Vapor Chamber Heat Sinks

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.A vapor chamber heat sink uses a sealed, flat chamber filled with a small amount of liquid to move heat quickly away from hot components. You rely on efficient heat management in places like consumer electronics, AI servers, and data centers. This technology spreads heat more evenly than traditional cooling methods, helping you protect sensitive equipment and avoid overheating.

Key Takeaways

- Vapor chamber heat sinks use a sealed chamber filled with liquid to quickly move heat away from electronic components.

- These heat sinks provide better heat distribution than traditional cooling methods, helping to prevent overheating.

- The two-phase heat transport process in vapor chambers allows for efficient heat transfer, keeping devices cool.

- Vapor chambers are ideal for high-power electronics, such as CPUs and GPUs, due to their low thermal resistance.

- They can be customized in shape and size to fit various industrial applications, maximizing space efficiency.

- Vapor chamber heat sinks require minimal maintenance, making them reliable for long-term use.

- These cooling solutions are increasingly used in data centers, consumer electronics, and automotive applications.

- Future trends include the use of new materials and smart cooling technologies to enhance performance.

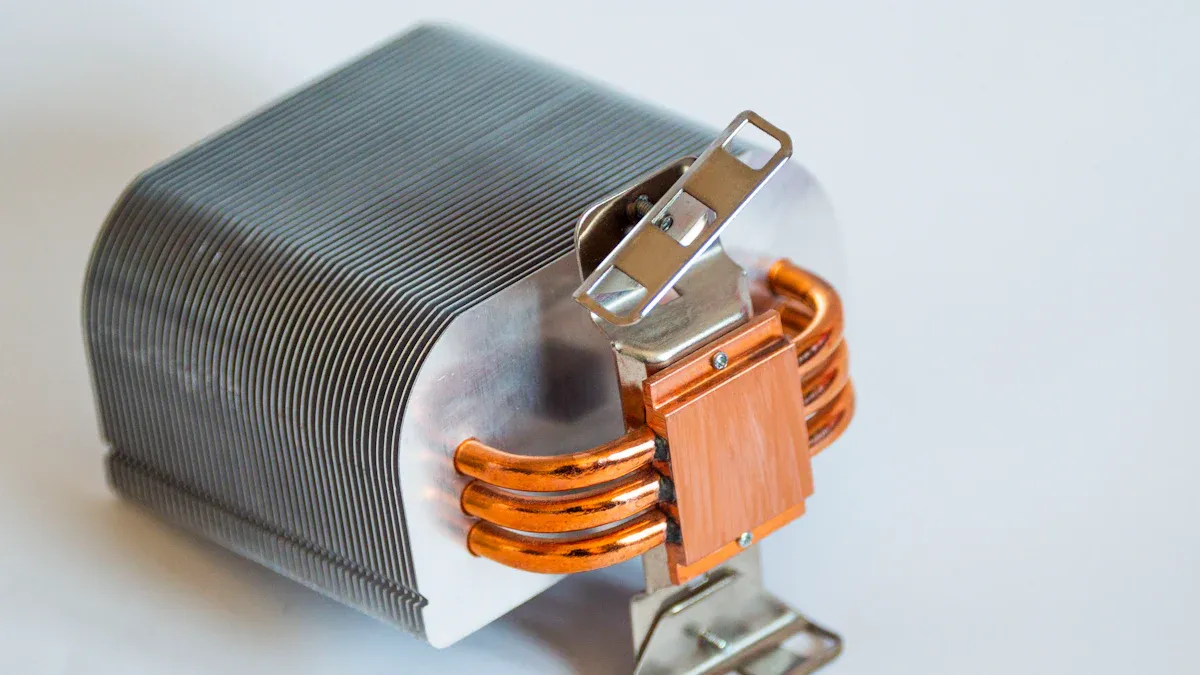

What is a vapor chamber heat sink?

Definition

A vapor chamber heat sink is a specialized device that spreads and removes heat from electronic components. You will find that it uses a sealed, flat chamber filled with a small amount of working fluid, usually water. The chamber operates under a partial vacuum, which allows the fluid to evaporate at lower temperatures. When heat from a component enters the chamber, the fluid turns into vapor and moves quickly to cooler areas. There, the vapor condenses back into liquid, releasing heat. The wick structure inside the chamber helps return the liquid to the heat source, creating a continuous cycle.

You can see the main structural components of a vapor chamber heat sink in the table below:

| Component | Description |

|---|---|

| Sealed Shell | A thin, vacuum-sealed shell that contains the working fluid for effective heat transport. |

| Working Fluid | A fluid that changes phase within the operational temperature range, essential for heat transfer. |

| Wick Structure | A structure that passively moves the fluid through the heat pipe, facilitating circulation. |

This design allows you to achieve efficient heat transfer and uniform temperature across the surface.

Key features

You will notice several features that set vapor chamber heat sinks apart from other cooling technologies:

- Flat, plate-shaped design enables efficient heat spreading across the entire surface.

- The chamber maintains a temperature difference of less than 10 ℃ from one side to the other, giving you more uniform heat distribution than traditional heat pipes.

- Low thermal resistance, typically around 0.25 ℃/W, makes these heat sinks suitable for high-power applications.

- The metal enclosure, often made of copper, provides high thermal conductivity.

- The wick structure ensures that condensed liquid returns to the heat source, supporting continuous operation.

- Vapor chambers can reduce conduction loss (Delta-T) in thermal assemblies by 50% or more.

- You can use vapor chambers in a wide range of applications because of their design flexibility.

- These heat sinks work especially well for high power density electronics, such as CPUs and GPUs.

Tip: Vapor chamber heat sinks can achieve effective thermal conductivity above 5000 W/m°C, far surpassing pure copper. This means you get much better heat management for demanding applications.

Industrial relevance

You rely on vapor chamber heat sinks in many high-performance industrial settings. These devices have proven their value in managing heat for electrical and electronic equipment. For example:

- Prototype vapor chamber heat spreaders have shown excellent results in thermal performance tests for electrical devices.

- Studies confirm that vapor chambers significantly improve thermal management in high-performance applications.

- Research on thin vapor chambers demonstrates enhanced cooling for high heat flux electronic devices.

- Some advanced vapor chambers, such as CFVC models, reach a critical heat flux of 180 W/cm², showing their ability to handle extreme heat loads.

You will find vapor chamber heat sinks in smartphones, tablets, high-performance laptops, data centers, servers, LED lighting, and even automotive electronics. Their ability to maintain uniform temperatures and manage high power densities makes them essential for modern industrial cooling solutions.

Vapor chamber vs. traditional heat sinks

Design differences

You will notice clear differences in how vapor chamber heat sinks and traditional finned heat sinks are built. Vapor chambers use a sealed, flat chamber that sits directly on the heat source. This design allows heat to spread evenly in all directions. Traditional heat sinks often rely on solid metal bases, usually copper or aluminum, with fins attached to increase surface area. These bases do not spread heat as uniformly.

Note: To get the best results from vapor chambers, you must pay attention to how they connect to the heat source. Proper integration boosts efficiency and ensures even heat distribution.

Here are some key design features:

- Vapor chambers provide direct contact with the heat source for uniform heat spreading.

- They enhance heat sink performance compared to standard copper solutions.

- In compact 1U heat sinks, vapor chambers reach effective thermal conductivities of 1000-1500 W/m-K.

- You can expect a thermal improvement of 3°C to 4°C (about 10%) over a solid copper base.

Performance comparison

You will see major differences in performance when you compare vapor chamber heat sinks to traditional models. Vapor chambers move heat faster and more evenly. Scientific studies show that vapor chamber heat sinks outperform finned plate heat sinks, especially for small heat sources.

| Study | Findings |

|---|---|

| Sauciuc et al. | Vapor chamber heat sinks worked better than finned plate heat sinks with thicker bases. |

| Chen et al. | Thermal resistance of vapor chamber heat sinks is 0.0765 K/W, lower than copper (0.1037 K/W) and aluminum (0.2248 K/W). |

| Wang et al. | Vapor chamber heat sinks kept substrate temperatures 12°C lower than aluminum plates. |

| Boukhanouf et al. | Vapor chamber heat sinks reduced thermal spreading resistance 40 times compared to copper blocks. |

You can see that vapor chambers deliver lower thermal resistance and better temperature control. This means your equipment stays cooler and runs more reliably.

Heat distribution

Uniform heat distribution is a major advantage of vapor chamber heat sinks. You will find that these devices handle high heat flux and keep temperatures steady across the surface. Several studies highlight their ability to maintain low thermal resistance and even temperature profiles.

| Study | Findings |

|---|---|

| Mo et al. | Vapor chambers manage high heat flux with low thermal resistance and uniform temperature. |

| Chen et al. | Simulations show heat source area affects vapor chamber performance. |

| Hassan and Harmand | Higher power input increases pressure differences, but vapor chambers still perform well. |

| Tang et al. | Achieved minimum thermal resistance of 0.08 K/W and heat transfer limit of 300 W/cm². |

| Ji et al. | Minimum thermal resistance of 0.09 K/W under 216 W/cm² heat flux density. |

| Peng et al. | Unique wick system improved temperature uniformity. |

| Wong et al. | Microgrooves lowered thermal resistance compared to conventional designs. |

| Yang et al. | Wetting-patterned substrate improved temperature uniformity. |

| Liu et al. | Super hydrophilic surface structure boosted thermal performance. |

You benefit from more consistent cooling, fewer hotspots, and better protection for sensitive electronics. Vapor chamber heat sinks give you the edge in demanding industrial environments.

How does a vapor chamber work?

Two-phase heat transport

You can understand the core of vapor chamber technology by looking at its two-phase heat transport process. This process uses both liquid and vapor states of a working fluid, usually water, to move heat efficiently. Here is how it works:

- Heat from your electronic component enters the chamber and causes the liquid inside to vaporize.

- The vapor carries the heat away from the source as it moves to cooler areas within the chamber.

- When the vapor reaches these cooler areas, it condenses back into liquid, releasing the absorbed heat.

- The wick structure inside the chamber uses capillary action to return the liquid to the heat source, starting the cycle again.

This cycle allows for fast and efficient heat transfer. You get better thermal management compared to traditional solid metal heat spreaders. Studies show that vapor chambers with enhanced condensation mechanisms can reduce thermal resistance by 34% compared to older designs. Two-phase closed thermosyphons, which use a similar principle, also show improved heat transfer under different conditions. This means you can rely on vapor chambers for superior cooling efficiency in demanding environments.

Heat spreading

You benefit from excellent heat spreading when you use a vapor chamber. The design uses several mechanisms to move heat across its surface:

- Phase Change: The heat source causes the liquid to turn into vapor. This creates pressure that pushes the vapor toward cooler areas, where it condenses and releases heat.

- Capillary Action: The wick structure draws the condensed liquid back to the heat source, so the process continues without interruption.

- Wick Structure: The design and material of the wick, including its porosity and surface area, play a big role in how well the chamber spreads heat.

These features help you achieve uniform temperature across the entire surface. You avoid hot and cold spots, which is important for protecting sensitive electronics. The vapor chamber’s ability to spread heat quickly and evenly makes it a top choice for high-power devices.

Hotspot reduction

You often face the challenge of hotspots in high-power electronics. Vapor chamber heat sinks help you solve this problem by spreading heat more evenly. Here is how they work to reduce hotspots:

- The two-phase heat transfer process moves heat away from the source and spreads it across the chamber.

- This technology lowers thermal spreading resistance, which is critical for high-density semiconductor applications.

- The vapor chamber vaporizes the working fluid at the heat source, then condenses it on cooler surfaces, redistributing heat.

- The wick structure’s capillary action lets the chamber work in any orientation, so you get consistent cooling.

- Water, as the working fluid, improves heat transfer because of its high latent heat and thermal conductivity.

You can see the impact of vapor chamber heat sinks in the table below:

| Heat Sink Type | Reduction in Thermal Resistance | Temperature Reduction (Degrees) |

|---|---|---|

| Aluminum Heat Sink | 30% | 3-10 |

| Copper Heat Sink | 20% | 3-10 |

With these reductions, you keep your devices cooler and more reliable. Vapor chamber heat sinks give you a clear advantage in managing heat and preventing damage from hotspots.

Advantages in industrial VC coolers

High thermal conductivity

You gain a major advantage when you choose vapor chamber heat sinks for industrial cooling. These devices offer extremely high thermal conductivity, which means they move heat away from critical components much faster than traditional solutions. The vapor chamber uses a sealed design and phase-change technology to transfer heat efficiently. You can see the difference in thermal performance in the table below:

| Cooling Solution | Thermal Conductivity (W/m K) | Max. Heat Flux (W/cm²) |

|---|---|---|

| Vapor Chamber | 5,000 – 100,000 | 750 |

| Aluminum Plate | Lower than vapor chamber | Lower than vapor chamber |

| Encapsulated Conduction Cooling | Lower than vapor chamber | Lower than vapor chamber |

This high thermal conductivity helps you keep sensitive electronics safe and maintain stable operation, even under heavy workloads. You can rely on vapor chamber heat sinks to handle intense heat loads in industrial environments.

Multiple heat sources

You often need to cool several processors or power modules in one system. Vapor chambers excel at managing heat from multiple sources. The chamber accepts heat from each component and spreads it evenly across the surface. You get uniform temperatures and avoid hotspots that can damage equipment. 3D vapor chambers take this a step further by promoting isothermal conditions throughout the assembly. You benefit from efficient cooling, even when your system has many heat-generating parts. Vapor chamber heat sinks connect multiple heat sources to a single cooling solution, such as an air-cooled heat sink or water-cooled edge rails. This integration simplifies your thermal management and improves reliability.

Note: Vapor chambers help you reduce hotspots and maintain consistent temperatures, which is critical for high-density industrial systems.

Space efficiency

You face space constraints in many industrial settings. Vapor chamber heat sinks offer a slim profile, making them ideal for compact environments. You can fit these cooling solutions into tight spaces without sacrificing performance. Here are some space-saving benefits:

- Vapor chamber heat sinks feature a thinner profile compared to traditional heat sinks, allowing for more compact designs.

- The slim profile of vapor chamber cooling systems makes them ideal for devices with limited internal space, integrating seamlessly into tight areas.

You maximize your available space and keep your equipment running cool. Vapor chamber heat sinks support modern industrial designs that demand both high performance and small footprints.

Tip: When you need to cool multiple heat sources in a compact system, vapor chamber heat sinks give you the flexibility and efficiency you need.

Applications of vapor chamber heat sinks

Vapor chamber heat sinks play a vital role in many industries that demand reliable and efficient cooling. You will find these solutions in environments where heat management directly affects performance, safety, and equipment lifespan. Uniform heat distribution is essential in these settings because it prevents hotspots and ensures stable operation.

Power electronics

You encounter power electronics in a wide range of sectors. These systems generate significant heat, especially in compact or high-power designs. Vapor chamber heat sinks help you manage this heat effectively. Here are some common applications:

- Consumer electronics, such as flagship smartphones, gaming laptops, VR headsets, and smart wearables, use vapor chambers to keep devices cool in tight spaces.

- Industrial platforms, including industrial PCs and medical imaging systems, rely on vapor chambers for consistent performance in demanding environments.

- The automotive industry uses vapor chambers in electric vehicle battery packs, inverters, and infotainment systems to maintain thermal safety and compact design.

- Data centers benefit from vapor chambers in high-density servers and GPUs, especially for AI workloads that require tight thermal control.

- Aerospace and defense sectors use vapor chambers in avionics and satellites, where passive cooling is necessary due to limited airflow and extreme temperatures.

You can see that vapor chamber heat sinks support both everyday devices and mission-critical systems. Their ability to spread heat evenly protects sensitive components and extends equipment life.

Data centers

Data centers require advanced cooling to handle the intense heat from servers and high-performance computing equipment. You can improve thermal management and energy efficiency by using vapor chamber heat sinks. Key benefits include:

- The Integrated Flat Thermosyphon Heat Sink (IFTHS) boosts thermal performance by 36% with a superhydrophobic condenser and minichannel evaporator.

- You can reduce overall thermal resistance by 19–41% and lower maximum temperatures by 8–25 °C compared to standard designs.

- Using vapor chambers increases the lifespan of electronic components by up to 17.75 times and reduces the cooling load, making your data center more efficient.

Uniform heat distribution is crucial in these environments. It prevents overheating, reduces energy costs, and keeps your servers running smoothly. Vapor chamber technology helps you meet the demands of modern data centers, especially as AI and cloud computing workloads grow.

LED systems

LED lighting systems generate concentrated heat that can shorten lifespan and reduce efficiency if not managed well. Vapor chamber heat sinks provide the cooling performance you need. The table below shows how this technology impacts LED systems:

| Evidence Description | Impact on LED Systems |

|---|---|

| Vapor chamber technology ensures efficient cooling of high-power LEDs. | Helps maintain optimal performance and prolongs the lifespan of the LED. |

| Maintaining lower operating temperatures improves reliability and longevity. | Leads to reduced maintenance costs and increased overall performance efficiency. |

| Even heat distribution prevents the formation of hotspots. | Reduces performance degradation and enhances efficiency. |

| Cofan’s vapor chambers are widely adopted in LED lighting systems. | Ensures better performance and a longer lifespan for high-power LEDs. |

| Advanced materials like vapor chamber heat sinks provide ultra-efficient cooling. | Essential for preserving the performance and longevity of LED lights. |

You can trust vapor chamber heat sinks to deliver uniform cooling for LED systems. This technology helps you avoid hotspots, reduce maintenance, and ensure your lighting solutions remain reliable and efficient.

Customization and integration

Design flexibility

You can tailor vapor chamber heat sinks to fit your unique industrial needs. The design allows for multiple steam compartments, which help you optimize heat distribution across complex layouts. This flexibility lets you replace bulky solid metal bases with slimmer, more efficient solutions. You can use custom shapes to match irregular component arrangements, improving contact with heat sources and boosting overall performance.

| Design Flexibility Option | Description |

|---|---|

| Shape | Custom shapes fit irregular layouts, improving contact with heat sources for better heat distribution. |

| Thickness | Thinner chambers suit low-profile devices, while thicker chambers enhance heat transfer and stability in high-power applications. |

You can also choose from a range of design options:

- Custom shapes for specific component arrangements

- Variability in thickness for different applications

- Integration with other cooling solutions for enhanced performance

This level of customization means you can address space constraints and thermal challenges in vertically limited environments. You gain the ability to design cooling systems that fit your equipment perfectly, ensuring reliable operation.

Material options

You have several material choices when designing vapor chamber heat sinks. Aluminum and copper are the most common. Copper offers high thermal conductivity, around 400 W/mK, which significantly improves heat transfer. However, copper costs three to four times more than aluminum and adds extra weight. Aluminum provides a lighter and more affordable option, but with lower thermal performance.

| Material/Design | Performance Improvement | Cost Increase |

|---|---|---|

| Baseline Aluminum | – | – |

| 3D Vapor Chamber | 17 °C | 150% |

| Copper Base Plate | 7-15% | Modest |

| U-shaped Vapor Chamber | 28% (15.2 °C) | 15% |

When you select materials, you must balance thermal performance, cost, and weight. Copper improves cooling but may not suit portable or weight-sensitive applications. Aluminum works well for less demanding environments or where budget is a concern. Design engineers often start by considering thermal conductivity, then weigh cost and weight before making a final choice.

Tip: Understanding how material selection affects thermal resistance helps you make better decisions for your cooling needs.

System integration

You may face challenges when integrating vapor chamber heat sinks into existing industrial systems. Thermal modeling can be complex, especially when simulating liquid flow and boiling processes inside the chamber. Cost is another factor that can affect the feasibility of integration. Vapor chambers also have some physical limitations compared to traditional heat pipes.

- Thermal modeling complexities, especially with liquid flow and boiling

- Cost considerations for large-scale or budget-sensitive projects

- Physical limitations in certain configurations

Despite these challenges, custom vapor chamber solutions give you the flexibility to meet demanding cooling requirements. You can work with engineers to design systems that fit your space, performance, and budget needs. Customization and careful integration help you achieve reliable, efficient cooling for your industrial applications.

Challenges and considerations

Complexity

You may notice that vapor chamber heat sinks have a more complex design than traditional cooling solutions. The chamber uses a sealed structure, a wick, and a working fluid. You need to understand how these parts work together. The manufacturing process requires precision. Engineers must control the vacuum level and the amount of fluid inside the chamber. If you want to customize the shape or thickness, you must work with experts who know how to design vapor chambers for your specific needs.

Note: You should plan for extra time during the design phase. Vapor chamber heat sinks need careful modeling and testing to ensure they meet your cooling requirements.

You may also face challenges when integrating vapor chambers into existing systems. The chamber must fit with other components. You need to check compatibility with your equipment. If you use advanced features like multi-compartment chambers, you must coordinate with your supplier to avoid errors.

Cost factors

You will see that vapor chamber heat sinks often cost more than standard heat sinks. The materials, such as copper, increase the price. The manufacturing process adds to the expense because it requires special equipment and skilled labor. If you choose custom designs, you may pay even more.

| Factor | Impact on Cost |

|---|---|

| Material (Copper) | Higher price |

| Custom shapes | Increased expense |

| Manufacturing steps | Added labor costs |

| Testing and modeling | Extra engineering fee |

You should compare the cost of vapor chamber heat sinks with their benefits. These devices offer better thermal performance and space savings. If your application needs high reliability and efficient cooling, the investment may be worth it. For budget-sensitive projects, you may need to balance performance with cost.

Tip: Ask suppliers for quotes on different materials and designs. You can often find a solution that fits your budget and meets your cooling needs.

Maintenance

You will find that vapor chamber heat sinks require little maintenance once installed. The sealed design keeps the working fluid inside, so you do not need to refill or replace it. You should inspect the heat sink during regular equipment checks. Look for signs of physical damage or corrosion. If you see a drop in cooling performance, check for poor contact between the chamber and the heat source.

- Clean the surface to remove dust and debris.

- Check mounting hardware for tightness.

- Inspect for leaks or dents.

You do not need special tools for basic maintenance. If you notice a problem, contact your supplier for advice. Vapor chamber heat sinks are reliable, but you should always monitor your system to catch issues early.

Alert: If you see overheating or temperature spikes, act quickly. Early detection helps you prevent damage to your equipment.

Future trends

New materials

You will see new materials changing the way vapor chamber heat sinks work. Manufacturers now explore advanced alloys and composite materials to improve thermal conductivity and reduce weight. Copper remains popular because it moves heat quickly, but researchers look for lighter options that still perform well. Some companies test graphene and carbon-based materials. These materials can spread heat even faster than copper and help make devices thinner and lighter. You may also notice coatings that protect against corrosion and extend the lifespan of the heat sink. As devices become smaller and more powerful, you need materials that keep up with higher heat loads.

Tip: Watch for new vapor chamber designs that use hybrid materials. These can offer the best balance between performance, cost, and durability.

Smart cooling

You now have access to smarter cooling solutions. The integration of AI technology in heat sink design improves efficiency and cooling performance. AI can monitor temperature changes in real time and adjust cooling power as needed. This means your system stays cool without wasting energy. Advanced cooling technologies, such as 3D-VC heat sinks and liquid-cooled systems, are increasingly used in AI and high-performance computing applications. These systems can handle the intense heat from modern processors and graphics cards. You benefit from better performance and longer equipment life.

- AI-driven cooling systems predict heat spikes and respond quickly.

- 3D vapor chambers spread heat in multiple directions, reducing hotspots.

- Liquid-cooled vapor chambers remove heat faster than air-cooled models.

You can expect more smart features in future vapor chamber heat sinks. These features help you manage complex systems with less effort.

Industrial outlook

You will notice big changes in the industrial cooling market. The vapor chamber technology market is undergoing significant changes due to the rising need for effective thermal management solutions in various sectors. As AI technology progresses, the thermal management requirements for AI servers and high-performance computing devices have become more demanding. Traditional cooling solutions have struggled to meet these needs, leading to the adoption of advanced cooling technologies, which are crucial for maintaining optimal performance in modern high-power devices. You will see more companies choosing vapor chamber heat sinks for data centers, power electronics, and LED systems. The demand for compact, reliable, and efficient cooling will keep growing.

Note: If you plan to upgrade your equipment, consider vapor chamber heat sinks. They offer the advanced cooling you need for the next generation of industrial devices.

Vapor chamber heat sinks give you powerful cooling, space savings, and reliable performance for industrial VC coolers. You can protect your equipment from overheating and boost efficiency. Understanding how vapor chambers work helps you make smart choices for your business.

Tip: Explore new vapor chamber technologies. You will see even better cooling and smarter designs in the future. Consider these solutions for your next project.

FAQ

What is the main benefit of a vapor chamber heat sink?

You get faster and more even heat spreading. This helps your equipment stay cool and work reliably, even under heavy loads.

Can you use vapor chamber heat sinks in any orientation?

Yes, you can install vapor chamber heat sinks in any direction. The wick structure inside the chamber returns liquid to the heat source using capillary action.

How long does a vapor chamber heat sink last?

You can expect a vapor chamber heat sink to last many years. The sealed design keeps the working fluid inside, so you do not need to refill or replace it.

Are vapor chamber heat sinks safe for sensitive electronics?

Yes. Vapor chamber heat sinks keep temperatures stable and prevent hotspots. This protects sensitive components from overheating and damage.

Do vapor chamber heat sinks require special maintenance?

You do not need special maintenance. Just check for dust, physical damage, or loose mounting during regular inspections. Clean the surface if needed.

How do vapor chambers compare to heat pipes?

Vapor chambers spread heat more evenly across a flat surface. Heat pipes move heat along a single path. You get better temperature uniformity with vapor chambers.

Can you customize vapor chamber heat sinks for your application?

Yes. You can choose custom shapes, sizes, and materials. This lets you match the heat sink to your equipment and cooling needs.