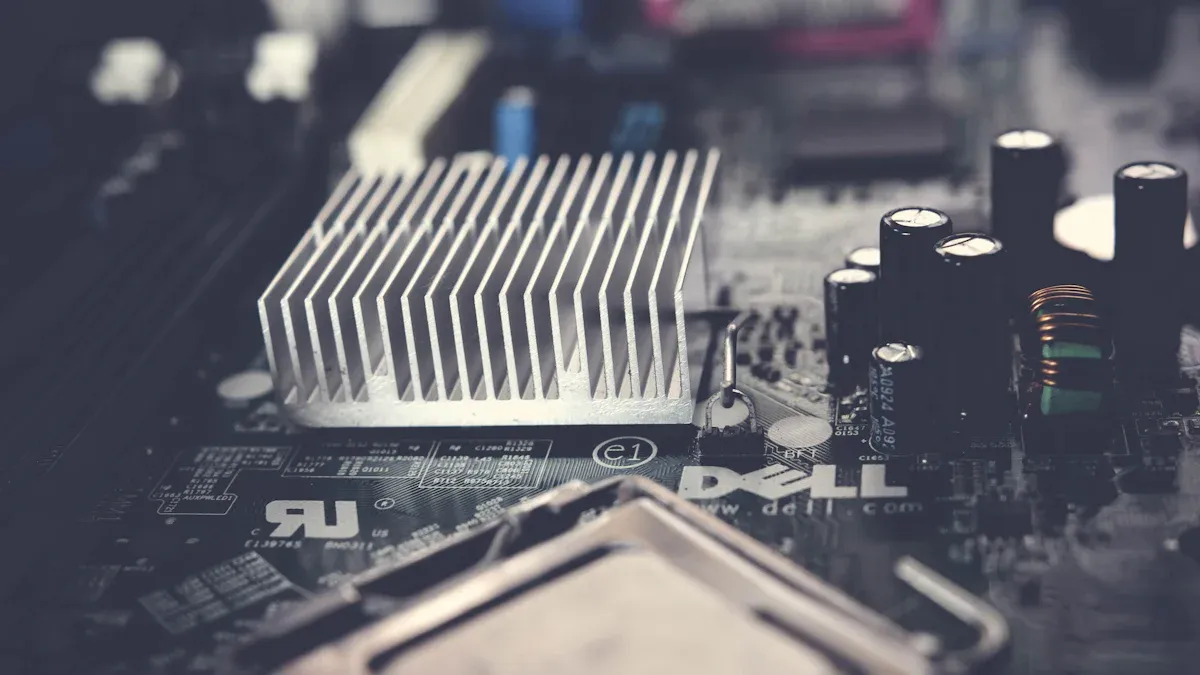

Die cast heat sink vs extruded heat sink

When you need to cool electronics, extruded heat sinks often work better. This is because they have higher thermal conductivity and smoother surfaces. The table below shows that extruded aluminum usually reaches 200 W/mK. Other materials can be different.

| Heat Sink Type | Thermal Conductivity (W/mK) |

|---|---|

| Skived Copper | 400 |

| Extruded Aluminium | 200 |

Die cast heat sinks can have more complex shapes. But they usually cost more at first. You should pick the right type based on your budget, design, and cooling needs.

Key Takeaways

- Extruded heat sinks move heat better than die cast heat sinks. This makes them good for cooling electronics. Die cast heat sinks can have more complex shapes and features. This makes them good for special designs. Pick die cast heat sinks for making many at once. This saves money over time, especially for tricky designs. Extruded heat sinks are cheaper for small amounts and simple shapes. They give a good mix of price and how well they work. Think about how much heat your device makes when picking a heat sink. Aluminum is a good choice to get rid of heat. Look at your budget closely. Die casting costs more at first but is cheaper for big orders. Think about how hard your design is. Die casting is better for special shapes. Extrusion is better for simple shapes. Always check how many you need to make. Die casting works better for big jobs. Extrusion is better for small projects.

Types

Die Cast Heat Sink

Die cast heat sinks are used in lots of electronics. Makers pour melted metal like aluminum or copper into a mold. The metal cools and gets hard. This makes the final shape. This way, you get strong parts that move heat well. Die casting lets you make tricky shapes. You can add things like holes for mounting or thin fins.

Die cast heat sinks mostly use aluminum alloys such as A380 and A356.0. Copper is another choice. It moves heat better but costs more.

Here is a quick look at common materials:

| Heat Sink Type | Common Materials | Notes |

|---|---|---|

| Die Cast Heat Sink | Aluminum, Copper | Copper moves heat best. Aluminum is used a lot but does not move heat as well. A380 and A356.0 are popular aluminum alloys. |

Die cast heat sinks are good for making lots of parts. You see them in LED lights, car electronics, and power supplies. They can be made in special shapes, so they work well for designs that need extra features.

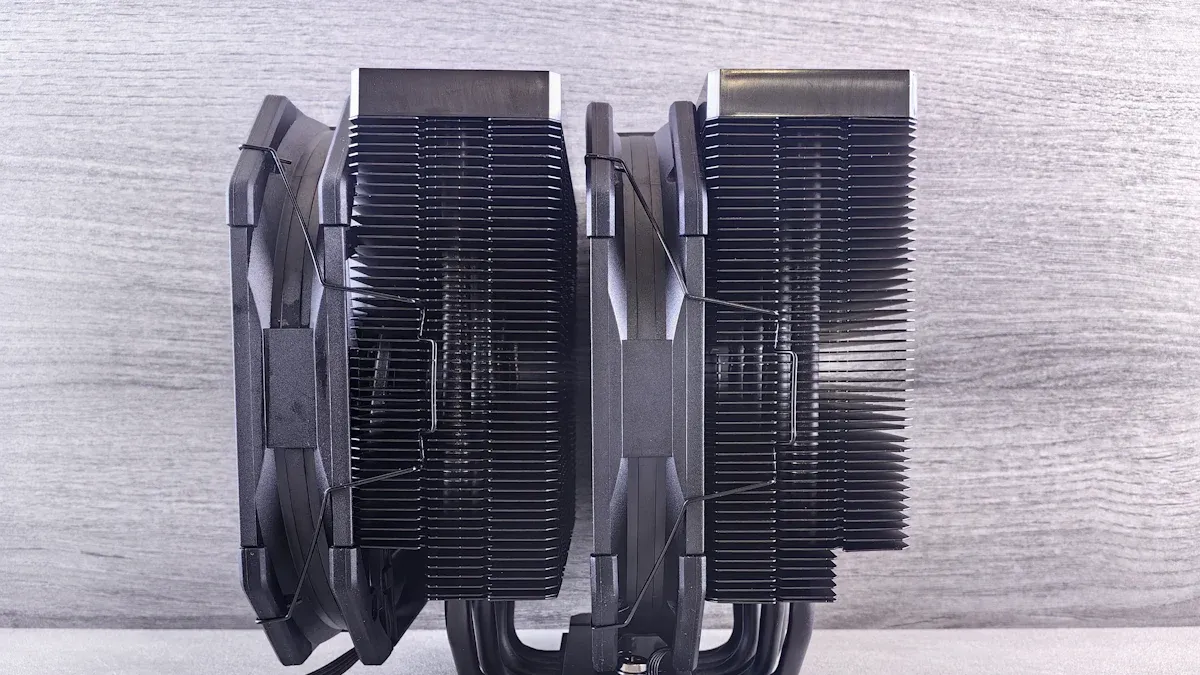

Extruded Heat Sink

Extruded heat sinks are found in many electronics and machines. Makers push aluminum through a die to get the shape they want. This way is cheap and lets you change the design easily. You can pick from many shapes. But the process keeps the product from being too wide.

Aluminum alloys 6061 and 6063 are used most for extruded heat sinks. These alloys move heat well and keep the heat sink light.

Here is a simple table about how they are made:

| Manufacturing Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Die Casting | Melted aluminum is poured into a mold and cools down. | Strong parts, moves heat well, can be recycled. | Not as flexible for design as extrusion. |

| Extrusion | Material is pushed through a die to make the shape. | Cheap, easy to change, lowers stress on the part. | Product cannot be very wide. |

Extruded heat sinks are used when price matters and simple designs are fine. You see them in computers, audio amps, and telecom gear. The process lets you change the length and shape, so you can fit your cooling needs.

- Die cast heat sinks are best for tricky, high-volume designs.

- Extruded heat sinks are good for saving money and making simple shapes.

If your design is special, die casting gives you more choices. If you want something simple and steady, an extruded heat sink is a good pick.

Manufacturing

Die Casting

Die casting gives you a way to make heat sinks with strong and detailed shapes. You use melted metal and force it into a mold under high pressure. This process works well for large batches and saves time when you need many parts.

Materials

You often see aluminum alloys like A380 and A356.0 in die cast heat sinks. These metals help move heat away from electronics. Copper is another choice, but it costs more and is heavier. Aluminum stays popular because it is light and easy to recycle.

Shapes

Die casting lets you create very complex shapes. You can add tiny fins, holes, and special features that help cool your device better. The high-pressure process makes it possible to include details that other methods cannot match.

You can see the difference in shape complexity in the table below:

| Heat Sink Type | Complexity Achievable |

|---|---|

| Die Cast | Very complex shapes with detailed designs |

| Extruded | Simpler shapes, less precise |

Die cast heat sinks work well for designs that need special features. You can make parts with thin walls and tricky details. This helps you get better cooling for your electronics.

Tip: Die casting minimizes waste. You can remelt extra aluminum and use it again.

- Initial tooling costs for die casting are higher than for extrusion.

- Die casting becomes more cost-effective in high-volume production because each part costs less.

- At around 5,000 pieces, the upfront cost is balanced by lower part costs.

- The process time is short, so you save money when you make many heat sinks.

Extruded Heat Sink Process

Extrusion gives you a simple way to make heat sinks. You push aluminum through a shaped die to get a long profile. This method is popular because it costs less and works for many designs.

Materials

You usually use aluminum alloys like 6061 and 6063 for extruded heat sinks. These alloys help move heat well and keep the heat sink light. You can also recycle these metals easily.

Shapes

Extrusion works best for simple shapes. You get long, straight profiles with fins that help cool your device. You cannot make very wide or detailed shapes with this method. Most extruded heat sinks have basic designs that fit many electronics.

- Extrusion has lower initial tooling costs than die casting.

- You can change the length of the heat sink easily.

- The process is cost-effective for small and medium batches.

- You get steady quality and simple shapes.

If you want a heat sink for a standard design, the extruded heat sink process gives you a good balance of cost and performance. You can choose from many profiles and sizes.

Design

Die Cast Options

Geometries

Die casting lets you make almost any shape you want. You can create heat sinks with tricky shapes for your needs. If you need thin fins or curved parts, die casting can do it. You can also add special spots for mounting. This process gives you lots of design freedom. You can pick shapes that help air move better and cool things faster.

- Die casting can make shapes that extrusion cannot.

- You can make parts in many sizes and shapes for hard designs.

- You can add things that help put the part together or move heat better.

Die cast heat sinks are good when you need a special part. You can make pieces that fit in small or odd spaces. This helps you fix hard cooling problems.

Features

Die casting lets you add cool features to your heat sink. You can put in holes for screws or even your logo. You can also make thin walls and tiny details to help cool better. These features make your heat sink easier to use and put in place.

Tip: You can mix many jobs into one die cast part. This means you need fewer parts in your device.

Die cast heat sinks often have things that save time when building. You can add snap tabs or guides to help line things up. These choices help you build faster and make fewer mistakes.

Extruded Heat Sink Options

Profiles

Extrusion gives you many profile choices. You can pick from shapes like straight fins or flat bases. The aluminum is pushed through a die, so the shape stays the same all the way. You can cut the piece to any length you want.

| Heat Sink Type | Design Flexibility |

|---|---|

| Extruded Heat Sinks | Only fixed shapes, not as tricky designs |

| Die Cast Heat Sinks | Can make tricky shapes and designs with molds |

You can pick a profile that fits your cooling needs. Most profiles work well for things like amps or power supplies.

Customization

You can change the length and look of an extruded heat sink. You can add a finish to stop rust. You can also drill holes or add slots after making it. But you cannot change the main shape once you pick the die.

Extrusion has some limits. You cannot make shapes with different thicknesses or curves. You must use a shape that stays the same all the way. This makes extrusion less flexible than die casting.

Note: If you want something simple and cheap, extrusion gives you lots of options. You can choose from many shapes and sizes in a catalog.

Think about what you need before you pick a method. Die casting lets you make more complex shapes and features. Extrusion is best for simple shapes and easy changes.

Cost

Die Cast Costs

Tooling

You face high initial tooling costs when you choose die cast heat sinks. The process needs custom molds made from steel. These molds must handle high pressure and heat. You pay more upfront for these molds. The cost can reach thousands of dollars before you make the first part. If you plan to produce only a few heat sinks, this method may not fit your budget. You need to consider the long-term savings if you expect large production runs.

Tip: Die casting molds last for many cycles. You save money over time if you make thousands of units.

Volume

Production volume changes the cost for die cast heat sinks. When you make more units, the cost per part drops. The high tooling cost spreads over many pieces. You get better value if you need thousands of heat sinks. Die casting works best for high-volume projects with complex shapes. If you only need a small batch, you pay more for each part.

- Die cast heat sinks become cost-effective at high volumes.

- You pay more per unit at low volumes because of tooling costs.

- Large orders help you lower the average cost per heat sink.

Extruded Heat Sink Costs

Tooling

You pay less for tooling when you choose extruded heat sinks. The process uses a die made from hardened steel. This die shapes the aluminum as it passes through. The cost for an extrusion die is much lower than a die casting mold. You can start production with a smaller investment. This method suits projects with tight budgets or short production runs.

Note: You can reuse extrusion dies for different lengths and profiles. This flexibility helps you save money.

Volume

Production volume affects the cost of extruded heat sinks. You see steady savings as you increase the number of units. The process scales well for both small and large batches. You get high cost efficiency and easy scalability. The average cost per unit for extruded heat sinks ranges from $2 to $5. This price stays low even for small orders.

Here is a table that shows cost efficiency and scalability for different heat sink types:

| Heat Sink Type | Cost Efficiency | Scalability for Production Volume |

|---|---|---|

| Extruded Heat Sinks | High | Easy to scale for large runs |

| Skived Heat Sinks | Moderate | Complex manufacturing process |

You benefit from lower costs and flexible production when you choose extruded heat sinks. You can order small batches or scale up for larger projects. The process gives you a good balance between price and performance.

- You pay less for tooling with extrusion.

- You get low unit costs at both low and high volumes.

- The extruded heat sink process helps you control your budget.

Performance

Die Cast Thermal

Conductivity

Die cast heat sinks are strong and can have tricky shapes. But they do not always move heat as well as other types. They use aluminum alloys, which are good at moving heat. Still, the casting process can make tiny air pockets inside. These air pockets are called pores. Pores stop heat from moving easily. When picking die cast heat sinks, think about how pores might hurt cooling.

Porosity

Porosity happens when gas gets trapped during casting. This makes it harder for the heat sink to move heat away. More pores mean the heat sink works less well. The table below shows how pores change thermal conductivity in die cast aluminum:

| Description | Impact on Thermal Conductivity |

|---|---|

| Pores in die cast Al alloy reduce thermal conductivity. | Decreases thermal conductivity. |

| Porosity often forms due to gas entrapment during molten metal injection. | Affects heat dissipation. |

| Thermal conductivity of aluminum foams decreases linearly with increasing porosity. | Direct correlation established. |

| Controlled die-casting pressures led to 12.6% decrease in thermal conductivity. | Quantitative impact noted. |

If you want the best cooling, watch out for pores in die cast heat sinks. Even small pores can make your device get hotter.

Extruded Heat Sink Thermal

Conductivity

Extruded heat sinks move heat better than die cast ones. The extrusion process uses solid aluminum. This means there are no air pockets inside. The metal is dense and even, so heat moves fast through it. You can count on extruded heat sinks to keep electronics cool. They work well when you need steady and strong cooling.

- Extruded heat sinks often reach about 200 W/mK.

- They get rid of heat better because they have no pores.

Finish

Extruded heat sinks also have smoother surfaces. The process makes clean lines and flat areas. This helps you stick on thermal pads or paste more easily. A smooth finish helps heat move from chips to the heat sink. This makes cooling better.

Pick an extruded heat sink if you want high thermal conductivity and a smooth finish. These features help most with sensitive electronics where cooling is very important.

Pros and Cons

Die Cast

Advantages

Die cast heat sinks have many good points. They help stop electronics from getting too hot. This keeps your devices working well. You can use them in cars and planes because they are light. Die cast heat sinks last a long time, even in rough places. If you need lots of heat sinks, you save money. They work well for electrical devices. You can pick from many designs.

Here is a table that shows the main advantages:

| Advantages of Die Cast Heat Sinks | Description |

|---|---|

| Efficient Heat Dissipation | Stops electronics from overheating and keeps them working. |

| Lightweight | Good for cars and planes where weight matters. |

| Corrosion Resistance | Lasts long even in tough places. |

| Cost-Effective | Saves money when you make many at once. |

| Efficient for Electrical Devices | Works well for electrical devices. |

| Variety of Designs | Many shapes and styles are possible. |

| Reduced Complexity | Needs less extra work because designs are simple. |

| Customizable | You can change them to fit your needs. |

You can change die cast heat sinks to fit what you want. You do not need extra parts because you can add features during casting.

Disadvantages

Die cast heat sinks have some problems. Making molds costs a lot at first. If you only need a few, each one costs more. Sometimes, tiny air bubbles get inside the metal. These bubbles make it harder for heat to move. Die cast heat sinks may not cool as well as other types.

- High starting cost for molds

- Air bubbles can lower heat movement

- Not good for small batches

- May need extra work to make surfaces smooth

Think about these problems if you want the best cooling or only need a few heat sinks.

Extruded Heat Sink

Advantages

Extruded heat sinks give strong and steady cooling. The metal is solid with no air bubbles. You can make lots of them fast and save money. They are tough and last a long time. You can pick from many shapes and sizes. This makes it easy to find what you need. You also get steady quality and built-in features.

Here is a table that lists the main advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| High-volume production | Fins cannot be packed close together |

| Rugged and durable | Need to pay for custom dies at first |

| Integrated features | Mostly made from aluminum |

| Standard fin geometry | Hard and costly to change designs after tooling |

Extruded heat sinks work well for most electronics. They give a good mix of price and performance.

Disadvantages

Extruded heat sinks have some limits. You cannot make very tricky shapes. You cannot change the main shape after you pick the die. The fins are not as close together because of how the die works. Most extruded heat sinks use aluminum, so you do not have many choices for materials.

- Not much design freedom

- Hard to change after making the die

- Usually only in aluminum

- Fins are not as close as die cast ones

Pick extruded heat sinks for simple and cheap cooling. If you need a special shape or material, try something else.

Applications

Die Cast Uses

High Volume

Die cast heat sinks are used when you need many parts. Manufacturers pick die casting for big batches because it saves money. Each heat sink is strong and works well. This method is good for electronics and machines. You find die cast heat sinks in LED lights. They help keep the lights cool and working longer. They are also used in power supplies and car electronics.

- Used in LED lights to get rid of heat and keep them working.

- Common in electronics to stop them from getting too hot.

- Important for making electronic parts last longer.

Die cast heat sinks are best when you need lots of parts that all work the same.

Complex Designs

Die casting lets you make heat sinks with special shapes. You can add thin fins, holes for screws, and other features. This helps you fix hard cooling problems. Die cast heat sinks are used in devices with small spaces or special needs. Makers use this process for products that need unique shapes or extra features.

| Application Area | Benefit of Die Cast Heat Sink |

|---|---|

| LED Lighting | Special shapes fit in small spaces |

| Automotive Electronics | Custom features help with mounting |

| Power Supplies | Thin fins help cool better |

Pick die cast heat sinks if your design needs more than a basic shape.

Extruded Heat Sink Uses

Cost-Sensitive

Extruded heat sinks are chosen when you want to spend less. The extrusion process keeps costs low and works for any batch size. You get a good product without paying a lot. This method is great for projects with small budgets or short runs. You see extruded heat sinks in computers, audio amps, and telecom gear.

- Used in electronics because they move heat well.

- Light and strong, helping LED parts last longer.

- Helps LED lights get rid of heat and stay bright.

You can buy standard shapes or ask for special lengths to fit your needs.

Standard Designs

Extrusion is best for simple and steady shapes. You get long pieces with straight fins that move heat away. Makers use extruded heat sinks for high-power LED lights. The round fin design helps air flow and cools better. You also find custom shapes for different LED setups.

- Made for high-power LED lights to keep them cool.

- Has round fins that help air move and cool things down.

- Custom shapes help cool different LED designs.

| Application Area | Benefit of Extruded Heat Sink |

|---|---|

| LED Lighting | Keeps things cool and works well |

| Power Electronics | Special shapes help cool better |

| Telecom Equipment | Simple shapes fit most devices |

Extruded heat sinks are good for projects that need easy, cheap cooling that works well.

Selection

Picking the right heat sink for your electronics is important. You need to think about what your device needs, how much money you have, and your design. Let’s look at what matters when you choose between die cast and extruded heat sinks.

Factors

Thermal Needs

First, find out how much heat your device makes. If you need to move heat fast, aluminum is a great choice. It helps keep your electronics cool and safe. Aluminum is also light, so it works well in things like planes or phones. Extruded heat sinks give good cooling and do not cost too much. They are used a lot in big projects.

- Aluminum moves heat better than zinc.

- Extruded heat sinks are good for making lots of parts.

- Light materials help in things that need to be carried.

Tip: Always check how much heat your device makes. This helps you pick a heat sink that stops it from getting too hot.

Budget

How much money you can spend is important. Die cast heat sinks cost more at first because you need special molds. If you make many heat sinks, die casting saves money later. Zinc heat sinks are cheaper but do not cool as well as aluminum. Stamping heat sinks are also cheap for simple jobs.

- Die casting costs more at first but saves money if you make a lot.

- Stamping and zinc heat sinks are good for small budgets.

- Extruded heat sinks give a good mix of price and cooling.

Note: Think about both the first cost and how much you save later.

Design

Think about how tricky your design is. Die casting lets you make hard shapes with things like holes or thin fins. This way, you waste less and can put many jobs into one part. Extrusion is best for simple shapes. If you need special shapes or features, die casting gives you more choices.

| Method | Advantages | Limitations |

|---|---|---|

| Heat Sink Extrusion | Good for making lots of simple shapes | Can only make simple shapes |

| Die Cast Heat Sinks | Good for big batches and tricky shapes | Costs more to start, not many material choices |

Match your design to the way you make it. Hard shapes are better with die casting. Simple shapes are better with extrusion.

Volume

How many heat sinks you need matters. If you need thousands, die casting is cheaper and lets you make tricky shapes. If you only need a few, extruded heat sinks are better because they cost less to start and are easy to make.

| Production Volume | Die Cast Heat Sinks | Extruded Heat Sinks |

|---|---|---|

| High Volume | Cheaper and good for tricky shapes | Not as good because starting costs are higher |

| Low Volume | Not worth it because of setup costs | Better for small batches |

Plan how many you need early. Big projects are better with die casting. Small projects work better with extrusion.

Checklist

Before you choose, check this list to make sure your heat sink is right:

| Checklist Item | Description |

|---|---|

| Material Type | Pick the right metal for cooling and weight. |

| Corner Radii | Use the right corner sizes so it stays strong. |

| Ventilation Design | Add slots or fins to help get rid of heat. |

| Safety Features | Make sure it is safe to use and stops accidents. |

| Installation Considerations | Make it easy to put in and take care of. |

| Protection Rating | Make sure it keeps out dust and water if needed. |

Go over each thing on this list. This helps you pick a heat sink that is safe, easy to use, and works well.

When you think about heat, money, design, and how many you need, you can pick the best heat sink for your electronics. No matter if you pick die cast or extruded, matching these things to your project helps your device work well for a long time.

When picking a heat sink, you need to think about design, cooling, and price. Die cast heat sinks can be made into many shapes. They work well for thick parts and use natural airflow to cool. Extruded heat sinks move heat better and can cool up to half more for strong electronics. You often find extruded aluminum in car computers and LED lights. This is because it cools things well and lasts a long time.

| Process Type | Advantages | Considerations |

|---|---|---|

| Die Casting | Can make many shapes, good for thick heat sinks | Best for tricky shapes, works best when making lots at once |

| Extrusion | Moves heat well, easy to shape | Fins can’t be too tall or thin, best for strong cooling needs |

Before you pick, check how much heat your device makes, how much money you have, and what shape you need. You get the best heat sink when you match it to your project.

FAQ

What is the main difference between die cast and extruded heat sinks?

Die cast heat sinks use molds to create complex shapes. Extruded heat sinks use dies to form simple profiles. You get more design options with die casting. Extrusion gives you better thermal performance.

Which heat sink type cools electronics better?

You get better cooling from extruded heat sinks. The solid aluminum structure moves heat quickly. Die cast heat sinks may have tiny air pockets that slow heat transfer.

When should you choose die cast heat sinks?

You should pick die cast heat sinks for high-volume production or when your design needs special shapes. Die casting works best for parts with thin fins, mounting holes, or custom features.

Are extruded heat sinks cheaper for small projects?

Yes, you save money with extruded heat sinks on small batches. The tooling costs stay low. You can order standard profiles and cut them to size.

Can you customize the shape of an extruded heat sink?

You can select from many profiles and lengths. You cannot change the main shape after you pick the die. Extrusion works best for simple, straight designs.

Do die cast heat sinks last longer than extruded ones?

Both types last a long time. You get strong, durable parts with either method. Die cast heat sinks resist corrosion well. Extruded heat sinks offer consistent quality.