How to Choose the Right Industrial Heat Sink for Your Application

Selecting an industrial heat sink requires you to match thermal performance, material, and design to your cooling requirements. If you choose incorrectly, you risk overheating, inefficiency, and equipment failure. The table below shows common consequences in manufacturing environments:

| Consequence | Description |

|---|---|

| Overheating | Can lead to reduced performance and potential damage to components. |

| Inefficiency | Results in higher operational costs and energy consumption. |

| Equipment failure | Frequent system failures can occur, leading to costly downtime. |

| Poor thermal performance | Improper fit or mounting can cause mechanical instability. |

| Increased operational expenses | Choosing low-cost options may lead to higher long-term costs. |

You must evaluate both technical calculations and practical constraints to achieve reliable cooling.

Key Takeaways

- Identify all heat sources in your system to understand total thermal load. This step is crucial for effective cooling.

- Calculate power dissipation accurately to determine how much heat your heat sink must remove. Use the formula: Power Dissipation = Pin – Pout.

- Know the maximum allowable temperature for each component. Exceeding this limit can cause damage and reduce lifespan.

- Select the right type of heat sink based on your application needs. Options include extruded, bonded, skived, stamped, forged, and CNC machined.

- Consider thermal resistance values when choosing a heat sink. Lower values indicate better heat dissipation.

- Evaluate cooling methods carefully. Passive cooling is simple and quiet, while active cooling offers higher capacity but requires maintenance.

- Pay attention to fin design and surface finish. These factors significantly impact heat dissipation efficiency.

- Always verify manufacturer data and test conditions to ensure compatibility with your specific application.

Thermal Requirements

Understanding your system’s thermal requirements forms the foundation for selecting the right industrial heat sink. You need to identify all sources of heat, calculate power dissipation, and determine the maximum allowable temperature for safe operation. This process ensures your cooling solution matches the demands of your application.

Heat Sources

Start by identifying every component in your assembly that generates heat. Each part contributes to the total thermal load. The table below outlines common heat-generating elements and factors that influence heat buildup:

| Component Type | Description |

|---|---|

| Power Components | Significant heat generators like voltage regulators and amplifiers. |

| High-Frequency Components | Generate substantial heat, e.g., microprocessors and radio-frequency modules. |

| Compact Layouts | Densely packed components can lead to heat buildup due to airflow restrictions. |

| Environmental Factors | Conditions like ambient temperature and humidity affect heat dissipation. |

You should also consider these best practices when evaluating heat sources:

- Use thermal interface materials to improve heat transfer between surfaces.

- Increase the surface area of high power density components to keep temperatures within safe limits.

- Implement thick copper traces for better heat distribution in high-power circuits.

Note: Thermal interface materials eliminate air gaps and optimize heat transfer. This step significantly improves cooling performance and the reliability of your industrial heat sink solution.

Power Dissipation

After identifying heat sources, calculate the total power dissipation. This value tells you how much heat your industrial heat sink must remove. Use the following approach:

- Calculate power dissipation as the difference between input and output power:

Power Dissipation = Pin - Pout - Assess the efficiency of your system using the formula:

Efficiency (ƞ) = Pout / Pin - Analyze critical components such as voltage regulators, transistors, and diodes under maximum load conditions. This ensures you do not exceed their safe operating limits.

You can also follow a systematic process to determine the total thermal load in your system:

| Step | Description |

|---|---|

| 1 | Estimate heat load by assuming all electrical energy is converted to heat. |

| 2 | Use the heat transfer equation: Q = m x Cp x ΔT. |

| 3 | Obtain values for mass flow rate (m) and temperature change (ΔT) experimentally. |

| 4 | Measure temperature differential using Type ‘T’ Thermocouples. |

| 5 | Measure flow rate using a Turbine Flow Meter. |

| 6 | Compute heat load using the specific heat of the fluid and the heat transfer equation. |

This step-by-step approach helps you accurately size your industrial heat sink for the application.

Maximum Temperature

You must know the maximum allowable temperature for each component and the overall system. Exceeding this limit can cause permanent damage or reduce the lifespan of your equipment. Industry standards provide guidance on safe temperature ranges for different heat sink types:

| Heat Pipe Type | Maximum Temperature (°C) | Material Used |

|---|---|---|

| Standard Heat Pipes | 250-300 | Standard metals |

| High-Temperature Heat Pipes | Up to 500 | Ceramic or refractory metals |

Always check the manufacturer’s datasheets for the recommended maximum temperature of your components. Select an industrial heat sink that keeps all parts below these thresholds, even under worst-case operating conditions.

Tip: Monitoring ambient temperature and humidity in your facility helps you anticipate changes in cooling performance and adjust your heat sink selection accordingly.

Thermal Resistance

Thermal resistance plays a critical role in determining how effectively your heat sink can transfer heat away from sensitive components. You need to understand how to calculate this value, recognize its practical limits, and interpret the data provided by manufacturers.

Calculation Formula

You can calculate thermal resistance to estimate how well your heat sink will perform in your application. The most common approach uses the temperature difference between the heat source and the environment, divided by the amount of heat that must be dissipated. The following table summarizes the key formulas:

| Formula | Description |

|---|---|

| ( R_{\mathrm{th}} = \frac{ \Delta T_{\mathrm{max}} } {Q [\mathrm{K/W}]} ) | Thermal resistance using maximum temperature difference. |

| ( R_{\mathrm{ins}} = \frac{\Delta T}{q [\mathrm{m^2 K/W}]} ) | Thermal insulance using average temperature difference. |

You should use these formulas to determine the required thermal resistance for your industrial heat sink. Lower thermal resistance values indicate better heat dissipation. Always ensure your calculations reflect the worst-case operating conditions.

Tip: When you calculate thermal resistance, use the maximum expected power dissipation and the highest allowable component temperature. This approach helps you avoid overheating and ensures long-term reliability.

Application Limits

Different types of heat sinks offer a wide range of thermal resistance values. You must select a heat sink that matches your application’s cooling requirements. The table below shows typical thermal resistance values for common industrial heat sink types:

| Heat Sink Type | Thermal Resistance (°C/W) |

|---|---|

| Large extruded aluminium (TO-3) | 0.4 |

| Clip-on heat sink (TO-92) | up to 85 |

Large extruded aluminum heat sinks provide very low thermal resistance, making them suitable for high-power applications. Clip-on heat sinks, on the other hand, have much higher thermal resistance and work best for low-power components. Always compare your calculated requirement with these typical values to ensure proper selection.

Note: If your application requires a thermal resistance lower than what standard products offer, you may need to consider custom designs or enhanced cooling methods.

Manufacturer Data

Manufacturers provide thermal resistance data to help you choose the right heat sink, but you must interpret this information carefully. Consider the following points when reviewing manufacturer specifications:

- Manufacturers often report thermal resistance from junction to case (Rth,j-c) because they cannot guarantee the complete thermal path from junction to ambient.

- The lack of information about your mounting method, heat sink dimensions, and coolant conditions can affect the accuracy of reported values.

- For modules with integrated heat sinks, manufacturers may provide junction-to-ambient values under specific test conditions, including details about the coolant and flow rate.

You should always review the test conditions and measurement methods used by the manufacturer. This practice ensures that the reported thermal resistance matches your real-world application as closely as possible.

Alert: Never rely solely on catalog values. Always verify that the test setup matches your installation, especially when working with high-power or mission-critical systems.

Industrial Heat Sink Types

Extruded

Extruded heat sinks stand out as one of the most common solutions in the industry. Manufacturers create these by forcing aluminum through a die, forming complex shapes with multiple fins. You benefit from their lightweight nature and efficient heat transfer. Extruded heat sinks offer great design flexibility, which allows you to match them to many electronic devices.

| Heat Sink Type | Advantages | Applications |

|---|---|---|

| Extruded | Lightweight, efficient heat transfer, flexible designs | General electronics, complex designs |

You often see extruded heat sinks in power supplies, amplifiers, and industrial control systems. Their cost-effectiveness and consistent quality make them a popular choice for many engineers. Aluminum remains the preferred material because it is easy to manufacture and keeps costs low. This type of industrial heat sink works well for both passive and active cooling setups.

Tip: Choose extruded heat sinks when you need a balance between performance, weight, and price.

Bonded

Bonded fin heat sinks use a different approach. Manufacturers bond individual fins to a base plate, often with a high-conductivity adhesive or solder. This method allows you to create taller and denser fin arrays than with extrusion alone. As a result, you achieve higher surface area and improved cooling performance.

- Bonded fin heat sinks excel in high-power applications.

- You can integrate advanced features, such as embedded heat pipes, for even better thermal management.

- These heat sinks support both aluminum and copper fins, giving you flexibility for demanding environments.

| Heat Sink Type | Advantages | Applications |

|---|---|---|

| Bonded Fin | High efficiency, flexible, supports advanced features | High-power applications |

You should consider bonded fin designs when your application requires maximum heat dissipation in a limited space. They often appear in telecommunications, power electronics, and industrial automation.

Skived

Skived heat sinks use a unique manufacturing process. A sharp blade skives thin fins directly from a solid metal block, usually copper or aluminum. This seamless construction gives you excellent thermal conductivity and strong mechanical integrity.

- Skived heat sinks provide high fin density, which increases surface area for heat dissipation.

- You can use them in compact designs where space is limited but cooling needs are high.

- Their seamless structure reduces thermal resistance between the base and fins.

| Heat Sink Type | Advantages | Applications |

|---|---|---|

| Skived Fin | Excellent conductivity, seamless, ideal for compact use | Laptops, small electronics |

You will find skived heat sinks in laptops, LED modules, and other small-scale electronics. Their ability to handle high heat loads in tight spaces makes them a top choice for modern, compact devices.

Note: Aluminum heat sinks dominate the market due to their lightweight and cost-effectiveness. Copper options offer better thermal performance but come at a higher price and weight.

Stamped

Stamped heat sinks offer you a cost-effective solution for low to moderate power applications. Manufacturers create these by pressing thin sheets of metal, usually aluminum or copper, into the desired shape using a stamping die. This process allows for high-volume production and consistent quality. You often see stamped heat sinks in consumer electronics, small power supplies, and LED lighting modules.

You benefit from stamped heat sinks when you need lightweight and compact cooling options. The process supports intricate fin designs, which help increase surface area and improve heat dissipation. However, stamped heat sinks usually have thinner fins and bases compared to other types. This design limits their ability to handle high thermal loads.

Advantages of Stamped Heat Sinks:

- Low manufacturing cost

- Lightweight construction

- High production speed

- Suitable for automated assembly

| Feature | Benefit |

|---|---|

| Thin metal sheets | Reduces overall weight |

| Simple shapes | Eases integration in tight spaces |

| Mass production | Lowers unit cost |

Note: Choose stamped heat sinks for applications where space and budget matter more than maximum cooling performance.

Forged

Forged heat sinks give you excellent mechanical strength and superior thermal conductivity. Manufacturers use a process called cold forging, where they press metal—often aluminum or copper—into a die under high pressure. This method creates dense, uniform material with minimal air gaps, which improves heat transfer.

You should consider forged heat sinks for demanding environments. Their robust structure resists vibration and shock, making them ideal for industrial machinery, automotive electronics, and outdoor equipment. Forged heat sinks can support complex fin shapes, which further enhance cooling efficiency.

Key Benefits of Forged Heat Sinks:

- High thermal performance

- Strong resistance to mechanical stress

- Long service life in harsh conditions

| Application Area | Reason for Use |

|---|---|

| Industrial controls | Withstands vibration |

| Automotive systems | Handles temperature extremes |

| Outdoor electronics | Resists corrosion and impact |

Tip: Use forged heat sinks when your industrial heat sink must survive tough operating conditions and deliver reliable cooling.

CNC Machined

CNC machined heat sinks provide you with unmatched precision and customization. Manufacturers use computer-controlled machines to cut and shape solid blocks of metal into complex designs. This process allows you to specify exact dimensions, fin patterns, and mounting features.

You gain flexibility with CNC machined heat sinks, especially for prototypes or low-volume production runs. You can select from a wide range of materials, including aluminum, copper, and advanced alloys. CNC machining supports intricate geometries that other methods cannot achieve.

When to Choose CNC Machined Heat Sinks:

- You require custom shapes or tight tolerances

- Your application involves unique mounting or airflow constraints

- You need rapid prototyping or small batch production

| Feature | Advantage |

|---|---|

| Custom geometry | Fits specialized equipment |

| Material flexibility | Matches specific requirements |

| High accuracy | Ensures consistent performance |

Alert: CNC machined heat sinks often cost more per unit, but they deliver the exact fit and performance you need for specialized applications.

Material Selection

Choosing the right material for your industrial heat sink affects thermal performance, cost, and weight. You must evaluate each option based on your application’s cooling needs and installation constraints.

Aluminum

Aluminum remains the most popular choice for industrial heat sinks. You benefit from its high thermal conductivity, which allows efficient heat transfer. Aluminum’s lightweight nature makes it easy to handle and install, especially in large assemblies. You also gain moderate cost advantages, which help control your project budget.

| Material | Thermal Conductivity (W/(m·K)) |

|---|---|

| Aluminum | High |

| Material Type | Cost Impact | Weight Impact | Thermal Conductivity |

|---|---|---|---|

| Aluminum | Moderate | Light | High |

You can shape aluminum into complex fin designs using extrusion or CNC machining. This flexibility supports both passive and active cooling methods. Aluminum resists corrosion, so you can use it in many industrial environments. If you need a balance of performance, cost, and weight, aluminum offers a reliable solution.

Tip: Select aluminum when you want a lightweight heat sink that delivers strong thermal performance without driving up costs.

Copper

Copper provides even higher thermal conductivity than aluminum. You achieve superior heat dissipation, which is critical for high-power electronics and compact layouts. Copper’s moderate weight adds stability, but you must consider its higher cost compared to aluminum.

| Material | Thermal Conductivity (W/(m·K)) |

|---|---|

| Copper | Higher than aluminum and steel |

| Material Type | Cost Impact | Weight Impact | Thermal Conductivity |

|---|---|---|---|

| Copper | High | Moderate | Very High |

You often see copper in applications where maximum cooling is essential. You can use copper for base plates or combine it with aluminum fins to optimize both cost and performance. Copper resists oxidation, but you may need to apply surface treatments for harsh environments.

Note: Choose copper when your system generates intense heat and you need the lowest possible thermal resistance.

Advanced Materials

Advanced materials such as graphite, plastic, and foam offer unique benefits for specialized applications. You can use graphite for its exceptional thermal conductivity, which ranges from 300 to 1900 W/(m·K). This property allows you to manage extreme heat loads in compact designs. Plastic and foam provide very light weight and low cost, but their thermal conductivity falls short of metals.

| Material | Thermal Conductivity (W/(m·K)) |

|---|---|

| Graphite | 300~1900 |

| Graphite | Up to 400 |

| Material Type | Cost Impact | Weight Impact | Thermal Conductivity |

|---|---|---|---|

| Plastic | Low | Very Light | Low |

| Foam | Low | Very Light | Moderate |

You may select advanced materials for applications where weight reduction is critical or where electrical insulation is required. You should always verify that the material’s thermal properties meet your cooling requirements before making a final decision.

Alert: Advanced materials can solve unique thermal challenges, but you must confirm compatibility with your industrial heat sink design and operating environment.

Cooling Methods

Selecting the right cooling method for your industrial heat sink determines how well your system manages heat. You can choose from passive, active, or hybrid cooling approaches. Each method offers unique benefits and challenges. Understanding these options helps you match your cooling strategy to your application’s demands.

Passive

Passive cooling relies on natural convection and radiation to dissipate heat. You do not need fans or pumps. The heat sink absorbs energy from components and releases it into the surrounding air. This method works best when your system generates moderate heat and operates in environments with good airflow.

You gain several advantages with passive cooling:

- Simple design reduces the risk of mechanical failure.

- Zero noise ensures quiet operation.

- Lower maintenance saves time and resources.

However, passive cooling has limitations. You may find that it cannot handle high thermal loads. Large heat sinks often require more space, which can restrict your design options. You also have less control over temperature, especially in fluctuating environments.

Tip: Use passive cooling when you want reliability and minimal upkeep, and your application does not demand high cooling capacity.

Active

Active cooling uses fans, blowers, or liquid pumps to increase airflow and improve heat transfer. You can achieve higher cooling capacity and maintain precise temperature control. This method suits applications with high power density or where components run hot.

Active cooling offers several benefits:

- High cooling capacity supports demanding systems.

- Temperature control lets you optimize performance.

- Scalability allows you to expand or upgrade as needed.

You must consider some drawbacks. Active systems add complexity and require ongoing power. Fans and pumps can introduce noise and vibration. Maintenance needs increase, and you may face higher operational costs.

Alert: Always monitor active cooling systems for signs of wear or failure. Regular checks help prevent unexpected downtime.

Hybrid

Hybrid cooling combines passive and active methods to optimize performance. You can use a large heat sink with a fan or integrate liquid cooling with natural convection. This approach lets you balance efficiency, reliability, and control.

Hybrid systems deliver the best of both worlds. You gain the simplicity and quiet operation of passive cooling, along with the power and precision of active methods. Many industrial applications use hybrid cooling to manage variable loads and harsh conditions.

| Cooling Method | Advantages | Disadvantages |

|---|---|---|

| Passive Cooling | Simplicity, Zero Noise, Lower Maintenance | Limited Capacity, Space Requirement, Less Control |

| Active Cooling | High Cooling Capacity, Temperature Control, Scalability | Complexity, Noise and Vibration, Ongoing Power Usage |

| Hybrid Cooling | Combines benefits of both methods to optimize performance | N/A |

Hybrid cooling helps you meet strict thermal requirements without sacrificing reliability or efficiency.

You should evaluate your system’s heat output, space constraints, and maintenance resources before choosing a cooling method. The right approach ensures your industrial heat sink delivers consistent performance and protects your equipment.

Design Features

Fin Design

You must pay close attention to fin geometry when selecting an industrial heat sink. The shape and arrangement of fins directly affect how efficiently heat moves away from your components. Different fin designs offer unique benefits for heat dissipation and airflow management.

| Fin Design | Impact on Heat Dissipation Efficiency |

|---|---|

| Inclined Fins | Improve heat transfer efficiency and reduce pressure drop. |

| W-type Fins | Achieve a maximum temperature drop of 4.6°C and an average drop of 2.9°C compared to parallel plate fins. |

| Innovative Designs | Enhance heat transfer while minimizing pressure drop. |

You should consider fin geometry that maximizes surface area. A larger surface area allows more heat to escape into the environment. Heat sinks with increased surface area perform better in surface-mount technology (SMT) designs. You also gain improved convective heat transfer, which helps maintain safe operating temperatures.

- Minimizing total thermal resistance is crucial for efficient heat dissipation.

- Heat sinks increase the surface area available for heat transfer.

- A larger surface area enhances convective heat transfer, enabling more heat to move from the heat sink to the environment.

Tip: Select fin designs that balance airflow and surface area. This approach ensures your heat sink works efficiently without causing excessive pressure drop.

Size and Space

You must evaluate the available space in your system before choosing a heat sink. Industrial environments often present space constraints that complicate thermal management. Densely populated printed circuit boards (PCBs) generate more heat and restrict airflow between components.

- Increased heat generation in crowded PCB layouts reduces airflow and complicates cooling.

- Mechanical attachment methods like push pins and standoffs require extra space and can hinder signal routing.

- In industrial inverters, semiconductor devices produce significant heat, demanding effective cooling solutions.

You should measure the dimensions of your enclosure and check for obstructions. Select a heat sink that fits within the available space while providing enough surface area for heat dissipation. Compact designs may require innovative fin arrangements or custom mounting options.

Note: Always verify that your chosen heat sink does not interfere with other components or signal paths.

Mounting

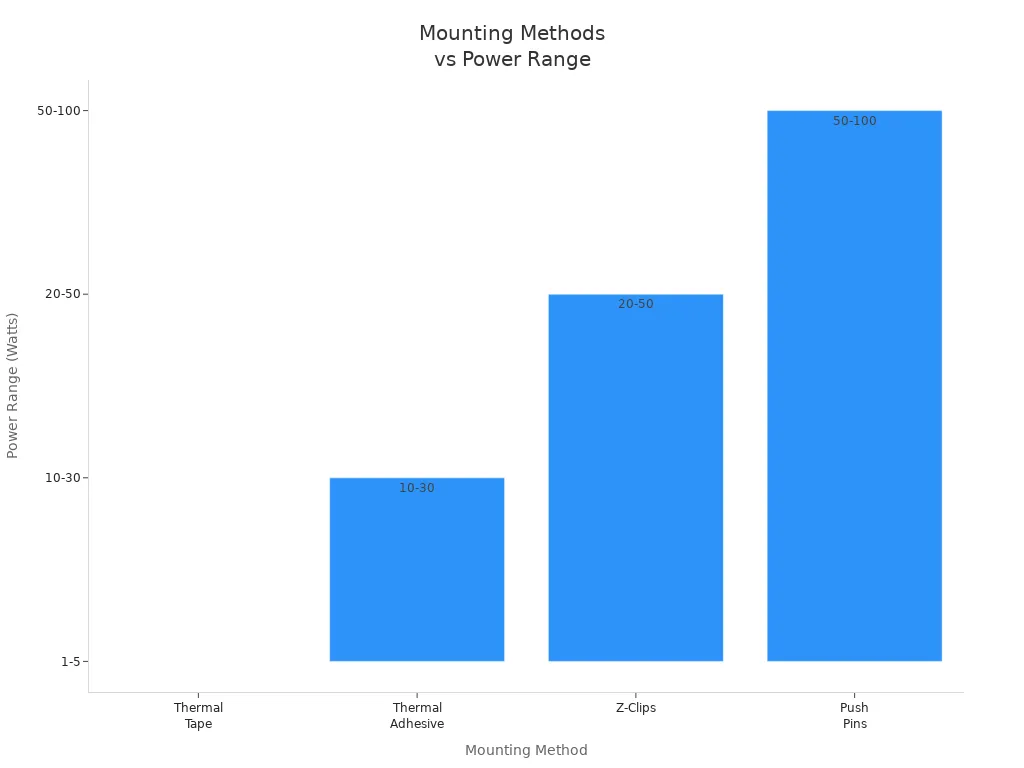

Mounting options play a critical role in installation reliability and thermal performance. You must choose a method that matches your power requirements, assembly process, and mechanical stability needs.

| Method | Thermal Conductivity (W/m·K) | Ease of Installation | Power Range (Watts) | Durability |

|---|---|---|---|---|

| Thermal Tape | 0.8-1.5 | Very Easy | 1-5 | Low |

| Thermal Adhesive | 1.5-3.0 | Moderate | 10-30 | High |

| Z-Clips | 3.0-5.0 (with TIM) | Moderate | 20-50 | Moderate |

| Push Pins | 3.0-5.0 (with TIM) | Easy | 50-100 | High |

You should consider several factors when selecting a mounting method:

- Thermal requirements for your components

- Mechanical stability in environments with vibration or shock

- Assembly process compatibility with your production line

- PCB design constraints that may affect layout or signal integrity

- Cost limitations for your project

Alert: Reliable mounting ensures consistent thermal contact and prevents failures in demanding industrial settings.

Surface Finish

You might overlook surface finish when choosing an industrial heat sink, but it plays a critical role in thermal management. The finish on your heat sink’s surface affects how efficiently it transfers heat to the surrounding environment. You can improve performance by selecting the right surface treatment and texture.

A well-chosen surface finish can enhance both convective and radiative heat transfer. Here are some key ways surface finish impacts thermal performance:

- High-emissivity coatings boost radiative heat loss. These coatings help your heat sink release more heat into the air, especially in applications where natural convection dominates.

- Surface roughness increases the local heat transfer coefficient. A slightly rough surface can create turbulence in the airflow, which helps move heat away from the fins more effectively.

- Superior thermal conductivity in the surface layer aids heat dissipation. However, as the base material’s conductivity rises, the impact of surface finish becomes less significant.

Tip: You should not assume that a shiny or smooth finish always works best. Sometimes, a matte or coated surface will outperform a polished one, especially in high-temperature or passive cooling environments.

You have several surface treatment options to choose from. Each method offers unique benefits for industrial heat sinks. The table below summarizes the most effective treatments and their advantages:

| Surface Treatment | Benefits |

|---|---|

| Anodizing | Improves thermal conductivity by removing oxide layers, enhancing heat transfer efficiency. |

| Electrochemical Polishing | Creates a smoother surface, reducing thermal barriers and improving heat dissipation. |

| Electroless Plating | Enhances surface density, contributing to better thermal performance. |

| Thermally Conductive Coatings | Increases surface radiation capacity for more efficient heat dissipation. |

| Passivation | Provides corrosion resistance, extending the service life of heat sinks. |

| Galvanizing | Protects against oxidation and corrosion in harsh environments. |

| Hard Anodizing | Increases surface hardness and wear resistance, maintaining structural integrity. |

When you select a surface finish, consider your application’s environment and cooling method. For example, anodizing not only improves heat transfer but also protects against corrosion. Thermally conductive coatings work well in passive cooling systems where radiative heat loss matters most. In harsh or outdoor environments, galvanizing and passivation extend the lifespan of your heat sink by preventing rust and oxidation.

You should also think about maintenance and durability. Hard anodizing and electroless plating provide extra protection against wear and mechanical damage. These treatments help your heat sink maintain its performance over time, even in demanding industrial settings.

Alert: The right surface finish can make a significant difference in your system’s reliability and efficiency. Always match the surface treatment to your specific thermal and environmental requirements.

By paying attention to surface finish, you ensure that your industrial heat sink delivers optimal performance and stands up to the challenges of your application.

Application Considerations

LEDs

When you design cooling for industrial LED systems, you face unique challenges. LEDs generate concentrated heat in small areas, which can shorten their lifespan if you do not manage it properly. You should always select materials and designs that match your LED application’s needs.

| Material | Thermal Conductivity | Weight | Cost Effectiveness | Applications |

|---|---|---|---|---|

| Aluminum | High | Light | Cost-effective | General LED applications |

| Copper | Higher | Heavy | More expensive | High-power LED applications |

| Graphite | Unique properties | Varies | Specialized uses | High-temperature environments |

| Ceramics | Insulating properties | Varies | Specialized uses | Electrical insulation needs |

You should focus on thermal resistance calculations to ensure effective heat dissipation. Fins increase the surface area, which improves heat transfer. Proper mounting and thermal interface materials help you achieve better heat conduction.

- Evaluate the heat transfer rates from the LED to the PCB.

- Consider using fans or liquid cooling for high-power applications.

- Optimize airflow around the heat sink to enhance cooling efficiency.

A well-chosen industrial heat sink keeps your LEDs cool, extends their service life, and maintains consistent light output.

Power Electronics

Power electronics require robust thermal management because they often operate at high power levels. You must pay close attention to several parameters that influence heat sink performance.

| Parameter | Description |

|---|---|

| Thermal resistance | Determines how efficiently the heat sink dissipates heat. |

| Airflow | Higher airflow improves cooling effectiveness. |

| Fin density | More fins increase surface area for heat exchange. |

| Fin spacing | Proper spacing ensures optimal airflow and heat transfer. |

| Material selection | Copper offers better conductivity; aluminum is more cost-effective. |

| Fan usage | Fans can boost airflow and enhance heat transfer rates. |

| Fin geometry | Plate fins suit directed airflow; pin fins work for multidirectional airflow. |

| Temperature limits | Always monitor junction temperature (TJMAX) for safe operation. |

You should select a heat sink with the right balance of fin density and spacing. Plate fins work well when you have directed airflow, while pin fins perform better in systems with airflow from multiple directions. Always check the maximum junction temperature for your components and ensure your cooling solution keeps temperatures below this limit.

Tip: Use fans or forced air when your system generates high heat. This approach helps maintain safe operating temperatures and prevents thermal shutdowns.

Harsh Environments

Industrial settings often expose heat sinks to extreme conditions. You must consider several environmental factors to ensure reliable performance.

- Extreme temperatures can cause thermal stress or material brittleness.

- Humidity and moisture may lead to corrosion or short circuits.

- Vibration and shock can damage components and mounting hardware.

- Dust and particulates may block airflow and cause overheating.

- Chemical exposure can degrade materials and coatings.

- Radiation can disrupt sensitive electronics, especially in aerospace.

| Environmental Challenge | Description |

|---|---|

| Sea Spray and Mist | Salt water droplets cause corrosion, especially in marine environments. |

| Industrial Emissions | Corrosive compounds like chlorine and petroleum attack metal surfaces. |

| Dust and Humidity | Dust with moisture leads to pitting and corrosion in HVAC/R systems. |

| Pitting Corrosion | Chloride/fluoride ions create small holes in metal surfaces. |

| Formicary Corrosion | Oxygen, water, and acids react with copper alloys, often unseen. |

You should use heat sinks with corrosion-resistant coatings or materials in these environments. Thermal interface materials improve heat transfer and help protect against moisture. For high-heat or outdoor applications, consider active cooling or thermal insulation to maintain safe temperatures.

Alert: Always verify that your heat sink design can withstand the specific environmental hazards present in your facility. This step ensures long-term reliability and reduces maintenance costs.

You can select the right industrial heat sink by following a step-by-step process: assess your thermal requirements, choose the best type and material, and optimize the design for your application. Avoid common mistakes such as relying only on manufacturer data or surface area. For complex needs, consult experts and consider these key factors:

| Factor | Description |

|---|---|

| Thermal Resistance | Heat dissipation capability |

| Material | Impacts conductivity and weight |

| Fin Configuration | Affects airflow and efficiency |

| Attachment Method | Influences thermal performance |

Recent trends highlight advanced materials and sustainable designs, which improve efficiency and reliability.

FAQ

What is the most important factor when choosing an industrial heat sink?

You should focus on thermal resistance. This value tells you how well the heat sink removes heat from your components. Lower thermal resistance means better cooling performance.

How do you know if a heat sink is large enough for your application?

You need to calculate your system’s total power dissipation. Then, check if the heat sink’s rated thermal resistance keeps your components below their maximum temperature. Always use manufacturer data for guidance.

Can you use aluminum and copper together in one heat sink?

Yes, you can combine aluminum fins with a copper base. This design gives you high thermal conductivity and keeps the heat sink lightweight. Many high-performance heat sinks use this approach.

Do you always need a fan with an industrial heat sink?

No, you do not always need a fan. Passive heat sinks work well for moderate heat loads and quiet environments. You should add a fan if your system generates high heat or operates in a confined space.

How does surface finish affect heat sink performance?

A good surface finish improves heat transfer. Anodized or coated surfaces release heat more efficiently. Rough surfaces can increase airflow turbulence, which helps move heat away from the fins.

What maintenance do industrial heat sinks require?

You should inspect heat sinks regularly for dust, debris, or corrosion. Clean the fins and check for loose mounting hardware. In active systems, test fans or pumps to ensure proper operation.

Can you use the same heat sink for different applications?

You can reuse a heat sink if the thermal requirements match. Always check the power dissipation, mounting method, and available space. Each application may need a different design or material.

What should you do if standard heat sinks do not meet your needs?

You should consult with a supplier or thermal engineer. Custom heat sinks or advanced materials may solve your cooling challenges. Request technical support for complex or high-power applications.