Custom cold plates

When you buy custom cold plates for your machines, you must say what thermal performance you want. You also need to pick the right material and how it will be made. These choices change how well your machines stay cool. They also change how long your machines work. You must think about how much money you can spend. You also need to make sure the cold plate works with your other machines.

Standard cold plates are about 55% of the world market.

Custom cold plates are growing fast at 9.5% each year.

Good planning helps you not make expensive mistakes. It also makes sure you get what you need.

Key Takeaways

Know what cooling you need before picking a custom cold plate. This helps your machines stay cool and work well.

Pick the best material for your cold plate. Copper cools better, but aluminum is lighter and costs less.

Think about the design and flow path of your cold plate. Good coolant movement makes cooling work better.

Talk clearly with your supplier. Give them detailed technical drawings to stop mistakes and get your order on time.

Look at warranty and after-sales help when picking a supplier. This keeps your equipment working and fixes problems fast.

Assess Application Needs for Custom Cold Plates

Define Thermal Performance Requirements

First, you need to know how much heat your system makes. This helps you pick the best way to cool it down. Every job has its own heat and temperature needs. If you know these numbers, you can choose custom cold plates that fit. The table below lists the main things to think about:

Factor | Description |

|---|---|

Heat flux | Measured in W/cm², shows how much cooling is needed. |

Operating temperature range | Makes sure things stay cool in different situations. |

Coolant flow rate | Changes how well the cooling works. |

You should also think about what your job needs. For example:

Electronics cooling stops CPUs and GPUs from getting too hot.

Food processing uses cold plates to keep food safe and cool.

Medical and lab tools need steady cooling for delicate equipment.

Factories use cold plates to control heat in machines.

If you know your cooling needs early, you can stop problems before they start. This also helps your machines work better and last longer.

Evaluate Space and Integration Constraints

You need to look at the space where you will put the cold plate. Many machines have small spaces or parts that cannot move. You might see these space problems:

Inlet or outlet spots that cannot change

Mounting holes that block the best place for the cold plate

Different fin shapes or deep spots inside the plate

You should talk with your engineers early in the project. This helps you fit the cold plate in without trouble. If you plan ahead, you can save money and time. Sometimes, you need to add islands in the fluid path or change the flow because of the shape of your parts. These changes can make the design harder and cost more.

Custom cold plates help your system by spreading heat out. They also let you change the design fast for special needs. Good fluid channel design keeps your machines cool and working well.

Determine Fluid Compatibility

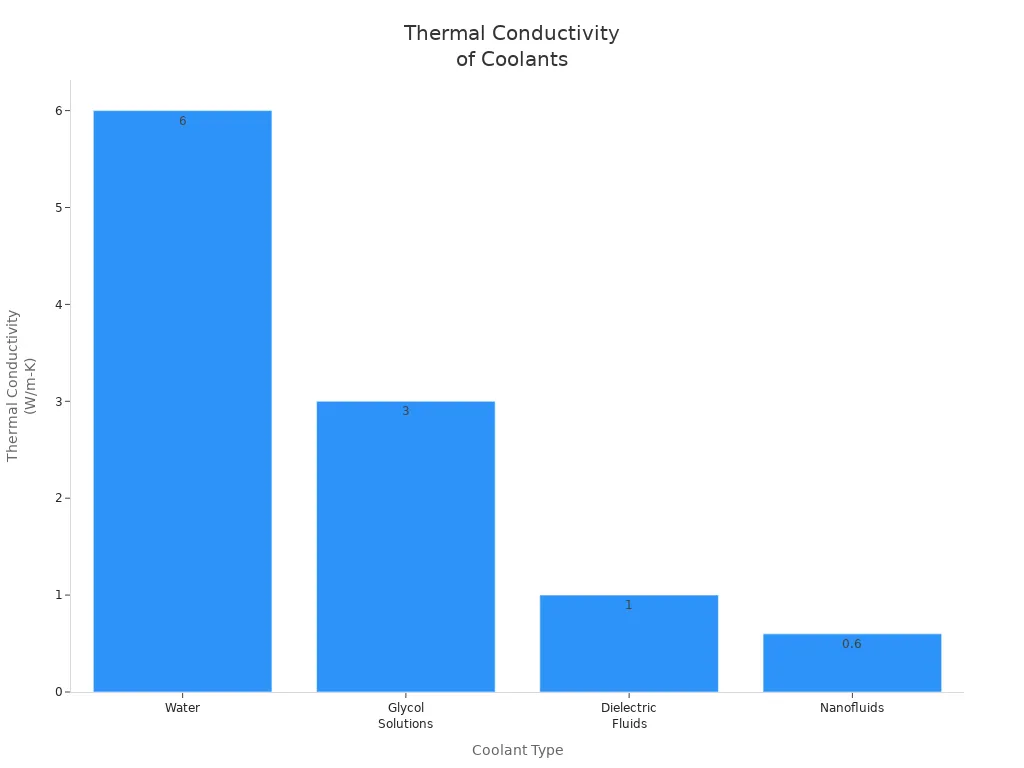

You need to pick a coolant that works with your system and the cold plate material. The most common fluids are water, glycol solutions, dielectric fluids, and nanofluids. Each one has good and bad sides. The table below compares them:

Coolant Type | Thermal Conductivity (W/M-K) | Pros | Cons |

|---|---|---|---|

Water | 6 | High thermal conductivity, low cost | Corrosive, limited temperature range |

Glycol Solutions | 3-0.4 | Freeze protection, wide temperature range | Lower thermal conductivity |

Dielectric Fluids | 1-0.2 | Non-conductive, safe for electronics | Low performance, high cost |

Nanofluids | Variable (0.6+) | May boost thermal conductivity | Stability issues, high cost |

You should always check if the coolant will react with the cold plate material. Some fluids can cause rust or leaks. If you pick the right fluid, your custom cold plates will last longer and work better.

Material and Design Choices

Select Optimal Materials

You need to choose the right material for your cold plate. The material changes how well heat moves away from your equipment. It also affects how long your cold plate lasts. You can see the difference in thermal conductivity between common materials in the table below:

Material | Thermal Conductivity (W/mK) |

|---|---|

Copper (Pure) | ~400 |

Aluminum (Alloys) | ~200-240 |

Copper moves heat very quickly. Aluminum is lighter and costs less. You might pick aluminum if you want a cold plate that is easy to handle and resists rust. Copper works best when you need top cooling and even temperatures. Some new materials, like copper-infused composites and advanced alloys, help heat leave faster. These materials also fight rust and wear, so your cold plate lasts longer in tough places.

Tip: If your system faces harsh chemicals or high moisture, choose a material that resists corrosion. This keeps your custom cold plates working longer.

Aluminum is light, resists rust, and saves money.

Copper gives better cooling and keeps temperatures steady, but it is heavier and costs more.

Choose Efficient Flow Path and Shape

You must think about how coolant moves inside your cold plate. The path and shape of the channels change how well your system cools. Research shows that a one-inlet two-outlet design works better than other setups. When the inlet and outlet line up with the flow channels, heat leaves faster. This design helps your cold plate cool more evenly.

High-performance cold plates need smart channel designs. You can use T-shaped or Y-shaped channels to move fluid better. These shapes help spread heat and keep temperatures even. If you change the size or shape of the channels, you can make cooling stronger. You should look at your equipment and pick a design that fits your space and cooling needs.

Note: Rapid design changes and testing help you find the best flow path for your cold plate. Try different channel shapes to see which one cools your system best.

Consider Mechanical and Pressure Requirements

You need to check how strong your cold plate must be. Some systems use high pressure or face heavy loads. If your cold plate is too thin or weak, it might bend or break. You should pick a material and thickness that can handle your system’s pressure. Make sure the cold plate fits tightly with other parts. This stops leaks and keeps cooling steady.

You can ask your supplier about the best thickness and support for your cold plate. If you use strong materials and smart designs, your cold plate will last longer and work better. Always test your cold plate under real conditions before you use it in your machines.

Tip: If you plan to use your cold plate in a high-pressure system, tell your supplier early. This helps them design a plate that will not fail.

Custom cold plates work best when you match the right material, flow path, and strength to your job. You get better cooling, longer life, and safer machines.

Manufacturing Methods for Custom Cold Plates

Compare Common Manufacturing Techniques

There are different ways to make custom cold plates. Each way has something good about it. Pioneer Thermal uses friction stir welding and tunnel brazing for different jobs. Brazing joins parts with a filler metal. This lets you make tricky shapes inside the plate. It also gives strong thermal performance. Friction stir welding makes a solid bond. It is good for big aluminum plates and is very reliable. Machining uses tools to cut and shape the plate. This way is very exact and works well for testing or special shapes. Die casting is best if you need many plates. It costs less but does not cool as well as other ways.

Here is a quick look at the main methods:

Manufacturing Method | Key Advantage | Best For |

|---|---|---|

Brazing | High Performance | Complex internal fin geometries |

FSW | High Reliability | Large, robust aluminum plates |

Machining | High Precision | Prototypes, complex features |

Die Casting | High Volume | Mass production, lower costs |

Tip: If you want your electronics to stay cool, try brazing or FSW. These ways let you design the plate just how you need it.

Match Method to Budget and Performance

You should pick a way to make your cold plate that fits your money and how well you want it to work. Friction stir welding gives the best cooling and strong plates. It costs more at first but saves money if you make a lot of plates. Brazing is good for tricky designs but can cost more if the shape is hard. Machining is best for small groups or when you want to test new ideas. Die casting is cheapest for big orders but does not cool as well.

Think about these things before you choose:

How much heat your system makes

How much money you have

How big and heavy the plate can be

How easy it is to put in and fix

What fluid you will use

Where you will use the plate (hot, wet, or tough places)

If you need to add more plates later

You get the best results when you pick a way that fits your cooling needs and your money. Custom cold plates work best when you match the right way to your job.

Technical Drawings and Documentation

Essential Elements to Include

You need to give your supplier clear technical drawings when you order custom cold plates. Good drawings help you get the right product. They also save you time and money. Here are the main things you should include:

Dimensions: Show the length, width, and thickness of the cold plate. Use clear units like millimeters or inches.

Tolerances: Tell how much size can change. This helps the supplier know what is okay and what is not.

Port Locations and Sizes: Mark where the fluid goes in and out. Show the size and type of each port.

Mounting Holes: Draw all holes for screws or bolts. Give their size and exact spot.

Channel Layout: Show the path of the coolant inside the plate. Use arrows to show flow direction.

Material Type: Write the exact material you want, like “6061 Aluminum” or “C110 Copper.”

Surface Finish: Say if you need a smooth or rough surface.

Special Features: Add notes for things like sensors, coatings, or extra fittings.

Tip: You can use a table in your drawing to list all important details. This makes it easy for your supplier to check everything.

Avoiding Common Documentation Errors

You can avoid many problems by checking your drawings before you send them. Many people make the same mistakes. Here are some to watch out for:

Common Error | How to Prevent It |

|---|---|

Missing dimensions | Double-check all sides and features |

Unclear tolerances | Use standard symbols and notes |

Wrong port sizes | Match ports to your hoses and fittings |

No material listed | Always write the full material name |

Overlooked mounting holes | Count and mark every hole needed |

You should always review your drawings with your team. Ask your supplier if they have questions. Clear drawings help you get the cold plate you want. They also stop delays and extra costs.

Note: If you use 3D models, send them with your drawings. This helps your supplier see the design from all angles.

Supplier Evaluation and Communication

Vetting Supplier Experience and Quality

You should pick a supplier who knows how to make custom cold plates that work well and last a long time. Find companies that have made good cold plates before. They should follow the rules for making safe and strong products. Some suppliers use special tools like 3D modeling and AI. These tools help them design cold plates that cool better. Check if the supplier can make a cold plate just for your needs. Good suppliers give you a fair price and good performance. This means you get a good deal for your money.

Here is a table to help you compare suppliers:

Criteria | Description |

|---|---|

Quality | Strong track record, adherence to industry standards, rigorous testing for performance and integrity. |

Technology | Use of advanced tools like 3D modeling and AI for design, improving heat transfer efficiency. |

Customization | Tailored solutions based on specific cooling requirements, optimizing flow paths for efficiency. |

Pricing | Influenced by materials, manufacturing processes, and demand, balancing cost with performance needs. |

Tip: Ask the supplier to show you old projects. This helps you see if they can handle different cooling jobs.

Key Questions Before Ordering Custom Cold Plates

Before you buy, ask questions about how long it takes to get your cold plates, how they check quality, and what help they give you. Good suppliers test every cold plate to make sure it works right. Many suppliers use ISO rules, do pressure and heat tests, and keep track of all the parts they use.

Here is a table showing common quality control measures:

Quality Control Measure | Description |

|---|---|

ISO Certifications | Framework ensuring products meet required standards, commonly ISO 9001:2015. |

Testing Protocols | Durability tests under harsh conditions, including pressure and heat tests. |

Traceability Systems | Allows tracking of components used in production to ensure quality and identify failures. |

You can ask these questions to learn more:

How long will it take to make and send my cold plates?

What tests do you do to check if the cold plates are good?

Do you have ISO certifications?

Can you track each cold plate and its parts?

What kind of help do you give after I get my order?

Note: If you talk clearly with your supplier, you will not have as many mistakes or delays. You get better results when you ask questions early.

Cost, Lead Time, and Support Considerations

Factors Affecting Price and Delivery

When you buy custom cold plates, many things change the price and delivery time. You should know what makes the cost higher or lower. The main things that change the price are:

How many plates you need each year

What material you pick

How long it takes to machine

Extra steps in making the plate

How smooth or flat the surface is

If the surface has special shapes

How hard the plate is

Special mounting spots

Liquid connection details

Machining takes time and uses energy, so it costs more. If you want special shapes or finishes, you pay extra. Flat surfaces help cooling, but rough ones cost more and do not help much. More features mean a higher price.

The material and how you make the plate also change how fast you get it. Copper plates cool better but take longer and cost more. Aluminum plates are made faster and cost less. Machining lets you change the design, but it is slower. Extrusion is quicker but gives you fewer choices.

Lead Time Impact | Cost | Design Flexibility | |

|---|---|---|---|

Machining | Slower | Higher | High |

Extrusion | Faster | Lower | Limited |

Material | Thermal Performance | Production Speed | Cost Impact |

|---|---|---|---|

Copper | High | Slower | Higher |

Aluminum | Moderate | Faster | Lower |

Custom cold plates usually cost more than regular air cooling or all-in-one systems. Prices can be like custom loops, which cost $300 to $1,000 or more.

Understanding Warranty and After-Sales Support

Before you buy, check the warranty and support. Most suppliers give a limited warranty. This covers problems with the material or how the plate was made. If you find a problem, you can ask for a new plate. The warranty is usually for one year after you get your order. Suppliers only pay for the plate or give you a new one. They do not pay for other damages.

Warranty Type | Description |

|---|---|

Covers problems with material or making. Replacement offered. Other warranties not included. | |

Limitation of Liability and Remedies | Only pays for the plate or replacement. Claims must be made in one year. No extra damages. |

After you get your cold plate, you might need help. Good suppliers help you keep your equipment working. They help you fix problems and give advice. Some have online support for fast answers. You can ask for technical help if you have trouble or need tips.

Service Type | Description |

|---|---|

Helps your equipment work well. | |

Troubleshooting | Helps you solve problems after buying. |

Consulting Services | Gives expert advice for best results. |

Comprehensive Support | Helps with many technical issues. |

Online Support | Gives help through the internet. |

Tip: Always ask your supplier about the warranty and support before you buy. This helps you avoid problems and keeps your equipment working well.

You can get the best custom cold plate if you follow some simple steps. First, share clear details and talk often with your supplier. The table below shows what you should focus on:

Critical Step | Description |

|---|---|

Supplier Evaluation | Check certifications and testing abilities |

Material Selection | Match materials to your cooling needs |

Design Specifications | Give exact sizes and conditions |

Engineering Responsiveness | Make sure you get quick feedback |

CFD Analysis | Ask for heat flow analysis |

Planning ahead and keeping good records help your team work well. If you think about both cost and how well it works, you will get a cold plate that lasts and does its job.

FAQ

A custom cold plate is a cooling device made to fit your machine’s needs. You choose the size, shape, and material. This helps your equipment stay cool and work better.

You should pick a material based on how much heat your system makes. Copper cools best. Aluminum costs less and weighs less. Ask your supplier for advice if you are not sure.

No, you must match the coolant to the cold plate material. Some fluids can cause rust or leaks. Always check with your supplier before you pick a coolant.

Lead time depends on design, material, and order size. Most suppliers need two to six weeks. Ask your supplier for a clear timeline before you order.