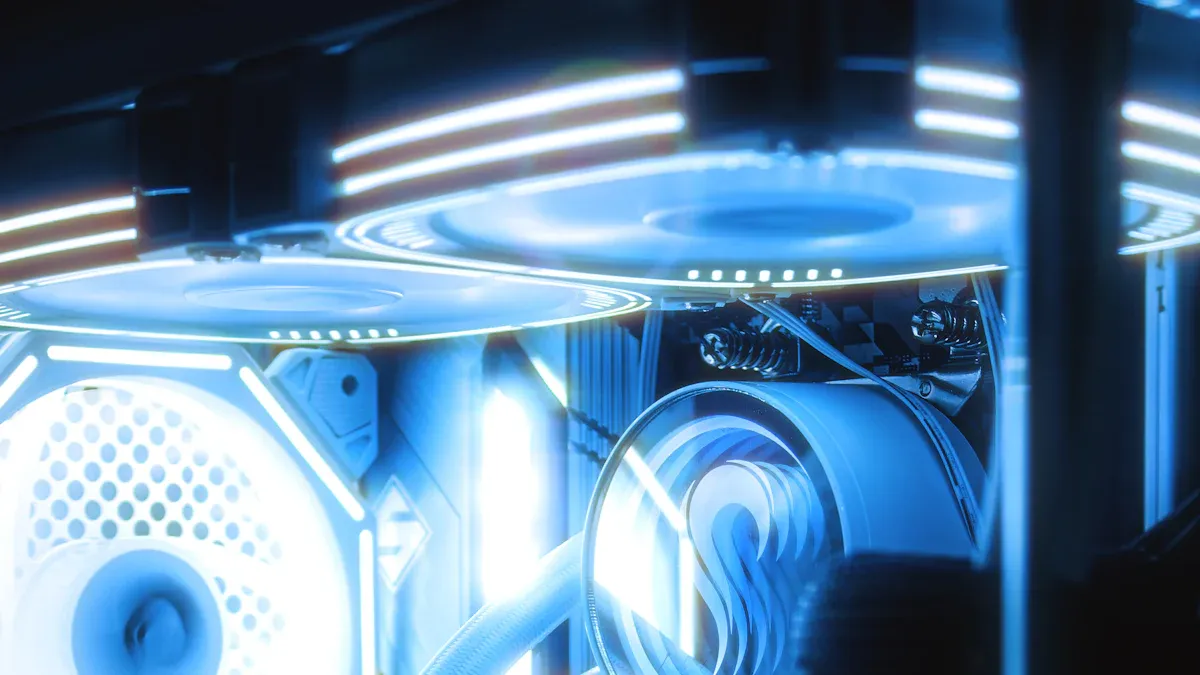

Custom liquid cold plate and heat sink

You use a liquid cold plate and a heat sink to keep electronics cool. These devices remove heat from critical components, preventing them from overheating. Custom cooling solutions, such as liquid cold plates and heat sinks, are now essential in electric vehicles and data centers, where managing high power in compact spaces is crucial. Recent research highlights that advanced designs like LTCC liquid cold plates outperform traditional options. They control heat more effectively with reduced coolant flow, making systems with liquid cold plates and heat sinks more efficient and reliable.

Key Takeaways

Liquid cold plates and heat sinks help cool electronics. They are very important for high-power things like electric cars and data centers.

Custom liquid cold plates make cooling work better. This helps move heat away faster and keeps electronics working longer.

Picking the best materials and fluids is very important. Copper moves heat very well. Aluminum is light and does not cost much.

Putting cooling systems in the right way helps control heat. It also stops leaks and makes electronics more reliable.

Working with makers during design helps build special cooling systems. These systems fit your needs and make everything work better.

What are liquid cold plates and heat sinks

Definition and basic function

You use a liquid cold plate or a heat sink to help control heat in electronics. Both devices move heat away from important parts, but they do this in different ways. A heat sink has metal fins that spread heat into the air. A liquid cold plate uses a liquid coolant to take heat away from the hot part. You can find these devices in computers, electric cars, and big machines.

Here is a table that shows the main differences between a liquid cold plate and a heat sink:

Feature | Liquid Cold Plates | Heat Sinks |

|---|---|---|

Heat Transfer Mechanism | Conducts heat to liquid, which circulates away | Conducts heat to fins, dissipates to air |

Efficiency | High efficiency due to liquid’s thermal properties | Limited by air’s thermal properties |

Design | Sealed structure with internal channels | Solid structure with external fins |

Applications | High-power, high-density applications | Moderate heat loads in consumer electronics |

Cost and Complexity | Higher initial costs and complexity | More cost-effective and simpler to implement |

You can see that a liquid cold plate is better for high-power systems. A heat sink is easier and costs less, but it cannot handle as much heat.

You also need to pick the right material for your cooling device. Here are some common materials:

Material | Properties |

|---|---|

Copper | Excellent thermal conductivity |

Aluminum | Lighter and cheaper |

Stainless Steel | Corrosion-resistant |

Polymer-based | Alternative to metal-based heatsinks |

How liquid cold plates work

A liquid cold plate has a special design to move heat away from electronics. You attach the cold plate to the hot part. Coolant, like water or another fluid, flows through channels inside the plate. These channels touch the hot surface, so the coolant picks up heat and carries it away.

Liquid coolants move through channels in the cold plate.

The channels have a big surface area to touch the coolant and help heat move.

The coolant takes heat from the electronic part and moves it out of the system.

This keeps your equipment cool and helps it last longer.

You can use a liquid cold plate to cool batteries, power electronics, or other strong devices. Water works well because it can hold more heat than air. Liquid cold plates can handle five to ten times more heat than a heat sink of the same size. Most air-cooled heat sinks have trouble with heat above 500 watts, but a liquid cold plate can handle several kilowatts.

Heat sink integration

You often need to use a liquid cold plate with a heat sink for the best results. The cold plate takes heat from the source and gives it to the coolant. The heat sink then helps get rid of this heat into the air or another cooling system.

When you design a system with a liquid cold plate and a heat sink, you need to:

Make sure coolant flow and surface area are good for cooling.

Keep pressure drop low so the coolant moves easily.

Use special channel shapes, like loops or microchannels, to cool better.

Make sure the cold plate has a flat mounting surface, inside paths for liquid, and clear inlet and outlet spots.

Some new designs use technology to make cold plates without leaks or joints. This lowers the chance of leaks and helps the system last longer. You can also pick different ways to make them, like friction stir welding or vacuum brazing, to fit your needs.

Tip: Always check that your liquid cold plate and heat sink fit your system and cooling needs before you install them.

Benefits of custom liquid cold plate solutions

Performance advantages

When you pick a custom liquid cold plate, your system cools much better. Custom designs let you make the cooling plate fit your needs. This means heat moves away faster and parts stay cooler. Engineers use different ways to check how well a liquid cold plate works. Here is a table that explains the main ones:

Metric | Description |

|---|---|

Thermal Resistance | Shows the temperature difference across the cold plate for a given heat load. |

Coefficient of Performance (COP) | Tells you how efficiently the plate removes heat compared to the power used for pumping. |

Heat Transfer Efficiency | Measures how well the plate moves heat away from the source. |

Pressure Drop | Shows how much pressure the coolant loses as it flows through the plate. |

Custom liquid cold plates keep strong electronics cool. You can use special channel shapes, like pin-fin or winding paths, to help the coolant move and take away heat. These shapes spread cooling across the whole device. Parts stay cooler than with air cooling, so electronics last longer and work better.

If air cooling cannot keep electronics safe, single-phase liquid cooling works very well.

Your system also stays steady when working hard. The liquid coolant grabs heat fast and moves it away. This keeps everything at a safe temperature.

Design flexibility

You can make a liquid cold plate or heat sink fit almost any space. Custom options let you pick the size, shape, and how you mount it. This helps you cool things in small or odd spaces. Here are some design types you can choose:

Friction Stir Welded (FSW) Cold Plates: Good for high-pressure systems.

Vacuum Brazed Cold Plates: Leak-proof and great for complex shapes.

Tube Embedded Heat Sinks: Cost-effective and flexible for moderate cooling needs.

Die Cast Liquid Cold Plates: Lightweight and easy to customize for consumer electronics.

Extruded Liquid Cooling Heat Sinks: Strong and efficient for industrial use.

Gun Drilled Liquid Cold Plates: Precise coolant flow paths for targeted cooling.

You can pick the best design for your job. You might need a light plate for a small device. Or you may want a strong heat sink for big machines. Custom designs let you add special features, like tiny channels or drilled holes, to move heat better. You can also pick materials, like copper for good heat movement or aluminum for less weight.

Cost-effectiveness and efficiency

You save money and get better results with a custom liquid cold plate or heat sink. When you let experts make your cooling system, you use new technology without hiring your own team. You do not pay for extra workers or training. You also share research costs with other customers.

Superior Thermal Conductivity: Liquids move more heat than air, so you get better cooling with less energy.

Compact Design: You do not need big fans or air tubes, so your system is smaller and lighter.

Extended Component Lifespan: Cooler parts do not overheat or break, so electronics last longer.

Stable Performance: Your system keeps the same temperature, even when working hard.

Icing Prevention: You can use coolants like ethylene glycol and water to stop freezing in cold places.

A cooling plate system gives you lots of cooling in a small space. You can use this in new electronics, electric cars, and small devices. More companies want good cooling, so the market is growing fast. You can spend your time on your business while experts handle your cooling.

Applications for liquid cold plates and heat sinks

Power electronics and industrial use

Many industries use custom liquid cold plates and heat sinks. These cooling devices help keep electronics from getting too hot. High-power electronics, data centers, electric cars, and energy storage systems all need good cooling. If parts get too hot, they can stop working. Here is a table that shows where these cooling systems are used:

Industry | Application |

|---|---|

High-Power Electronics | Custom liquid cold plates and heat sinks |

Data Centers | Thermal management components |

Electric Mobility | EV batteries |

Energy Storage Systems | Thermal management solutions |

You use these cooling systems for lasers and power devices. They also work for electronics packed close together. You need cooling that touches the hot part directly. Leak-proof designs are important. Copper and aluminum are common materials. Water, glycol mixes, or special fluids help move heat better. Cold plates have fins and channels to help control temperature and flow.

Medical, automotive, and aerospace

Liquid cold plates help keep medical devices safe. They protect sensitive electronics and lasers from getting too hot. The plate moves heat into a liquid that flows to a radiator or chiller. This gives better temperature control and quieter operation. Medical imaging machines need steady temperatures to work well.

Liquid cold plates help medical devices by quickly taking away extra heat. This keeps the temperature steady and helps the system last longer. They are very useful in machines that need high precision, like imaging and diagnostics.

Custom heat sinks are used in cars and airplanes too. They help control heat from engines and electronics. These cooling devices keep important parts safe and working well, even in tough places.

Specialized cooling scenarios

Some jobs need special cooling solutions. High-heat systems, TEC mounting, and remote heat exchangers need custom designs. Aerospace may use light aluminum cold plates with strong welding. Medical devices may use copper plates with extra flow paths. These designs help meet strict rules for weight and reliability.

Liquid cold plates are great for getting rid of lots of heat.

They cool things faster than air and keep parts safe.

Custom designs help equipment last longer and stop overheating.

Design considerations for custom solutions

Material and fluid selection

You must pick the right materials and fluids for your custom liquid cold plate or heat sink. First, figure out how much heat your system needs to remove. Also, know the temperature range where it will work. Choose a cooling fluid that moves heat well and flows easily. The fluid should match the cold plate material so it does not cause rust or damage. Some surface treatments can make the plate last longer and work better. Always think about where your system will be used, like how hot or wet it gets. You can ask engineers for help to make a custom design that fits your needs.

Check how much heat you need to remove and the working temperature.

Pick a cooling fluid that moves heat well.

Make sure the fluid and material work together and do not cause rust.

Use surface treatments to help the plate last longer.

Think about the place where your system will run, like heat and wetness.

Tip: Good thermal performance and fluid matching keep your system safe and working well.

Geometry and mounting options

The size and shape of your cold plate or heat sink change how well it cools electronics. Microchannel geometry is important for how heat moves. You can change the aspect ratio, hydraulic diameter, and shape to control how the fluid flows and how much heat leaves. A bigger aspect ratio can make the fluid move in a twisty way. A smaller hydraulic diameter makes the fluid go faster, which helps move heat better. The channel shape also changes how the coolant moves and cools.

Mounting options let you attach your heat sink or cold plate to your device. Here is a table with common ways to mount them:

Mounting Method | Description |

|---|---|

Screws | Strong and reliable |

Spring Clips | Fast and low stress |

Push Pins | Quick, tool-less |

Rivets | Permanent, strong |

Thermal Adhesive | Clean, no screws |

Thermal Tape | Easy to use |

Standoffs + Screws | Strong, modular |

Pick a mounting way that fits your design and is easy to use.

System integration

You need to put your custom cold plate or heat sink into your system the right way. Clean both the cold plate and the hot part before you put them together. Add a thin layer of thermal interface material to fill small gaps and help heat move. Attach the cold plate tightly so it stays in place and does not leak. Connect the fluid lines with leak-proof parts that match the materials. These steps help your cooling system work well and keep your electronics safe.

Note: Careful setup and checking stop leaks and help your system last longer.

Getting started with custom liquid cold plates

Assessing cooling requirements

First, you need to know what needs cooling. Make a list of all the parts that get hot. Find out how much heat each part makes when working. Check the highest temperature each part can handle. Look at how much space you have for the cold plate. Decide what kind of fluid you want to use. Think about the place where your system will be, like if it is wet or shakes a lot. All this information helps you set goals for your custom cooling.

Tip: Use thermal maps to find hot spots in your system. This shows you which parts need the most cooling.

Working with manufacturers

You need to work with manufacturers to design your cold plate. Tell them what you need and share details about your system. Companies like ATS use special tools to make tiny channels inside the plate. These channels help cool better and make the plate lighter. VPE says working together helps make a cold plate that fits your needs. This makes your system work better and last longer. Kingka uses its skills to give you good solutions.

You look at design ideas and give your thoughts. The manufacturer checks the design with computer tools to see how the liquid moves. You talk about what materials to use and how to attach the plate. You can also ask for special features. Working together makes sure the cold plate fits your system well.

Prototyping and verification

When the design is ready, you make a sample cold plate. The manufacturer builds it so you can test it. You use computer tools to see how well the plate cools. You check the surface temperature and how much pressure the liquid loses. Sometimes, you change the way the liquid flows to cool important parts better.

Here are some best ways to test your prototype:

Make thermal maps to see where heat goes.

Try different ways for the liquid to flow.

Use computer tools to check your design.

Measure the highest surface temperature and pressure drop.

Change the liquid path for better cooling.

Put parts in smart places to keep temperatures even.

Work with engineers to make the design simple and save money.

You also test the sample with different inspection methods:

Inspection Type | Tools Used | Purpose |

|---|---|---|

Visual Inspection | Magnifying lamp, borescope | Find visible defects |

Dimensional Inspection | CMM, laser scanner | Check precise measurements |

Thermal Resistance Test | Thermocouples, data logger | Measure heat dissipation |

Airflow Test | Wind tunnel, anemometer | Evaluate cooling capacity |

Environmental Stress Test | Climatic chamber | Simulate real-world conditions |

You make sure the cold plate works before making a lot of them.

Custom liquid cold plates and heat sinks help move heat away fast. They are small and use less energy. Your electronics last longer and work well, even if they get hot or cold. Custom designs fix special cooling problems in new electronics. These devices use parts that control heat better. To begin, figure out how much heat you need to remove. Talk to a thermal engineer for advice. Test a sample to see if it works. Experts can help keep your system cool and working well.

FAQ

A liquid cold plate uses coolant to take away heat. A heat sink uses air to move heat away from electronics. You pick a cold plate for strong, high-power systems. You use a heat sink for simple or low-power devices.

You pick copper if you want to move heat very well. Aluminum is light and does not cost much. Stainless steel does not rust easily. Polymer-based materials are good for special uses. Pick the material that fits your cooling needs and where you will use it.

You can use water in most cooling systems. Add glycol if you need to stop freezing in cold places. Always make sure the water works with your plate material. This helps stop rust or leaks.

You need a custom solution if regular products do not fit. This can happen if you have a small space, need more power, or need a special way to mount it. Custom designs help fix hard cooling problems in advanced electronics or tight spots.