What Is a Cooling Heat Sink and How Does It Work

A cooling heat sink is a tool that helps move heat away from important electronic parts. It spreads the heat out over a bigger area. This lets the heat leave into the air. It helps keep your devices cool and working well. If electronics get too hot, they can break. Overheating causes more than 55% of electronic failures, as shown below:

| Cause of Electronic Device Failures | Percentage (%) |

|---|---|

| Overheating (Temperature-related) | Over 55% |

| Vibration | About 45% |

| Humidity | 19% |

| Dust | 8% |

Cooling heat sinks are made from materials like aluminum or copper. These materials help protect your electronics. They also help your devices last longer.

Key Takeaways

- Cooling heat sinks take heat away from electronic parts. This helps devices stay safe and work well. Using a heat sink stops overheating. Overheating causes more than half of electronic failures. Heat sinks spread heat over a big area. They let heat out into the air with fins and airflow. Aluminum and copper are good for heat sinks. These materials move heat well and last a long time. There are many types of heat sinks. Passive ones are quiet and simple. Active ones use fans. There are also hybrid, liquid, and heat pipe systems. You need to pick the right heat sink. Think about your device’s power, space, and cost. Custom cooling and expert help can make cooling better. This can help your device last longer. Heat sinks are very important in computers, LEDs, power devices, and car electronics. They help keep these things cool and working well.

Cooling Heat Sink Purpose

Overheating

You use electronics like computers and phones every day. These devices get hot when they work. If heat builds up, parts like CPUs and GPUs can get too hot. A cooling heat sink helps by taking heat away from these parts. It spreads the heat out so your device stays safe.

- Heat sinks keep devices at safe temperatures.

- They help remove extra heat from important parts.

- Materials like aluminum or copper move heat well.

- Fins make more space for heat to leave into the air.

- Without a cooling heat sink, your device can get too hot and stop working.

If your device overheats, it may slow down or freeze. Sometimes it shuts off without warning. Too much heat can break your device for good. Using a cooling heat sink stops these problems. It helps your electronics work better and last longer.

Tip: If your device keeps getting too hot, you might need a special cooling solution. Free tests and thermal checks can help you find the best design. You can ask for free drawings and get expert advice. Every product is checked to make sure it works well.

Device Longevity

Heat makes electronic devices wear out faster. If you control heat with a cooling heat sink, you protect your device. Heat sinks take away extra heat and stop damage. This helps your device last longer.

- Good heat sinks lower wear and tear.

- Stable temperatures protect solder joints and circuit boards.

- Devices work well for more time.

- Better cooling lets devices be smaller but still strong.

New heat sink designs can help devices run for up to an hour longer when hot. In electronics, cars, and machines, heat sinks help keep things working right. You get fewer repairs, spend less money, and your devices last longer.

If you want your device to last, look at custom cooling options. Free expert checks and tests can help you pick the best heat sink. You get advice on changes to keep your device safe for years.

How a Cooling Heat Sink Works

Heat Absorption

When your device is on, it gets hot. The cooling heat sink takes in this heat from the part. It works best when it touches the part tightly. Copper and aluminum move heat fast. You can use thermal grease or pads to fill small spaces. This helps the heat sink touch better.

- The part makes heat when it works.

- The heat goes into the heat sink by conduction.

- Materials that move heat well and special compounds help this.

Tip: Want better heat absorption? Ask for a free thermal check. Experts can help you pick the best materials and solutions for your cooling system.

Heat Spreading

After heat enters the cooling heat sink, it spreads out. You need materials like copper, aluminum, or graphite to move heat well. Some composites, like carbon fiber polymers and metal matrix composites, also help. These keep the temperature even and stop hot spots.

- Fins, pin fins, and microchannels make more space for heat.

- Phase change materials with metal foams can lower temperature by over 15 °C.

- Heat pipes and vapor chambers use special fluids to move heat fast.

You can pick different shapes and materials for your cooling heat sink. Custom designs let you change fin shapes and spaces. This lowers resistance and makes cooling better.

Note: Free drawing and simulation tools help you design the best heat sink. Every product gets checked to make sure it works well.

Heat Dissipation

After heat spreads, it needs to leave the device. The cooling heat sink lets heat out into the air by convection and some radiation. You can use natural airflow or add fans for forced convection. Fins and other shapes help by making more area touch the air.

Surface Area

A bigger surface area lets more heat escape. Fins and special shapes add area without making the heat sink huge. You can change the number and size of fins for your needs.

| Design Feature | Benefit |

|---|---|

| Fins | More surface area for heat transfer |

| Pin fins | Improved airflow and cooling |

| Microchannels | Faster heat removal in small spaces |

Airflow

Airflow moves heat away from the cooling heat sink. Natural convection happens when warm air rises and cool air comes in. Fans or blowers make forced convection and cool things faster.

- Good airflow lowers temperature quickly.

- Better flow paths lower resistance.

- CFD simulations help you find the best airflow.

Alert: Need extra cooling? Ask for free airflow checks and simulation. Experts can help you change your cooling for best results.

Most cooling problems can be fixed with the right cooling heat sink. Custom designs, free expert help, and full checks keep your device safe and working well.

Types of Cooling Heat Sinks

Passive

A passive cooling heat sink uses only natural ways to move heat. You do not need fans or pumps for this type. Heat goes from the hot part to the heat sink. Then, it spreads into the air by conduction, convection, and radiation. This works best for devices that do not make much heat or need to stay quiet.

You get many good things with passive cooling:

- There are no moving parts, so it does not break easily.

- It makes no noise, so it is great for quiet places.

- You do not have to fix it often, since there are fewer parts.

- It saves energy because it does not use extra power.

- It costs less to make because the design is simple.

But passive cooling also has some problems:

- It cannot cool big heat loads unless you use a large heat sink.

- You might need more space for bigger heat sinks.

- You cannot control the temperature as much.

- If the room is hot, it may not work as well.

| Advantage / Disadvantage | Explanation |

|---|---|

| Advantages: | |

| Simplicity | No moving parts like fans or pumps, so it breaks less |

| Zero Noise | Works quietly, good for places where noise matters |

| Lower Maintenance | Fewer things to fix or change |

| Energy Efficiency | Uses natural convection, so no extra power needed |

| Lower Manufacturing Cost | Simple design means it costs less to make |

| Disadvantages: | |

| Limited Cooling Capacity | Only uses natural heat flow, so it cannot cool big heat loads unless it is very large |

| Space Requirement | Needs bigger heat sinks or cases to cool well |

| Less Control | Hard to keep the temperature steady or cool down fast |

| Performance Limits in High Ambient Temperatures | May not keep things cool if the room is hot, unless you make it bigger or add more airflow |

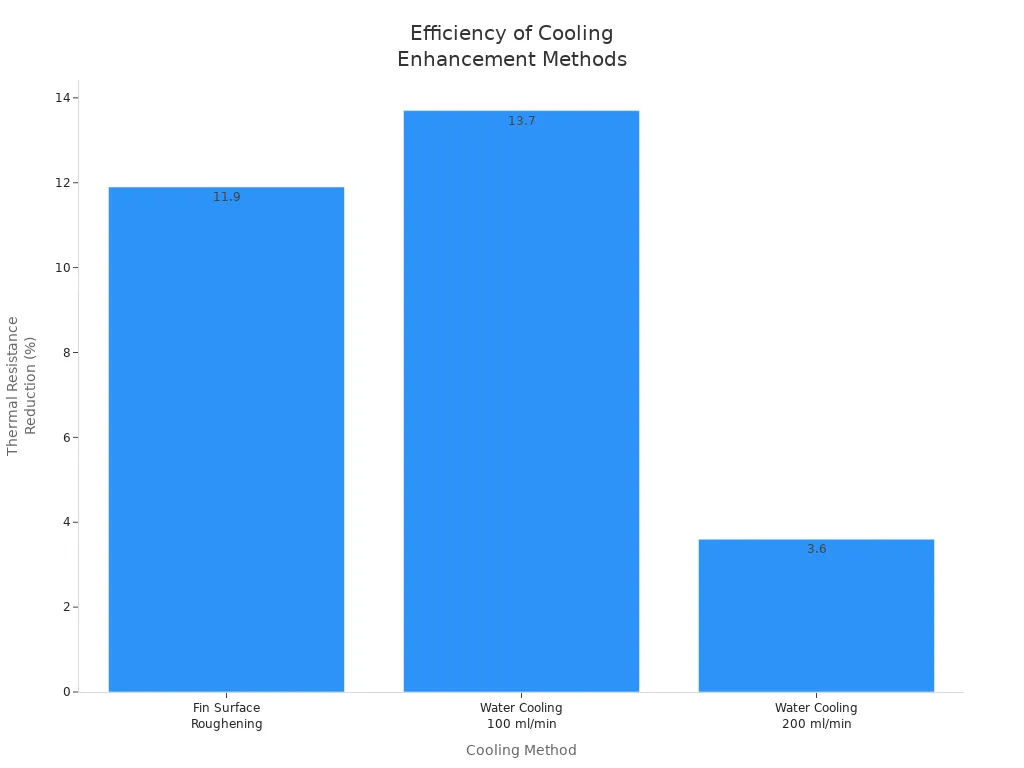

You can make passive cooling better by using special materials or changing the surface. For example, making the fins rough can lower thermal resistance by almost 12%. If you need help picking the right passive cooling, you can ask for a free thermal check and custom design. Experts can help you choose the best size, shape, and material, and every product is checked before you get it.

Active

Active cooling heat sinks use things like fans or blowers to move air. This helps take away heat faster. It works well for things that get very hot, like gaming computers or big machines.

Active cooling gives you many benefits:

- It cools better for tough jobs.

- You can change the power for different needs.

- It works well even when it is hot around the device.

But there are some downsides:

Fans and blowers use more power.

You might hear noise from the moving parts.

You have to fix or change fans sometimes.

The system can be bigger and take up more space.

Active heat sinks use fans or blowers to push air, so heat leaves faster.

They can handle higher heat and are good for strong devices.

You get high cooling power and can change the power level.

But they use more power, make noise, and need more care.

Active heat sinks are common in gaming PCs and big machines.

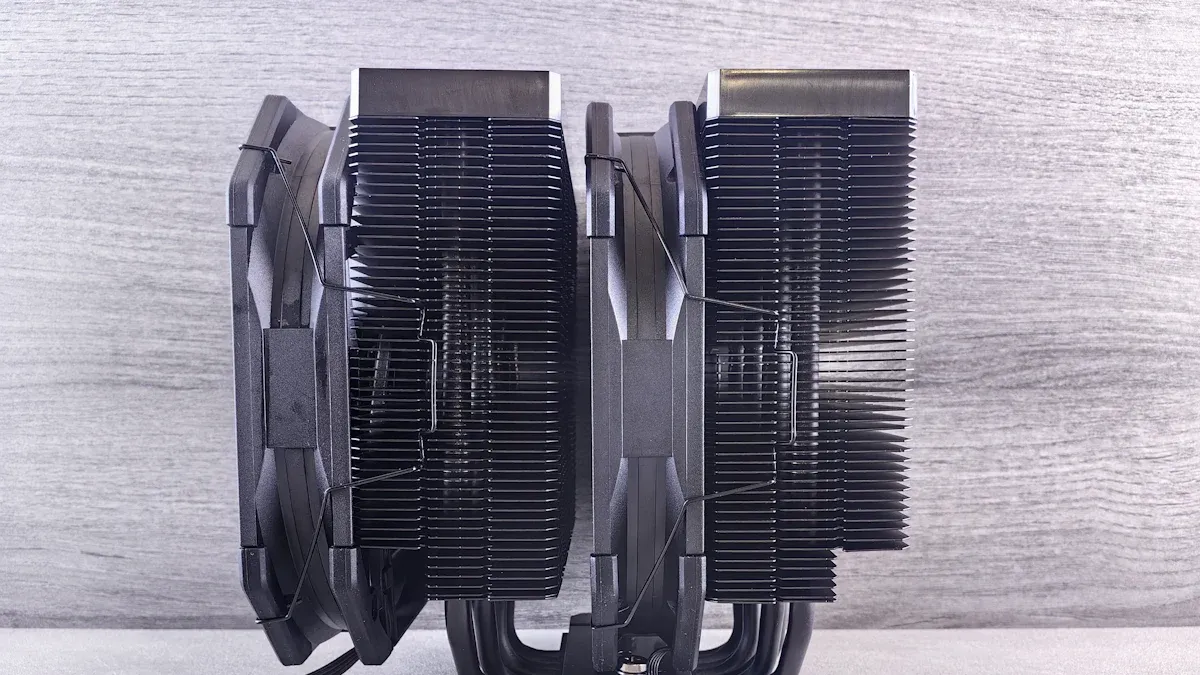

You can see how passive and active cooling work differently in the chart below:

If you want to make your cooling better, you can ask for a free airflow test or custom design. Experts can help you pick the right fan size and speed, and every product is checked before you get it.

Hybrid

Hybrid cooling heat sinks use both passive and active ways to cool. You get a big area for heat to leave and extra airflow from a fan or blower. Some hybrid systems use special materials like phase change materials or heat pipes to work even better.

Key things about hybrid cooling:

- It cools better by using both airflow and surface area.

- The designs can be small and light for tight spaces.

- It is quieter because fans can run slower.

- It keeps the temperature steady for sensitive electronics.

Hybrid cooling works well for many things:

- CPUs and servers in computers.

- LED lights.

- Car electronics like motor controllers.

- Big machines like power supplies.

| Cooling Method | Key Findings on Efficiency and Performance |

|---|---|

| Passive (PCM-based) | Using 1-hexadecanol PCM made process time shorter by 41-43% compared to just passive cooling; it also worked better for quick heat changes. |

| Hybrid (PCM + Heat Pipe) | Base temperature dropped by about 38-39% at heat fluxes of 2-3 kW/m²; energy use got better by about 83.3% over regular heat sinks. |

| Active (Air/Water Cooling) | Active cooling with rough surfaces and special fluids lowers thermal resistance and helps heat move faster. |

Hybrid cooling heat sinks with coolants like supercritical CO2 can move heat up to 50% better and lower base temperatures by about 10 K. These systems work better than old water-cooled designs and are good for hot and small spaces.

If you need a special hybrid cooling system, you can ask for a free check and test. Experts will help you design the best system for your device, and every product is checked before it is sent to you.

Liquid

Liquid cooling is a strong way to handle heat in electronics. You use water or special fluids as coolants. These coolants take heat away from hot parts. The system has cold plates, pumps, and heat exchangers. It works in a closed loop. You can set the temperature and flow rate exactly. This keeps your device working well, even when it gets very hot.

Liquid cooling works better than air cooling. The table below shows the main differences:

| Aspect | Liquid Cooling | Air Cooling |

|---|---|---|

| Thermal Conductivity | Coolants have much higher thermal conductivity | Air has low thermal conductivity |

| Heat Transfer Coefficient | Up to 10,000 W/m²K | Typically 10–100 W/m²K |

| Temperature Reduction | Can reduce equipment temperature by up to 20°C | Less effective in high heat or dense setups |

| Efficiency | More energy-efficient, better heat transfer | Less efficient, limited by air properties |

| Noise Level | Produces less noise due to fewer or slower fans | Higher noise due to high-speed fans |

| Complexity & Maintenance | More complex, costly, risk of leakage | Simpler, cheaper, easier maintenance |

| Application Suitability | Preferred for high-performance, high-density | Suitable for cost-sensitive, space-limited |

Liquid cooling moves heat much better than air. It can be up to four times more effective. You get lower temperatures and less noise. Your device works better and lasts longer. This system is best for gaming computers, data centers, and car electronics. It helps when there is lots of heat and not much space.

Tip: Need a custom liquid cooling system? You can ask for a free thermal check and simulation. Experts help you design the right system. You get free drawings and every product is checked before you get it.

Liquid cooling needs careful setup and regular checks. You must look for leaks and make sure pumps and hoses work. These systems cost more and need more care. But they give the best cooling for tough jobs.

Heat Pipe

Heat pipes are a smart way to move heat fast. You see them in laptops and servers. A heat pipe is a sealed tube with special fluid inside. When one end gets hot, the fluid turns into vapor. The vapor moves to the cool end. There, it turns back into liquid and gives off heat. The liquid goes back to the hot end through a wick. This cycle keeps going with no moving parts.

Heat pipes give you many good things:

- They move heat without using extra power.

- You can send heat from chips to far-away heat sinks.

- They work quietly and need little fixing.

- New wick designs and fluids make them work better.

- Strong materials like copper alloys help them last longer.

- Some systems mix vapor chambers and heat pipes for better cooling.

Modern heat pipes are thin and bend easily. You can use them in small devices and powerful chips. Putting them in the right spot helps handle more heat and keep things cool.

Note: You can get free expert help and custom heat pipe designs. Thermal tests and full checks make sure your cooling system works well.

Heat pipes help you fix hard cooling problems. Your electronics stay safe, quiet, and work well, even when things get tough.

Materials

Picking the right material for your heat sink is important. The material affects how well your device stays cool. You want a material that works well, is not too heavy, and does not cost too much. It should also last a long time. Let’s see which materials are used most and how they help your cooling system.

Aluminum

Aluminum is the most common material for heat sinks. It has high thermal conductivity, about 237 W/m·K. This means it moves heat away from parts quickly. Aluminum is also light, with a density of about 2.70 g/cm³. This low weight is good for portable electronics and aerospace devices.

Manufacturers like aluminum because it is easy to shape. They can use extrusion, die-casting, or machining. You can get custom or complex designs for less money. Aluminum has a natural oxide layer that stops corrosion. This helps your heat sink last longer, even in tough places.

Tip: If you need a custom aluminum heat sink, you can get free thermal analysis and drawings. Experts will help you change the design for your needs. Every product is checked before you get it.

Here is a quick table comparing aluminum and copper heat sinks:

| Aspect | Aluminum Heat Sinks | Copper Heat Sinks |

|---|---|---|

| Thermal Conductivity | ~200-237 W/m·K | ~400 W/m·K |

| Weight (Density) | ~2.70 g/cm³ | ~8.96 g/cm³ |

| Cost | Lower | Higher |

| Corrosion Resistance | Excellent | Good |

| Manufacturing | Easy, cost-effective | More labor-intensive |

| Application Suitability | Portable, cost-sensitive devices | High-performance, heat-intensive devices |

Copper

Copper has better thermal conductivity than aluminum, up to 400 W/m·K. It moves heat faster and more efficiently. This is important for high-performance electronics like gaming laptops and power devices. Copper spreads heat quickly and keeps your device safe, even when it works hard.

Copper is heavier and costs more than aluminum. Its density is about 8.96 g/cm³, so it adds weight. If you need the best cooling, copper is a great choice. But you must think about the extra weight and price.

Copper does not rust easily and can handle high temperatures. You can shape it into complex forms. Special surface treatments make it last longer. Copper can change color over time, but this does not hurt how it works.

| Property/Factor | Advantages | Considerations/Limitations |

|---|---|---|

| Thermal Conductivity | High (~398 W/m·K), enables quick heat transfer | Heavier than aluminum, may be a drawback in weight-sensitive designs |

| Heat Capacity | Absorbs and stores significant heat energy | More expensive than aluminum |

| Malleability & Ductility | Easy to shape into complex designs | Can oxidize over time, affecting appearance |

| Corrosion Resistance | Good resistance, ensures longevity and reliability | Effectiveness depends on proper design and thermal interface |

Note: If you want a custom copper heat sink, you can get free simulation and expert advice. You get help with design changes. Every product is checked before shipping.

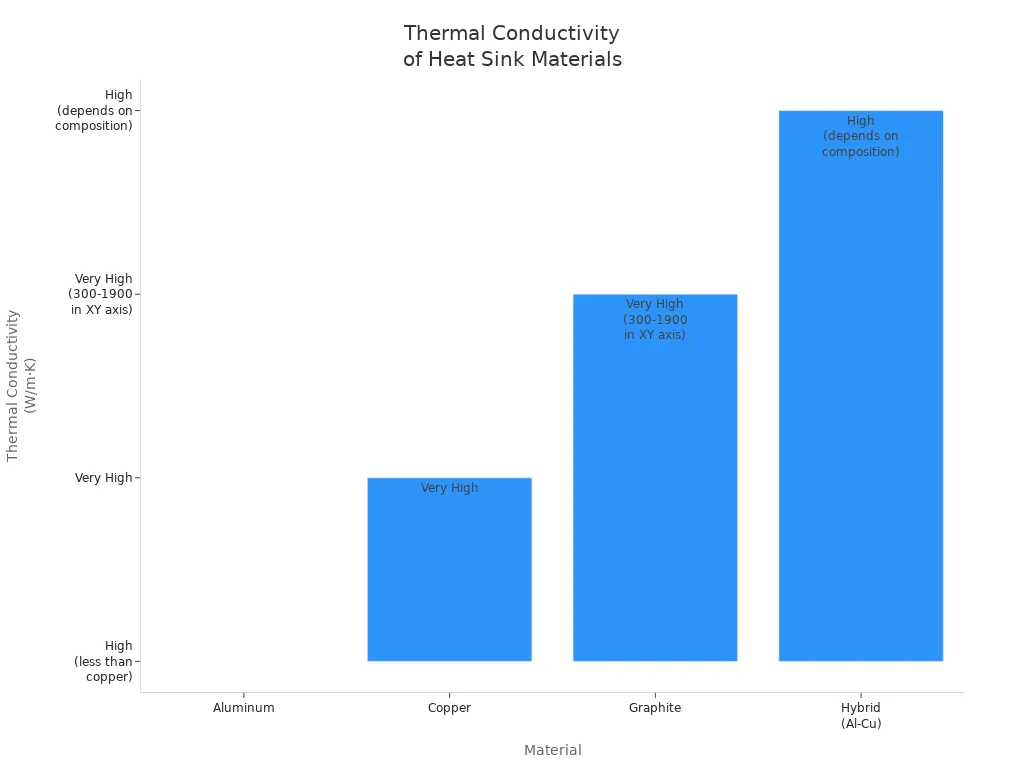

Performance

The material you pick changes how well your heat sink works. Copper and graphite foam have the highest thermal conductivity. They are best for devices that make a lot of heat. Aluminum is a good choice if you want something that is not too heavy or expensive. That is why most consumer electronics use it.

Think about these points when picking a material:

- Aluminum is best for light and low-cost devices.

- Copper is good for systems that need the most cooling.

- Graphite foam is light and works well, but it costs more and can break easily.

- Hybrid designs use more than one material to balance cost, weight, and performance.

If you want the best cooling, you can get free thermal simulation and analysis. Experts will help you pick the right material and design. Every custom solution is checked to make sure it works well.

Choosing a Heat Sink

Picking the right heat sink is very important. You need to think about many things to keep your electronics safe. Every device is different, so you must match the heat sink to your system. Custom cooling can fix special problems. Our company gives free analysis, simulation, and drawing help. Each product gets checked before it is sent to you.

Power Output

First, look at how much power your device uses. Power output shows how much heat your device makes. More power means more heat. You need a heat sink that can handle this heat. A heat sink with low thermal resistance moves heat away faster. Makers give thermal resistance curves to show how much heat a heat sink can handle at different power levels.

You can use this formula to help you choose:

TJ = TA + PD × θ

- TJ: Junction temperature (the hottest part of your device)

- TA: Ambient temperature (the air around your device)

- PD: Power dissipation (how much heat your device makes, in watts)

- θ: Thermal resistance of the heat sink (in °C/W)

If your device makes more heat, pick a heat sink with lower thermal resistance. This keeps your device safe and helps it last longer. Smaller and stronger devices may need better cooling.

Tip: You can get a free thermal simulation to see how much heat your device makes. Our experts help you pick the best heat sink for your power needs.

Space

Space is tight in modern electronics. Measure the area where the heat sink will go. Make sure it fits and does not block other parts or airflow. Small devices need special designs. Microfin heat sinks and vapor chambers work well in small spaces. These give more surface area without using extra room.

- Check the space before picking a heat sink.

- Think about the height and weight of the heat sink.

- Use thin or low-profile designs for small devices.

- Make sure the heat sink does not block airflow or other parts.

Some devices use hybrid heat sinks to balance performance and space. You can also try graphene-based or built-in cooling for tiny devices.

Note: Our team gives free drawings and ideas for custom designs. We help you change your cooling to fit your space.

Cost

Cost is important when you pick a heat sink. Different types cost different amounts. The table below shows how cost changes with design and material:

| Heat Sink Type | Cost Level | Main Cost Drivers |

|---|---|---|

| Extruded Aluminum | Low | Mass production, simple design |

| Bonded-Fin | High | Complex assembly, mixed materials |

| Skived | High | Precision machinery, slow process |

| Forged | High | Strong build, high material and process cost |

| Die Cast | Moderate | Flexible design, alloy choice |

| Material Choice | Varies | Copper costs more than aluminum |

Aluminum heat sinks cost less and work well for most devices. Copper and complex designs cost more but cool better. Think about system-level costs too. A better heat sink can lower fan power, reduce noise, and cut repairs. This saves money over time.

Alert: We give free cost checks and help you find the best value. Our experts suggest ways to lower your total cost. Every product gets checked before shipping.

Applications

Computers

People use computers for many things like work and games. Inside a computer, the CPU and GPU get hot when they run. Cooling is needed to keep these parts safe and fast. Most heat sinks in computers are made of aluminum or copper. These metals pull heat away from the processor. The heat spreads out over a bigger area. Fins on the heat sink give more space for heat to leave. Fans blow air over the fins to cool them faster. Some computers use heat pipes or vapor chambers. These help move heat quickly and keep things cool even when working hard.

Thermal paste fills small spaces between the processor and heat sink. This helps heat move out faster. If you play games or do design work, you need stronger cooling. High-performance heat sinks with heat pipes or vapor chambers can lower chip temperatures by up to 50°C. This stops slowdowns and keeps your computer running well.

Different computer uses need different cooling:

| Application Category | Common Applications | Performance Requirements and Considerations |

|---|---|---|

| High-performance computing | GPUs, CPUs | High thermal dissipation, vapor chambers, heat pipes, low thermal resistance |

| Consumer electronics | Laptops, tablets | Compact, lightweight, extruded aluminum, size and weight limits |

If you want a special cooling system, you can get free thermal checks and drawings. Experts help you pick the best design for your computer. Every product is checked before it is sent to you.

LEDs

LED lights are used in homes and on streets. LEDs make light by sending electricity through a chip. This makes heat. If you do not control the heat, LEDs get dim and change color. High heat can make LEDs stop working early. A good heat sink keeps LEDs cool and working well.

Aluminum and copper heat sinks move heat away from the LED chip. Fins and special shapes give more area for heat to escape. Powerful LEDs may need fans or liquid cooling. This keeps the temperature low and helps LEDs last longer.

Heat sinks help LEDs in these ways:

| Aspect | Explanation | Impact on LED Efficiency and Lifespan |

|---|---|---|

| Heat Dissipation | Heat sinks manage heat from LEDs, keeping junction temperatures safe | Prevents color shifts, aging, and performance loss |

| Lumen Degradation | High heat speeds up aging, reducing light output | Lifespan at 75°C ~39,000 hours vs. 90,000 hours at 50°C |

| Heat Sink Design | Aluminum or copper, optimized surface area, thermal interface materials | Maintains LED performance and reliability |

If you need help with LED cooling, you can ask for free checks and custom designs. Experts can suggest ways to improve cooling. Every solution is checked for quality.

Power Devices

Power devices like transistors and inverters handle lots of electricity. These parts get very hot when they work. You must keep them cool to stop damage and help them work well. Heat sinks take in and spread heat from these devices. This stops overheating and helps them last longer.

You can pick from extruded aluminum, high-performance, or liquid-cooled heat sinks. Each type fits different needs. PCM-impregnated heat sinks help with sudden heat in GaN transistors. These designs keep temperatures safe, even when loads are high.

| Aspect | Explanation |

|---|---|

| Temperature Management | Heat sinks absorb and dissipate heat, preventing thermal stress |

| Reliability and Longevity | Keeps devices within safe temperature ranges, extending lifespan |

| Efficiency | Controlled temperature improves performance under heavy loads |

| Types of Heat Sinks | Custom, extruded aluminum, high-performance, and liquid-cooled heat sinks for specific needs |

| Applications | Used in power supplies, inverters, converters, LED drivers, electric vehicles, and data centers |

You can get free thermal tests and expert advice for your power devices. Custom solutions help fix cooling problems and make devices more reliable. Every product is checked before you get it.

Automotive

Automotive electronics work in hard places. Cars get very hot and shake a lot. There is also dust inside vehicles. Engine control units and power modules need good cooling. Lighting systems also need to stay cool. If heat is not managed, parts can break early. Sometimes they stop working when you need them most.

Many cars use aluminum extrusion heat sinks. These heat sinks move heat away fast. Aluminum has high thermal conductivity. The heat sinks are light, so cars stay efficient. Aluminum costs less and can be shaped in many ways. You can change the design for your car’s cooling needs.

Most automotive heat sinks use passive cooling. This means heat moves by conduction, convection, and radiation. No extra power or moving parts are needed. Engineers make passive cooling better by changing fin density. They also change surface area and how the heat sink is mounted. Heat spreads out to stop hot spots. Special surface treatments help heat leave faster. You get cooling that works well and needs little care. This is good for tough car conditions.

Car electronics must handle big temperature changes. They work from -40 °C to 125 °C. Coolants and materials must stand up to shaking, dust, and chemicals. You need cooling that stays safe and steady, even when things change fast. Engineers use smart tools to pick the best coolants and materials. They check thermal conductivity, viscosity, dielectric constant, and stability. This gives you a cooling system that lasts a long time.

Automotive heat sinks help powertrain and lighting systems. They keep power electronics and LED lights cool. Your car’s important parts work better and last longer. Custom cooling lets you change the design for your car’s needs.

Tip: You can ask for free thermal checks and custom drawings for your car’s cooling. Experts help you fix hard cooling problems. Every product is checked before you get it, so you know it will work.

- Aluminum extrusion heat sinks move heat fast and are light.

- Passive cooling is reliable and needs little care in cars.

- Engineers change fin density and surface area to help heat leave.

- Strong coolants and materials stand up to tough conditions.

- Custom designs keep your car’s electronics cool and safe.

A cooling heat sink keeps your electronics from getting too hot. It moves heat away from important parts. This helps your devices last longer and work better. Picking the right design, material, and airflow makes cooling stronger. New shapes and smart materials help cool future devices even more. If you need help, you can get free checks, custom designs, and full testing to fix cooling problems.

FAQ

What is a custom cooling system?

A custom cooling system is made just for your device. It is built to fit your electronics, space, and power needs. Custom systems help remove heat and keep your device safe.

How do I request a free cooling analysis?

You tell our team about your device. We run free thermal tests and give you advice. You get help to fix your cooling problem.

Tip: Share your device details to get a free drawing and check.

Can you modify an existing heat sink design?

Yes, we can change or redesign your heat sink. We give free ideas and drawings. You get a solution that fits your space and cooling needs.

What materials can I choose for my custom heat sink?

You can pick aluminum, copper, graphite, or hybrid materials. Our experts help you choose the best one for your device and budget.

| Material | Benefit |

|---|---|

| Aluminum | Lightweight |

| Copper | High conductivity |

| Graphite | Very efficient |

How do you ensure product quality?

We check every cooling system before sending it out. You get a product that passes a full inspection. This makes sure your electronics are safe and work well.

What if my device has unique cooling challenges?

You tell our experts about your problem. We do free tests and suggest custom fixes. You get steps to change your cooling system for hard problems.

Do you offer support after installation?

Yes, you get help even after you install your system. Our team helps you make changes and solve problems. You get advice for upgrades and fixing issues.

How long does it take to get a custom cooling solution?

You get a quick answer after you ask for help. Free tests and drawings take a few days. Then we make and check your solution, so you get it fast.