what is the function of heat sink

A heat sink helps you keep sensitive electronic components cool by absorbing and transferring excess heat away from them. You rely on this device to prevent overheating, which protects your equipment and ensures optimal performance. Most heat sinks use a base and multiple fins to increase the surface area, allowing for efficient heat dissipation. For example:

- CPU heat sinks feature large surface areas for improved thermal resistance.

- Specialized designs, such as those for TO-220 packages, exist for different applications.

Technicians often measure temperature at the heat sink’s base, both with and without a fan, to evaluate its effectiveness.

Key Takeaways

- A heat sink absorbs and transfers excess heat from electronic components, preventing overheating and ensuring optimal performance.

- Materials like copper and aluminum are essential for effective heat transfer due to their high thermal conductivity.

- The design of a heat sink, including its surface area and shape, significantly impacts its cooling efficiency.

- Regular maintenance, such as cleaning dust and checking thermal paste, is crucial for maintaining heat sink performance.

- Choosing the right type of heat sink—passive or active—depends on your device’s heat output and space availability.

- Proper placement of the heat sink ensures efficient heat transfer and airflow, enhancing cooling effectiveness.

- Investing in a quality heat sink can extend the lifespan of your electronics by reducing thermal stress and preventing damage.

- Understanding the specific cooling needs of your device helps you select the most suitable heat sink material and design.

heat sink operation

heat absorption

You rely on a heat sink to draw heat away from electronic components. This process starts when your device generates heat during operation. The heat moves from the hot component into the heat sink through direct contact. Materials like copper and aluminum, known for their high thermal conductivity, help this transfer happen quickly and efficiently. Here’s how the process works:

- The electronic component produces heat that must be removed.

- Heat travels from the component into the heat sink by conduction, depending on the material’s ability to conduct heat.

- The heat spreads throughout the heat sink, moving from hotter areas to cooler ones.

- Finally, the heat leaves the heat sink, carried away by air or another fluid through convection.

This sequence ensures that your sensitive electronics stay within safe temperature limits.

heat transfer

Once the heat enters the heat sink, it must move out into the surrounding environment. Three main physical principles govern this process:

- Conduction: Heat flows through the solid material of the heat sink, moving from the base to the fins.

- Convection: The heat transfers from the surface of the heat sink to the air or liquid around it. Moving air, either from a fan or natural airflow, helps carry the heat away.

- Radiation: At higher temperatures, the heat sink also releases energy as electromagnetic waves, adding to the cooling effect.

You benefit from these combined processes because they work together to keep your devices cool and reliable.

surface area

The design of a heat sink plays a crucial role in its performance. You often see heat sinks with many fins or pins. These features increase the surface area, allowing more heat to escape into the air. When the surface area grows, the heat sink can transfer more heat at once. Even small changes, like making the surface rougher, can boost efficiency. For example, increasing the roughness of a copper heat sink can improve its heat transfer rate by about 9%. This improvement happens because the rougher surface creates more turbulence in the air, which helps move heat away faster. By choosing a heat sink with a larger or specially treated surface, you ensure better cooling for your electronics.

importance

overheating prevention

You depend on a heat sink to keep your electronic devices safe from overheating. When your device runs, it generates heat that can quickly build up, especially in high-performance electronics or compact gadgets. If you do not manage this heat, you risk several problems:

- Reduced efficiency and slower performance

- Data loss or system crashes

- Permanent damage to sensitive components

- Increased wear and tear in smaller, denser devices

A heat sink absorbs and moves heat away from critical parts, maintaining a stable temperature. This process prevents thermal runaway, a dangerous situation where rising temperatures cause even more heat, leading to catastrophic failure. By using materials with high thermal conductivity, such as copper or aluminum, you help your device transfer heat efficiently and avoid these risks. You can trust a well-designed heat sink to keep your electronics running safely, even under heavy loads.

performance

A reliable heat sink does more than just prevent damage—it also boosts your device’s performance. When your components stay cool, they work faster and more efficiently. High temperatures can slow down processors, reduce clock speeds, and cause your system to crash. You want your device to deliver consistent results, whether you are gaming, editing videos, or running complex calculations.

Tip: Choosing the right heat sink design can make a measurable difference in performance. For example, a triangular fin heat sink maintains lower peak temperatures and performs up to 6.7% better than a no-fin design at higher power levels.

Here is a quick comparison of cooling performance:

| Heat Sink Type | Power Level (W) | Temperature Rise (%) | Performance Improvement (%) |

|---|---|---|---|

| No Fin Heat Sink (NFHS) | 4 | 56.7 | N/A |

| Triangular Fin Heat Sink (TFHS) | 4 | Lower than NFHS | 4.3 |

| NFHS | 12 | 89 | N/A |

| TFHS | 12 | 92.3 | 6.7 |

With the right heat sink, you keep your device stable and responsive, even during demanding tasks.

lifespan

You want your electronics to last as long as possible. Excessive heat accelerates wear and tear, shortening the lifespan of your components. When you use a heat sink, you help maintain stable operating temperatures and reduce thermal stress. This protection extends the operational life of your device.

- Heat sinks prevent overheating, which can cause permanent damage.

- They help your components stay durable by dissipating heat effectively.

- Stable temperatures mean less thermal stress and fewer failures over time.

By investing in proper cooling, you protect your devices from early breakdowns and save money on repairs or replacements. A quality heat sink is a simple way to ensure your electronics stay reliable for years.

heat sink types

When you select a cooling solution, you often choose between passive and active heat sinks. Each type offers unique benefits and fits different applications.

passive

A passive heat sink works without any moving parts. You rely on natural convection and radiation to move heat away from your device. This type suits low to moderate heat-generating components. You benefit from a simple design, lower cost, and almost no maintenance. Passive heat sinks last longer because they do not have fans or pumps that can fail. You often find them in small electronics, power supplies, and devices where silence and reliability matter most.

active

An active heat sink uses extra components, such as fans or pumps, to boost cooling. You see these in high-performance computers, gaming consoles, and industrial equipment. The fan or liquid system forces air or coolant over the heat sink, removing heat faster than passive designs. You get higher cooling capacity and better efficiency, but you must handle more maintenance and higher costs. Fans can collect dust, and pumps may need regular checks. Active heat sinks also take up more space and may produce noise.

Tip: Choose an active heat sink for powerful processors or graphics cards. For simple devices, a passive heat sink often works best.

Here is a quick comparison to help you decide:

| Factor | Active Heat Sinks | Passive Heat Sinks |

|---|---|---|

| Cooling Capacity | Higher, handles more heat with forced air or liquid | Lower, relies on natural airflow |

| Efficiency | More efficient due to increased airflow or coolant | Less efficient, depends on natural convection |

| Cost | More expensive, higher operational costs | Cheaper, minimal operational costs |

| Space | Needs more space for fans or pumps | Compact, fits tight spaces |

| Maintenance | Requires cleaning and monitoring | Negligible maintenance |

| Lifespan | Shorter, moving parts can wear out | Longer, no moving parts |

shapes

The shape of your heat sink affects how well it cools your device. You can choose from several designs, each with its own strengths.

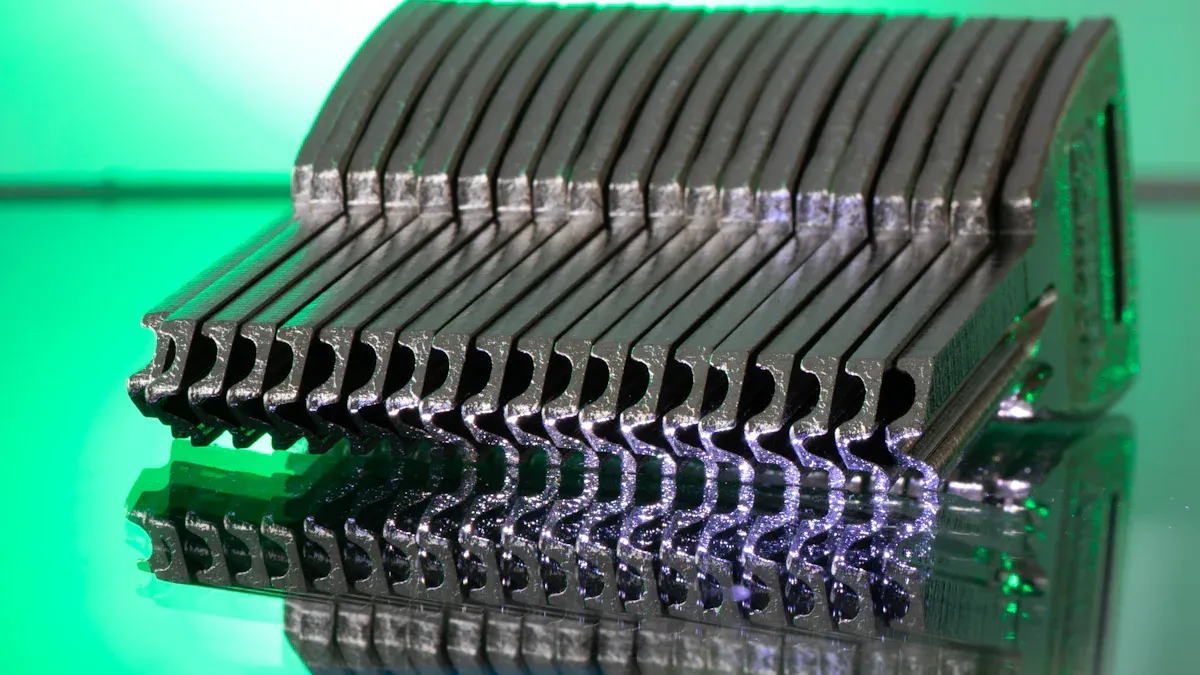

finned

Finned heat sinks use thin metal plates, or fins, to increase surface area. You get better heat transfer because more air touches the metal. Some designs use V-type or W-type fins to improve airflow and reduce resistance. Perforated fins create turbulence, which helps move heat away faster.

pin

Pin-fin heat sinks use a grid of pins instead of flat fins. You benefit from lower thermal resistance and higher heat transfer rates, especially with elliptical pins. Staggered pin arrays outperform straight-line designs by increasing turbulence and airflow. Pin-fin shapes work well in devices with unpredictable airflow.

plate

Plate-fin heat sinks use parallel plates to guide air over the surface. You see these in many electronics because they are easy to manufacture and install. However, airflow can slow down as it moves along the plates, limiting performance. V-type and W-type plate fins improve this by enhancing airflow and reducing resistance.

Here is a summary of how different shapes perform:

| Heat Sink Type | Performance Insights |

|---|---|

| Pin-Fin | Lower thermal resistance; elliptical pins give highest heat transfer rates |

| Plate-Fin | Limited by airflow; V-type fins improve performance |

| W-Type Plate-Fin | Reduces resistance; offers superior thermal performance |

- Perforated fins boost heat transfer by increasing turbulence.

- Staggered pin arrays provide better cooling than in-line pins.

- V-type and W-type fins enhance airflow and reduce thermal resistance.

By understanding these types and shapes, you can select the best cooling solution for your needs.

heat sink materials

When you choose a heat sink, the material matters as much as the design. The right material helps you move heat away from sensitive components quickly and efficiently. You often see three main types: aluminum, copper, and composites. Each offers unique advantages for different applications.

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Aluminum | 150–235 |

| Copper | ~400 |

| Steel | 50.2 |

| Ceramics | 40–400 |

aluminum

You find aluminum in most consumer electronics. Manufacturers prefer it because it is lightweight, affordable, and easy to shape. Aluminum offers good thermal conductivity, usually around 205 W/m·K. This means it transfers heat well, though not as quickly as copper. You benefit from its low cost and corrosion resistance. Laptops, LED lights, and power supplies often use aluminum heat sinks because they balance performance and price.

- Lightweight, so it does not add much weight to your device.

- Good thermal performance for most everyday electronics.

- Easy to machine into complex shapes, which increases surface area for better cooling.

- Resistant to rust, so it lasts longer in many environments.

Note: Aluminum works best when you need a balance between cost, weight, and cooling efficiency.

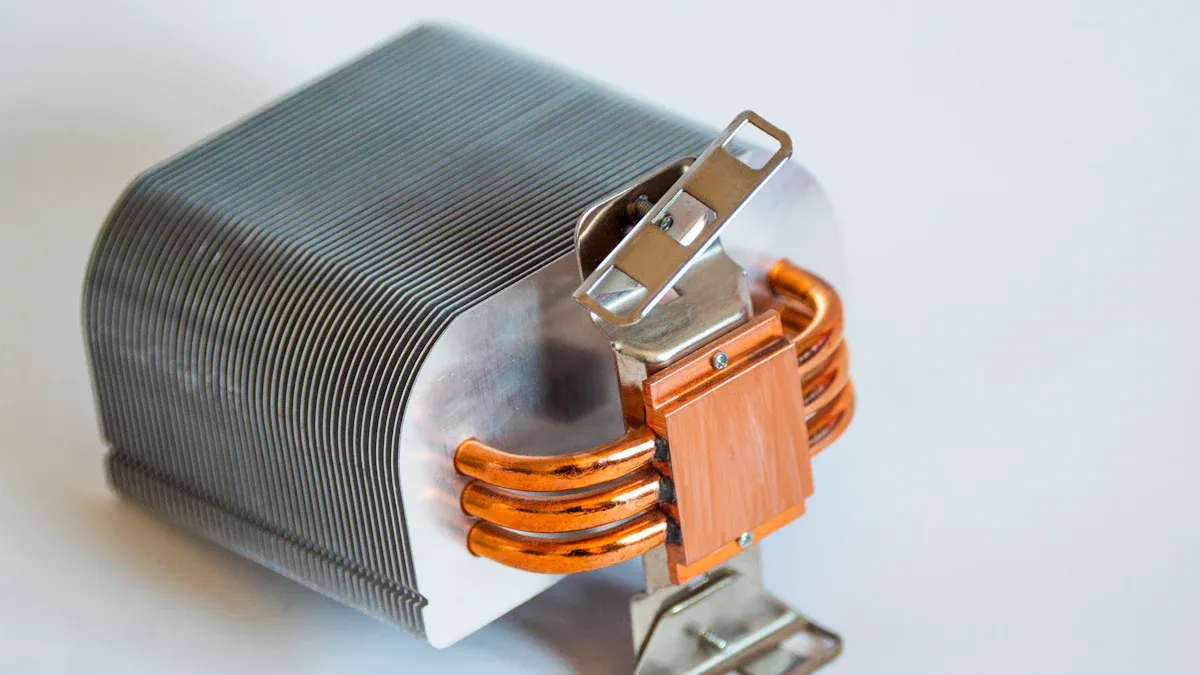

copper

You turn to copper when you need maximum heat transfer. Copper has a thermal conductivity of about 385–400 W/m·K, almost double that of aluminum. This high value means copper moves heat away from hot components very quickly. You often see copper in high-performance computers, gaming consoles, and industrial equipment.

- Superior thermal conductivity for rapid heat dissipation.

- Heavier than aluminum, which can add weight to your device.

- More expensive, so you usually find it in premium or specialized products.

- Can corrode over time, but many copper heat sinks use coatings to prevent this.

Tip: Choose copper if you need the best cooling for powerful processors or graphics cards.

composites

You also see composite materials in advanced heat sink designs. These combine metals like aluminum or copper with ceramics or graphite. Composites let you customize properties such as weight, strength, and thermal performance. Some ceramics offer thermal conductivity close to metals, ranging from 40 to 400 W/m·K. You benefit from composites when you need a specific balance of durability, electrical insulation, and heat transfer.

- Combine the strengths of different materials for specialized needs.

- Offer electrical insulation, which protects sensitive circuits.

- Used in aerospace, automotive, and high-end electronics.

When you select a heat sink, consider the material’s thermal conductivity, weight, and cost. The right choice ensures your device stays cool and performs at its best.

performance factors

size

You should always consider the size of your cooling solution. A larger heat sink can absorb and dissipate more heat because it has a greater surface area. When you use a bigger model, you give your device more room to transfer heat into the surrounding air. However, you must balance size with available space inside your device. Oversized heat sinks may not fit in compact electronics or may block airflow to other components. Manufacturers often use advanced materials and designs, such as fins or pin arrays, to maximize surface area without increasing overall size. Recent innovations, like 3D printing, allow you to create custom shapes that improve cooling without taking up extra space.

Tip: Choose the largest heat sink that fits your device for the best cooling, but always check for clearance and compatibility.

placement

Where you install your cooling solution matters just as much as its size. You want to place the heat sink directly on the component that generates the most heat, such as a processor or power transistor. Good contact ensures efficient heat transfer. You should also position it so that air can flow freely around the fins or pins. Avoid placing it near walls or other parts that block airflow. In some cases, you can use fans or ducts to direct air over the heat sink, boosting its performance. Hybrid cooling solutions, which combine passive and active methods, can increase efficiency by about 30%. Proper placement helps you get the most out of your cooling system and keeps your device running smoothly.

environment

Environmental conditions have a big impact on cooling efficiency. High ambient temperatures make it harder for your device to release heat. If you use your electronics in a hot room, the heat sink cannot cool as effectively. Airflow also plays a key role. Strong airflow increases the convective heat transfer coefficient, which means your device loses heat faster. The table below shows how ambient temperature and airflow affect performance:

| Ambient Temperature (°C) | Input Power (W) | Thermal Resistance (K/W) | Convective Heat Transfer Coefficient (W/m²K) |

|---|---|---|---|

| 40 | 33 | 2.75 | 32.17 |

| 30 | 33 | 2.80 | 30.68 |

| 40 | 33 | 3.81 | 19.61 |

You can see that higher ambient temperatures and lower airflow reduce cooling efficiency. To improve performance, you should keep your device in a cool, well-ventilated area. Recent advancements, such as liquid cooling and the use of advanced composites like graphene and copper, can boost thermal conductivity by up to 20%. These technologies help you maintain safe temperatures even in challenging environments.

installation

compatibility

You need to check compatibility before installing a heat sink. The right fit ensures your device runs safely and efficiently. Start by matching the heat sink’s size and shape to your electronic component. If the heat sink does not fit properly, it cannot transfer heat effectively. You should also verify that the heat sink meets the thermal requirements of your device. If you use a heat sink with insufficient cooling capacity, your component may overheat.

Consider the material as well. Some heat sinks use electrically non-conductive materials to prevent short circuits. You want to avoid accidental electrical contact that could damage your device. Pay attention to the coefficient of thermal expansion (CTE) of the heat sink material. If the CTE does not match your component, thermal stress can build up and cause cracks or failures over time.

Tip: Always check your system specifications and choose a heat sink designed for your exact model.

Key compatibility checks:

- Match the heat sink’s size and shape to your component.

- Confirm the heat sink meets your device’s thermal needs.

- Use electrically non-conductive materials to prevent shorts.

- Consider the CTE to reduce thermal stress.

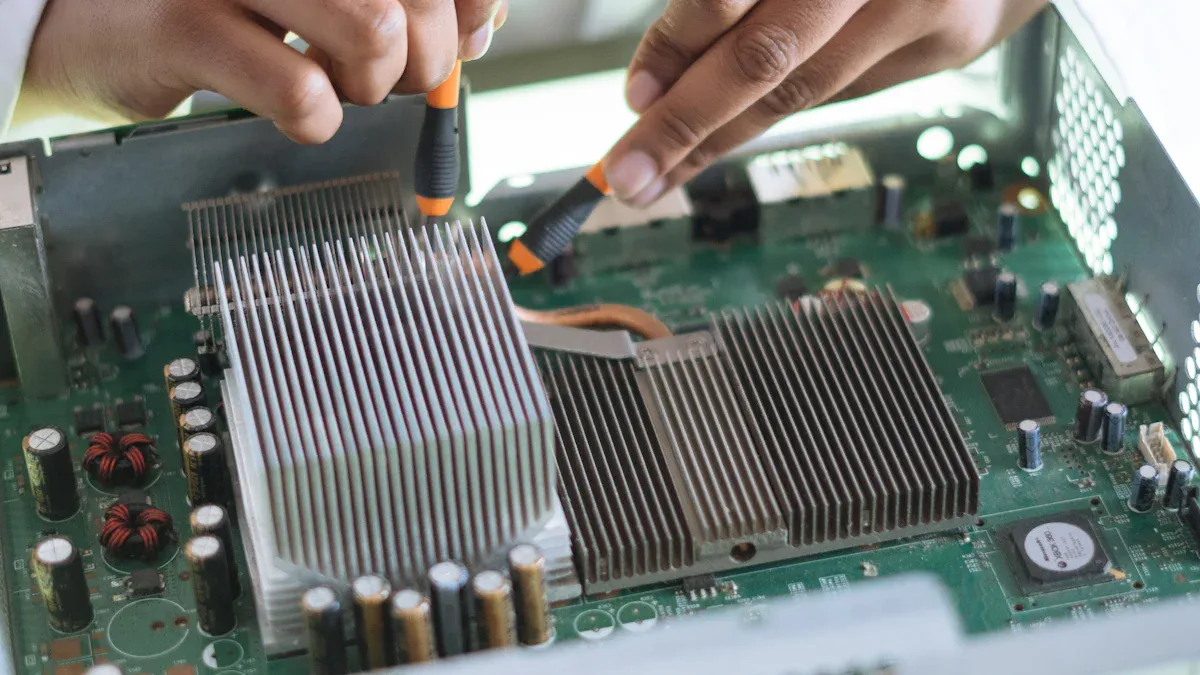

mounting

Proper mounting maximizes the heat sink’s performance. You want to ensure direct, even contact between the heat sink and the component. Clean the processor surface with isopropyl alcohol before installation. This step removes oils and dust, improving thermal conductivity. Apply a pea-sized amount of thermal paste to the center of the component. Avoid spreading it manually, as this can create air gaps.

Secure the heat sink evenly. Tighten screws in a cross pattern to distribute pressure. Uneven mounting can lead to poor heat transfer and overheating. Align the heat sink fins with the main airflow direction in your device. Good airflow helps carry heat away faster. For large heat sinks, use extra mounting points or support brackets to prevent movement.

Follow these best practices for mounting:

- Place high-power components close to the heat sink.

- Use thick copper planes on the PCB for better heat spreading.

- Add thermal vias under high-power parts.

- Align fins with airflow.

- Keep clear areas around the heat sink for mechanical clearance.

- Add temperature sensors near critical components.

- Separate high-power and low-power PCB sections.

- Design for EMI shielding if needed.

- Use extra supports for large heat sinks.

- Check that mounting fits your assembly process.

- For flexible PCBs, attach heat sinks to rigid sections.

Note: Blocked airflow and poor cable management can reduce cooling. Organize cables and keep vents clear.

maintenance

Regular maintenance keeps your heat sink working at its best. Dust and debris can build up between the fins, blocking airflow and trapping heat. Clean your heat sink every few months, or more often in dusty environments. Use compressed air to blow out dust from the fins. This simple step helps maintain optimal heat dissipation.

Check the thermal paste during maintenance. Over time, thermal paste can dry out and lose effectiveness. Reapply fresh thermal paste if you notice higher temperatures or if you remove the heat sink for cleaning. Always inspect for signs of corrosion or physical damage.

Maintenance checklist:

- Clean dust from the heat sink and fans regularly.

- Use compressed air to remove debris from fins.

- Check and reapply thermal paste as needed.

- Inspect for corrosion or damage.

Tip: Regular cleaning and proper mounting extend the life of your device and prevent overheating.

By following these steps, you ensure your heat sink delivers reliable cooling and protects your electronics for years to come.

cooling comparison

fans

You often see fans paired with heat sinks in computers and other electronics. Fans help move air across the fins or pins of a heat sink, which speeds up heat removal. This combination works well for most consumer devices. You get a balance between cost, performance, and ease of use. Fans can handle moderate to high heat loads, but they do have some drawbacks.

In testing with a 250W heat load, the Thermalright Frozen Prism produced noise levels of 53.2dBA, which was significantly higher than the Liquid Freezer III 360 at 39.8dBA. This indicates that while both coolers manage heat, the Frozen Prism is less efficient in terms of noise relative to its cooling performance.

You may notice that fans can get noisy, especially when they run at high speeds. Dust buildup can also reduce airflow and cooling efficiency. Regular cleaning helps, but you still need to replace worn-out fans over time. If you want a quiet system, you may need to look for larger, slower-spinning fans or advanced designs.

liquid cooling

Liquid cooling systems use pumps, tubes, and radiators to move heat away from your components. You get higher cooling efficiency because liquid absorbs and carries heat better than air. This method works best for high-performance computers, gaming rigs, and servers with dense hardware.

| Feature | Liquid Cooling Systems | Heat Sinks (Air Cooling) |

|---|---|---|

| Heat Dissipation Efficiency | High due to direct contact with cooling medium | Relatively low, relies on fan to exhaust hot air |

| Heat Capacity | Large, can absorb more heat, improving stability | Limited, may lead to overheating in high temperatures |

| Cost | Higher due to additional equipment and complexity | More cost-effective, simpler structure |

| Maintenance | Requires professional support and regular checks | Simpler maintenance, no need for media replacement |

You benefit from liquid cooling if you need to keep temperatures low under heavy loads. However, you must consider the higher cost and more complex setup. Maintenance can be challenging, as you need to check for leaks and replace coolant. For most users, air-cooled heat sinks offer enough performance with less hassle.

selection

You should choose your cooling solution based on your needs and environment. Start by looking at your device’s heat output and how much space you have for cooling hardware. Consider the climate where you use your device, as high ambient temperatures make cooling harder. Think about noise levels, maintenance, and your budget.

| Criteria | Description |

|---|---|

| Location | Climate, load, and adopted codes and ordinances |

| Building characteristics | Equipment placement |

| Indoor environmental quality | Ventilation, filtration, comfort, and noise |

| Cost | First cost, operational cost, and risk of failure |

- Choose a cooling solution for long-term reliability and ease of maintenance.

- Look for systems that offer:

- Accessible service panels and diagnostics

- Readily available replacement parts

- Support from experienced service technicians

- Clear manufacturer warranties

When you select a liquid cooling system, check your device’s cooling requirements, such as the Thermal Design Power (TDP) and hardware density. For most home and office devices, a well-designed heat sink with a fan provides reliable, quiet, and cost-effective cooling. For high-performance or specialized systems, liquid cooling may offer the best results. Always match your cooling solution to your specific needs for the best performance and reliability.

You rely on a heat sink to protect your devices from heat damage and ensure reliable performance. Choosing the right type and material is essential for long-term success.

- Determine your device’s power needs and select a design that matches.

- Compare materials—aluminum offers light weight, copper provides superior heat transfer.

| Material | Thermal Conductivity (W/mK) | Notes |

|---|---|---|

| Aluminum | 205 | Lightweight, cost-effective |

| Copper | 398 | Best for high heat loads |

Select wisely to keep your electronics safe and efficient in today’s fast-paced world.

FAQ

What is the main purpose of a heat sink?

You use a heat sink to move heat away from electronic components. This process keeps your devices cool and prevents overheating. A heat sink helps your equipment run safely and efficiently.

How do you know if your device needs a heat sink?

You should check if your device gets hot during use. If you notice performance drops, crashes, or high temperatures, you likely need a heat sink. High-power processors and graphics cards almost always require one.

Can you use any heat sink for any device?

No, you must match the heat sink to your device’s size, shape, and power needs. Using the wrong type can lead to poor cooling or even damage.

How often should you clean your heat sink?

You should clean your heat sink every three to six months. Dust and debris can block airflow and reduce cooling. Use compressed air for best results.

What happens if you do not use a heat sink?

- Your device may overheat.

- You risk permanent damage to components.

- Performance drops and system crashes can occur.

Which material is better: aluminum or copper?

| Material | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, affordable | Lower conductivity |

| Copper | Superior heat transfer | Heavier, more costly |

You should choose based on your device’s needs and budget.

Do heat sinks work without fans?

Yes, passive heat sinks work without fans. You rely on natural airflow and radiation. These work best for low to moderate heat loads. For high-performance devices, you should use a fan for extra cooling.