How does a heat sink work

A heat sink works by pulling heat away from electronic parts so they stay cool and safe. You rely on this simple device to keep your computer, phone, or game console running smoothly. Too much heat can cause serious problems.

- Overheating leads to more than 55% of electronic device failures.

You need a heat sink because it prevents damage and keeps your devices working longer.

Key Takeaways

- A heat sink keeps electronic devices cool by absorbing and spreading heat away from sensitive components.

- Overheating can cause more than 55% of electronic device failures, making heat sinks essential for device longevity.

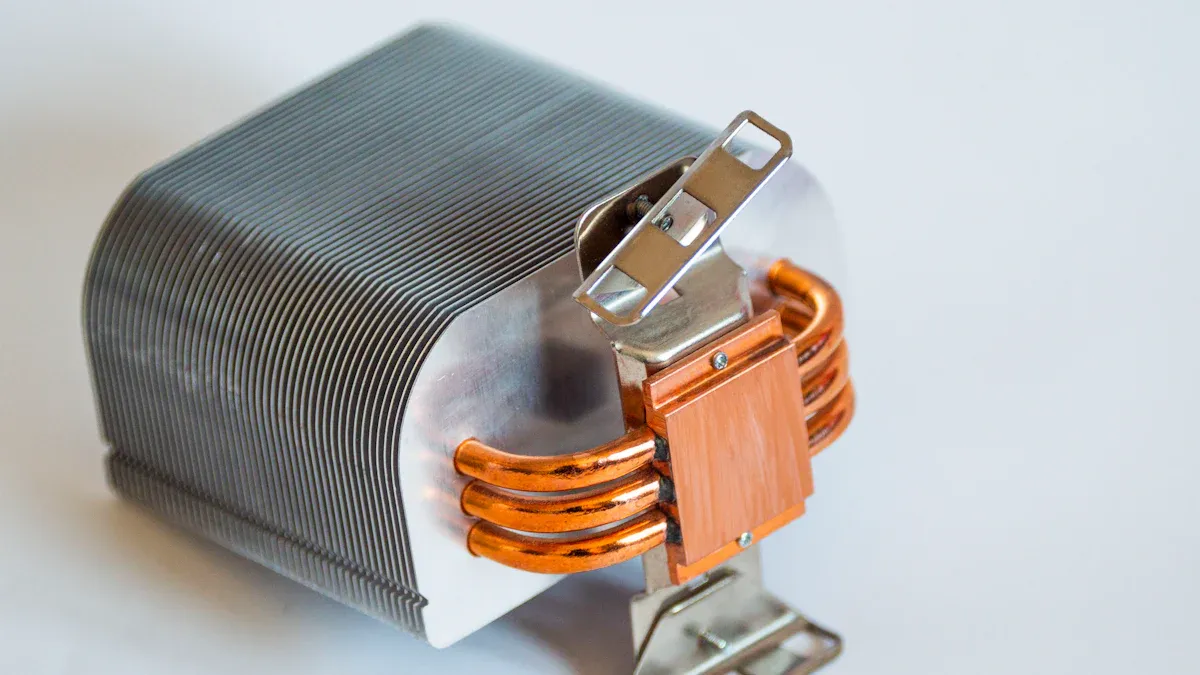

- Heat sinks use materials like aluminum and copper for their excellent heat transfer properties, with copper being more efficient but heavier.

- Effective heat sinks rely on conduction, convection, and radiation to manage heat, ensuring devices operate safely.

- Fins on heat sinks increase surface area, allowing more heat to escape and improving cooling performance.

- Proper airflow around heat sinks is crucial; using fans can significantly enhance cooling efficiency.

- Regular maintenance, such as cleaning dust from heat sinks and vents, helps prevent overheating and extends device life.

- Choosing the right heat sink for your device’s power and size is vital to ensure effective cooling and prevent damage.

Heat Sink Basics

What Is a Heat Sink

You encounter heat sinks in many electronic devices. A heat sink is a passive device that absorbs heat from components like processors and spreads it out so the heat can escape into the air. You need a heat sink because electronic parts generate heat during operation. If you let this heat build up, your device can slow down, malfunction, or even fail. The heat sink acts as a bridge, moving heat away from sensitive parts and helping your device stay cool.

You often see heat sinks made from aluminum alloys or copper. These materials work well because they transfer heat quickly. Take a look at the table below to see why manufacturers choose these materials:

| Material | Thermal Conductivity (W/mK) | Advantages | Disadvantages |

|---|---|---|---|

| Aluminum Alloys | 205 | Affordable, lightweight, good thermal conductivity | Less efficient than copper |

| Copper | 400 | Exceptional thermal conductivity, ideal for high-performance cooling | Heavier, more expensive than aluminum |

Main Function

You rely on heat sinks to keep your electronics safe. The main function of a heat sink is to absorb heat from components and release it into the surrounding air. This process prevents overheating and keeps your device running smoothly. You can think of a heat sink as a safety net for your electronics. Without it, parts like CPUs and GPUs would get too hot and stop working.

Tip: If your device feels warm during use, the heat sink is working hard to protect it.

Here are the key roles a heat sink plays:

- Dissipates excess heat from electronic components

- Maintains safe temperature limits

- Ensures efficient operation and prevents damage

Where Heat Sinks Are Used

You find heat sinks in many places because they solve the problem of overheating. Here are some common devices that rely on heat sinks for thermal management:

- Central Processing Units (CPUs)

- Graphics Processing Units (GPUs)

- Power Electronics

- Integrated Circuits (ICs)

- LEDs and Displays

You also see heat sinks in different industries. The table below shows where heat sinks play a vital role:

| Industry | Application Examples |

|---|---|

| Electronics | Consumer and enterprise electronics, telecommunications |

| Automotive | Automotive cooling systems |

| Medical Devices | Medical device thermal management |

| Industrial | Industrial applications requiring thermal management |

You depend on heat sinks in everything from your laptop to your car. These devices need heat sinks to keep working reliably and safely. When you use electronics, you benefit from the increased surface area that heat sinks provide, which helps dissipate heat and extends the life of your device.

Heat Transfer

Heat sinks protect your electronics by moving heat away from sensitive components. You rely on three main methods for this process: conduction, convection, and radiation. Each method plays a unique role in keeping your devices cool and safe.

Conduction

Conduction acts as the first step in heat transfer. You can picture it like passing a hot potato from your hand to a metal tray. The heat travels directly from the electronic component into the heat sink. This happens because the heat sink touches the component, allowing energy to move through the solid materials.

- Conduction is critical for transferring heat from the heat source to the heat sink.

- Heat moves through the component’s metal or semiconductor substrate.

- The contact area between the component and the heat sink matters. A larger area lets more heat flow.

- Materials like copper and aluminum work best because they have high thermal conductivity.

- Direct contact allows heat to transfer through molecular interactions.

- Thermal interface materials, such as thermal paste, help fill tiny gaps and improve contact.

You need effective conduction to spread heat throughout the heat sink before it can escape. If the heat sink uses poor materials or has a small contact area, your device may overheat.

Convection

Convection takes over once heat reaches the surface of the heat sink. You can think of it as the breeze that cools you off on a hot day. The heat sink releases energy into the surrounding air, which carries the heat away.

- Convective heat transfer moves heat from the heat sink to the air.

- Natural convection happens when warm air rises and cooler air flows in to replace it. This process works well for passive heat sinks.

- Forced convection uses fans to push air over the heat sink, increasing cooling power. You see this in computers and gaming consoles.

You depend on convection to remove heat from the heat sink and keep your device at a safe temperature. Without airflow, heat would build up and threaten your electronics.

Radiation

Radiation provides another way for heat to leave the heat sink. You can imagine it as warmth you feel from the sun, even if the air is cool. The heat sink emits energy as infrared waves, which travel through the air without needing direct contact.

| Condition | Significance of Radiation |

|---|---|

| Low Reynolds Numbers | Radiation is important when velocities < 5 m/s. |

| Large Body Dimensions | Increased boundary layer thickness enhances radiative contribution. |

| Forced Convection | Radiation can often be neglected unless specific conditions are met. |

- In low-air velocity situations, radiation becomes more important.

- The percentage of heat lost through radiation increases as the heat sink gets hotter.

- At higher temperatures, radiation can account for over 5% of total heat dissipation.

You benefit from radiation when convection is limited, such as in tightly packed devices or low airflow environments. Radiation helps keep temperatures in check, especially when other cooling methods cannot keep up.

Tip: You get the best cooling when all three methods—conduction, convection, and radiation—work together. This combination protects your electronics and extends their lifespan.

How a Heat Sink Works

Absorbing Heat

You rely on a heat sink to absorb heat from electronic components and keep your devices safe. This process starts with careful planning and precise installation. Here is how you ensure your heat sink absorbs heat effectively:

- You determine the thermal resistance of the heat sink. Lower thermal resistance means better heat absorption.

- You calculate the size of the heat sink based on the power your component will dissipate, the ambient temperature, and the maximum safe temperature for the device.

- You cut the heat sink to the right size if needed, making sure it fits perfectly.

- You attach the heat sink directly to the component, creating a solid contact area.

- You use a mica insulator and a thermo-conductive silicone or silver paste, or a flexible silicone insulator, to improve thermal contact and provide electrical isolation.

- You may add a fan to boost heat absorption and dissipation if your device generates a lot of heat.

Note: You need good thermal contact between the heat sink and the component. Thermal paste fills tiny gaps, making heat transfer more efficient.

You follow these steps because poor absorption leads to overheating and device failure. Each step helps you maximize the heat sink’s ability to protect your electronics.

Spreading Heat

Once your heat sink absorbs heat, it must spread that energy across its structure. You benefit from this process because it prevents hot spots and allows for more efficient cooling. Here are the main ways your heat sink spreads heat:

- Heat pipes move large amounts of heat with minimal temperature difference, helping distribute energy quickly.

- Vapor chambers use a solid metal enclosure to transfer heat evenly and smooth out temperature differences.

- Heat spreaders conduct thermal energy from the source to a secondary cooler, using materials with high thermal conductivity.

- Solid heat spreaders, often made of copper or aluminum, transfer heat away from the source efficiently.

- Phase-change mechanisms, like heat pipes and vapor chambers, use the latent heat of vaporization to transport heat. The working fluid inside vaporizes at the hot end, travels to a cooler area, condenses, and returns to the heat source, repeating the cycle.

You need effective heat spreading because it allows the heat sink to use its entire surface area for cooling. This process keeps your device running smoothly and prevents damage from localized overheating.

Releasing Heat

After your heat sink absorbs and spreads heat, it must release that energy into the surrounding environment. You depend on three main mechanisms for this process:

| Mechanism | Description |

|---|---|

| Convection | Heat transfers as air moves over the heat sink, carrying energy away from the surface. |

| Conduction | Heat moves through the air in direct contact with the heat sink, transferring thermal energy. |

| Radiation | The heat sink emits thermal energy as infrared radiation, which depends on its temperature. |

You rely on convection as the primary way your heat sink releases heat, especially when fans increase airflow. Conduction helps transfer heat to the air touching the heat sink, while radiation becomes more important at higher temperatures or in low-airflow environments.

Tip: You get the best cooling when your heat sink uses all three mechanisms together. This combination keeps your electronics safe and extends their lifespan.

Role of Fins and Surface Area

You depend on fins and surface area to make your heat sink work efficiently. When you look at a heat sink, you often see rows of thin metal fins. These fins play a critical role in cooling because they increase the surface area available for heat to escape.

- Fins allow heat to spread over a larger area, which helps your device cool down faster.

- More surface area means more space for heat to transfer from the heat sink into the air.

- Fins boost convection cooling by letting air flow around and between them, carrying heat away.

- A larger contact surface speeds up heat transfer, keeping your electronics at safe temperatures.

Tip: If you notice your device has many thin fins on its heat sink, it is designed for better cooling performance.

You need fins and increased surface area because they help prevent overheating. Without them, heat would build up quickly, and your device could fail. Fins make sure heat leaves the heat sink as efficiently as possible, protecting your electronics and extending their lifespan.

Airflow and Cooling

You rely on airflow to maximize the cooling power of your heat sink. Air moves heat away from the surface, and this process becomes even more effective when you use fans or other forced convection methods.

The cooling performance of a heat sink improves dramatically with good airflow. Studies show that when you increase the velocity of air moving through the fins, the heat transfer coefficient rises. Overlapping heat sinks can boost cooling by up to 35% because faster airflow carries heat away more quickly. You do not need to change the shape of the heat sink to see these benefits—just manage airflow well.

Note: You can improve cooling by keeping vents clear and using fans to direct air over the heat sink.

You need proper airflow because it helps your device stay cool under heavy use. Without enough air movement, heat can get trapped, causing temperatures to rise and risking damage. Airflow works together with fins and surface area to keep your electronics safe and reliable.

Heat Sink Types

You have several options when choosing a heat sink for your device. Each type offers unique benefits and works best in different situations. Understanding these types helps you pick the right cooling solution and keep your electronics safe.

Passive Heat Sink

You use passive heat sinks when you want silent and reliable cooling. These heat sinks do not need fans or external power. They rely on conduction and convection to move heat away from your device. Conduction transfers heat from the component to the heat sink, just like heat travels along a metal rod. Convection lets the heat escape into the air as it rises naturally.

Passive heat sinks often feature large finned structures. These fins increase the surface area, allowing more heat to dissipate. Manufacturers use materials like aluminum and copper because they transfer heat quickly. Designers use computer simulations to create shapes that help air flow around the fins without needing fans.

- Silent operation keeps your device quiet.

- No moving parts mean less risk of failure.

- You save energy because passive heat sinks do not use electricity.

You find passive heat sinks in low-wattage devices, such as routers and small LED lights. These devices do not generate much heat, so passive cooling works well.

Active Heat Sink

You choose active heat sinks when your device needs powerful cooling. These heat sinks use fans or pumps to move air or liquid over the surface, speeding up heat removal. You see active heat sinks in computers, gaming consoles, and servers, where components like CPUs and GPUs produce a lot of heat.

Active heat sinks include several extra parts that boost cooling:

| Component | Function |

|---|---|

| Fans | Circulate air to increase heat dissipation. |

| Pumps | Move liquid coolant for better performance. |

| Heat Pipes | Transfer heat efficiently from the source to the heat sink. |

| Thermal Interface Materials (TIM) | Improve contact between the heat sink and electronic parts. |

Active cooling gives you superior thermal performance and precise temperature control. You can use compact designs for high-performance devices. However, fans and pumps make noise and require power.

Hybrid Heat Sink

You benefit from hybrid heat sinks when you need flexibility. These heat sinks combine a passive base with an optional fan. You can switch between silent passive cooling and powerful active cooling, depending on your device’s temperature.

Hybrid heat sinks work well in smart devices and power-saving electronics. You get quiet operation during light use and extra cooling when your device heats up. This design helps you save energy and reduce noise.

Hybrid heat sinks are especially useful when your device faces changing power levels or when you want to minimize noise. You get the advantages of both passive and active cooling, making your device more efficient and reliable.

Tip: If you want a cooling solution that adapts to your needs, consider a hybrid heat sink.

Here is a quick comparison of the three types:

| Type of Heat Sink | Characteristics | Applications |

|---|---|---|

| Passive | No moving parts, relies on natural convection, best for low-power systems | Low-wattage devices |

| Active | Includes a fan, requires power, offers faster cooling | CPUs, GPUs, servers |

| Hybrid | Combines passive base with optional fan, can switch modes | Smart or power-saving devices |

You make the best choice by matching the heat sink type to your device’s needs. This decision helps you prevent overheating and keep your electronics running smoothly.

Performance Factors

Material Choice

You need to pay close attention to the material of your heat sink because it directly affects how well your device stays cool. The type of metal you choose changes how quickly heat moves away from sensitive components. Here’s why material matters:

- Copper has a higher thermal conductivity than aluminum. This means copper spreads heat more evenly and keeps the temperature across the heat sink uniform.

- You benefit from copper’s higher volumetric heat capacity, which lets it handle bigger thermal loads without overheating.

- The density of copper gives it an edge in thermal performance, especially in demanding applications.

- Aluminum stands out for its lightweight nature and lower cost. You often see aluminum heat sinks in consumer electronics because they are easier to manufacture and install.

- Each material brings unique benefits. Aluminum resists corrosion and is easy to shape, while copper excels at transferring heat but adds weight and expense.

Tip: You should choose copper for high-performance cooling and aluminum for lightweight, budget-friendly solutions.

| Material | Thermal Conductivity | Weight | Cost | Durability | Best Use Case |

|---|---|---|---|---|---|

| Copper | High | Heavy | High | Good | High-power devices |

| Aluminum | Moderate | Light | Low | Excellent | Everyday electronics |

Design and Size

You must consider the design and size of your heat sink because these features control how efficiently heat escapes. The shape and arrangement of fins, the overall size, and the type of material all work together to keep your device safe. Here’s why design and size matter:

- Thermal resistance measures how much heat faces obstacles as it moves through the heat sink. Lower resistance means better cooling.

- The arrangement, shape, and location of fins play a big role. Fins increase surface area, letting more heat transfer into the air.

- You need to match the size of the heat sink to your device’s power output. A heat sink that is too small cannot remove enough heat, risking overheating.

- Oversized heat sinks may waste space and add unnecessary weight without improving performance.

Note: You should look for a heat sink with well-designed fins and the right size for your device’s needs.

Placement

You must place your heat sink correctly to get the best cooling results. Where you position the heat sink inside your device changes how well it can move heat away. Here’s why placement matters:

- Proper sizing and selection optimize cooling efficiency. If you pick a heat sink that fits your device and matches its heat output, you prevent overheating.

- Placing heat sinks in the right spots, especially near the hottest components, helps lower peak temperatures.

- Segregating heat sinks on different heat-generating parts improves cooling. You avoid hot spots and keep your device running smoothly.

- If you put a heat sink in a cramped or poorly ventilated area, airflow drops and cooling suffers.

Tip: You should always check that your heat sink has enough space and airflow around it for maximum performance.

You need to think about material, design, size, and placement because each factor helps your heat sink protect your electronics. When you make smart choices, you keep your devices cool, safe, and reliable.

Importance

Preventing Overheating

You need a heat sink because it protects your electronics from overheating. When your device runs, it generates heat. If you do not control this heat, your device can slow down or stop working. You face several common causes of overheating:

- Excessive heat loads can overwhelm your device’s cooling system.

- Poor airflow or blocked vents trap heat inside.

- Incorrect application of thermal interface material reduces heat transfer.

- Dust builds up on surfaces, creating an insulating layer that blocks cooling.

You can avoid these problems by using a heat sink that matches your device’s needs. Good airflow and regular cleaning help your heat sink work better. When you keep your device cool, you prevent sudden shutdowns and keep performance steady.

Tip: You should check your device’s vents and clean them often to help your heat sink do its job.

Device Longevity

You want your electronics to last as long as possible. A heat sink plays a key role in extending the life of your device. When you use a heat sink, you manage the heat that builds up during operation. This keeps internal temperatures safe and prevents wear and tear on sensitive parts.

- Heat sinks preserve performance and longevity by dissipating heat.

- They prevent overheating, which can cause components to fail early.

- Proper heat management becomes more important as devices get smaller and generate more heat.

- By absorbing and spreading excess heat, heat sinks maintain optimal operating temperatures.

You benefit from a longer-lasting device when you use effective cooling. Your computer, phone, or gaming console stays reliable, and you avoid costly repairs or replacements.

Note: You can extend your device’s lifespan by making sure the heat sink is clean and installed correctly.

Risks Without a Heat Sink

You face serious risks if your device does not have a proper heat sink. Without effective cooling, heat builds up and causes damage. The table below shows what can happen when you ignore heat management:

| Risk/Failure | Description |

|---|---|

| Performance Degradation | Overheating leads to slower speeds and reduced efficiency. |

| Reduced Lifespan | Excessive heat shortens the life of electronic components. |

| Thermal Runaway | Rising temperatures cause even more heat, risking total failure. |

| Catastrophic Failures | Severe overheating can result in fires or complete device breakdown. |

| Component Degradation | Parts lose functionality due to constant exposure to high temperatures. |

| Premature Failure | Devices stop working much earlier than expected. |

You can avoid these risks by choosing the right heat sink and maintaining it well. When you protect your device from heat, you keep it running safely and efficiently.

⚠️ Always pay attention to signs of overheating, such as unexpected shutdowns or hot surfaces. Quick action can prevent permanent damage.

Choosing a Heat Sink

Matching to Device

You need to match the right heat sink to your device to prevent overheating and keep your electronics working efficiently. If you choose the wrong heat sink, your device may run too hot, which can shorten its lifespan or cause sudden failures. You should consider several important criteria when making your choice:

- Evaluate the maximum power your device will dissipate. This helps you understand how much heat the heat sink must handle.

- Calculate the expected temperature rise. You want to keep your device below its safe operating temperature.

- Determine the thermal conductivity of the material. Materials like copper and aluminum transfer heat well.

- Measure the available mounting area. The heat sink must fit your device without blocking other components.

- Consider any size or shape restrictions. Some devices have limited space for cooling solutions.

- Assess possible fin configurations. Fins increase surface area and improve cooling.

- Analyze how airflow will affect performance. Good airflow helps the heat sink release heat faster.

- Balance performance with cost. You want effective cooling without overspending.

You make these choices because each factor affects how well your heat sink can protect your device. If you ignore these steps, you risk poor cooling and device failure.

Installation Tips

Proper installation ensures your heat sink works as intended. If you install it incorrectly, you may lose thermal contact or block airflow, which reduces cooling efficiency. You should follow best practices to get the best results:

- Place high-power components close to the heat sink for better heat transfer.

- Use thick copper planes and connect multiple layers with thermal vias to spread heat evenly.

- Add an array of thermal vias under high-power parts to move heat away quickly.

- Align the fins with the direction of airflow. This helps air move through the heat sink and carry heat away.

- Leave enough space around the heat sink for mechanical clearance.

- Install temperature sensors near critical parts to monitor heat levels.

- Separate high-power and low-power areas on your circuit board to control heat flow.

- Design for electromagnetic interference (EMI) shielding if needed.

- Add extra mounting points for large heat sinks to reduce stress on your device.

- Use thermal simulation software to test your design before building.

- Make sure your mounting method matches your assembly process.

- For flexible circuit boards, attach the heat sink to rigid sections.

You follow these steps because good installation improves heat transfer and prevents damage. Skipping these tips can lead to overheating and costly repairs.

Maintenance

You need to maintain your heat sink to keep your device cool and reliable. Dust and debris can block airflow, which reduces cooling performance. Regular maintenance helps you avoid these problems.

- Schedule inspections at least every three months. This helps you catch issues before they cause overheating.

- Check your heat sinks, fans, and vents every month. Remove dust and debris to keep air moving freely.

Tip: Clean your device’s vents and heat sinks with a soft brush or compressed air. This simple step can extend your device’s life.

You perform maintenance because a clean heat sink works better. If you neglect this task, your device may overheat, slow down, or fail unexpectedly. Regular care ensures your electronics stay safe and efficient.

Heat sinks redirect heat flow away from hot devices by increasing surface area, keeping components safe from overheating.

You depend on proper cooling to keep your electronics reliable and efficient. When you use a heat sink, you protect your devices from costly repairs and extend their lifespan.

- Steady thermal control prevents failures.

- High-performance systems run better at safe temperatures.

- Regular maintenance boosts reliability.

Consider checking your devices for dust or blocked vents. Explore more about cooling solutions to keep your electronics performing at their best.

FAQ

Why do you need a heat sink in electronics?

You need a heat sink because it prevents your device from overheating. Without it, heat builds up and damages sensitive parts. A heat sink keeps your electronics safe and running smoothly.

Why does a heat sink have fins?

You see fins on a heat sink because they increase the surface area. More surface area lets more heat escape into the air. Fins help your device cool down faster and work more efficiently.

Why should you clean your heat sink regularly?

Dust and debris block airflow around your heat sink. When you clean it, you let air move freely. This helps your heat sink remove heat better and keeps your device from overheating.

Why do some heat sinks use fans?

Fans push air over the heat sink, which removes heat faster. You need fans when your device produces a lot of heat. Fans help keep temperatures low during heavy use.

Why does material choice matter for heat sinks?

Different materials transfer heat at different rates. Copper and aluminum move heat quickly, so your device stays cooler. Choosing the right material helps your heat sink work better.

Why can a device fail without a heat sink?

Without a heat sink, heat stays trapped inside your device. High temperatures cause parts to slow down, break, or stop working. You risk losing your device much sooner.

Why do you need to match the heat sink to your device?

Each device creates a different amount of heat. You need a heat sink that fits your device’s size and power. The right match ensures safe temperatures and reliable performance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.