The basic function of a heat sink

The basic heat sink function is to absorb and dissipate excess heat from electronic or mechanical devices, preventing overheating and ensuring reliable operation. You may notice your laptop slows down or even shuts off when it gets too hot. This occurs because heat can degrade performance and threaten the lifespan of your device. A heat sink acts as a passive heat exchanger, moving heat away from sensitive parts.

| Thermal Management Techniques | Description |

|---|---|

| Effective thermal management | Prevents overheating, which is essential for maintaining component performance and preventing device failure. |

| Intelligent thermal designs | Engineers use smart designs to reduce heat-related failures and extend the life of electronic systems. |

Key Takeaways

- Heat sinks absorb and dissipate excess heat from electronic devices, preventing overheating and ensuring reliable operation.

- Materials like aluminum and copper are commonly used in heat sinks due to their excellent thermal conductivity.

- The design of a heat sink, including the use of fins, increases surface area for better heat dissipation.

- Good contact between the heat sink and components is crucial for efficient heat transfer; thermal paste can enhance this contact.

- Active heat sinks use fans for improved cooling, while passive heat sinks rely on natural airflow and are quieter.

- Proper airflow management around heat sinks is essential; ensure there is enough space for air to circulate freely.

- Choosing the right size and shape of a heat sink is vital for effective cooling; larger and well-designed heat sinks perform better.

- Regular maintenance, such as cleaning dust from heat sinks, helps maintain their efficiency and prolongs the lifespan of your devices.

What Is a Heat Sink

Definition

You encounter heat sinks in many electronic devices, but what exactly are they? In engineering terms, a heat sink is a passive heat exchanger. It transfers heat generated by an electronic or mechanical device to a fluid medium, such as air or a liquid coolant. This process allows the device to regulate its temperature and maintain safe operation.

A heat sink moves thermal energy from a hot component to a cooler fluid, which then carries the heat away.

You often find heat sinks attached to parts that generate significant heat, like computer processors or power transistors. The heat sink function relies on materials that conduct heat efficiently, spreading the heat over a larger surface area for better cooling.

Purpose

The main purpose of a heat sink is to keep your electronic components cool. When you use a computer or a smartphone, the processor and other parts generate heat. If this heat builds up, it can damage the components or cause them to stop working efficiently.

- A heat sink absorbs the heat from these components.

- It then dissipates the heat into the surrounding air.

- This process prevents overheating and ensures your device runs smoothly.

You depend on heat sinks to protect your devices from thermal damage. Without them, your computer’s CPU or GPU could overheat during demanding tasks, leading to slowdowns or even permanent failure. The heat sink function is essential for reliable and efficient operation.

Common Uses

You see heat sinks in a wide range of applications, both in consumer electronics and industrial equipment.

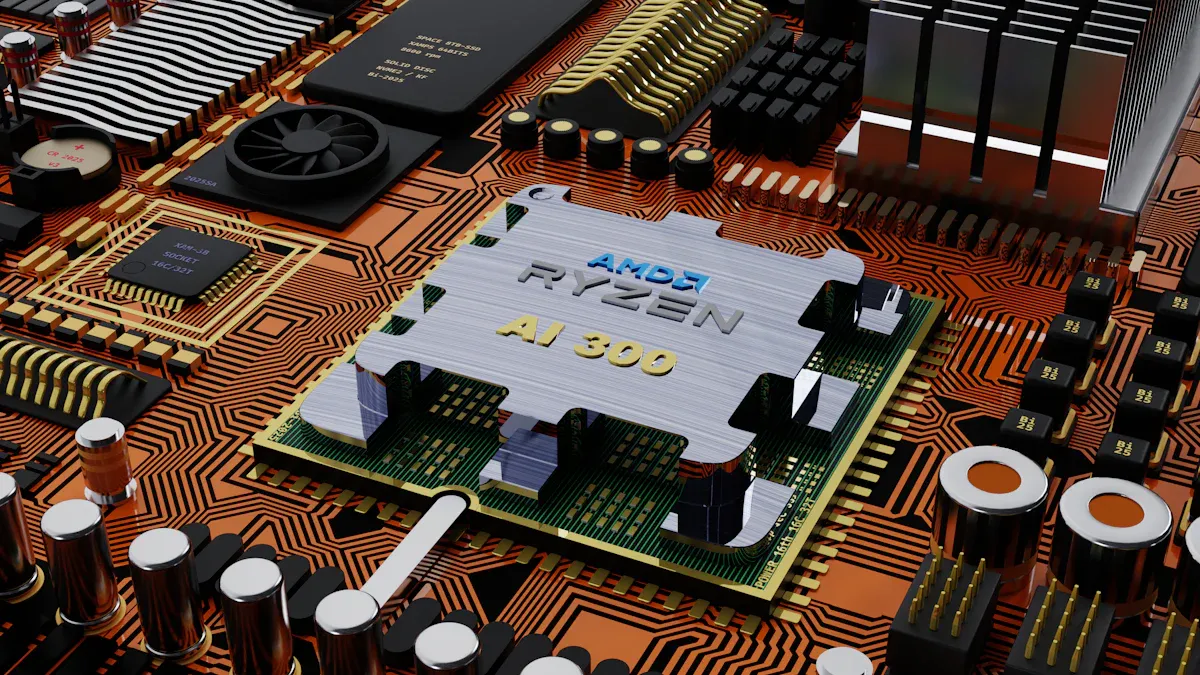

- In computers and cell phones, heat sinks help maintain optimal operating temperatures.

- Computer processors (CPUs) and graphics cards (GPUs) use heat sinks to prevent overheating during activities like gaming or video editing.

- Industrial systems rely on heat sinks in power electronics, motor drives, and control systems to handle high thermal loads and ensure reliable performance.

Whenever you use a device that gets warm during operation, a heat sink is likely working behind the scenes to keep it safe and efficient.

Heat Sink Function

Absorbing Heat

You rely on the heat sink function to keep your devices safe. The process starts when the heat sink absorbs heat from a hot component, such as a CPU or power transistor. The heat travels from the component into the heat sink through direct contact. This transfer uses a physical principle called conduction. The heat sink material, often aluminum or copper, conducts heat away from the source quickly. You benefit from this because the heat sink lowers the temperature of the component, protecting it from damage.

- Conduction moves heat from the hot part into the heat sink.

- Thermally conductive materials, like copper and aluminum, make this process efficient.

- Lower temperatures help your devices last longer and work better.

Dissipating Heat

Once the heat sink absorbs heat, it must release it into the surrounding environment. This step is crucial for the heat sink function. The heat leaves the heat sink through convection and radiation. Air or liquid coolant flows around the heat sink, carrying heat away. Some heat also escapes as electromagnetic waves.

Surface Area

The design of a heat sink matters. Fins play a key role by increasing the surface area. More surface area means more heat can move from the heat sink into the air. You see this in the way fins are arranged to maximize airflow and exposure to cooling air. The larger the surface area, the more effective the heat sink function becomes.

Tip: When you choose a heat sink, look for designs with many fins. These designs improve cooling by spreading heat over a bigger area.

Contact with Components

Good contact between the heat sink and the component is essential. You want the heat sink to touch the component directly, with no gaps. Thermal paste or pads help fill tiny spaces, making the heat transfer more efficient. The better the contact, the more heat the heat sink can absorb and dissipate.

Enhancing Cooling

You depend on the heat sink function to keep your electronics running smoothly. The heat sink spreads heat over a large area, allowing more efficient cooling. Air or liquid coolant moves heat away from the surface. This process keeps temperatures low and prevents overheating.

- Improved component lifespan: Lower temperatures help your devices last longer.

- Enhanced performance: Stable temperatures keep your electronics working at their best.

- Increased reliability: Effective heat dissipation reduces the risk of failures.

| Benefit | Description |

|---|---|

| Longer Lifespan | Lower heat means your devices last longer. |

| Better Performance | Stable temperatures keep your electronics fast and stable. |

| More Reliability | Good cooling prevents sudden failures. |

You see the heat sink function at work every time your computer stays cool during heavy use. The combination of absorbing and dissipating heat, using thermally conductive materials, and maximizing surface area ensures your devices remain reliable.

How It Works

Understanding how a heat sink works helps you make better choices for your devices. The heat sink function relies on the movement of heat from hot components to cooler surroundings. This process uses three main methods: conduction, convection, and radiation.

Heat Transfer Process

You can break down the heat transfer process into several important steps. Each step ensures that your device stays cool and operates safely.

- Determine the operating point of the fan and heat sink combination.

- Calculate the optimum fin spacing for effective heat dissipation.

- Assess the thermal resistance of the fan/heat sink combination.

- Calculate the average heat transfer coefficient from the heat sink fins.

- Determine the total thermal resistance of the heat sink based on the wetted surface area.

These steps help engineers design heat sinks that move heat away from sensitive parts efficiently.

Conduction

Conduction starts the process. When you attach a heat sink to a hot component, heat flows directly from the component into the heat sink. Materials like copper and aluminum work well because they conduct heat quickly. Good contact between surfaces improves this step. You often see thermal paste or pads used to fill tiny gaps and boost heat transfer.

Convection

After conduction, convection takes over. Air or liquid moves across the surface of the heat sink, carrying heat away. Fins on the heat sink increase the surface area, which lets more heat escape into the air. You may notice fans blowing air over heat sinks in computers. This airflow speeds up the cooling process and keeps temperatures low.

Radiation

Radiation also plays a role, though it is less significant than conduction or convection. The heat sink emits some heat as infrared energy. This energy leaves the surface and moves into the surrounding space. While radiation does not remove as much heat as the other methods, it still helps lower the temperature.

Note: All three methods—conduction, convection, and radiation—work together to keep your devices safe from overheating.

Passive vs. Active

You can choose between passive and active heat sinks, depending on your needs. Passive heat sinks rely on natural airflow and do not use moving parts. They work best in quiet, low-power devices. Active heat sinks use fans or pumps to move air or liquid over the fins. This approach increases cooling power and suits high-performance systems.

| Aspect | Passive Heatsink | Active Heatsink |

|---|---|---|

| Cooling Efficiency | Lower | Higher |

| Best For | Low-heat, silent applications | High-heat, performance-critical |

Passive heat sinks offer silent operation and fewer parts that can fail. Active heat sinks provide better cooling for demanding tasks. You should match the heat sink function to your device’s needs for the best results.

Types

Passive

You encounter passive heat sinks in many everyday devices. These heat sinks rely on natural convection to move heat away from components. You do not find any moving parts in passive designs, which means they operate silently and offer high reliability. Manufacturers often use aluminum or copper to construct passive heat sinks because these metals conduct heat efficiently.

Passive heat sinks work best in environments with moderate power loads and good ventilation. You see them in LED lighting, low-power CPUs, and industrial controllers where fans are impractical.

Here is a quick overview of passive heat sink characteristics and their ideal scenarios:

| Characteristic/Scenario | Description |

|---|---|

| Heat Dissipation Method | Relies on natural convection for heat dissipation. |

| Moving Parts | Absence of moving parts, which contributes to quieter operation. |

| Materials Used | Commonly made from aluminum or copper for effective heat transfer. |

| Effectiveness Scenarios | Most effective in moderate power loads and environments with proper ventilation. |

| Common Applications | Used in LED lighting, low-power CPUs, and industrial controllers. |

You benefit from passive heat sinks when you need silent operation and long-term reliability. You do not need to worry about maintenance or energy consumption.

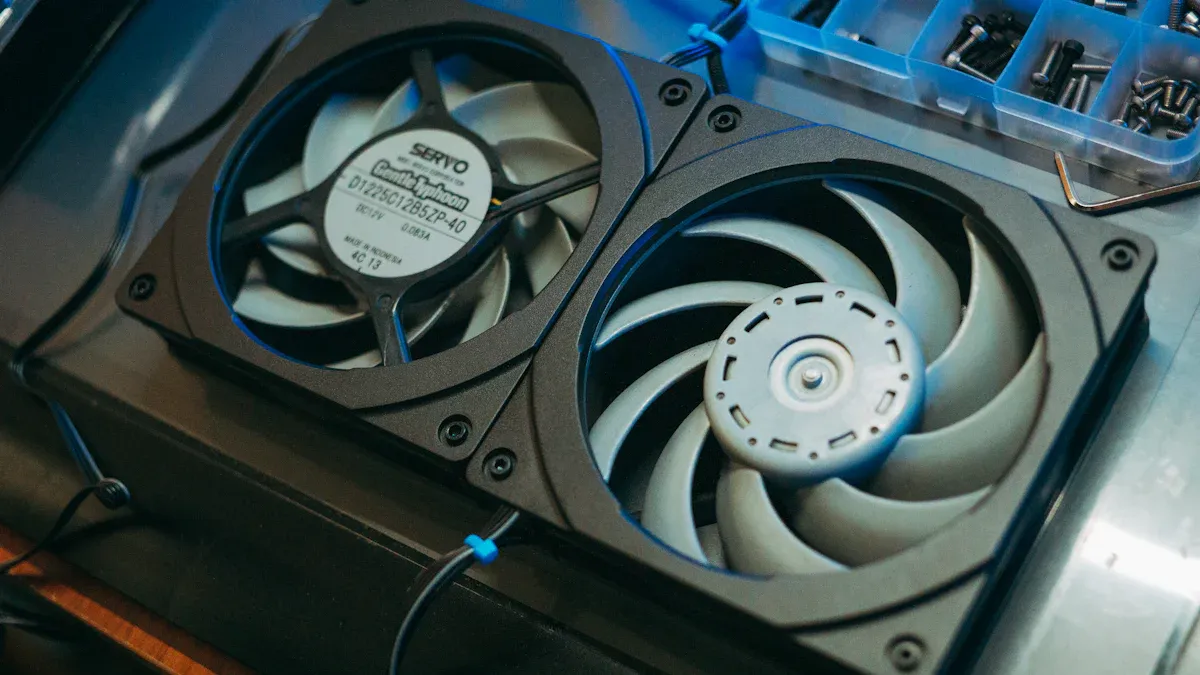

Active

Active heat sinks use fans or pumps to increase airflow or liquid movement across the heat sink surface. You see these designs in high-performance computers, gaming consoles, and industrial equipment that generate significant heat. The addition of moving parts boosts cooling capacity, allowing active heat sinks to handle higher thermal loads.

You should consider the following comparison between active and passive heat sinks:

| Feature | Active Heat Sinks | Passive Heat Sinks |

|---|---|---|

| Cooling Capacity | Superior cooling, handles high heat loads | Limited cooling capacity |

| Design Flexibility | Adjustable fan sizes, compact designs | Larger designs for equivalent performance |

| Cost | Higher initial and operational expenses | Generally lower costs |

| Noise | Can be noisy due to fans | Silent operation |

| Power Consumption | Increases energy consumption | Energy-efficient |

| Reliability | Moving parts may fail over time | More reliable due to no moving parts |

You gain better cooling performance with active heat sinks, but you must accept higher costs, increased noise, and possible maintenance. You should use active heat sinks for devices that demand maximum thermal management, such as gaming PCs or advanced industrial controllers.

Tip: You can extend the lifespan of your high-performance electronics by choosing an active heat sink with a quality fan and regular maintenance.

Specialized

You find specialized heat sinks in advanced and unique applications. These designs address specific cooling challenges in embedded AI systems, smartphones, robotics, and high-performance computing environments. For example, pumped liquid heat sinks use water to cool large machines like data centers. Two-phase heat sinks convert liquid to gas, providing efficient cooling for advanced servers. Skived fin heat sinks feature thin fins for high-temperature chips, while bonded fin heat sinks offer extra cooling area and durability for medium-power devices.

| Heat Sink Type | Application Description |

|---|---|

| Passive Heat Sink | Used for cooling AMD Kria K24 System-on-Modules (SOMs) without a fan, suitable for less demanding applications. |

| Active Heat Sink | Required for AMD Kria K26 SOMs in applications needing enhanced cooling performance due to higher heat output. |

| NVIDIA Jetson AGX Orin | Designed for AI applications, can be passively cooled, ideal for environments with dust and debris. |

| Pumped Liquid Heat Sink | Utilizes water for cooling large machines like data centers, effective for high heat loads. |

| Two-Phase Heat Sink | Converts liquid to gas for cooling advanced servers, suitable for extreme heat conditions. |

| Skived Fin Heat Sink | Features thin fins for cooling high-temperature chips, effective for compact designs. |

| Bonded Fin Heat Sink | Provides extra cooling area for medium-power devices, known for durability due to glued or soldered fins. |

You see specialized heat sinks in:

- Embedded AI systems (such as NVIDIA Jetson modules)

- Smartphones with compact heat sink designs

- Data centers using pumped liquid heat sinks

- Robotics applications for cooling K24 and K26 SOMs

- Security surveillance systems with Orin Nano modules

You should select a specialized heat sink when your application requires advanced cooling, compact size, or enhanced durability. You ensure optimal performance and reliability by matching the heat sink type to your device’s unique needs.

Materials

Aluminum

You often see aluminum used in heat sinks because it offers a strong balance of performance and cost. Aluminum conducts heat well, though not as efficiently as copper or silver. You benefit from its lightweight nature, which makes it ideal for devices where weight matters, such as laptops and smartphones. Manufacturers choose aluminum for its affordability and ease of manufacturing. You also help the environment when you select aluminum, since it is highly recyclable and reduces the environmental footprint of your devices.

Aluminum heat sinks provide reliable cooling for most consumer electronics. You can trust them to keep your devices running efficiently without adding extra weight.

Here is a comparison of thermal conductivity values for common heat sink materials:

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Silver | 429 |

| Copper | 400 |

| Aluminum | 237 |

Aluminum’s thermal conductivity falls behind copper and silver, but you gain advantages in cost and sustainability. You also see aluminum alloys used for heat sinks, which balance thermal performance with lower weight and cost.

Copper

You choose copper for heat sinks when you need maximum thermal performance. Copper conducts heat much better than aluminum, making it the preferred choice for high-performance computers, gaming consoles, and industrial equipment. You pay more for copper, but you receive long-term reliability and efficient heat management. Copper resists corrosion and maintains its performance even in extreme conditions.

| Feature | Copper Heat Sinks |

|---|---|

| Thermal Conductivity | Exceptional, ensuring efficient heat dissipation |

| Durability | High resistance to thermal fluctuations and corrosion |

| Long-term Performance | Maintains efficiency over time, reducing overheating risks |

| Stability in Extreme Conditions | Performs consistently under high temperatures and demanding environments |

Although copper costs more upfront, you save money over time because copper heat sinks last longer and require fewer replacements. You also find copper heat sinks in custom designs for specialized applications, where precise thermal management is critical.

- Copper heat sinks deliver efficient cooling for demanding tasks.

- You benefit from their durability and stability in harsh environments.

- You invest in copper when reliability and performance matter most.

Advanced Materials

You see rapid innovation in heat sink materials as technology evolves. Manufacturers now use advanced alloys, graphene, and carbon nanotubes to push the limits of thermal management. You benefit from these materials because they offer higher thermal conductivity and lower weight compared to traditional metals. Additive manufacturing, such as direct metal laser sintering (DMLS), allows for complex 3D structures that optimize fluid flow and heat dissipation.

| Material | Thermal Conductivity (W/m·K) | Benefits |

|---|---|---|

| Copper | 385-400 | Excellent heat conductor, rapidly transfers heat, highly effective but heavier and costlier. |

| Aluminum | 205-250 | Lightweight, cost-effective, reasonable thermal conductivity, efficient with proper design. |

| Aluminum Alloys | 100-200 | Balanced thermal performance, weight, and cost, commonly used despite lower conductivity. |

You also see trends toward using sustainable materials and designing heat sinks for easy recycling. Advanced alloys and biodegradable options help you reduce the environmental impact of your devices. Recent research shows that new thermal design strategies and 3D printing can improve heat dissipation efficiency by over 25% compared to traditional metals.

You stay ahead in thermal management by choosing advanced materials that deliver better cooling, lower energy consumption, and a smaller environmental footprint.

Choosing a Heat Sink

Size

You must consider the size of a heat sink when selecting one for your device. Size directly affects how well the heat sink can remove heat. Larger heat sinks offer more surface area, which allows them to dissipate heat more efficiently. You see this advantage in devices that generate a lot of heat, such as gaming computers or industrial controllers.

- Larger heat sinks have a greater surface area, which improves heat dissipation.

- Design factors like fin thickness and spacing are important for optimizing airflow.

- The overall shape of the heat sink affects heat transfer efficiency.

When you choose a heat sink, you need to balance size with available space inside your device. If you select a heat sink that is too large, it may not fit. If you choose one that is too small, it may not cool your components effectively. You should also pay attention to the arrangement of fins. Thin fins with proper spacing allow air to flow more easily, which helps carry heat away.

Tip: Always check the manufacturer’s recommendations for heat sink size based on your device’s power output and space constraints.

Shape

Shape plays a key role in how a heat sink manages airflow and cooling performance. You find many shapes, including flat plates, pin arrays, and finned designs. Each shape influences how air moves around and through the heat sink. Overlapping fins, for example, can boost cooling performance by increasing the velocity of air inside the channels.

| Key Findings | Description |

|---|---|

| Heat Transfer Coefficient | Improved due to increased velocity inside the channel, despite decreased flow rate. |

| Cooling Performance | Enhanced by up to 35% with overlapping fins. |

| Space Efficiency | Volume occupied by the system decreased with overlapping fins. |

You should select a shape that matches your device’s airflow pattern. If your device uses a fan, finned designs with proper spacing work well. If you need to save space, overlapping fins can help you achieve better cooling without increasing the size of the heat sink.

Note: The right shape can improve cooling performance and save space inside your device.

Thermal Resistance

Thermal resistance is a critical factor when you choose a heat sink. You measure thermal resistance in degrees Celsius per watt (°C/W). This value tells you how much the heat sink resists the flow of heat. You use a heat flow meter to measure thermal resistance, which relies on temperature sensors and a heat source. The calculation uses Fourier’s Law of Heat Conduction, relating the temperature difference across the material to the heat flux.

You want a heat sink with low thermal resistance. Low thermal resistance means heat moves away from your components quickly, keeping them cool. Factors such as thermal conductivity, thickness, and surface area all influence thermal resistance. When you select a heat sink, you should look for one that matches your device’s heat dissipation needs.

You also need to consider other important factors:

- Thermal resistance

- Material selection

- Manufacturing methods

- Space constraints

- Heat dissipation requirements

- Size constraints

Choosing the right heat sink ensures your device stays cool, performs well, and lasts longer. Always match the heat sink’s thermal resistance to your device’s specific needs for the best results.

Airflow

You must pay close attention to airflow when selecting a heat sink for your device. Airflow determines how efficiently your heat sink can remove heat from critical components. If you optimize airflow, you improve cooling performance and extend the lifespan of your electronics.

Proper airflow starts with the layout inside your enclosure. You should give extra space to components that generate significant heat. This space allows hot air to escape and prevents heat buildup. Cooler components can sit closer together since they do not need as much airflow.

You also need to maintain clearance from walls and doors. When you keep heat sinks away from these surfaces, you enhance air circulation. Air can move freely around the heat sink, which helps carry heat away more effectively.

Fan placement plays a major role in airflow management. You should position internal fans so they direct air toward the heat sink and AC intakes. This setup boosts cooling efficiency. Avoid placing fans where they block airflow or create dead spots. Dead spots trap hot air and reduce cooling performance.

Consider the pressure setup inside your enclosure. Positive pressure pushes air out, while negative pressure pulls air in. You can use either method to manage airflow, but you must ensure that air moves smoothly over heat-generating components.

Here are best practices for optimizing airflow around a heat sink:

- Give extra space to hot components for better heat exhaust.

- Place cooler components closer together.

- Maintain clearance from enclosure walls and doors.

- Direct airflow from fans toward AC intakes.

- Position fans to avoid blocking airflow.

- Create a clear path for ambient air to enter and flow over heat sinks.

- Carefully position intake and exhaust vents.

- Avoid short-circuiting hot exhaust air back into intakes.

Tip: Always check for dead spots inside your enclosure. These areas can trap hot air and cause overheating. You can use airflow visualization tools or smoke tests to identify and fix these problems.

| Airflow Optimization Step | Benefit |

|---|---|

| Extra space for hot components | Improves heat exhaust |

| Clearance from walls and doors | Enhances air circulation |

| Strategic fan placement | Prevents dead spots |

| Proper vent positioning | Maximizes cooling efficiency |

| Avoiding air short-circuiting | Keeps intake air cool |

You should always create a clear path for air to enter and exit your enclosure. Intake vents bring in cool air, while exhaust vents remove hot air. If you position these vents carefully, you prevent hot air from re-entering the system. This strategy keeps your heat sink working at peak efficiency.

When you optimize airflow, you protect your device from overheating. You also improve reliability and performance. Good airflow ensures your heat sink can do its job, keeping your electronics safe and cool.

Importance

Preventing Overheating

You depend on your devices to work smoothly, but heat can quickly become a problem. Overheating often results from poor airflow, high power consumption, or inadequate cooling solutions. When your device gets too hot, performance drops, and you risk permanent damage. Heat sinks play a crucial role in preventing these issues.

- Heat sinks increase the surface area available for heat transfer.

- Fins and grooves allow more heat to escape into the surrounding air.

- Materials like aluminum and copper conduct heat away from critical components.

A heat sink acts as a passive cooling device. It absorbs excess heat from electronic parts and releases it into the environment. This process keeps your device at a safe temperature and helps maintain optimal functionality. You avoid sudden shutdowns and slowdowns by relying on effective heat sink designs.

Tip: Choose heat sinks with larger surface areas and high-conductivity materials to maximize cooling efficiency.

Protecting Components

Sensitive components such as CPUs and GPUs generate significant heat during operation. Without proper cooling, these parts can suffer thermal damage, leading to data loss or hardware failure. You protect your investment by using heat sinks that shield these components from excessive temperatures.

- The CPU or GPU produces heat as it processes data.

- Heat moves from the component into the heat sink through conduction.

- The heat spreads throughout the heat sink, with the hottest area near the source.

- The heat dissipates into the air or a cooling liquid, lowering the temperature of the component.

You ensure reliable performance by maintaining safe operating temperatures. Heat sinks made from copper or aluminum transfer heat efficiently, reducing the risk of overheating. You also benefit from thermal interface materials, such as thermal paste, which improve contact between the heat sink and the component.

Note: Regular maintenance, like cleaning dust from fins, helps your heat sink work at peak efficiency.

Improving Lifespan

You want your devices to last as long as possible. Effective heat sink integration directly impacts the operational lifespan of your electronics. By managing temperatures, heat sinks enhance both performance and longevity.

| Evidence Description | Key Points |

|---|---|

| Heat sinks manage temperatures | They enhance performance and longevity of electronic devices. |

| Innovations in design | Techniques like fluid topology optimization improve cooling. |

| Critical components | Heat sinks maintain optimal operating temperatures. |

| Overheating issues | Causes reduced efficiency, data loss, and permanent damage. |

| Real-world case studies | Improved device reliability and lifespan through heat sink use. |

Engineers have documented many cases where heat sinks have extended the life and reliability of electronics. You avoid costly repairs and replacements by keeping your devices cool. Advanced heat sink designs, such as optimized fin configurations and new materials, further improve cooling efficiency.

- Heat sinks prevent overheating, which reduces wear and tear.

- You experience fewer failures and longer intervals between upgrades.

- Devices with proper thermal management deliver consistent performance over time.

Investing in quality heat sinks ensures your electronics remain dependable and efficient for years to come.

You rely on heat sinks to protect your electronics from overheating and extend their lifespan.

- High thermal conductivity materials like copper and aluminum alloys boost reliability.

- Optimized fin geometry and advanced thermal interface materials improve heat transfer.

- Combining passive and active cooling methods enhances device performance.

- Comprehensive testing ensures durability in extreme conditions.

Effective heat dissipation through well-designed heat sinks increases reliability and efficiency for both personal and industrial electronics. Consider thermal management when choosing or maintaining your devices to ensure long-term performance.

FAQ

What is the main purpose of a heat sink?

You use a heat sink to absorb and release heat from electronic components. This process keeps your devices cool and prevents overheating, which protects sensitive parts and improves reliability.

How do you know if your device needs a heat sink?

You should check if your device gets hot during use or slows down unexpectedly. Devices with powerful processors or high energy consumption often require heat sinks for safe operation.

Which material works best for heat sinks?

You benefit most from copper and aluminum. Copper offers superior thermal conductivity, while aluminum provides a lightweight and cost-effective solution. Both materials help you achieve efficient cooling.

Can you clean a heat sink yourself?

You can clean a heat sink using compressed air or a soft brush. Remove dust and debris regularly to maintain optimal airflow and cooling performance. Always power off your device before cleaning.

What happens if you use the wrong size heat sink?

You risk overheating if you choose a heat sink that is too small. Oversized heat sinks may not fit inside your device. Always match the heat sink size to your device’s heat output and available space.

Do passive heat sinks work as well as active ones?

You get silent operation with passive heat sinks, but active heat sinks cool more effectively. Fans or pumps in active designs move heat away faster, making them better for high-performance devices.

How often should you replace thermal paste?

You should replace thermal paste every two to three years or when you notice higher temperatures. Fresh thermal paste improves contact between the heat sink and component, boosting heat transfer.

Are heat sinks only used in computers?

You find heat sinks in many devices, not just computers. Smartphones, LED lights, industrial machines, and power supplies all use heat sinks to manage heat and ensure reliable performance.