The Essential Role of Liquid Cooling for AI Performance

Liquid cooling stands as a necessity for AI performance. You face hardware that produces unprecedented levels of heat and demands more energy than ever before. Traditional air cooling cannot handle these requirements.

- In early 2024, 22% of data center operators used direct liquid cooling technology.

- Adoption of liquid cooling is projected to climb to 39% by 2026.

You must rethink your approach to AI data center cooling if you want to keep pace with industry growth.

Key Takeaways

- Liquid cooling is essential for managing the high heat output of AI servers, which can exceed 100 kW per rack.

- Traditional air cooling systems struggle with rising power densities, making liquid cooling a more effective solution for modern AI workloads.

- Adopting liquid cooling can lead to significant energy savings, with potential reductions of 30% or more in operational costs.

- Liquid cooling technologies, such as direct-to-chip and immersion cooling, provide better thermal management and extend hardware lifespan.

- Implementing liquid cooling can reduce your data center’s environmental impact by lowering greenhouse gas emissions and minimizing water usage.

- AI-powered cooling systems enhance efficiency by predicting cooling needs and optimizing temperature control in real-time.

- To successfully transition to liquid cooling, assess your data center’s specific needs and plan for phased deployment.

- Consider integrating renewable energy sources with your cooling strategy to further improve sustainability and reduce costs.

AI Workloads and Cooling Needs

Data Center Growth

You see rapid expansion in data center capacity as AI workloads surge. The demand for advanced computing infrastructure grows every year. AI models require more servers, more storage, and more networking power. This trend drives a dramatic increase in the size and complexity of data centers worldwide.

Data centers now expand at rates never seen before. You must plan for this growth to avoid bottlenecks and downtime.

The following table shows the projected annual growth rates for global data center capacity driven by AI workloads through 2030:

| Aspect | Growth Rate |

|---|---|

| Overall Data Center Capacity | 22% annually |

| Generative AI Workloads | 39% annually |

| Advanced AI Capacity | 33% annual increase in percentage of total demand |

You need to anticipate these changes and scale your infrastructure accordingly. AI data center cooling becomes a critical factor in supporting this growth.

Power and Heat Challenges

AI servers generate much more heat than traditional servers. You face rising power densities that push the limits of conventional cooling systems. Over the past decade, the average power density in data centers has increased sharply:

- A decade ago, average power densities were around 4-5 kW per rack.

- Today, you see average densities of 12-17 kW per rack.

- Projections show densities could exceed 100 kW per rack in the near future.

- AI workloads are expected to require 60–120 kW per rack.

The heat output from AI-optimized servers far surpasses that of traditional servers. The table below highlights typical heat output levels:

| Server Type | Heat Output (kW per rack) |

|---|---|

| Traditional Servers | 7-10 |

| AI-Optimized Servers | 30 to over 100 |

| Average in AI Facilities | 60+ |

You must address these challenges to maintain reliable operations. AI data center cooling solutions help you manage this intense heat and prevent hardware failures.

Air Cooling Limits

Traditional air cooling systems struggle to keep up with the demands of modern AI workloads. You encounter significant limitations as power densities rise:

- Air cooling becomes inadequate at power densities of 20-30 kW per rack.

- Exceeding this range leads to inefficiencies and possible equipment throttling.

- AI workloads often require power densities double or triple this threshold.

You cannot rely on air cooling alone for high-density AI deployments. The need for advanced AI data center cooling technologies becomes clear as you plan for future growth and performance.

Air vs. Liquid Cooling

Technical Barriers

You face several technical barriers when you rely on air cooling for high-density AI environments. Air cooling systems struggle to keep up with the intense heat generated by modern AI hardware. The following table highlights the main limitations you encounter:

| Limitation Type | Description |

|---|---|

| Thermal Density Challenges | AI workloads drive thermal densities far beyond the limits of legacy cooling systems. |

| Resource Constraints | AI workloads increase pressure on water and energy resources, complicating cooling options. |

| Power Infrastructure Issues | Existing power grids are not designed for the continuous high demands of AI cooling systems. |

| Compressed Deployment Timelines | Rapid AI adoption leads to rushed cooling system deployment, affecting long-term efficiency. |

You must address these barriers to maintain reliable performance. Liquid cooling offers a solution by transferring heat more effectively than air, especially in high-density environments. Liquids possess much higher thermal conductivity than air, which allows you to remove heat quickly and keep your servers running at optimal temperatures.

Cost and Efficiency

You need to consider both upfront costs and long-term savings when comparing air and liquid cooling. Liquid cooling systems often remove the need for chillers and computer room air handlers (CRAHs), which can save you money on switchgear and uninterruptible power supplies (UPS). However, you must account for additional expenses such as dry coolers, computer room air conditioners (CRACs), pumps, and piping. Liquid cooling technology also incurs a premium at the server and rack level.

The following table compares annual energy consumption and cost savings between air and liquid cooling:

| Cooling Type | Annual Energy Consumption (MWh) | Energy Savings (MWh) | Cost Savings ($) |

|---|---|---|---|

| Air Cooling | 1000 | 0 | 0 |

| Liquid Cooling | 1000 | 300 | 30,000 |

You see that liquid cooling can deliver significant energy and cost savings over time. Operational costs over five years show even greater benefits:

| Aspect | Liquid-Cooled Data Centers | Air-Cooled Data Centers | Difference |

|---|---|---|---|

| Total Cost Savings (5 years) | €1.16 million | N/A | €1.16 million |

| Amortization Period | 2 years | N/A | N/A |

| Energy Efficiency Improvement | 30%+ | N/A | N/A |

| Carbon Emissions Reduction | 35 tons/year | N/A | N/A |

| Server Density | Up to 130 kW per cabinet | N/A | N/A |

You benefit from improved energy efficiency, lower operational costs, and higher server density. Liquid cooling enables tighter temperature control and better performance under heavy workloads. Enhanced thermal management can extend the lifespan of your hardware and help you meet ASHRAE thermal guidelines.

Tip: Air-cooled data centers cost about $7.02 per watt, while liquid-cooled data centers cost about $6.98 per watt. The costs are roughly equal, but liquid cooling offers specific savings and efficiency improvements.

Environmental Impact

You must consider the environmental impact of your cooling strategy. Traditional air-cooled data centers often rely on evaporative cooling systems, which consume large amounts of water. Liquid cooling systems can minimize water use or operate in a closed-loop system that recirculates coolant, reducing the need for continuous water input.

When you set up liquid cooling for zero water usage, you can save as much as 33 million gallons of water per year. Some advanced systems, like Nautilus’ water technology, can save up to 380 million gallons annually in a 100MW data center. The following table shows the reductions in greenhouse gas emissions, energy use, and water use for different liquid cooling methods:

| Cooling Type | Greenhouse Gas Reduction | Energy Use Reduction | Water Use Reduction |

|---|---|---|---|

| Cold Plate | 15% to 16% | 15% | 31% to 50% |

| One-Phase | 13% to 16% | 15% | 45% to 80% |

| Two-Phase | 20% to 21% | 20% | 48% to 82% |

You reduce your environmental footprint by choosing liquid cooling. Many setups use closed-loop designs, which significantly decrease water consumption and greenhouse gas emissions. You support sustainability and meet regulatory requirements more easily with these advanced cooling solutions.

Note: Liquid cooling systems help you achieve lower emissions and higher energy efficiency, making them a smart choice for AI data center cooling.

AI Data Center Cooling Technologies

Modern AI data center cooling relies on advanced liquid cooling technologies to manage extreme heat and power densities. You must understand the differences between direct-to-chip and immersion cooling to choose the best solution for your facility.

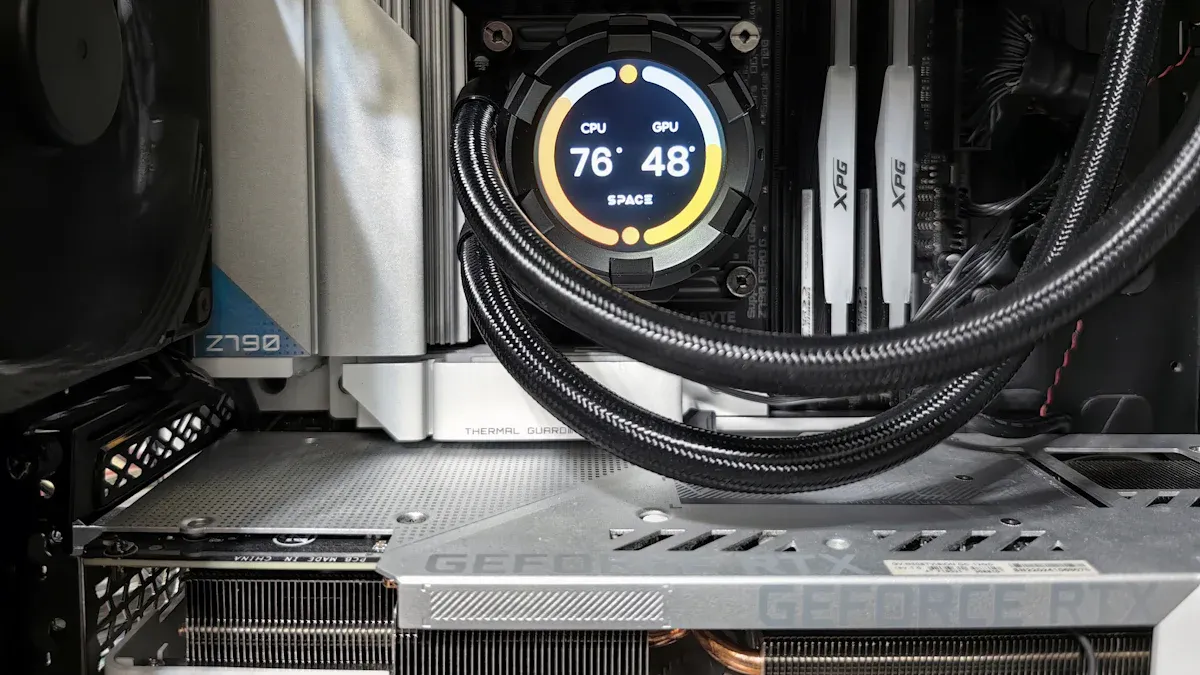

Direct-to-Chip Cooling

Direct-to-chip cooling circulates coolant directly to heat-producing components like CPUs and GPUs. This method maximizes cooling efficiency and minimizes heat transfer to the environment. You can use cold plates attached to processors, which absorb heat and transfer it to a closed-loop coolant system.

| Cooling Technology | Description | Application |

|---|---|---|

| Direct-to-Chip Cooling | Circulates coolant directly to heat-generating components. | Offers unparalleled efficiency and cooling effectiveness. |

| Cold-plate Cooling | Attaches a cold plate to components, circulating coolant to absorb heat. | Effective for cooling individual high-heat components. |

Single-Phase and Two-Phase

You can choose between single-phase and two-phase direct-to-chip cooling. Single-phase systems use water or glycol-based coolants that remain in liquid form. Two-phase systems use fluids that change from liquid to vapor, absorbing more heat during the phase change.

- Single-phase cooling: Simple design, reliable operation, and easy maintenance.

- Two-phase cooling: Higher heat absorption, improved efficiency, and reduced coolant flow rates.

Direct-to-chip cooling provides several advantages:

- Greater efficiency: Transfers heat directly from processors to the cooling medium, reducing thermal resistance.

- Lower energy costs: Reduces power consumption compared to air cooling.

- Scalability: Modular cooling distribution units (CDUs) allow incremental upgrades.

- Reduced water consumption: Closed-loop systems minimize water use.

Environmental Concerns

You must consider environmental and regulatory factors when selecting direct-to-chip cooling. Some coolants contain PFAS (per- and polyfluoroalkyl substances), which face increasing regulation due to environmental risks. You should choose coolants with low environmental impact and comply with local regulations. Closed-loop systems help you minimize water usage and reduce your facility’s environmental footprint.

Immersion Cooling

Immersion cooling submerges servers in a thermally conductive, electrically insulating liquid. This method absorbs heat directly from all components, making it ideal for high-density AI workloads.

| Cooling Technology | Description | Application |

|---|---|---|

| Immersion Cooling | Components are submerged in a thermally conductive but electrically insulating liquid. | Ideal for high-performance computing environments. |

Efficiency and Adoption

Immersion cooling delivers impressive energy savings. You can reduce cooling energy consumption by 60-80% and achieve additional server energy savings of 5-10%. This method maintains stable temperatures, allowing hardware to operate at peak performance for longer periods. Heat dissipation through liquid is much more effective than air, resulting in lower energy consumption.

You see rapid adoption of immersion cooling in hyperscale data centers. North America leads the market, driven by major cloud providers like Google, Microsoft, and AWS. These companies use tank-based immersion cooling systems to manage racks exceeding 50kW per cabinet. The global immersion cooling market is projected to reach $7.2 billion by 2034, with a compound annual growth rate of 18.3%. Hyperscale data centers accounted for over 35% of the revenue share in 2024, highlighting the importance of immersion cooling for advanced AI data center cooling.

Tip: Immersion cooling enables you to deploy more servers in less space, improve energy efficiency, and reduce operational costs.

Performance and Efficiency Gains

Lower PUE

You achieve remarkable improvements in Power Usage Effectiveness (PUE) when you switch to liquid cooling. PUE measures how efficiently your data center uses energy; a lower value means less energy wasted on non-computing tasks. Liquid cooling systems deliver several advantages over traditional air cooling:

- Lenovo’s liquid cooling solution offers a 3.5x improvement in thermal efficiencies compared to air-cooled systems.

- You can see up to a 40% reduction in power consumption with Lenovo’s liquid cooling.

- A 75% transition from air cooling to liquid cooling can lead to a 27% reduction in facility power consumption.

- Lenovo’s solution claims to achieve a PUE of 1.1, which signals a significant leap in energy efficiency.

Cooling systems account for 25-40% of the energy consumption in data centers. By adopting liquid cooling, you reduce total energy use by 10–30%. You lower operational costs and support sustainability goals.

Lowering your PUE means you spend less on energy and help the environment.

Server Density

Liquid cooling enables you to pack more computing power into smaller spaces. You support higher heat density and maintain consistent performance. The following table compares liquid cooling and air cooling across key metrics:

| Benefit | Liquid Cooling | Air Cooling |

|---|---|---|

| Energy Efficiency | More efficient heat removal | Less efficient, higher operational costs |

| Heat Density Capacity | Supports higher heat density in smaller spaces | Requires more space and complex airflow management |

| Reliability and Performance | Consistent temperature control, reduces thermal throttling | Excessive heat can lead to performance issues |

| Hardware Lifespan | Longer lifespan due to reduced thermal stress | Shorter lifespan due to temperature fluctuations |

| Space Efficiency | More compact design, less space required | Requires additional space for ducts and fans |

You increase server density and maximize your data center’s footprint. You also extend hardware lifespan and reduce the risk of overheating.

Case Studies

Energy and Cost Savings

You find real-world examples that highlight the benefits of liquid cooling. Organizations across different sectors have documented significant gains:

| Case Study | Sector | Innovative Approach | Outcomes |

|---|---|---|---|

| Advanced Solutions Division | High-Performance Computing | Direct-to-chip cooling technology | Performance boost, maintenance minimization, future readiness |

| National Laboratory | Research and HPC | Immersive cooling in fluid bath | Elevated cooling proficiency, energy optimization, space optimization |

| Data Centers | Data Hosting & Cloud Services | Two-phase liquid cooling solution | Scalability triumph, eco-friendly operations, cost efficiency |

You see performance boosts, reduced maintenance, and future-ready infrastructure. You also achieve energy optimization and cost savings.

Emissions Reduction

Liquid cooling helps you lower your carbon footprint. You reduce greenhouse gas emissions and water usage. Many organizations report eco-friendly operations after switching to liquid cooling. You support regulatory compliance and sustainability targets.

When you invest in AI data center cooling, you gain efficiency, reliability, and environmental benefits.

Sustainability and Energy Reuse

Lower Emissions

You play a vital role in reducing carbon emissions when you choose liquid cooling for your AI data center. Liquid cooling technologies transfer heat up to 1,000 times faster than air cooling. This rapid heat transfer leads to significant energy savings and lower carbon output. You can achieve up to 50% reductions in both embodied and operational carbon emissions compared to traditional air cooling. You also benefit from near zero water usage and a 50% smaller data center building size. These improvements help you lower embodied carbon and minimize resource use.

By adopting liquid cooling, you support your organization’s sustainability goals and meet stricter environmental regulations.

Energy Reuse

You can turn waste heat from your AI data center into a valuable resource. Liquid cooling systems make it easier to capture and reuse heat, which would otherwise be lost to the environment. You have several options for energy reuse:

- Transfer heated water to neighboring communities for building heating.

- Reuse heat within your own data center to support other processes.

- Integrate heat recovery systems to prevent thermal pollution.

Building Heating

You see growing interest in using data center waste heat for building heating. In Europe, new regulations require large data centers to assess waste heat recovery options. Sweden leads the way by repurposing waste heat to warm schools and residential apartments. You can follow this example and provide sustainable heating solutions for your local community.

| Country | Application | Impact |

|---|---|---|

| Sweden | School and apartment heating | Reduced fossil fuel use |

| Germany | District heating projects | Lowered energy costs |

| France | Community heating systems | Improved energy efficiency |

Agriculture and Industry

You can also direct waste heat to support agriculture and industrial processes. Heated water from your data center can warm greenhouses, helping farmers grow crops year-round. Industrial facilities can use this heat for manufacturing or drying operations. You create new revenue streams and strengthen your sustainability profile.

Tip: Partner with local businesses to maximize the benefits of energy reuse and build stronger community relationships.

Nature-Based Cooling

You can enhance sustainability by exploring nature-based cooling solutions. These systems use natural resources, such as groundwater or ambient air, to supplement liquid cooling. You reduce your reliance on mechanical cooling and further lower your energy consumption. Nature-based cooling works well in regions with favorable climates and abundant water sources.

- Use groundwater for heat exchange.

- Harness cool outside air during colder months.

- Combine natural and liquid cooling for optimal efficiency.

You position your data center as a leader in environmental stewardship. You meet regulatory requirements and attract clients who value green technology.

Sustainable cooling strategies help you future-proof your AI data center and contribute to a cleaner planet.

Adoption and Best Practices

Assessing Needs

You must start by evaluating your data center’s unique requirements before adopting liquid cooling. Power density and heat generation continue to rise as AI workloads expand. You need to consider environmental sustainability goals and space optimization imperatives. The rise of edge computing also influences your cooling strategy.

When you assess your needs, focus on these key factors:

- Increasing power density and heat generation in your racks.

- Environmental sustainability targets set by your organization.

- Space optimization to maximize your facility’s footprint.

- The impact of edge computing on cooling demands.

You should review your business drivers and operational characteristics. Financial and operational priorities will shape your decision. If you plan to retrofit an existing facility, examine your current cooling mechanisms. For new builds, design with scalability in mind. Compliance with regulations, such as the American Innovation & Manufacturing (AIM) Act, is essential. Proactive implementation helps you avoid future compliance costs.

Tip: A thorough assessment ensures your cooling solution aligns with both current and future needs.

Choosing Solutions

Selecting the right liquid cooling solution requires a careful analysis of your AI workloads and infrastructure. You must measure the thermal footprint and airflow requirements for your servers. Assess flow rates to determine the cooling capacity needed for each rack. Decide if you need to upsize your cooling system for future upgrades.

The following table outlines important criteria for choosing a solution:

| Criteria | Description |

|---|---|

| Measure the thermal footprint | Determine the heat load and airflow needs for your AI servers. |

| Assess flow rates | Calculate cooling capacity based on compute power to prevent overheating. |

| Upsize cooling if needed | Plan for additional cooling to support future IT equipment upgrades. |

| Choose high-density solutions | Use technologies that efficiently dissipate heat and minimize energy consumption. |

| Consider chilled water onsite | Utilize chilled water systems for continuous cooling operations. |

| Deploy CDUs without chilled water | Explore alternatives if chilled water is unavailable. |

| Create cooling redundancy | Organize multiple cooling units for reliability and IT load support. |

| Implement controls | Use digital tools to monitor and optimize cooling performance. |

| Plan maintenance | Establish regular protocols to ensure efficient operation. |

You should prioritize solutions that offer flexibility and scalability. High-density cooling technologies help you manage intense workloads while minimizing energy use.

Implementation Tips

You can achieve a smooth transition to liquid cooling by following best practices. Gradual deployment works best, allowing you to implement solutions step by step. Interim options, such as rear door heat exchangers, provide immediate relief without a full overhaul. Flexibility is key; mix and match cooling methods to meet specific IT demands.

Regular maintenance ensures your system operates efficiently. Schedule periodic inspections and follow industry standards. Monitor water quality and refresh coolant in closed-loop systems to prevent issues. Liquid cooling offers a heat transfer capacity 3,500 times greater than air, which can significantly improve Power Usage Effectiveness (PUE) and reduce energy costs. Closed-loop systems also minimize water waste by reusing coolant.

You may encounter challenges during the transition. IT equipment design modifications might be necessary. You will still need small air-side systems to handle minor heat loads. Humidity control becomes important since liquid-cooled racks do not provide dehumidification.

Note: IT and telecom companies prioritize liquid cooling to boost energy efficiency and lower long-term costs. You can expect energy efficiency gains of 30–50%, leading to better performance and reduced operating expenses.

AI-Powered Cooling

You face new challenges as AI workloads push your data center to its limits. Advanced cooling management platforms now use artificial intelligence to help you overcome these obstacles. AI-powered cooling systems analyze data from sensors and equipment in real time. You gain insights that allow you to make smarter decisions and keep your servers running efficiently.

AI platforms use predictive analytics to forecast cooling needs before problems arise. You can adjust your cooling strategy based on expected demand, not just current conditions. This approach reduces energy waste and keeps your facility at optimal temperatures. Dynamic temperature control lets you respond instantly to changes in server activity. You maintain stable conditions even when workloads spike.

Zonal cooling targets specific areas that need more attention. You direct cooling resources to racks or zones with higher heat output. This method conserves energy and prevents overcooling in less active areas. AI systems monitor each zone and adjust cooling levels automatically. You avoid hot spots and keep your hardware safe.

AI-powered platforms also integrate renewable energy sources into your cooling operations. You align cooling schedules with periods of high renewable energy availability. This strategy helps you lower your carbon footprint and meet sustainability goals. You use clean energy when it is most abundant, making your data center more environmentally friendly.

Predictive maintenance is another key benefit. AI analyzes equipment performance and predicts when failures might occur. You schedule repairs before breakdowns happen, reducing downtime and improving reliability. This proactive approach saves you money and keeps your cooling systems running smoothly.

The following table summarizes how AI innovations contribute to energy efficiency in your data center:

| AI Innovation | Contribution to Energy Efficiency |

|---|---|

| Predictive Analytics | Forecasts cooling requirements to reduce energy wastage. |

| Dynamic Temperature Control | Adapts cooling settings in real-time to maintain optimal temperatures. |

| Zonal Cooling | Directs cooling resources to high-demand areas, conserving energy. |

| Renewable Energy Integration | Aligns cooling operations with renewable energy availability. |

| Predictive Maintenance | Predicts equipment failures to prevent downtime and optimize performance. |

Tip: You can combine AI-powered cooling with liquid cooling technologies to maximize efficiency and increase IT capacity.

You benefit from lower energy costs, improved reliability, and a stronger sustainability profile. AI-powered cooling platforms help you optimize every aspect of your data center’s operation. You stay ahead of industry trends and prepare your facility for future growth. By adopting these advanced solutions, you ensure your AI workloads run smoothly and your data center remains competitive.

Liquid cooling drives efficient, reliable, and scalable AI operations. You gain key advantages:

- Lower power demand and improved energy efficiency, since cooling systems use up to 40% of data center electricity.

- Enhanced sustainability through renewable energy integration and innovative methods like geothermal or rainwater collection.

To future-proof your strategy, consider these steps:

- Change your mindset and review standards.

- Research direct liquid cooling systems.

- Measure benefits and plan phased deployment.

You position your data center for growth and environmental leadership.

FAQ

What makes liquid cooling better for AI workloads than air cooling?

Liquid cooling removes heat faster and more efficiently. You can support higher server densities and maintain stable performance. This method helps you avoid overheating and hardware throttling in demanding AI environments.

Can you retrofit liquid cooling into an existing data center?

You can retrofit liquid cooling systems. Many solutions, such as rear door heat exchangers or direct-to-chip modules, integrate with current infrastructure. You should assess your facility’s layout and cooling needs before starting the upgrade.

Does liquid cooling increase maintenance requirements?

Liquid cooling systems require regular inspections and coolant quality checks. You must monitor for leaks and replace coolant as needed. With proper maintenance, you can extend hardware lifespan and reduce downtime.

How does liquid cooling impact energy costs?

Liquid cooling lowers energy consumption by improving heat transfer. You spend less on cooling and reduce overall operational costs. Many facilities report energy savings of 30% or more after switching to liquid cooling.

Is liquid cooling environmentally friendly?

Liquid cooling uses closed-loop systems that minimize water waste. You reduce greenhouse gas emissions and support sustainability goals. Choosing eco-friendly coolants helps you comply with environmental regulations.

What are the risks of using liquid cooling?

You face risks such as leaks or coolant contamination. You must follow best practices for installation and maintenance. Modern systems include sensors and alarms to help you detect problems early.

Can AI help optimize liquid cooling systems?

AI-powered platforms analyze sensor data and predict cooling needs. You gain real-time insights and automate temperature control. This technology helps you maximize efficiency and prevent equipment failures.

How do you choose the right liquid cooling solution?

You should evaluate your power density, heat output, and future growth plans. Compare direct-to-chip and immersion cooling options. Consult with vendors and review case studies to find the best fit for your data center.