Heat Sink Material Tips for Better Performance

You want to choose the best heat sink material for your project, but picking the right one can seem hard. Your choice changes how well your device handles heat. Research shows that good thermal conductivity helps lower temperatures and spreads heat more evenly, so your device stays cooler and lasts longer.

Key Takeaways

- Pick heat sink materials that move heat well, like copper or aluminum. This helps your device stay cool and last longer.

- Think about the weight and size of the heat sink. Aluminum is light and good for devices you carry. Bigger heat sinks cool better but might not fit in small spaces.

- Test how well your heat sink works. Use thermal imaging or thermocouple measurements. This makes sure it cools your device enough.

Heat Sink Material Factors

When you pick a heat sink material, you need to think about a few things. These things change how cool your device stays and how long it works. Here is what you should know.

Thermal Conductivity

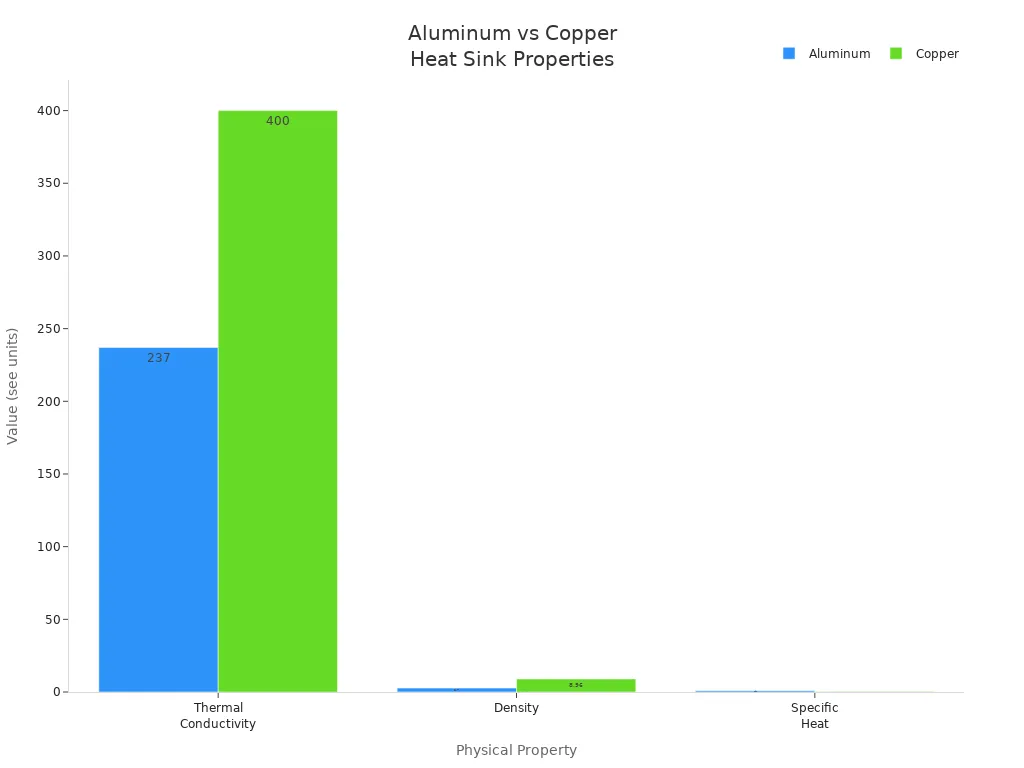

Thermal conductivity shows how fast heat moves away from your device. If you use a heat sink material with high thermal conductivity, your device stays cooler. Copper and aluminum are good choices because they move heat fast.

Tip: A heat sink works better when thermal conductivity is higher.

Here is a table that compares some common materials:

| Material | Thermal Conductivity (W/m•K) |

|---|---|

| Copper | 398 |

| Aluminum | 237 |

| Graphite | 168 |

You should pick the right thermal conductivity for your device. Copper is best for devices that use a lot of power. Aluminum is good for most electronics you use every day.

Thermal Resistance

Thermal resistance tells you how much a material slows down heat. Lower thermal resistance means your device cools better. If your device gets hot quickly, you need a heat sink material with low thermal resistance.

- Materials with low thermal resistance help stop overheating.

- Aluminum and copper both have good thermal resistance for most devices.

| Material | Thermal Resistance Range (°C/W) |

|---|---|

| Aluminum | 0.4 (large sink for TO-3) to 85 (clip-on for TO-92) |

| Copper | Excellent thermal conductivity, around 400 W/(m·K) |

Note: For high-power devices, lowering thermal resistance is very important.

Weight and Size

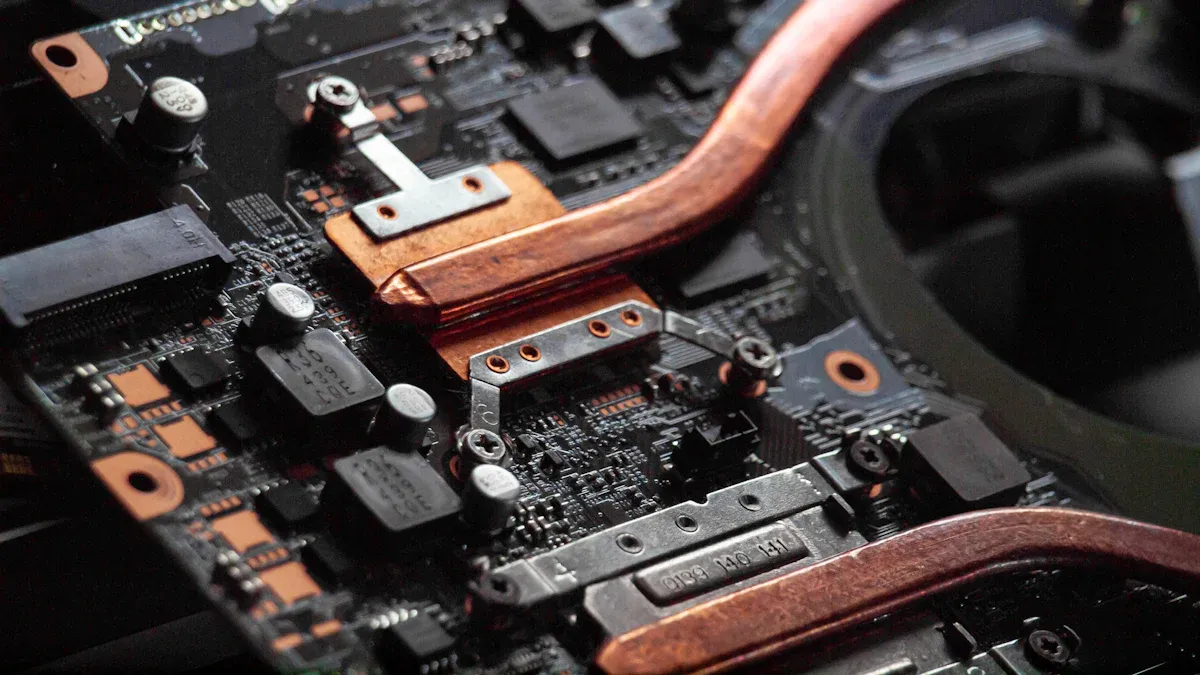

Think about how heavy and big your heat sink material is. Heavy heat sinks are not good for things you carry, like laptops or tablets. Aluminum is light, so it is good for portable devices.

- Bigger heat sinks cool better but may not fit everywhere.

- Thinner heat sinks are lighter, which is good for portable devices, but they may not cool as well.

Tip: Always check your device’s size and weight limits before you choose a heat sink material.

Cost

Cost is important, especially if you make many devices. Aluminum is the cheapest heat sink material. Copper costs more but works better. Graphite and composites cost the most and are used for special jobs.

| Material | Average Cost (per metric ton) | Cost Effectiveness |

|---|---|---|

| Aluminum | $1,800 | Most cost-effective |

| Copper | $6,500 | More expensive |

| Graphite | N/A | Expensive |

The price of materials also changes shipping and making costs. Lighter heat sinks are cheaper to ship. Recycling aluminum can help save money.

Durability

You want your heat sink material to last a long time. Some materials handle hot and cold better than others. Aluminum can rust in salty or wet places, so coatings or anodizing help protect it.

- Engineers want materials that do not rust and last longer.

- Humidity and other weather can make your heat sink wear out faster.

Note: If your device will be in tough places, pick a heat sink material that is strong and does not rust easily.

Manufacturability

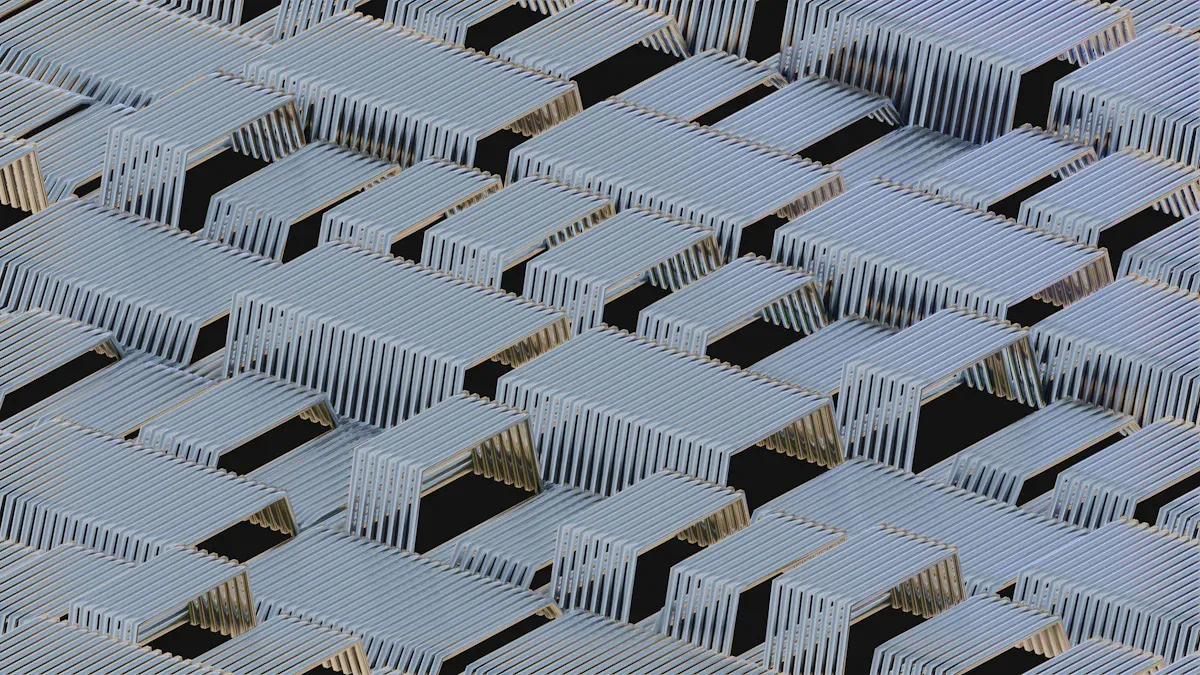

Manufacturability means how easy it is to make your heat sink material into the shape you want. Aluminum is easy to shape and fits many designs. Copper is harder to shape but is good for special uses.

| Process | Description |

|---|---|

| Milling | Cuts material from a blank piece, and is cheap. |

| Extrusion | Pushes hot metal through a mold, fast and cheap for aluminum. |

| Casting | Pours melted metal into a mold, good for tricky shapes. |

| Skiving | Slices material for thin, exact fins. |

| 3D Printing | Builds custom shapes layer by layer. |

- Extrusion is the most common and best way for aluminum heat sinks.

- Skiving and milling help make special shapes and thin fins.

- 3D printing is becoming popular for custom heat sink shapes.

Tip: Choose a heat sink material that is easy to make into your design. Easy-to-make materials save time and money.

Common Materials

Aluminum

Aluminum is used in many electronics. It is light and easy to shape. Aluminum does not cost a lot. If you want a heat sink material that keeps your device cool and light, aluminum is a good choice. You can make aluminum into many shapes. It fits lots of designs.

Here is a table that shows how aluminum and copper compare:

| Property | Aluminum | Copper |

|---|---|---|

| Thermal Conductivity | 237 | 400 |

| Density (g/cm³) | 2.7 | 8.96 |

| Specific Heat (J/g·K) | 0.91 | 0.39 |

| Relative Cost | Lower | Higher |

| Machinability | Excellent | Good |

Aluminum is lighter and easier to use. Copper moves heat faster.

Pros:

- Light

- Cheap

- Easy to shape

Cons:

- Does not move heat as fast as copper

Copper

Copper gives the best thermal performance. If your device gets very hot or uses lots of power, copper is the best choice. Copper moves heat better than aluminum, even when things get hot quickly.

- Copper’s thermal conductivity is about 231 BTU/(hr·ft⋅°F), much higher than aluminum.

- Copper works well at high temperatures.

- Copper costs more and is heavier.

Graphite & Advanced

Graphite heat sinks are very light. They move heat quickly, especially from side to side. You might see graphite in thin devices or where weight is important.

| Material | Thermal Conductivity (W/m K) | Weight (g/cm³) |

|---|---|---|

| Graphite Foam | Up to 1900 | 80% lighter than aluminum |

| Graphite Sheets | 350~900 (Horizontal) | 1.3-1.5 |

Graphite foam is much lighter than aluminum. It handles heat well.

Composites

Composites mix metals and ceramics. This gives you strength, low weight, and good heat transfer. You can use composites for special jobs.

- Laminated composites for PCBs weigh 43% less than aluminum.

- They bend less, so your device stays safe.

- Metal matrix composites can be made to fit your needs. They have high thermal conductivity and low density.

Composites help solve hard problems in modern electronics.

Application Fit

Consumer Electronics

You use things like phones and tablets every day. These devices need to stay cool to work well. The heat sink material should be light and easy to shape. Aluminum is a good choice because it keeps devices cool and does not add much weight. It also helps save money, which is important when making many devices.

Here’s what matters most for these gadgets:

| Criteria | Description |

|---|---|

| Thermal Performance | How well the heat sink cools your device |

| Weight | Lighter is better for portable gadgets |

| Cost | Lower cost helps with mass production |

| Application Needs | Pick what fits your device’s special requirements |

Tip: For smartphones and tablets, using lightweight extruded aluminum heat sinks is smart.

Industrial Equipment

Big machines get hot and need strong cooling. You should pick a heat sink material that can handle high heat and hard work. Copper and bonded fin heat sinks are good for these jobs. Airflow is important too. Faster airflow cools things down, but you still need a material that moves heat well.

- Bonded fin heat sinks are great for big machines.

- Copper is best for high heat.

- The heat sink must fit the space you have.

Space-Limited Uses

Sometimes, there is not much room for a heat sink. In these cases, you need thin designs that still cool well. Skived fin heat sinks fit in small spaces and move heat fast. Graphite is another good choice because it is light and thin.

- Small designs need to get rid of heat well.

- Skived fins and graphite sheets work in tight spots.

Harsh Environments

If your device faces dust, water, or very hot and cold places, you need a heat sink material that lasts. Aluminum with coatings or composites can stop rust and damage. You want something strong that keeps working, even when things get rough.

Note: Always pick a heat sink material that matches the place it will be used. Tough places need tough materials.

Selection Tips

Prioritize Needs

You want your device to stay cool and work well. First, think about what is most important for your project. Here are some things you should check:

- Thermal resistance

- Material properties

- Fin configuration

- Fin size and shape

- Fin efficiency

- Heat sink attachment method

- Thermal interface material

Aluminum alloys and copper are good choices because they move heat fast. Copper costs more and is heavier, but it also does not rust and can stop germs. Diamond is another choice if you need very high thermal conductivity, but it is not used much in normal products.

Tip: Always pick a heat sink material that fits your device’s needs. If you want something light, choose aluminum. If you need the best cooling, copper could be better.

Consult Experts

You do not have to do everything by yourself. Thermal management experts help you design systems that keep your device from getting too hot. They find problems early and give advice that fits your budget and weight needs.

- Experts know how to stop overheating and device failure.

- They tell you the best materials for your project.

- You get answers that balance cost, weight, and cooling.

Note: Talking to an expert saves time and helps you avoid mistakes.

Test Performance

Testing shows how well your heat sink material works. You can use different ways to check cooling and find problems.

| Testing Method | Description |

|---|---|

| Thermal Imaging | Lets you see temperature changes and find hot spots. |

| Thermocouple Measurements | Uses sensors to measure heat movement and temperature. |

| Computational Fluid Dynamics | Uses computer models to predict airflow and heat transfer. |

Try these tests before you finish your design. You will see what works best and can make changes if you need to.

Tip: Testing helps you choose the right material and avoid problems later.

Picking the best heat sink material means you should think about how well it cools, how much it costs, how heavy it is, and what your project needs. These things are important:

- Aluminum and copper are good for most uses.

- Fins that are taller help cool things better.

- If thermal conductivity is high, cooling works better.

| Factor | Why It Matters |

|---|---|

| Thermal Conductivity | Moves heat away faster |

| Weight and Size | Lighter is better for portable devices |

| Cost | Aluminum saves money |

| Corrosion Resistance | Lasts longer in tough places |

| Application Needs | Fits your unique project |

Remember to ask experts for help and test your design early. Try making a sample and use rules from the industry. Your project should have great cooling, so pick what works best for you!

FAQ

What is the best heat sink material for my laptop?

Aluminum works well for laptops. You get good cooling, low weight, and a lower price. Most portable devices use aluminum heat sinks.

Tip: Check your laptop’s specs before you buy a replacement.

Can I use copper for small electronics?

You can use copper, but it feels heavy and costs more. Aluminum is lighter and easier to shape for small gadgets.

| Material | Weight | Cost |

|---|---|---|

| Aluminum | Light | Low |

| Copper | Heavy | High |

How do I know if my heat sink is working?

Touch your device. If it feels cool, your heat sink works. You can also use a thermal camera to spot hot areas.