and again. It helps spread heat fast.

Here are the main ideas that make these devices work:

The working fluid turns into vapor when it gets hot and turns back into liquid when it cools down.

Capillary action inside the pipe helps the liquid go back to the hot spot.

Vapor chambers can spread heat in two directions, so they are good for flat surfaces.

The outside is made from materials like aluminum, which helps move heat better.

Porous parts or wicks help the fluid move between hot and cold spots.

You can see how the materials compare in this table:

Material | Thermal Conductivity (W/m·K) |

|---|---|

Copper | 385 |

Aluminum | 205 |

Aluminum does not move heat as well as copper, but it is lighter. It still works well for many cooling jobs.

Aluminum heat pipe structure and materials

The way an aluminum heat pipe is built helps it move heat well. The pipe has three main parts: the metallic tube, the working fluid, and the wick. The tube is usually made from aluminum. Aluminum is light and strong. The working fluid can be water, methanol, or ammonia. The wick can have different shapes, like grooves or mesh. It helps the fluid move inside the pipe.

Here is a table that shows the main parts and what they do:

Component | Description | Impact on Performance |

|---|---|---|

Metallic pipe | Can be aluminum, copper, or stainless steel; must be compatible with fluid. | Stops chemical reactions that could hurt performance. |

Working fluid | Includes methane, water, ammonia, and sodium; choice depends on temperature. | Changes how well heat moves and what temperatures the pipe can handle. |

Wick | Comes in various shapes (axial groove, fine fiber, screen mesh, sintering). | Different wicks move heat in their own way and change how well the pipe works. |

Flat heat pipes, micro-port extrusion, and thin planar designs help heat spread out more evenly. These designs use tiny channels and grooves to move the fluid faster. This means heat spreads better and the temperature stays even across the surface. This is important for things that need quick and even cooling.

Integration with heat sinks

You can make your cooling system work better by using aluminum vapor chambers and heat pipes with heat sinks. Here are some good ways to do this:

Put a vapor chamber, aluminum frame, and fin pack together for fast heat movement.

Place vapor chambers at the bottom of a heat sink to cool better.

Put vapor chambers right in the fin stack to get rid of heat faster.

Use thin designs for small spaces.

When you use these ways, you get much better cooling than with regular heat sinks. For example, an aluminum vapor chamber can reach thermal conductivity above 1500 W/m·K. A solid copper heat spreader only gets to 400 W/m·K. This means your devices stay cooler and work better.

You can also find new designs, like roll-bond flat vapor chambers with spiral mesh wicks. These designs help the fluid move faster and spread heat more evenly. You will see these solutions in electronics, LED lights, and high-performance computers. Keeping things cool is very important in these areas.

Benefits of aluminum heat pipe solutions

Superior thermal performance

You want your devices to stay cool and work well. Aluminum heat pipe solutions help with this. They use phase change technology to move heat fast. Heat goes from hot spots to cooler places. This lowers the temperature difference in your device. When you put aluminum heat pipes above parts, heat moves better. You get less thermal resistance than with copper or aluminum plates. Vapor chambers spread heat over big areas. This helps electronics, LED lights, and computers run longer and safer.

Experts say vapor chambers and heat pipes spread heat better than old cooling ways. You can use less energy in high-performance computers. Vapor chambers also last longer. This saves you money over time.

Lightweight and cost-effective

You want a cooling system that is light and easy to use. Aluminum heat pipe solutions are good for this. They weigh much less than regular aluminum heat sinks. You can cut your cooling system’s weight by half. This makes devices easier to carry and install.

You also save money with aluminum heat pipes. Here are some ways you benefit:

Devices can work up to 50% better.

Cooling system weight can drop by 50%.

Component temperatures can be up to 25°C lower.

You spend less on materials and assembly.

You get a strong and reliable cooling system for less money.

Design flexibility

You need cooling that fits your special designs. Aluminum heat pipe technology gives you many choices. The extrusion process lets you make complex shapes. You can pick different fin sizes and thicknesses. You can add copper tubes or more heat pipes if you need extra cooling.

Here are some ways aluminum heat pipes help you design better:

You can shape the heat pipe to fit your device.

You can add special parts for more cooling.

You can use them in many fields, like electronics and lighting.

Aluminum heat pipes keep devices at a steady temperature. They do this by moving fluid inside the pipe. The fluid turns into vapor and then back to liquid. This cycle spreads heat evenly, even in odd-shaped devices. The sealed shell and wick help the fluid move fast and stay inside. You get high thermal conductivity and even cooling every time.

Tip: If you pick aluminum heat pipe solutions, you get a light, cheap, and flexible way to keep your devices cool.

Applications of aluminum vapor chamber heat pipes

Electronics cooling

Aluminum vapor chamber heat pipes are used in many electronics. They help cool parts that get hot quickly. You need fast heat spreading for these parts. These heat pipes are found in:

High-performance CPUs and GPUs

Smartphones and tablets

Electric vehicle battery packs

Aerospace systems

Telecommunications equipment

They can handle power densities from 20 W/cm² to 500 W/cm². This keeps your devices safe and working well. Heat spreads to bigger areas quickly. Using these heat pipes stops electronics from overheating.

LED lighting

You want LED lights to last longer and shine brighter. Aluminum vapor chamber heat pipes help control the heat from strong LEDs. If you do not manage heat, the LED junction temperature goes up. This can make your lights less reliable and not last as long.

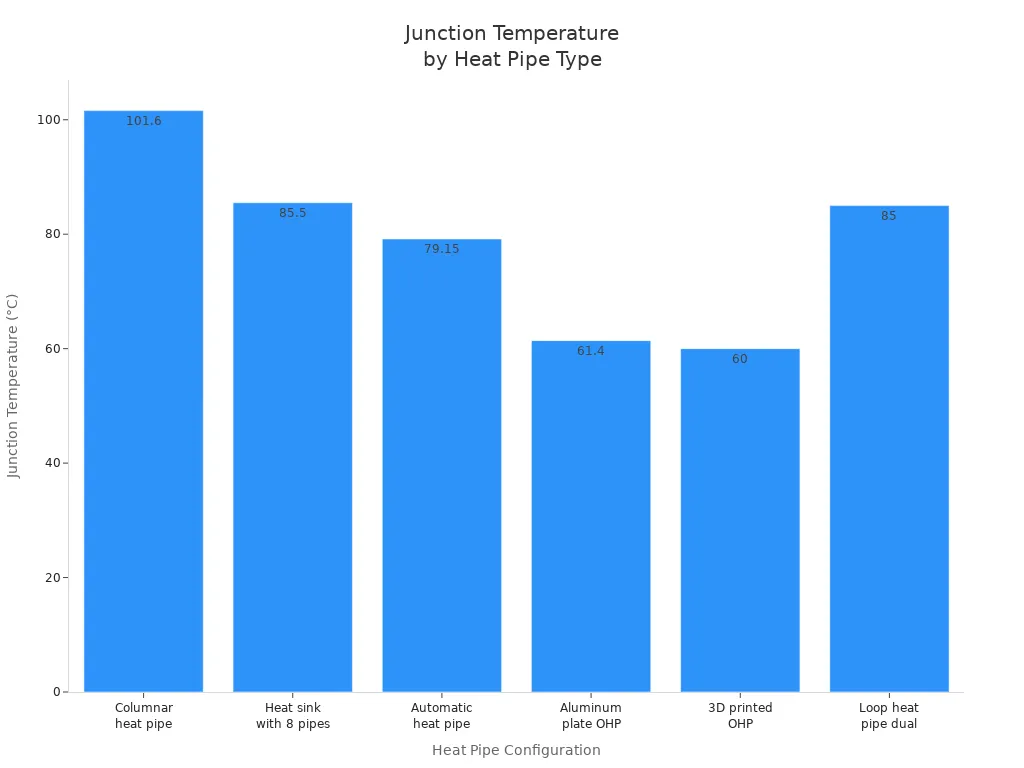

Here is a table that shows how different heat pipe setups change LED temperature:

Study | Configuration | Junction Temperature (°C) | Thermal Resistance (K/W) |

|---|---|---|---|

Tang et al. | Columnar heat pipe (∅16 mm, L 80 mm) | 101.6 | N/A |

Pekur et al. | Heat sink with 8 radial heat pipes | 85.5 | 0.131 |

Xiao et al. | Automatic heat pipe heat sink (∅6 mm, L 128 mm) | 79.15 | 5.953 |

Lin et al. | Aluminum plate oscillating heat pipe (180×120×4mm) | 61.40 | N/A |

Chang et al. | 3D printed aluminum flat-plate oscillating heat pipe (90×60×5mm) | 60 | N/A |

Li et al. | Loop heat pipe with dual condensers (30×30×15mm) | < 85 | N/A |

These solutions keep the LED junction temperature low. This helps your lights last longer and work better.

High-performance computing

High-performance computers need strong cooling. These computers use lots of power and make a lot of heat. Aluminum vapor chamber heat pipes move heat away from CPUs and GPUs fast. This keeps performance stable and protects your hardware.

You find these heat pipes in data centers, gaming computers, and workstations. They help keep temperatures even when computers work hard. Aluminum heat pipe technology keeps your system cool and reliable.

Customization and design considerations

Design options and parameters

You can change your cooling system by picking different design parts. Each part changes how well your system cools things down. The table below shows what is important when you make an aluminum heat pipe:

Design Factor | Description |

|---|---|

Effective Thermal Conductivity | This tells you how well your heat pipe moves heat. |

Internal Structure | You can change wick porosity and thickness to make it work better. |

Physical Characteristics | The size and shape of your heat pipe matter, especially if you bend it. |

Your heat pipe should fit with your heat sink for the best cooling. |

Pick the right size and shape for your device. You can change the wick to help fluid move faster. You can also match the heat pipe with your heat sink for better cooling.

Manufacturing processes

You need to know how making the pipe changes your cooling system. The shell material is very important. Aluminum is good because it moves heat fast. You must be careful about corrosion if your device touches acids or bases. The fluid inside the pipe must work with the shell. For example, water can make bad gases in aluminum pipes. These gases can make heat transfer worse. You should pick materials and fluids that work well together.

Tip: Ask your supplier if the pipe resists corrosion and if the fluid works with the shell before you buy.

Supplier collaboration

You can fix design problems by working with your supplier. Some problems are making very thin vapor chambers and building big, good wick structures. You can use multilayer mesh sintering and special brazing to make the pipe work better. Your supplier can help you test samples and give advice. You should tell your supplier what you need and ask for samples before you choose.

You get better results if you talk to your supplier early.

You can ask for special shapes or wick designs.

You can test samples to see how they work in your device.

Note: Working well with your supplier helps you get the best aluminum heat pipe for your project.

Choosing the right aluminum heat pipe solution

Evaluating thermal requirements

You need to know how much heat your device makes before you pick an aluminum heat pipe. Start by finding the hottest parts in your system. Check how much power these parts use. Write down the highest temperature your device can handle. This helps you set your cooling goals.

You can use thermal simulation tools to make your job easier. These tools let you test different designs on a computer. You do not need to build each one. Here are ways these tools help you:

You can use CFD (Computational Fluid Dynamics) simulations to see how heat moves in your design. This helps you find the best way to place your heat pipes.

Analytical tools help you pick the right size for your heat sink. You save time because you do not need to test every option.

You can find the best thickness for your heat pipe base. For example, a 5 mm base might work best. You can check this quickly before you do more tests.

You get better results when you use these tools. You can see problems before you build your device.

Steps for selection and optimization

You should follow clear steps to pick and improve your aluminum heat pipe solution. The table below shows what you need to think about:

Selection Guidelines | Design Considerations |

|---|---|

Heat source characteristics | Proper sizing |

Space constraints | Orientation planning |

Budget considerations | Temperature range compatibility |

Orientation requirements | Interface quality |

Performance needs | Environmental factors |

Start by looking at your heat source. Make sure you know how big your device is and how much space you have. Think about how you will place the heat pipe. Check your budget and the temperatures your device will face. Make sure the heat pipe fits well with other parts. Think about where you will use your device, like in a hot or cold place.

Tip: Work with your supplier early. You can ask for advice and test samples. This helps you get the best cooling for your project.

You can use these steps to choose the right aluminum heat pipe. You will keep your device cool and safe.

You get lots of good things when you pick custom aluminum vapor chamber and heat pipe solutions. You can change the size, shape, and setup to fit what you need. These solutions work in many places and even in small spaces. The materials and how they are made are always high quality. New software and smart ways of making things help them work better.

Here is a table that shows the main benefits:

Advantage | Description |

|---|---|

Customization Capabilities | Options for size, shape, and configuration for your needs. |

Design Flexibility | Fits many industries and tight spaces. |

Quality Assurance | High standards in materials and manufacturing. |

Technological Innovations | Advanced software and techniques boost performance. |

These solutions help fix today’s cooling problems. Custom designs fit your device and stop hot spots. They also keep important parts safe. Your electronics stay safe and work well.

To begin, you can:

Figure out how much space your heat pipe needs.

Use Excel to check your design and see how heat moves.

Test your ideas with CFD models.

Make your design 25% bigger to be safe.

Try different choices in Excel to find the best one.

You can make your next project cooler, safer, and work better with custom aluminum heat pipe solutions.

FAQ

You use a custom aluminum vapor chamber heat pipe to move heat away from hot spots. It uses a special fluid inside. The fluid changes from liquid to vapor and back. This keeps your device cool and safe.

You start by measuring the space in your device. You check how much heat your parts make. You pick a heat pipe that fits and handles the heat. You can ask your supplier for help.

Yes, you can. Aluminum heat pipes come in thin and flat shapes. You fit them into small spaces like tablets or LED lights. They keep your device cool without adding much weight.

You get a lighter, cheaper, and flexible solution with aluminum.

Feature | Aluminum | Copper |

|---|---|---|

Weight | Lighter | Heavier |

Cost | Lower | Higher

|

Flexibility | Easy to shape | Less flexible |

You do not need special tools for most installations. You can use regular screws or clips. Always follow the instructions from your supplier for the best results.