What Are Heat Sink Cooling Systems and How Do They Work

You use heat sink cooling systems to protect your electronics. These systems take away extra heat from parts. They move the heat so your device does not get hurt or slow down. A heat sink stands between the hot part and the air. It spreads the heat so it can leave. If you do not control this heat, your device may get too hot and stop working.

Good heat transfer is very important for your electronics. It helps them work well and last longer.

Metric | Value/Improvement |

|---|---|

Heat Transfer Coefficient (W/m²K) | Up to 160 |

Overall Thermal Performance | 15-100% better |

Key Takeaways

Heat sink cooling systems help electronics stay safe. They take away extra heat. This stops damage and keeps things working well. Good airflow helps cooling work better. Make sure your device has space for air to move. You can use fans to help with this. Pick the right heat sink for your device. Think about how much heat your device makes. Passive systems are quiet. Active systems cool better. Choose the best material for your needs. Aluminum is light and cheap. Copper moves heat better for strong cooling. Clean your heat sink often. Remove dust and check connections. This helps your heat sink work well. It also helps your device last longer.

Function of Heat Sink Cooling Systems

Managing Excess Heat

You rely on heat sink cooling systems to keep your devices from getting too hot. When your electronics work, they make heat. If you do not remove this heat, your device can slow down or even stop working. Heat sink cooling systems help you manage this extra heat in several ways:

They use conduction to move heat away from the electronic parts. The heat travels through the material of the heat sink.

The heat then spreads out across the surface of the heat sink. This large surface area helps the heat leave faster.

Convection takes over next. Air moves around the heat sink and carries the heat away. Sometimes, a fan helps move the air even more.

The design of the heat sink matters. Fins, material choice, and the size of the base all help the system work better.

Tip: Good airflow around your device helps the heat sink cool even more.

If you do not use a heat sink cooling system, your device can face many problems:

Reduced performance because the device slows down to avoid damage.

Shorter lifespan since heat wears out the parts faster.

Failures like crashes or even fires if the heat gets too high.

Protecting Electronic Components

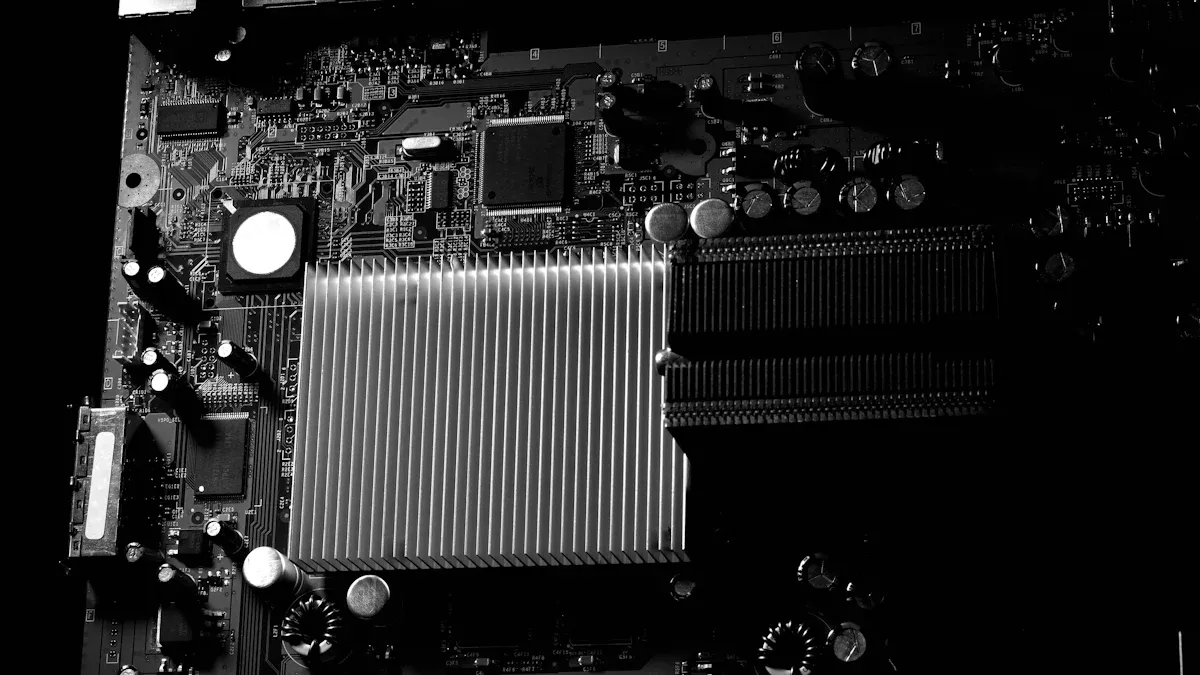

You want your electronics to last and work well. Heat sink cooling systems protect the sensitive parts inside your device. They do this by moving heat away from the most important components, like CPUs or GPUs. The heat sink sits right on top of these parts and pulls the heat out.

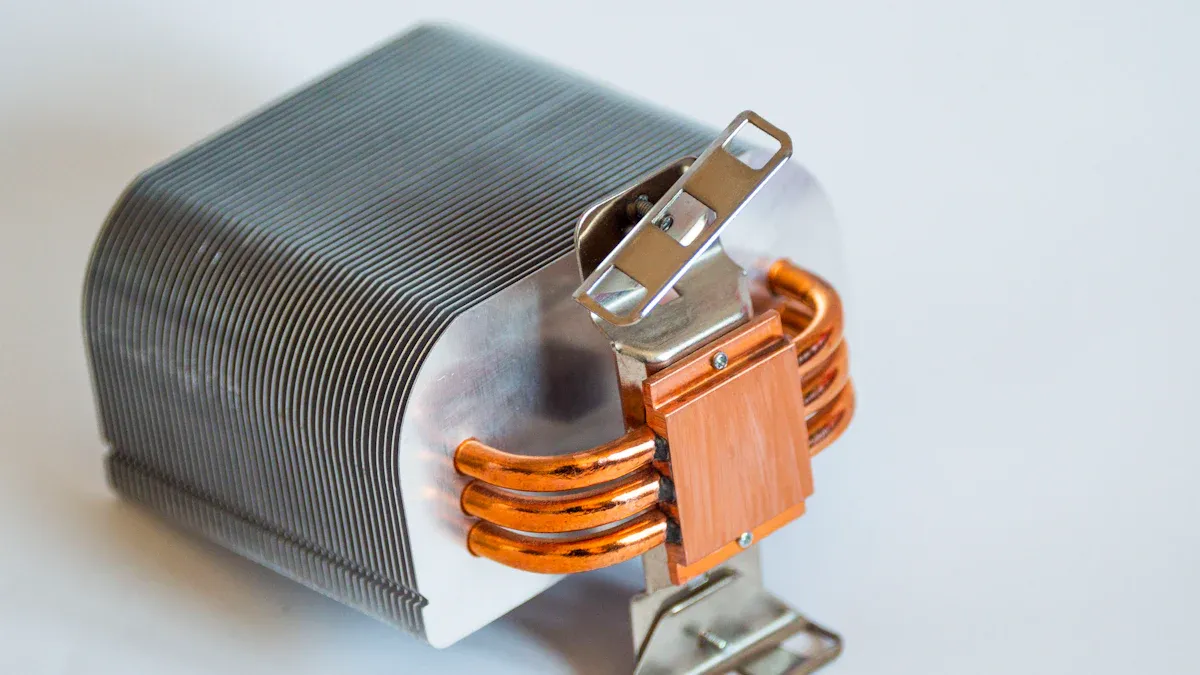

The heat sink has a metal base that touches the component. This makes sure heat moves quickly from the part to the sink.

Fins stick out from the base. These fins give more space for the heat to spread out and escape.

Sometimes, a fan blows air over the fins. This helps the heat leave even faster.

When you use heat sink cooling systems, you keep your device safe from damage. Too much heat can break the tiny connections inside your electronics. Over time, this can cause the device to fail early. By keeping things cool, you help your device last longer and work better.

Note: Excessive heat can cause serious problems, like warping, circuit failures, or even fires. Using a heat sink cooling system is one of the best ways to avoid these risks.

How Heat Sink Cooling Systems Work

Heat Transfer Process

You need to understand how heat moves inside your device. When your electronics run, they create heat. This heat must leave the sensitive parts quickly. Heat sink cooling systems help you by moving this heat away from the source and out into the air or liquid around your device.

Here is how the process works:

First, heat travels from the electronic component to the heat sink through conduction. The heat moves because the heat sink touches the hot part directly.

Next, the heat spreads out across the heat sink. Materials like aluminum and copper work well because they let heat move fast.

After that, the heat leaves the heat sink and enters the air or a cooling liquid. This happens through convection. Air or liquid flows over the heat sink and carries the heat away.

Sometimes, you use a fan to push more air over the heat sink. This is called forced convection. It helps remove heat faster.

In some cases, you might use a liquid coolant or even special pipes that move heat using a phase change. These methods work well for devices that get very hot.

Tip: The better the contact between your component and the heat sink, the faster the heat moves away.

You want your device to stay cool so it works well. High thermal conductivity materials, like copper and aluminum, make this possible. They move heat quickly from the component to the heat sink. If the contact is poor, heat will not move as fast, and your device may overheat.

Role of Fins and Surface Area

You may notice that many heat sinks have thin metal fins. These fins play a big role in cooling. They increase the surface area of the heat sink, which helps more heat escape into the air.

Here is why fins and surface area matter:

Fins give the heat sink more space for heat to move from the metal into the air.

A larger surface area means more air can touch the heat sink at once. This helps the heat leave faster.

Good airflow around the fins helps carry away the heat. If you use a fan, the air moves even quicker, making the cooling better.

Fins also give heat more paths to travel from the base to the edges, so the whole heat sink works together to cool your device.

Note: The bigger the surface area, the better your heat sink cooling systems can get rid of heat.

You want your device to stay safe and work well. By using fins and increasing the surface area, you help your heat sink cooling systems remove heat more efficiently. This keeps your electronics running smoothly and protects them from damage.

Types of Heat Sink Cooling Systems

Passive Systems

You use passive heat sink systems when you want a simple and quiet way to cool your electronics. These systems rely on natural heat movement. They do not have fans or pumps. The heat travels from the hot part to the heat sink, then moves into the air by conduction and convection. You often see passive systems in devices that do not get very hot or where silence is important, like in some home electronics.

Here is a quick look at the pros and cons:

Type | Advantages | Disadvantages |

|---|---|---|

Passive Heatsinks | Simple, reliable, low cost, silent operation | Limited cooling, may need to be large, affected by room temperature |

Tip: You can use passive systems in places where you want less noise and less maintenance.

Active Systems

You choose active heat sink systems when your device needs more cooling power. These systems use fans, pumps, or blowers to move air or liquid over the heat sink. This helps remove heat much faster than passive systems. You find active systems in gaming PCs, servers, and aerospace electronics. These devices create a lot of heat and need strong cooling.

Active systems handle higher heat loads.

They work well in tight spaces because they do not need to be as large.

You can control the temperature more closely.

However, active systems can make noise and need more care because of moving parts.

Hybrid Systems

You get the best of both worlds with hybrid heat sink systems. These systems combine passive and active methods. The heat sink works on its own when the device is cool. When things heat up, a fan or pump turns on to help. This setup saves energy and keeps noise low most of the time.

Hybrid systems offer flexibility. They use natural airflow and only turn on fans when needed.

You see them in computers, LED lighting, cars, and industrial equipment.

They often have a compact design and can run quietly.

Note: Hybrid systems are great for devices that sometimes get hot but do not always need full cooling power.

Materials Used in Heat Sinks

Heat sinks use many materials to control heat. You must pick the best material for your device. Each choice has special features. These features change how well it works, how much it costs, and if it is easy to use.

Aluminum

Aluminum is common in heat sinks. It gives a good mix of weight, heat movement, and price. Its thermal conductivity is about 237 W/mK. This means it moves heat fast. Aluminum can hold more heat per gram than copper. It is light, so your device is not heavy. This helps with laptops, phones, and aerospace gear.

Aluminum heat sinks are cheaper than copper ones. You pay about $1,800 for a ton of aluminum. Copper costs around $6,500 for the same amount. Aluminum is only one-third the weight of copper. Your device stays light.

Aluminum Properties Table

Material | Key Properties |

|---|---|

Aluminum | Balance of weight, conductivity, and cost |

Aluminum is good for making lots of heat sinks.

You get solid results without spending too much.

Copper

You pick copper for the best cooling. Copper’s thermal conductivity is 398 W/mK. This is higher than aluminum. Copper moves heat away even faster. It can handle high temperatures and keeps its shape. You use copper in gaming computers and strong electronics.

Copper Advantages

Great thermal conductivity for moving heat fast.

Handles high temperatures and stays strong.

Works well for a long time and stops overheating.

Copper vs. Aluminum Table

Property | Copper Value | Comparison with Aluminum |

|---|---|---|

Thermal Conductivity | 398 W/(m·K) | Higher (237 W/(m·K)) |

Ductility and Malleability | Excellent | Good |

Corrosion Resistance | Good | Moderate |

Copper heat sinks are heavier and cost more. They can make your device heavy and pricey. Copper can rust in wet places. This may make it work less well.

Other Materials

Some devices need special materials. Graphite is light and works in thin electronics. Aluminum-copper mixes use both metals for better results and lower cost. Heat pipes and vapor chambers spread heat in small spaces. Aluminum silicon carbide gives high conductivity and controlled growth for power modules.

Alternative Materials Table

Material | Key Features | Preferred Scenarios |

|---|---|---|

Graphite | High thermal conductivity, lightweight | Wearable electronics, thin-profile devices |

Aluminum-Copper Hybrids | Combines aluminum and copper for cost-effectiveness and performance | High-power cooling applications |

Heat Pipes | Closed-loop system, high effective thermal conductivity | Efficient heat transfer over distance |

Vapor Chambers | Uniform temperature distribution, low mass | Microprocessors, RF transmitters, thermoelectric devices |

Aluminum Silicon Carbide | Tailored properties, high conductivity, controlled thermal expansion | Power module bases, direct die attachment |

Pick the material that matches your device’s needs. Think about weight, price, and how much heat you need to move.

Choosing the Right Heat Sink

Key Selection Factors

You want your device to stay cool and work well. Picking the right heat sink is important. Start by looking at the heat your component makes. You need to know how much heat energy your device gives off. This helps you choose a heat sink that can handle the job.

Determine the Thermal Needs: Find out how much heat your part makes. This tells you how strong your heat sink must be.

Pick the Right Type: Decide if you need a passive or active heat sink. Passive types use natural airflow. Active types use fans for more cooling.

Check Thermal Resistance: Lower thermal resistance means better cooling. You want a heat sink that moves heat away fast.

Look at Airflow: Good airflow helps your heat sink work better. More air moving over the fins means more heat leaves your device.

Choose the Right Size: Make sure the heat sink fits your space. Bigger heat sinks cool better but need more room.

Tip: Always balance size, airflow, and cooling needs for the best results.

You also need to think about the material. Aluminum is light and cheap. Copper cools better but is heavier and costs more.

Material | Thermal Conductivity | Cost | Weight |

|---|---|---|---|

Aluminum | Moderate | Low | Lightweight |

Copper | High | High | Heavy |

Other things like temperature changes, humidity, dust, and vibration can affect your choice. You want a heat sink that can handle your device’s environment.

Installation and Maintenance

You must install your heat sink the right way to get the best cooling. Use the correct material and make sure the heat sink touches the part well. Apply thermal paste thinly to help heat move from the part to the heat sink. Mount the heat sink with even pressure so it stays in place.

Pick the right material for your needs.

Use fins that help spread heat.

Make sure the heat sink fits your device without causing stress.

Align the fins with the airflow for better cooling.

Keep the airflow path clear.

Regular maintenance keeps your system working well. Clean dust from the fins and fans. Check for loose parts. Replace thermal paste if it dries out.

Efficiency stays high when you keep your heat sink clean.

Your device lasts longer with good care.

You avoid big repairs by fixing small problems early.

Clean systems use less energy and save money.

Note: A well-installed and well-maintained heat sink protects your electronics and saves you trouble in the long run.

You need heat sink cooling systems to keep your electronics safe. If your device gets too hot, it can break. Overheating causes many devices to fail. Even a small temperature rise can make your device less reliable. When you pick a heat sink, think about the type, the material, and how you will put it in. Proper size and good airflow help your device work better. If you mount the heat sink well, you stop hot spots from forming. Some heat sinks have special fins that cool even more.

Remember: The right heat sink makes your device last longer and work better.

FAQ

You use a heat sink to move heat away from electronic parts. This keeps your device cool and working well. Without a heat sink, your device can overheat and stop working.

If your device gets warm or slows down during use, you likely need a heat sink. Devices like computers, gaming consoles, and power supplies often need extra cooling.

Yes, you can install a heat sink if you follow the instructions. Make sure you use thermal paste and press the heat sink firmly onto the part. Always check that it fits your device.

Dust blocks airflow.

Heat cannot escape.

Your device may overheat or slow down.