Why AI Robotics Require Advanced Custom Cooling Solutions

AI Robotics are changing how industries work very fast. There are now 4,664,000 industrial robots in 2024. This number has doubled in the last ten years.

- AI-powered robots are growing at 18.4% each year from 2023 to 2032.

- Asia has 74% of all new robots.

| Year | Average TDP (watts) for GPUs | Average TDP (watts) for CPUs |

|---|---|---|

| 2019 | 300 | 200-250 |

| 2024 | 1000 | 500 |

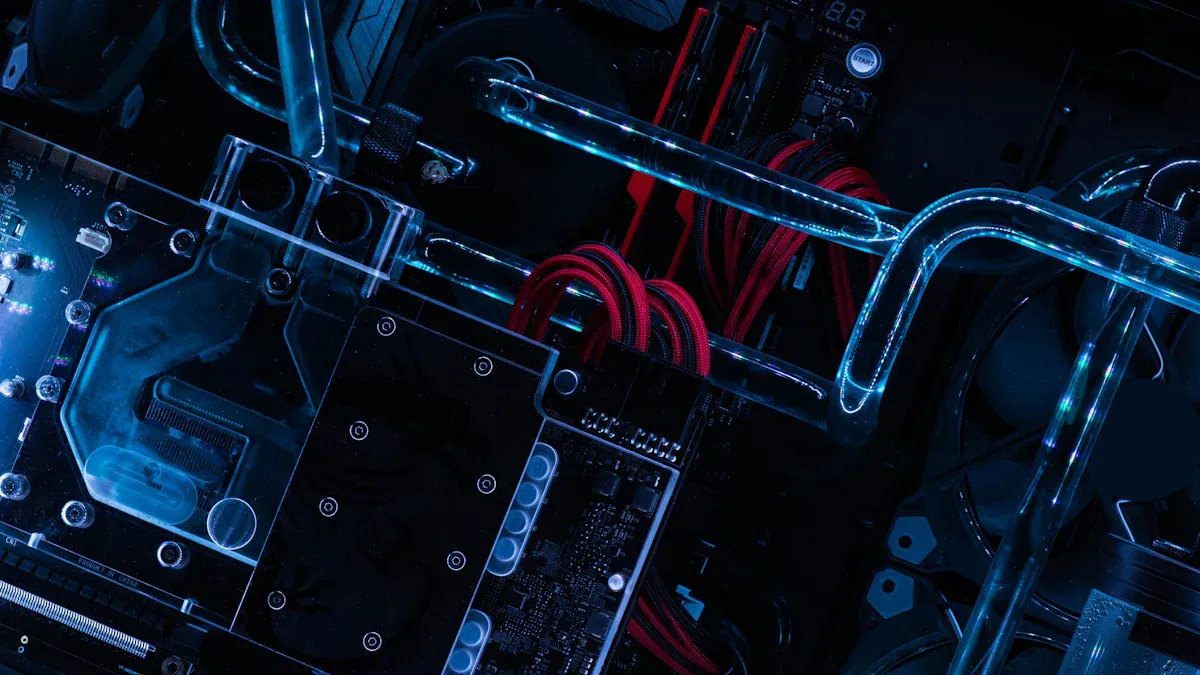

AI chips that work very fast make a lot of heat. Regular cooling systems cannot handle this much heat. You need special cooling to keep robots working well and for a long time. New cooling methods, like liquid cooling, help control heat better and let robots keep getting better.

Key Takeaways

- AI robotics are growing fast. There are over 4.6 million industrial robots in 2024. This shows we need good cooling solutions. High-performance AI chips get very hot. They need special cooling, like liquid cooling, to work well. Small AI robots do not have much space for air to move. This makes special cooling important to stop them from getting too hot. Custom cooling helps robots last longer. It stops heat from breaking them and keeps them working right. Robots in tough places, like factories or hospitals, need special cooling. These systems help them handle dust, heat, and shaking. Regular cooling systems do not always work for AI robots. Custom cooling is needed to make them work better. New cooling methods, like direct liquid cooling and phase-change materials, help control heat and save energy. Working with experts in custom cooling can make robots work better and get used faster.

AI Robotics Heat Challenges

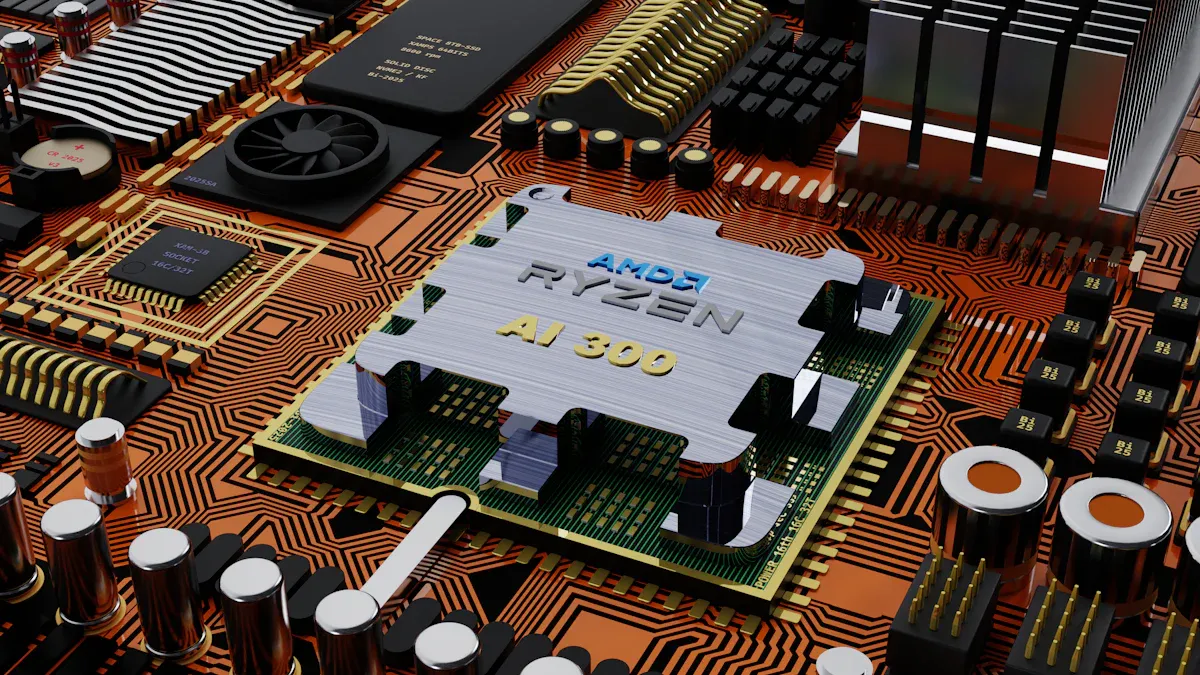

High TDP Chips

AI Processors

High-performance AI processors make a lot of heat. These chips work fast and get very hot. Artificial skin materials do not let heat escape easily. This traps heat inside the processor. Robots need cooling systems that keep them cool and moving. If heat is not managed, robots can slow down or stop.

- Artificial skin does not let heat out well.

- Cooling systems must let robots move and bend.

GPUs

GPUs also get very hot in AI Robotics. They do hard math and run for a long time. Advanced cooling keeps them safe from heat. Standard cooling can hurt the GPU or make it die sooner. Custom cooling helps control heat and keeps robots working.

Compact Designs

Limited Airflow

AI Robotics are often small to save space and weight. Small spaces do not let air move well. This makes heat stay inside the system. Cooling these small robots needs extra care. Without good airflow, heat builds up and causes problems.

Dense Integration

Many parts are packed close together on the PCB. This makes overheating more likely. Good PCB cooling stops failures and helps parts last longer. Special cooling like thermal vias and custom heat sinks help keep things cool.

- Thermal vias move heat away from hot spots.

- Custom heat sinks pull heat from crowded places.

- Cold plate cooling uses liquid to take heat away, which works better than air in small robots.

- Coolant channels or tubes help spread heat out in powerful AI robots.

AI and machine learning keep getting better. Cooling must get better too. Small robots make more heat. New cooling ideas help robots work well and stay safe.

Continuous Use

24/7 Operation

AI Robotics often work all day and night. Cooling must handle heat all the time. Without strong cooling, robots can get too hot and break.

Long Lifespan

You want robots to last for years. Heat makes electronics break early. Custom cooling protects your robots and helps them last longer.

Harsh Environments

Industrial

AI robotics often work in factories with heat, dust, and shaking. These places are tough for every part of the robot. Machines make the air hot, and there is not much fresh air. This can make the inside of robots get hot fast. If you use normal cooling, robots can overheat and break down a lot.

Custom cooling is needed in these hard places. You need cooling that handles heat from chips and outside machines. A custom heat sink with a bigger area or vapor chambers can pull heat away from important parts. Liquid cooling can move heat out, even if dust blocks the air.

Tip: Pick cooling parts that do not rust or collect dust. This helps your AI robotics last longer in rough places.

Vibration is also a problem. Robots in factories work near big machines. You must mount your cooling parts tightly so they do not get damaged. This keeps your robot safe and working. Using the right cooling for your robot saves money and time.

Medical

Medical places need a different kind of cooling. Here, AI robotics must stay cool and quiet. Hospitals and clinics need low noise and robots that always work. If robots get too hot, they can stop working and put patients at risk.

Custom cooling for medical robots is made to be silent and keep the right temperature. You might use special heat sinks with no fans or materials that soak up heat without moving. These ways keep robots cool and quiet.

Note: Medical robots work near other important machines. Fans or pumps can make signals that mess up other devices. Custom cooling can stop this by using shielded or quiet systems.

You also must keep things clean. Smooth and sealed cooling parts stop germs from growing and are easy to clean. Picking the right custom cooling helps your AI robotics work safely and well in all medical places.

Standard Cooling Limits

Off-the-Shelf Issues

Poor Fit

If you use off-the-shelf cooling, you may have problems. These coolers do not fit the special shapes of AI robots. Many robots are small and have parts close together. Standard coolers can block moving pieces or use too much space. Sometimes, these coolers do not touch the hottest spots on the circuit board. This means some areas do not cool down enough and can get too hot.

- Standard cooling does not work well in small robots.

- Many off-the-shelf coolers cannot fit new AI systems.

- Robots may not work as well if cooling does not fit.

Inadequate Dissipation

Air cooling cannot handle the heat from strong AI tasks. Air cooling works only up to 35°C. When robots do hard jobs, they get much hotter. Off-the-shelf coolers cannot cool robots with 50-100 kilowatts, which is common now. You need custom cooling to handle this much heat.

- Old air cooling is not enough for today’s AI.

- Moving from air to liquid cooling is now needed.

- Standard coolers often cannot protect chips and custom heat sink spots.

Tip: Always check if your cooling can handle your robot’s real heat, not just the average.

Overheating Risks

Performance Loss

If cooling cannot keep up, robots slow down. High heat makes processors and GPUs run slower to stay safe. This means AI Robotics cannot work as fast. You may see delays, slow answers, or mistakes when training AI models.

System Failures

Too much heat can break hardware. Circuit boards and connectors can crack or snap. Storage can lose data or slow down. Robots may crash or restart during important jobs. The table below shows what can go wrong when robots overheat:

| Evidence Type | Description |

|---|---|

| Damage to Circuit Boards and Connectors | High heat can crack solder joints and break circuits, causing communication problems. |

| Risk of Data Loss in Storage Devices | Too much heat can slow reading and writing, causing data loss for AI. |

| System Crashes and Downtime | Over-temperature protection can shut down robots, stopping AI work. |

| Calculation Errors and Reduced Precision | High heat can change how electricity works, causing mistakes in AI training. |

| Abnormal Software Operation | Unstable heat can make software freeze or send wrong data. |

| Increased Energy Consumption | Cooling uses more power when it is hot, costing more money. |

| Hardware Repair and Replacement Costs | More hardware breaks from heat, so repairs cost more. |

| Business Interruption Losses | Server downtime can lose money and hurt your reputation. |

Shorter Lifespan

Heat hurts electronics. If robots get too hot, their parts break faster. You will need more repairs and spend more money. Over time, overheating can even cause safety problems, like fire in old robots. Using custom cooling and a custom heat sink keeps your robots safe and working longer.

Advanced Cooling Solutions

Direct Liquid Cooling

Chip-Level Cooling

High-performance chips in AI Robotics get very hot. Direct-to-chip liquid cooling helps manage this heat well. Coolant moves over the hottest parts like CPUs and GPUs. This method removes heat much faster than air cooling. It is up to 3,000 times more effective than air cooling. Robots can run fast without getting too hot. You also use less energy, which saves money.

Tip: Direct liquid cooling is best for high compute density. It helps stop thermal throttling.

System Integration

You can add direct liquid cooling to the whole robot. Cooling plates, tubes, and pumps connect to all important parts. This setup removes heat evenly from the device. System integration allows custom cooling for different robot shapes. You can design cooling for tight spaces and complex boards. This protects your robots and helps them last longer.

Air-Assisted Liquid Cooling

Hybrid Methods

You can mix air and liquid cooling for hybrid systems. Liquid absorbs heat from chips, and air moves heat away from the liquid. Hybrid cooling uses smaller and lighter parts. These systems fit into small robots and still work well. Hybrid methods let you match cooling to your robot’s needs.

- Liquid cooling moves heat better and faster.

- Hybrid systems give higher thermal performance in small robots.

- You can handle heat from strong AI tasks.

Efficiency Gains

Liquid cooling transfers heat up to four times better than air. Robots stay cooler even when working hard. Good thermal management is important for AI jobs. The table below compares cooling methods:

| Cooling Method | Heat Transfer Efficiency | Suitability for AI Workloads |

|---|---|---|

| Air Cooling | Lower | Less effective |

| Liquid Cooling | Higher (up to 4X) | More effective |

Air-assisted liquid cooling boosts efficiency and reliability. This helps stop overheating and keeps robots working longer.

Phase-Change Materials

Heat Absorption

Phase-change materials help absorb heat in robots. These materials, like shape-memory alloys, use mechanical force to cool. Bending or pressing them makes a temperature change. This cools the area and manages heat from high TDP chips. The super elastic effect lets them go back to their original shape. You get good heat management without big cooling systems.

- Phase-change materials improve heat absorption.

- They cool using mechanical stress.

- Elastocaloric cooling uses the super elastic effect for better heat control.

Application Areas

You can use phase-change materials where space is small and heat builds up fast. These materials work well in custom cooling for compact robots. They are good for medical robots, edge devices, or places needing quiet and safe cooling. They support custom heat sink designs and help meet safety and performance rules.

Note: Phase-change materials give a new way to cool AI Robotics. They do not add noise or extra weight.

Advanced Heat Sinks

Custom Designs

You need advanced heat sinks to keep your AI robotics cool and reliable. Custom heat sink designs fit the exact shape and size of your robot’s components. This approach gives you better contact with hot spots and removes heat more efficiently than standard options. You can choose from many materials, such as copper or aluminum, to match your robot’s needs.

- Advanced Thermal Solutions now offers heat sinks made for NVIDIA Jetson modules. These modules power many AI robotics systems.

- You can select passive or active heat sinks. Passive heat sinks use only metal fins to spread heat. Active heat sinks add small fans for extra airflow.

- Some custom heat sinks reach thermal resistance as low as 0.21°C/W. This level of performance keeps high-performance AI chips cool, even in tight spaces.

Custom cooling solutions let you design heat sinks that fit around moving parts or inside compact enclosures. You can also add features like thermal pads or direct mounting to the chip. This flexibility helps you solve the unique heat problems in AI robotics.

Tip: Always match your custom heat sink to the power and layout of your AI system. A good fit means better cooling and longer life for your robot.

Vapor Chambers

Vapor chambers give you another powerful way to manage heat in AI robotics. These flat, sealed chambers use a small amount of liquid inside. When your chip gets hot, the liquid turns to vapor and spreads heat quickly across the chamber. The vapor then cools and returns to liquid, repeating the cycle.

You can use vapor chambers in custom heat sink designs for even cooling. This method works well for high TDP chips and crowded circuit boards. Vapor chambers move heat away from hot spots and spread it over a larger area. This keeps your AI robotics running at top speed without overheating.

- Vapor chambers weigh less than thick metal blocks.

- You can fit vapor chambers into thin or oddly shaped spaces.

- Many engineers use vapor chambers in edge devices and compact robots.

Custom cooling solutions that use vapor chambers help you meet strict size, weight, and performance goals. You get stable operation, less risk of thermal throttling, and longer service life for your AI robotics.

Note: Vapor chambers work best when you need fast, even heat spreading in a small space. They support the next generation of AI robotics and high-performance edge devices.

Cooling Benefits

AI Robotics Performance

Stable Operation

You want your robots to work well, even with hard jobs. Advanced cooling solutions keep your AI systems at the right temperature. Custom cooling solutions help robots run for many hours without overheating. Stable operation means robots do not stop or slow down during important tasks. You can trust your robots to give the same results every time.

- Advanced cooling solutions boost energy efficiency and reliability in robotics.

- They let you use lower power systems, which makes cooling easier.

- You get better performance and longer life for your AI systems.

Tip: Stable temperatures help robots avoid sudden shutdowns and keep your projects moving.

No Throttling

If robots get too hot, their processors slow down to stay safe. This is called throttling. With a custom heat sink and advanced cooling, you stop this slowdown. Robots keep working at full speed, even with heavy workloads. No throttling means your AI models process data faster and finish tasks on time.

Energy Efficiency

Lower Power Use

Efficient cooling systems help you save energy. When robots stay cool, fans and pumps do not work as hard. You use less electricity, which lowers your operating costs. Custom cooling solutions let you design systems that fit your robot’s needs, so you do not waste power.

Reduced Emissions

Better cooling does more than save energy. It also helps protect the environment. In 2016, engineers at Google used AI to cut the energy needed for cooling their data centers by 40%. This big drop in energy use led to fewer greenhouse gas emissions. When you use advanced cooling in your robots, you help lower your carbon footprint. AI-powered cooling systems make robots greener and more efficient.

Reliability

Fewer Failures

You want your robots to work every day without problems. Good thermal management keeps hardware at safe temperatures. Liquid cooling systems help keep stable temperatures, so your AI hardware works well for longer. This lowers the risk of sudden failures or costly repairs.

Longer Service

Good cooling means robots last longer. Advanced thermal management solutions keep AI systems running well in many industries. When you use the right cooling, robots stay reliable and serve you for years. You spend less on replacements and keep your operations running smoothly.

Note: Keeping robots cool is important for long-term success. Pick the right cooling to protect your investment in AI Robotics.

AI Robotics Applications

Industrial Robots

Industrial robots work in hard places like factories. These robots need to stay cool to do big jobs. Motors and controllers inside get very hot. If you do not cool them, robots can slow down or stop.

Motors

Motors in these robots run for many hours. They face heat and dust all the time. You need custom cooling solutions to keep motors safe. High-flow ventilation moves air fast around the motor. Spot cooling cools the hottest spots so heat does not build up. Some robots use aprons or blast panels to block heat from outside.

| Cooling Method | Description |

|---|---|

| High-flow ventilation packages | Moves more air to cool robot parts. |

| Spot cooling | Cools certain areas to stop heat buildup. |

| Full-suit environmental control units | Controls the whole suit’s temperature. |

| Aprons and blast panels | Blocks heat from outside to protect the robot. |

You can use heat-resistant materials and insulation for motors. Special coated fabrics add extra safety. These steps help motors last longer and work better.

Controllers

Controllers are like the robot’s brain. They send signals to motors and sensors. If controllers get too hot, they can make mistakes or stop. You need a custom heat sink to pull heat away. Custom cooling solutions keep controllers cool, even in tough places.

Cooling systems should fit tightly around controllers. This helps move heat away faster. Insulation and heat-resistant coatings protect electronics from outside heat. With good cooling, controllers stay reliable and work right.

Service Robots

Service robots help people in hotels, airports, and offices. These robots work in public, so cooling must be small and quiet.

Compact Cooling

Service robots are small. You need custom cooling solutions that fit tight spaces. A custom heat sink made for your robot’s shape removes heat without using much room. Liquid cooling tubes or small fans can fit inside the robot. This keeps the robot cool and lets it move easily.

Tip: Pick cooling parts that do not block joints or sensors. This helps your robot move well and react fast.

Quiet Operation

Noise is important in public places. Fans and pumps can be loud. You should use passive cooling, like heat sinks with no moving parts, to keep robots quiet. Phase-change materials can soak up heat without making noise. These ways help service robots work quietly and not bother people.

Medical Robots

Medical robots work in hospitals and clinics. They must always be stable and safe.

Stability

Medical robots need steady temperatures to work well. Custom cooling solutions stop sudden heat changes. This keeps sensors and processors working their best. Stable cooling helps avoid mistakes during surgeries or care.

Safety

Safety is most important in medical places. You need cooling that does not leak or spread germs. Sealed custom heat sinks and smooth surfaces are easy to clean. Quiet, fanless cooling keeps things calm for patients and staff. With the right cooling, medical robots stay safe, clean, and reliable.

Edge Devices

GPU/FPGA Cooling

Edge devices are very important in AI robotics today. People use these devices for things like real-time data, machine vision, and smart automation. These devices work at the edge of a network, not in big data centers. Edge servers usually do not have normal cooling systems. So, you need advanced custom cooling solutions to keep the hardware safe.

GPUs and FPGAs in edge devices get very hot. Server GPUs often use 200W to 400W of power. Some home GPUs use about 150W. High-end GPUs need big custom heat sinks and strong fans. Sometimes, they even need liquid cooling to stay cool. If you do not control the heat, your AI robotics can slow down or stop working.

- Edge servers use conductive cooling because air does not move much.

- Strong GPUs need advanced cooling like liquid cooling or heat pipes.

- You must keep GPU core temperatures between 70℃ and 85℃.

Custom cooling solutions help with these problems. You can make a custom heat sink that fits small spaces in edge devices. Liquid cooling plates or heat pipes move heat away fast. These ways keep your AI robotics running well, even in tight spots.

Tip: Always check the temperature of your edge device’s GPU or FPGA. Keeping the temperature steady helps your device work better and last longer.

Deployment

When you set up edge devices, you face special problems. Sometimes, you put AI robotics in far-away places or outdoors. There may not be much airflow. Normal cooling does not work well in these places. Custom cooling solutions let you change your design for any place.

You can use tough custom heat sinks that block dust, water, and shaking. Sealed liquid cooling systems stop leaks and protect the electronics. Some edge devices use passive cooling, which means no moving parts. This lowers the chance of breaking. Passive cooling is good for quiet or rough places.

| Deployment Challenge | Custom Cooling Solution |

|---|---|

| Limited airflow | Conductive or passive cooling |

| High ambient temperature | Liquid cooling or heat pipes |

| Dust and moisture | Sealed heat sinks and enclosures |

| Vibration | Ruggedized mounting and design |

Custom cooling solutions help your edge AI robotics stay safe and work well. With the right design, your devices work in tough places. You can use AI robotics anywhere without worrying about overheating or breaking.

Note: Picking the right custom cooling solution keeps your edge devices safe and helps the future of AI robotics.

Custom Cooling Partnerships

Making advanced AI Robotics needs more than good hardware. You also need partners who know how to make custom cooling solutions for your robots. These experts have special skills and tools to help you. They use proven ways to build cooling systems that work well.

Expert Support

Design

You begin with a smart design. Expert partners help you make cooling systems that fit your robot’s size and shape. They use simulation tools to test airflow and heat before building anything. This helps you avoid mistakes and makes sure your custom heat sink fits right. Every part of your robot gets cooled, even in small spaces.

Testing

Testing is just as important as design. Your partner builds prototypes and tests them in real life. They check how the cooling system works in different places and with different jobs. This finds weak spots and lets you fix them early. You can trust your custom cooling solutions to work well in factories, hospitals, or outside.

Tip: Pick a partner who does both design and testing. This gives you better results and fewer problems.

Streamlined Production

Cost Savings

Working with expert manufacturers saves you money. They help you avoid expensive mistakes and cut down on extra prototypes. You get bulk pricing and steady supply chains. This means you spend less and avoid delays.

Speed

Speed is important in today’s market. Custom cooling partnerships help you launch your AI Robotics faster. Your partner handles design, testing, and production all together. This cuts waiting time and helps you release new robots quickly.

Here is a table showing the main benefits of working with expert manufacturers:

| Benefit | Description |

|---|---|

| Regulatory Compliance | You meet safety rules and can launch your robots more easily. |

| Customization Capabilities | You get exact voltage and thermal control for better energy use. |

| Supply Chain Stability | You avoid shortages and get reliable parts. |

| Technical Support | You get help and updates to keep your robots working well. |

- Many robotics companies now team up with cooling system providers to make custom cooling solutions.

- These partnerships use AI-driven cooling algorithms to change performance based on the job and place.

- Early results show energy efficiency is 25-35% better than old cooling methods.

Note: Picking the right partner for custom cooling solutions lowers R&D costs and helps you launch products faster. You get reliable, efficient robots that stand out in the market.

Future Trends

Smart Cooling

AI Integration

AI is now changing how cooling works in robots. Smart cooling uses AI to look at temperature data. It can guess problems before they happen. This helps stop sudden breakdowns. Robots can work longer with smart cooling. AI changes cooling power based on robot work. You save energy and waste less.

Here is a table with smart cooling trends in AI robotics:

| Trend Description | Details |

|---|---|

| Predictive Maintenance | AI looks at data to find problems early. This means fewer breakdowns and longer robot life. |

| Real-time Monitoring | IoT lets systems change temperature when needed. It helps manage energy during busy times. |

| Robotics for Maintenance | Drones and robots check HVAC systems with sensors. They find leaks and blockages safely. |

You can use smart cooling with your custom cooling solutions. AI-powered systems keep your custom heat sink working well. You get more robot uptime and spend less on repairs.

IoT Monitoring

IoT devices connect cooling systems to the internet. You can see temperatures and energy use right away. IoT sensors send alerts if robots get too hot or cooling stops. You can change settings from anywhere. This makes robots safer and more reliable.

Smart cooling with IoT lets you control many robots at once. You find problems early and fix them fast. This technology helps custom cooling solutions by giving you data to make better designs.

Sustainability

Green Materials

You want robots to help the planet. Many companies use green materials in custom cooling solutions. These materials lower emissions and make robots safer for nature. You can pick recycled metals or bio-based plastics for your custom heat sink. This can cut emissions by up to 40%.

- Using green materials in robots can lower emissions by up to 40%.

Energy Recovery

Energy recovery systems help save power. Robotic arms can catch energy when moving and use it for cooling. This lowers electricity costs and peak charges. You get better AI robotics and spend less on energy.

- Many robotic arms now use energy recovery systems to cut electricity costs by up to 25%.

- Energy recovery systems catch energy during movement and reuse it, lowering peak charges.

You can add energy recovery to your custom cooling solutions. This makes robots greener and saves money.

Future Advancements

New cooling technologies are coming soon. These will make AI robotics more efficient and green. Here is a table with what you can expect:

| Advancement Type | Description |

|---|---|

| Active Thermal Containment | This manages heat right at the source. It helps save energy. |

| Adaptive Cooling | Systems change cooling based on real-time heat. This makes them respond faster. |

| High-Efficiency Air Systems | New air cooling moves more air and uses less energy. |

| Hybrid Air-Liquid Technologies | These mix air and liquid cooling for better heat control in crowded places. |

| Delta³ Cooling System | This special air cooling works for high power robots and saves lots of energy. |

You can use these new systems with your custom cooling solutions and custom heat sink designs. These trends help you build AI robotics that last longer, use less energy, and protect nature.

Tip: Keep learning about smart cooling and green trends. This helps your AI robotics stay ahead and ready for new challenges.

AI Robotics are getting stronger, and this brings new problems. Direct liquid cooling and air-assisted liquid cooling help control heat better. These cooling methods can lower carbon emissions by up to 87%. They also let you use less space for server racks. Your robots work better, last longer, and cost less to run. To get the best results, work with experts who know how to build good cooling systems and give you support. Protect your robots and help new ideas grow by choosing the right partners.

FAQ

What makes custom cooling solutions essential for AI robotics?

You need custom cooling solutions because AI robotics use high-power chips that make a lot of heat. Standard cooling cannot handle this much heat. Custom systems help your robots stay safe and work well.

How does a custom heat sink improve robot performance?

A custom heat sink matches your robot’s shape and parts. This design moves heat away from important spots faster. Your robot works better and lasts longer.

Can I use off-the-shelf cooling for my AI robotics project?

Off-the-shelf cooling does not fit AI robotics well. These coolers often miss hot spots or block moving parts. Custom cooling solutions fit right and control heat better.

What cooling method works best for compact AI robotics?

Direct liquid cooling and vapor chambers are good for small spaces. You can also use phase-change materials for quiet, strong cooling. These ways keep small robots cool and safe.

How do custom cooling solutions help with energy efficiency?

Custom cooling solutions use less power by cooling only where needed. You do not need fans and pumps to work as hard. This saves energy and helps your robots be greener.

Are custom cooling solutions safe for medical and industrial robots?

Yes. You can make custom cooling solutions with sealed surfaces and quiet parts. These features keep places clean and meet safety rules.

How do I choose the right custom heat sink for my AI robotics?

First, check your robot’s power and space needs. Work with experts to design a custom heat sink that fits your robot. This gives you the best cooling and performance.

Do custom cooling solutions increase the lifespan of AI robotics?

Yes. Good thermal management stops overheating and damage. Your AI robotics last longer and need fewer repairs.

Tip: Always watch your robot’s temperature. Fix problems early to avoid big failures and downtime.