How heat sinks are made?

You make a heat sink by following several important steps. First, you choose the right material. Aluminum is popular because it is light and conducts heat well. Copper works even better for heat transfer, but it costs more and weighs more. You then shape and finish the heat sink to help it cool electronics. Each step in the heat sink process affects how well it removes heat and keeps devices safe.

Key Takeaways

- Pick the best material for heat sinks. Aluminum is not heavy and costs less. Copper moves heat better than aluminum.

- Learn about the main parts of a heat sink. The base, fins, and thermal interface material are important. These parts work together to cool electronics.

- Use a careful design and testing process. Try different shapes and materials to find the best way to move heat.

- Pick the right way to make the heat sink. Extrusion, forging, and CNC machining are some choices. Each way has special good points for different cooling jobs.

- Use quality checks. Test the materials and finished heat sinks. This makes sure they work well and last a long time.

What is a heat sink?

Function and purpose

You often find heat sinks in electronics like computers and motor drivers. A heat sink is a device or substance that absorbs or removes unwanted heat from a process or an electronic device. When you use electronics, they generate heat as electricity flows through their parts. If you do not control this heat, your device can overheat and stop working.

A heat sink helps by moving heat away from sensitive components. Here is how it works:

- The heat sink absorbs heat from the electronic part.

- It spreads this heat over a larger surface area.

- The larger surface area lets the heat move into the surrounding air more easily.

- Sometimes, you use thermal paste or another thermal interface material to help transfer heat from the component to the heat sink.

Tip: Using a heat sink keeps your electronics cool and helps them last longer.

You can think of a heat sink as a bridge that carries heat away from where it is not wanted. This process keeps your devices at a safe temperature.

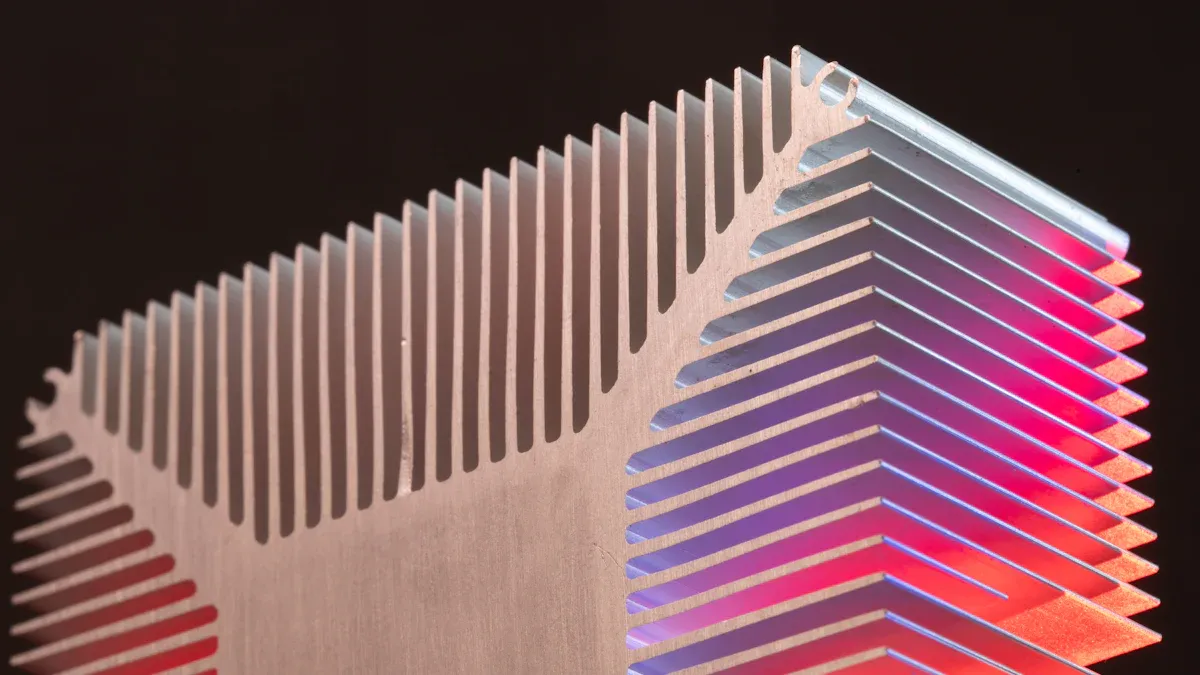

Basic structure

A typical heat sink has several important parts. Each part plays a role in moving heat away from the electronic component. Here are the main components:

- Base: This is a flat block or sheet made from a material that conducts heat well, like aluminum or copper. The base sits right on top of the part that gets hot.

- Fins: These are thin pieces that stick out from the base. Fins increase the surface area, so more heat can move into the air.

- Heat Pipes: Some heat sinks use special tubes called heat pipes. These pipes move heat quickly from one part of the heat sink to another.

- Thermal Interface Material: This material fills tiny gaps between the heat sink and the component. It helps heat move from the component to the heat sink.

- Mounting Hardware: You use screws, clips, or other hardware to attach the heat sink firmly to the device.

When you look at a heat sink, you see a simple object. However, each part works together to keep your electronics safe and cool.

Material selection and design

Material selection: aluminum vs copper

When you start the heat sink process, you must choose the right material. Most heat sinks use either aluminum or copper. You pick these metals because they both conduct heat well and are easy to shape.

Here is a quick look at how they compare:

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Copper | 390 – 400 |

| Aluminum | 136 – 205 |

Copper moves heat faster than aluminum. This means copper heat sinks can cool electronics more quickly. However, copper is much heavier and costs more. Aluminum is lighter and easier to work with. It also costs about one-third as much as copper. This makes aluminum a better choice for most large-scale projects.

- Aluminum is much cheaper than copper.

- Aluminum costs about one-third of copper’s price.

- This represents significant cost savings in industrial applications.

You often see aluminum heat sinks in computers and home electronics. You might find copper heat sinks in high-performance devices where cooling is critical.

Note: The choice between aluminum and copper affects both the cost and the performance of your heat sink.

Design and prototyping

The design of your heat sink shapes how well it removes heat. You want to lower the thermal resistance so heat can move away from your device quickly. Engineers look at each part of the heat sink process to improve performance.

| Factor | Description |

|---|---|

| Thermal resistance | Controls how easily heat moves from the device to the air. |

| Fin efficiency | Fins help spread heat. Their shape and size matter. |

| Spreading resistance | Shows how heat spreads from a small area to a larger one. |

| Fin arrangements | Different fin shapes, like pin fins or straight fins, change how well the heat sink works. |

| Surface color | In some cases, the color of the heat sink can help it cool better by radiating heat. |

When you create a new heat sink, you follow several steps:

- Define what your device needs, like how much heat it makes and how much space you have.

- Use computer models to test different shapes and materials.

- Draw your design and make changes to improve it.

- Build a sample using special tools.

- Test the sample to see how well it works.

- Make changes based on your test results.

- Approve the final design for production.

Each step helps you make a heat sink that keeps your electronics safe and cool.

Heat sink process: manufacturing methods

There are many ways to make a heat sink. Each way gives the heat sink special features. Let’s look at the main ways to make them and how they fit into the heat sink process.

Extrusion process

The extrusion process is a common way to make heat sinks. In this method, heated aluminum is pushed through a shaped die. The metal comes out in long pieces. These pieces have the same shape as the die. You cut them to the right size.

This method is good for many cooling needs. You can make complex shapes in one step. The extrusion process is fast and saves money. It is great if you need many heat sinks. Aluminum is used because it is light and moves heat well.

Here is a table that shows why the extrusion process is popular:

| Advantage | Description |

|---|---|

| Cost-Effectiveness | Lower tooling and production costs compared to other methods |

| Design Flexibility | Ability to create complex cross-sections in a single operation |

| Good Thermal Performance | Adequate for many general cooling applications |

| Material Properties | Aluminum offers excellent thermal conductivity to weight ratio |

| Production Speed | High output rates for large volume requirements |

Tip: If you need a heat sink for a computer or home device, the extrusion process often gives you the best mix of price and performance.

Forging and skiving

Forging and skiving are advanced ways to make heat sinks. Forging uses high pressure to shape metal into a strong form. Skiving slices thin layers from a block to make fine fins.

Forged and skived heat sinks are used when you need strong cooling. These ways let you make very thin fins. Thin fins give more surface for heat to escape. The heat sink process here makes a product that works well for tough jobs.

You can find forged and skived heat sinks in many places:

- Computer systems: cools CPUs and GPUs in laptops, desktops, and servers.

- Telecommunications equipment: cools power amplifiers and transistors.

- Automotive systems: cools engine control units, alternators, and other electronics.

- Aerospace systems: cools parts in aircraft and space systems, including power supplies.

- Industrial equipment: cools electronic parts in factories and machines.

- Power supplies: manages heat in devices that provide power.

- LED lighting: helps LEDs stay cool and last longer.

- Medical equipment: cools electronics in medical devices, like lasers and scanners.

Note: Forged and skived heat sinks cost more, but they give you the best performance for high-power electronics.

Stamping and die-casting

Stamping and die-casting are other ways to make heat sinks. Each has its own strengths.

Stamping uses strong pressure to shape metal sheets. Aluminum or copper is used most often. The metal is pressed into a die to make fins and holes. This way lets you make many heat sinks fast and cheap. The fins made by stamping help move heat away.

- Stamping uses strong pressure on metal sheets.

- Aluminum or copper is used most often.

- The process makes fins that help heat move away.

Stamped heat sinks are good for small electronics and devices that do not need much cooling.

Die-casting pours melted metal into a mold to make the heat sink. This way lets you make complex shapes and thin walls. Die-cast heat sinks are light and do not rust. They are best when you need many heat sinks at once.

Here is a table that shows the good and bad sides of die-casting:

| Benefits | Limitations |

|---|---|

| Efficient heat dissipation | Occupying large area |

| Lightweight | Costly to manufacture |

| Corrosion resistance | Loudness during operation |

| Cost-effective for high volume | Inaccessibility to certain parts |

Tip: Use die-casting when you need a lot of heat sinks with special shapes, but remember it can be costly for small batches.

CNC machining

CNC machining uses computer tools to cut and shape metal very accurately. You can make detailed and complex heat sinks this way. CNC machining works for both aluminum and copper.

- CNC machining gives you very high accuracy. This is important for making designs that move heat well.

- You can make complex shapes that help cooling.

- CNC machines can be very exact, so every detail matches your design.

Custom CNC machined heat sinks are used in:

- Grid arrays

- RF/EMI shielding

- PC board thermal management

You use CNC machining for special projects where you need a unique shape or very tight fit.

Note: CNC machining costs more than other methods, but it gives you the best fit for custom jobs.

Heat pipes and vapor chambers

Some heat sinks use heat pipes or vapor chambers to move heat faster. You add these parts to the heat sink process when you need to spread heat from a small area to a bigger one.

Heat pipes are tubes with a special fluid inside. When the fluid gets hot, it turns into vapor and moves to a cooler part. There, it cools down and turns back into liquid. This cycle moves heat quickly.

Vapor chambers work like flat heat pipes. They spread heat over a wide area. You use vapor chambers when you need to cool a small, hot spot by spreading the heat to a bigger heat sink.

- Vapor chambers should cover an area at least 10 times bigger than the heat source for best results.

- They work best for spreading heat to local heat sinks, not for moving heat far away.

- You can attach vapor chambers to many types of heat sinks, like zipper fins or machined bases.

Here is a table that compares heat pipes and vapor chambers:

| Feature | Heat Pipes | Vapor Chambers |

|---|---|---|

| Heat Carrying Capacity | Max around 125 watts | Up to 450 watts |

| Isothermality | Less consistent temperature | Maintains consistent temperature |

| Design Flexibility | High flexibility in installation | Limited to flat layouts |

| Size | Tubular, limited in thinness | Ultra-thin and wide |

| Durability | Robust in dynamic environments | Consistent under high heat loads |

| Cost | Generally the most economical | Higher due to complex manufacturing |

Tip: If you need to cool a powerful chip in a small space, vapor chambers and heat pipes can help the heat sink process and keep your device safe.

The heat sink process uses many ways to meet different needs. By picking the right way, you make sure your electronics stay cool and work well.

Assembly and surface finishing

Fins and bonding

You must put the fins and base together to finish the heat sink process. Fins help cool things down. They make the surface bigger, so more heat can leave the heat sink and go into the air. Fins can have different shapes. Some fins are wavy or have small bends. These shapes make the air move in a messy way, which helps heat leave faster.

To connect the fins and base, you do these steps:

- Clean the base and fins. Use aluminum or copper for the best results.

- Put glue, like epoxy or a thermal paste, on the base.

- Set the fins on the base and press them down.

- Heat or shine UV light on the glue to make it hard.

- Add screws or thermal pads if you need them.

Some heat sinks have grooves in the base. You slide the fins into these grooves and fill them with glue. Then, you hold everything in place and bake it in an oven at 100 degrees Celsius for about an hour.

If your fins have more surface, your heat sink can remove more heat. This is why the way you design fins matters a lot in the heat sink process.

Surface treatments: anodizing and polishing

After you build the heat sink, you treat the surface to make it work better and last longer. The most common treatments are:

- Anodizing: This makes a tough layer on the surface. It stops rust and makes the heat sink look nice.

- Nickel Plating: Adds a layer that stops rust and helps heat move.

- Copper Plating: Makes heat move even better because copper is great for heat.

- Blackening or Coating: A black layer helps the heat sink send out heat faster.

- Thermal Spray Coatings: Adds special stuff to help heat leave the heat sink.

Anodizing is very good for aluminum heat sinks. It makes a layer with tiny holes that makes the surface bigger. This layer helps the heat sink let go of heat, especially when there is no fan. Plain aluminum bounces heat away, but anodized aluminum lets out much more heat. The thin anodized layer does not stop heat from moving, so you get better cooling without losing how well it works.

Anodizing can make aluminum much better at letting out heat, raising its ability from about 0.05 to 0.85. This makes your heat sink much better at getting rid of heat.

Quality control and shipping

Testing and inspection

You want your heat sink to work well for a long time. To make sure this happens, you check every step. Quality control starts with the materials you use. You must pick pure copper, aluminum, or other metals that meet strict rules. If you use the wrong material, your heat sink will not cool your device right.

You also test each new part before making a lot of them. This helps you find mistakes early. When you start making many heat sinks, you test every one. You look for leaks and check if it can handle high heat. You also see if it follows all the rules.

Here is a table that shows the main quality control steps:

| Quality Control Measure | Description |

|---|---|

| Raw Material Quality Control | Strict material control for copper, powdered metal, and working fluid to ensure performance. |

| First Article Validation Testing | Verification of new parts against specifications to prevent defects and ensure compliance. |

| Mass Production Testing | 100% testing of devices including burn-in, leak checks, and performance validation. |

You also test how the heat sink works. You measure how well it moves heat. You check if it can handle bumps or drops. You make sure there are no leaks. The table below shows the main tests:

| Testing Type | Description |

|---|---|

| Thermal Resistance | Tests the thermal conductivity of the heat sink material, crucial for assessing performance. |

| Mechanical Testing | Evaluates shock resistance and impact to ensure no deformation or damage occurs. |

| Fluid Testing | Checks for leakage under specific fluid pressure conditions, ensuring the integrity of the welding. |

| Thermal Testing | Measures thermal resistance value, a key factor affecting chipset stability. |

Tip: Careful testing and checking help you avoid problems. This keeps your devices safe.

Packaging and delivery

After testing, you need to pack the heat sinks so they do not break. You use heat shrink wrap to cover each heat sink. This wrap fits tightly when you add heat. It keeps out dust, dirt, and water. This is very important for electronics. Even a little dust can cause trouble.

You also face problems when you ship heat sinks worldwide. Sometimes, it is hard to get raw materials. Shipping can be slow. You must follow different rules in each country. The table below shows some common problems:

| Challenge | Description |

|---|---|

| Supply Chain Fragmentation | Disruptions in raw material sourcing and logistical bottlenecks lead to delays and increased costs. |

| Regulatory and Certification Barriers | Evolving environmental standards and safety regulations create compliance risks and entry barriers. |

When you pack and ship heat sinks the right way, you protect your product. This makes sure it arrives safely to your customer.

You have learned that every step is important when making a heat sink. Picking the right material and testing it carefully both matter a lot. Each stage helps make the heat sink work well and last longer:

| Stage | Why It Matters |

|---|---|

| Design & Engineering | Helps the heat sink get rid of heat faster |

| Material Selection | Makes sure heat moves through the heat sink easily |

| Manufacturing | Builds the heat sink to fit what is needed |

| Surface Treatment | Stops rust and helps the heat sink work better |

| Quality Testing | Checks that the heat sink is safe and works right |

Today, there are cool new things like graphene, tiny designs, and new ways to make heat sinks. These changes help heat sinks cool things even better. When you use electronics, think about the science and hard work that goes into these small but important parts!

FAQ

What is the best material for a heat sink?

You usually choose aluminum for most heat sinks. Aluminum costs less and weighs less. Copper works better for heat, but you pay more and carry more weight.

How do you clean a heat sink?

You use a soft brush or compressed air to remove dust. You can wipe the surface with a dry cloth. Avoid water or harsh chemicals.

Why do heat sinks have fins?

Fins increase the surface area. You get better cooling because more heat leaves the heat sink and enters the air.

Can you reuse a heat sink?

You can reuse a heat sink if it stays clean and undamaged. Check for bent fins or old thermal paste before you install it again.

Do heat sinks need fans?

Some heat sinks work without fans. You add a fan when you need extra cooling for powerful devices.