what is a heat sink in a computer

A heat sink in a computer acts as a metal device that pulls heat away from critical chips like the CPU and GPU. You rely on this component to keep temperatures low and protect your system from overheating. When chips run too hot, especially above 85 °C, performance drops and lifespan shortens.

- Efficient cooling extends the life of your hardware.

- Lower thermal resistance from a heat sink keeps your computer stable.

Key Takeaways

- A heat sink is essential for cooling critical computer components like the CPU and GPU, preventing overheating and ensuring optimal performance.

- Heat sinks come in two main types: passive, which rely on natural airflow, and active, which use fans for enhanced cooling efficiency.

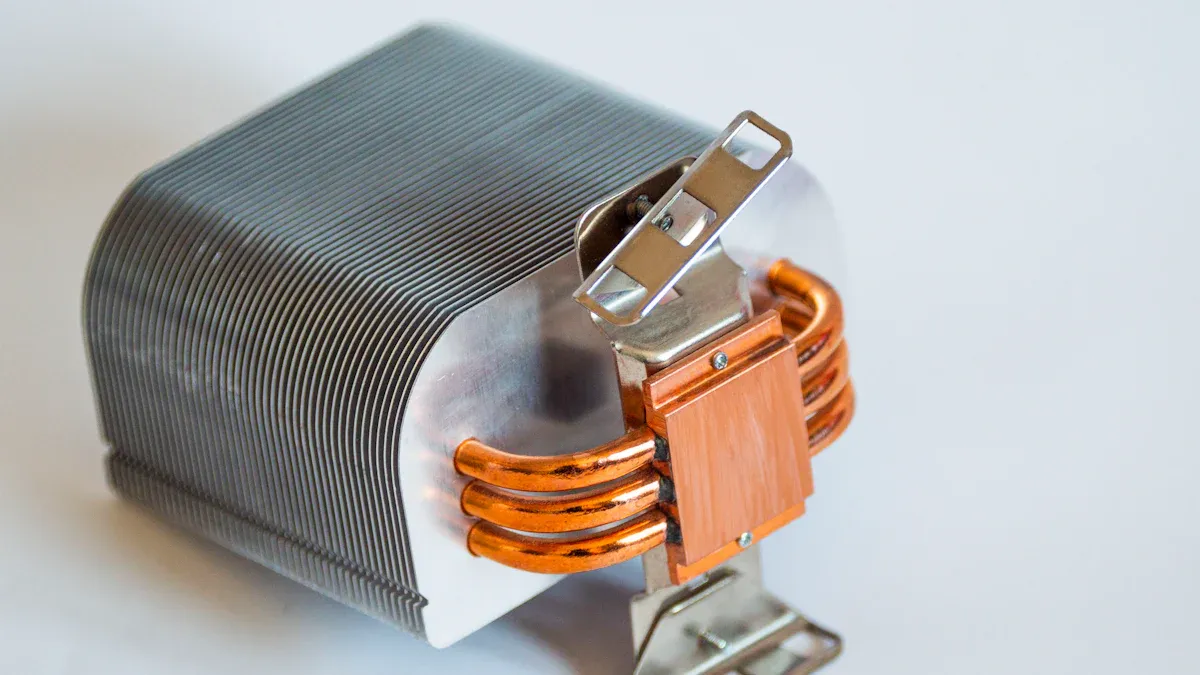

- Materials like aluminum and copper are commonly used in heat sinks, with aluminum being lightweight and cost-effective, while copper offers superior thermal conductivity.

- Proper installation and regular cleaning of heat sinks are crucial for maintaining system stability and performance, helping to avoid overheating issues.

- Choosing the right heat sink involves considering factors like thermal design power (TDP), airflow, and compatibility with your computer’s components.

Heat Sink Basics

What It Is

You can think of a heat sink as a specialized metal component that sits directly on top of chips like your CPU or GPU. Its main job is to draw heat away from these electronic parts. The design of a heat sink increases the surface area available for heat transfer. Most heat sinks use fins or similar structures to help air flow over them, which improves cooling. By using materials such as aluminum or copper, a heat sink absorbs heat from the chip and moves it into the surrounding air. This process uses conduction, convection, and sometimes radiation to keep your computer running at safe temperatures.

Note: A heat sink does not generate cooling by itself. Instead, it acts as a bridge, moving heat from the chip to the air or another cooling medium.

Main Function

The main function of a heat sink is to prevent your computer’s critical components from overheating. When you run demanding applications or games, your CPU and GPU generate a lot of heat. If you do not manage this heat, your system can slow down or even shut off to protect itself. A heat sink helps maintain optimal performance by keeping temperatures in check.

Here is how a heat sink works to protect your CPU and GPU:

- Heat Generation: Your CPU or GPU produces heat during operation.

- Heat Transfer: The heat moves from the chip into the heat sink through direct contact, often with the help of thermal paste.

- Heat Distribution: The heat spreads throughout the heat sink, moving from hotter areas to cooler areas.

- Heat Dissipation: The heat sink releases the heat into the surrounding air, often with the help of airflow from a fan.

You will find heat sinks in several key components inside your computer. The table below shows where you are most likely to see them and why they are necessary:

| Component Type | Reason for Heat Sink Use |

|---|---|

| CPUs | Generate significant heat during operation |

| GPUs | Generate significant heat during operation |

| Power Transistors | Generate significant heat during operation |

Without a heat sink, these components would quickly reach unsafe temperatures. By using a heat sink, you ensure your computer stays reliable and performs at its best.

How It Works

Heat Transfer

When your computer runs, the CPU and GPU generate heat as they process data. You rely on the heat sink to move this heat away from the chip and into the surrounding environment. The process uses three main physical principles: conduction, convection, and radiation. Each principle plays a unique role in keeping your system cool.

| Heat Transfer Mechanism | Description |

|---|---|

| Conduction | Heat travels through direct contact. The heat sink absorbs heat from the chip and spreads it across its metal surface. Fins on the heat sink help transfer heat to the air. |

| Convection | Air moves heat away from the heat sink. Natural convection happens when warm air rises and cool air replaces it. Forced convection uses fans to push air over the heat sink, improving cooling. |

| Radiation | The heat sink emits energy as infrared radiation. The material and surface finish can increase this effect, helping the heat sink lose heat faster. |

You benefit from these mechanisms working together. The heat sink first absorbs heat through conduction. Then, convection and radiation help release the heat into the air or, in some cases, into a liquid cooling system.

Dissipation Methods

You can choose between passive and active heat exchange methods for your computer. Each method has strengths and weaknesses, depending on your cooling needs.

Passive Heat Sinks

Passive heat sinks rely on natural convection and radiation. You do not need any moving parts or power. The heat sink uses its large surface area and metal fins to let air flow over it. Heated air rises, and cooler air moves in to replace it. This method works best for low-power components or silent systems.Active Heat Sinks

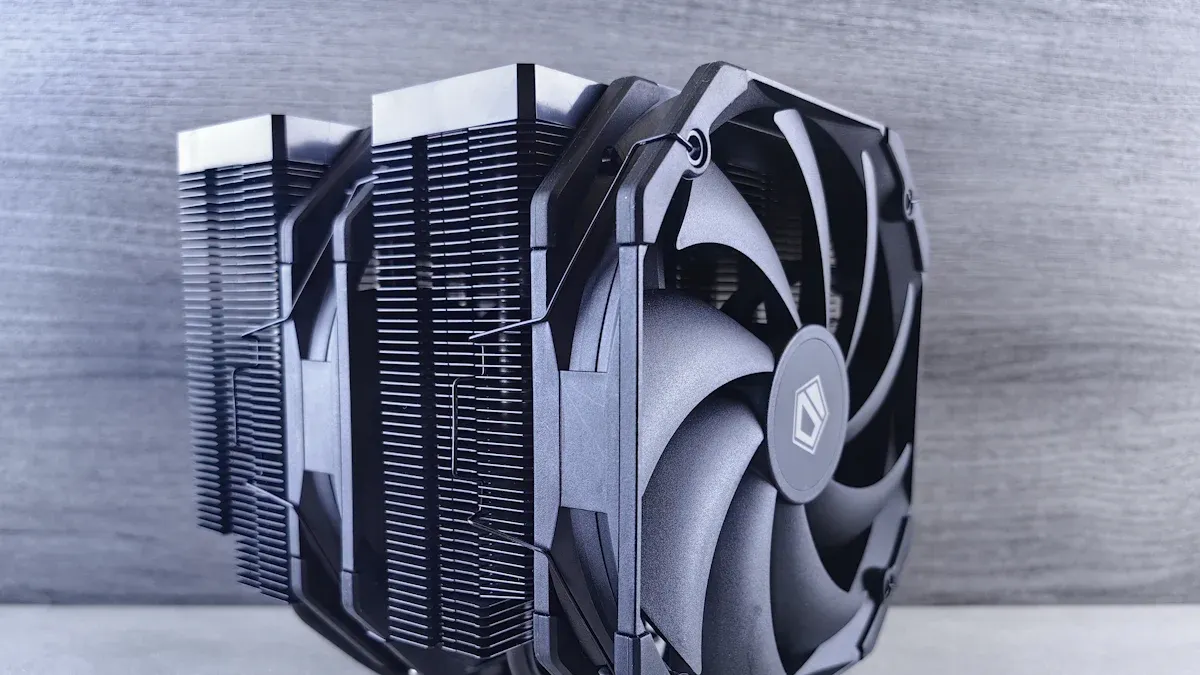

Active heat sinks use fans or blowers to force air across the heat sink. You get much higher cooling efficiency because forced convection moves air quickly and creates turbulence. This method handles high-power chips and demanding applications. You must supply power for the fan, and you may notice some noise.

| Aspect | Passive Heatsink | Active Heatsink |

|---|---|---|

| Cooling Efficiency | Lower | Higher |

| Noise Level | Silent | Noisy |

| Power Consumption | None | Requires power for fan |

| Maintenance | Low (no moving parts) | Higher (fan can fail) |

| Size | Larger for same cooling | Smaller for same cooling |

| Cost | Generally lower | Generally higher |

| Best For | Low-heat, silent applications | High-heat, performance-critical |

💡 Tip: If you want maximum cooling for gaming or heavy workloads, choose an active heat sink. For quiet operation and low-power devices, a passive heat sink may be enough.

Airflow plays a critical role in heat dissipation. When you use a fan, you increase the speed of air moving over the heat sink. This forced convection boosts cooling efficiency and helps your computer handle more heat. Fins on the heat sink increase surface area, allowing more heat to escape. You should always consider airflow when selecting or installing a heat sink.

Types of Heat Sinks

Passive and Active

You will find two main categories of heat sinks in computers: passive and active. Each type uses a different method to manage heat. Passive heat sinks have no moving parts. You see them made from aluminum or copper. They rely on natural convection, which means air moves over the surface without help from a fan. You often use passive heat sinks in low-power electronics where silent operation matters.

Active heat sinks include a fan or blower. The fan pushes air across the metal fins, which increases cooling speed. You use active heat sinks in high-performance computing, such as gaming PCs, servers, and workstations. These systems generate more heat and need faster cooling.

Here is a quick comparison:

| Heat Sink Type | Characteristics | Applications |

|---|---|---|

| Passive Heat Sinks | No moving parts, made of aluminum or copper, rely on natural convection, used in low-power systems | Low-power electronics |

| Active Heat Sinks | Include a fan or blower, require power, offer faster cooling, common in CPUs, GPUs, servers | High-performance computing |

Tip: Choose a passive heat sink for quiet, low-power devices. Use an active heat sink when you need maximum cooling for demanding tasks.

Hybrid Designs

Hybrid heat sinks combine the best features of passive and active designs. You get a passive base that can work alone or with a fan. Some hybrid models switch between passive and active modes based on temperature. This smart approach helps you save energy and reduce noise when your computer does not need extra cooling. You often see hybrid heat sinks in specialized applications, such as smart devices or compact PCs.

| Heat Sink Type | Characteristics | Applications |

|---|---|---|

| Hybrid Heat Sinks | Combine passive base with optional fan, can switch modes based on temperature, useful in smart devices | Specialized applications |

Custom-Made Options

Sometimes, you need a heat sink that standard models cannot provide. Custom-made options solve unique cooling challenges. You might need a specific fin height, base size, or shape to fit your device. Custom heat sinks also help when you want better thermal performance than off-the-shelf products offer. If you produce devices in large quantities, custom designs can lower costs and reduce material waste.

Here are common scenarios for custom-made heat sinks:

| Scenario Type | Requirement Description |

|---|---|

| Specific Design Requirements | When standard models cannot meet specific design needs such as fin height or base size. |

| Unique Shapes or Features | Needed for applications that require enhanced thermal performance beyond standard options. |

| High Production Quantity | Justifies the creation of new tooling to reduce production costs and material waste. |

Note: You should consider a custom heat sink if your project has special size, shape, or performance needs that standard products cannot meet.

Heat Sink Materials

Aluminum

You often see aluminum used in computer cooling because it offers a strong balance of cost, weight, and performance. Aluminum alloys resist corrosion and provide medium to high strength, making them reliable for daily use. Most manufacturers choose aluminum for its lightweight nature, which helps keep your system easy to handle and install.

- Aluminum’s thermal conductivity is about 205 W/m·K.

- 6061 aluminum, a common alloy, has a thermal conductivity of around 167 W/m·K.

- Aluminum outperforms steel and titanium in heat transfer, but copper and graphite still conduct heat better.

Aluminum heat sinks are cost-effective and easy to shape into complex designs. You benefit from their ability to cool most consumer electronics without adding much weight or expense.

| Material | Properties |

|---|---|

| Aluminum Alloys | Corrosion resistance, heat treatability, medium to high strength |

📝 Note: Aluminum is the most practical choice for many users because it balances performance and affordability.

Copper

Copper stands out for its superior thermal conductivity, which reaches about 385 W/m·K. You get faster heat transfer, which helps keep high-performance chips cooler under heavy loads. Copper also offers excellent heat capacity and resists corrosion.

| Advantages of Copper Heat Sinks | Disadvantages of Copper Heat Sinks |

|---|---|

| High Thermal Conductivity | Weight: Copper is denser than some other materials, which may be a factor in applications where weight is critical. |

| Excellent Heat Capacity | Oxidation: Copper can oxidize over time, affecting its appearance, though this typically doesn’t impact thermal performance. |

| Ductility and Malleability | Conductivity Dependency: The effectiveness of copper relies on proper design and thermal interface materials. |

| Corrosion Resistance |

Copper heat sinks deliver about 50% higher thermal performance than aluminum. However, you may notice that copper is heavier and more expensive. You usually find copper in systems where top cooling performance matters more than cost or weight.

Hybrid Materials

Hybrid materials combine the strengths of different substances to improve cooling. You might see phase change materials (PCMs), hybrid gels, or advanced heat spreaders in modern designs. These materials help manage temperature spikes and keep your computer running smoothly.

| Material Type | Key Benefits | Challenges |

|---|---|---|

| Phase Change Materials (PCMs) | Absorb and release large amounts of thermal energy during phase transitions, maintaining stable temperatures. | Require complex integration to prevent leakage. |

| Hybrid Gels | High thermal conductivity and conformability, ensuring good thermal contact. | Careful handling needed to avoid air bubbles. |

| Heat Spreaders | Efficiently distribute heat over a larger area, improving cooling system performance. | Do not store thermal energy; limited by interface thermal resistance. |

- Hybrid materials offer superior thermal conductivity and excellent conformability.

- They provide long-term reliability and low thermal resistance, which helps minimize temperature differences across the heat sink.

💡 Tip: If you want the best performance, consider hybrid materials for advanced cooling solutions. These options work well in high-end computers and specialized devices.

Choosing a Heat Sink

Performance Factors

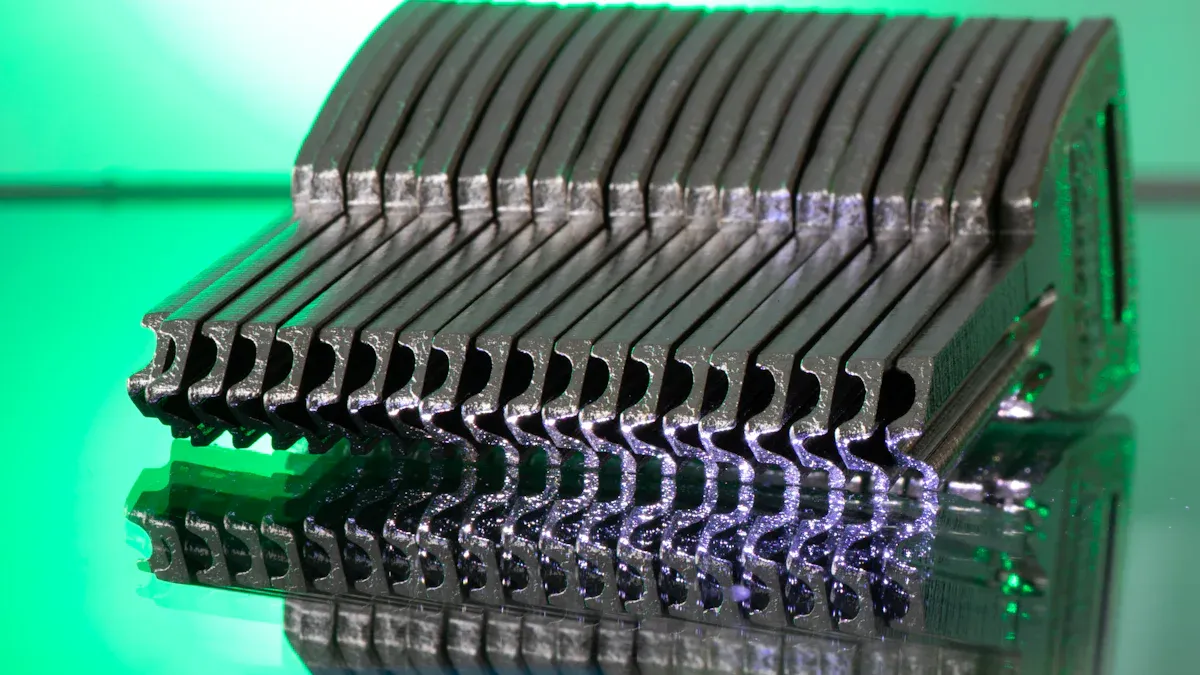

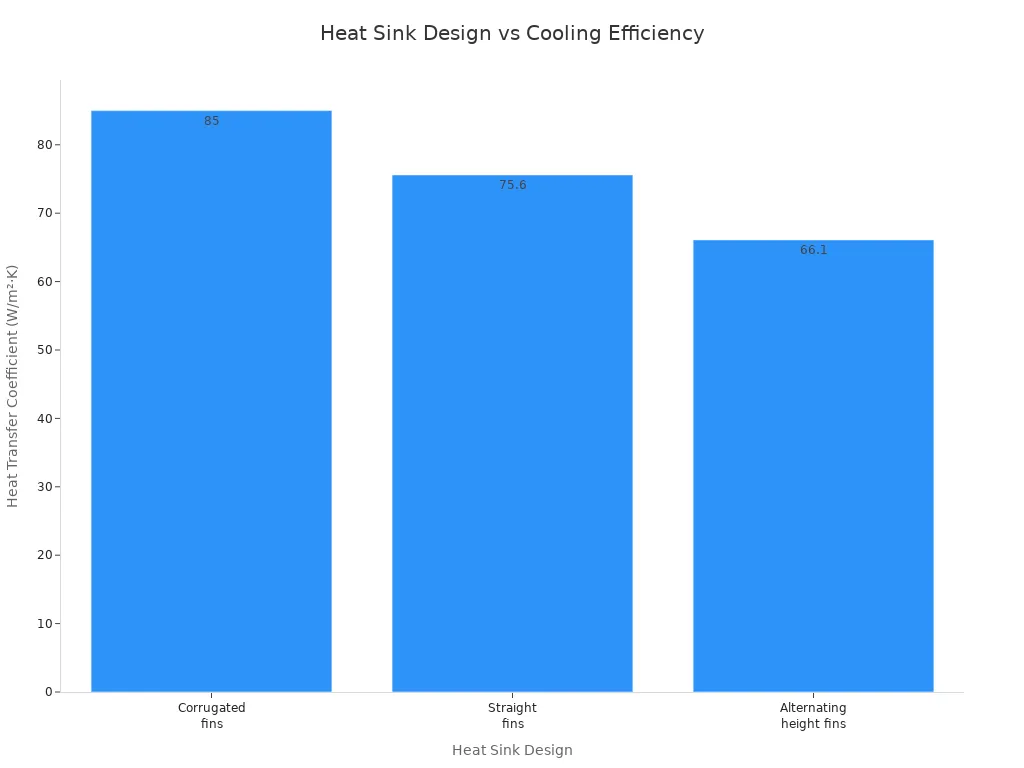

When you select a cooling solution, you must consider several factors that directly affect performance. The design and density of the fins play a major role. More fins increase the surface area for heat transfer, but if the fins are too close together, airflow can become restricted. Airflow conditions also matter. Passive systems rely on natural convection, but adding a fan can greatly improve cooling. The connection between the chip and the heat sink is critical. Any gaps can trap air and reduce heat transfer, so always use thermal paste to lower thermal interface resistance. The temperature of the air around your computer also impacts cooling. If the room is hot, it becomes harder to remove heat from your components.

| Factor | Description |

|---|---|

| Thermal Resistance | Lower resistance improves heat transfer. |

| Material Choice | Copper and aluminum offer different levels of thermal conductivity. |

| Fin Design | More fins increase surface area, but too many can block airflow. |

| Airflow Conditions | Fans or open airflow paths enhance cooling. |

| Thermal Interface Resistance | Gaps reduce heat transfer; thermal paste helps. |

| Ambient Temperature | Cooler air improves heat dissipation. |

You can see from the chart below that different fin designs affect cooling efficiency:

Selection Tips

You should always match the heat sink to your CPU or GPU’s thermal design power (TDP) rating. This ensures your cooling solution can handle the maximum heat output. Check the size of your case and the space around the CPU socket. Some heat sinks are large and may block memory slots or other components. Manufacturers like Dell and HPE often use unique mounting systems, so confirm compatibility before you buy. Choose a material that fits your needs. Copper cools better but weighs more and costs more than aluminum. Consider the fan’s size and speed. Larger fans move more air with less noise.

💡 Tip: Never focus only on the lowest price. A cheap heat sink may not provide enough cooling, leading to higher costs in the long run.

Installation

Proper installation ensures your cooling system works as intended. Always clean the chip’s surface and apply a thin layer of thermal paste before mounting the heat sink. Secure the mounting hardware evenly to avoid gaps. Make sure the heat sink sits flat on the chip for the best contact. Pay attention to airflow direction inside your case. Position fans to move hot air out and bring cool air in. Avoid blocking airflow with cables or other parts.

Common mistakes include choosing the wrong material, ignoring size requirements, and neglecting airflow. Failing to integrate the heat sink properly can cause poor cooling and system instability.

- Clean and prepare all surfaces.

- Use thermal paste to reduce resistance.

- Tighten mounting hardware evenly.

- Check airflow paths and fan orientation.

🛠️ Note: Good installation techniques improve both thermal transfer and mechanical stability, protecting your computer’s most valuable components.

Other Cooling Methods

Fans

You often see fans paired with heat sinks in most computers. Fans use forced air to move heat away from components, which increases cooling efficiency. When you use a fan, you create active air-cooling. This method works well because it pushes heated air away from the heat sink, allowing cooler air to take its place. You benefit from higher reliability, reasonable cost, and adaptability in different systems.

| Cooling Method | Heat Dissipation Efficiency |

|---|---|

| Active Cooling (Fans) | Higher, due to forced air movement |

| Passive Cooling (Heat Sinks) | Lower, relies on natural convection |

Fans offer more efficient heat transfer than passive heat sinks. You can see this in high-performance systems, where fans help maintain safe temperatures during heavy workloads. However, fans require regular maintenance and can add noise to your system.

💡 Tip: If you want the best balance between cost and performance, use a fan with your heat sink for active cooling.

Liquid Cooling

Liquid cooling uses coolant fluids to absorb and transfer heat away from your computer’s components. You might choose this method for its superior cooling capacity and energy efficiency. Liquid cooling can dissipate heat up to 1,000 times more efficiently than air cooling. This method often results in a smaller system size and lower operating costs over time.

| Aspect | Liquid Cooling | Traditional Heat Sinks |

|---|---|---|

| Heat Transport Efficiency | Better | Less efficient |

| System Size | Smaller | Larger |

| Energy Consumption | Lower | Higher |

| Reliability | No fans needed | Relies on fans |

| Upfront Investment | Higher | Lower |

| Cooling Efficiency | Significantly higher | Lower |

You gain excellent heat management and quieter operation with liquid cooling. However, you must consider the higher upfront investment and the need for careful installation. Closed-loop systems are harder to modify, while open-loop systems require more assembly.

Thermal Pads

Thermal pads serve as a thermal interface material between a heat source, such as a CPU, and a heat sink. You use them to eliminate air gaps, which are poor conductors of heat. The soft, squishy texture of thermal pads allows them to fill microscopic imperfections on surfaces. This creates a solid path for heat to travel, reducing thermal resistance and improving heat transfer.

- Thermal pads provide a reliable way to maintain optimal operating temperatures.

- You benefit from easier installation compared to thermal paste.

- They help improve the performance and longevity of your computer components.

📝 Note: Always ensure the thermal pad covers the entire contact area for the best results. Thermal pads work best in situations where you need a quick, clean, and effective solution for heat transfer.

You protect your computer’s performance and stability by choosing the right heat sink. Select copper for maximum energy efficiency or aluminum for lighter builds. Standard models offer affordability, while custom designs deliver tailored cooling. Regular cleaning and proper installation prevent overheating and instability.

| Cleaning Type | Frequency |

|---|---|

| Light Dusting | Every 1-2 weeks |

| Surface Cleaning | Once a month |

| Deep Cleaning | Every 3-6 months |

Consistent maintenance and correct mounting ensure optimal cooling and long-term reliability.

FAQ

How often should you clean your computer’s heat sink?

You should clean your heat sink every one to three months. Dust buildup reduces cooling efficiency. Use compressed air or a soft brush. Regular cleaning helps maintain stable temperatures and prevents overheating.

Can you replace a heat sink without professional help?

You can replace a heat sink yourself if you follow the manufacturer’s instructions. Make sure you use thermal paste and secure the mounting hardware evenly. If you feel unsure, ask for help from a technician.

What signs show your heat sink is not working properly?

You may notice higher temperatures, frequent system shutdowns, or loud fan noise. Your computer may slow down during heavy use. These signs suggest poor heat transfer or airflow problems.

Tip: Monitor your CPU and GPU temperatures with free software tools.

Does every computer need a custom heat sink?

Most computers use standard heat sinks. You need a custom heat sink only for unique designs or high-performance systems. Custom options fit special size, shape, or cooling requirements.

How do you know which heat sink fits your CPU?

Check your CPU’s socket type and thermal design power (TDP) rating. Review the manufacturer’s compatibility list. Measure the space in your case. Choose a heat sink that matches these specifications for best results.